文章编号:1004-0609(2009)07-1176-06

镁合金铸造缺陷塑性变形弥合与修复过程

曹韩学1, 2,龙思远1, 2,游国强1, 2,廖惠敏1

(1. 重庆大学 材料科学与工程学院,重庆 400045;

2. 重庆大学 国家镁合金材料工程技术研究中心,重庆 400030)

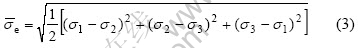

摘 要:通过电子显微镜、透射电镜并结合塑性变形数值模拟,观察镁合金铸造缺陷(晶间缩松和缩孔)在变形过程中的形貌变化及缺陷附近应力分布,讨论塑性变形消除铸造缺陷的力学行为,提出镁合金铸造缺陷塑性变形弥合过程为:缺陷体积压缩→界面闭合→界面两侧基体相切变→界面附近再结晶→缺陷部分弥合。结果表明:变形过程中缺陷附近应力集中明显,变形后应力集中大大降低,部分铸造缺陷得以弥合与修复。

关键词:镁合金;铸造缺陷;塑性变形

中图分类号:TG 146 文献标识码:A

Closing and repairing process of Mg alloy casting imperfections in

plastic deformation

CAO Han-xue1, 2, LONG Si-yuan1, 2, YOU Guo-qiang1, 2, LIAO Hui-min1

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400045, China;

2. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400030, China)

Abstract: The effects of press deformation on the morphologies evolution of Mg alloy casting imperfections (shrinkage porosity and cavity) and the stress distribution around the casting imperfections were observed by electro microscopy, transmission electron microscopy (TEM) and numerical simulation. The mechanical behavior of casting imperfections closing in pressing was investigated. The closing mechanism of press deformation on Mg alloy casting imperfections was proposed, which was volume of casting imperfections shrinking→interfaces closing→shearing deformation of α-Mg matrix grains around interfaces→dynamic recrystallization around interfaces→casting imperfections closing partly. The results show that the stress concentration becomes more evident in pressing and reduces greatly after deformation. At the same time, the casting imperfections are closed and repaired partly.

Key words: magnesium alloy; casting imperfections; plastic deformation

研究材料内部的组织及演化,对于改进材料的力学性能和预测失效行为具有重要意义。在材料的制造过程中,常常形成某些空洞和裂纹(如铸造中的缩松、缩孔和微裂纹)等缺陷。断裂力学研究结果表明,材料韧性断裂的微结构机理就在于金属材料中缺陷的存在以及它们之间的相互聚合作用[1]。镁合金中的铸造缺陷(缩松、缩孔),会成为材料失效的裂纹源。缺陷对材料行为的不可逆劣化导致材料的损伤,损伤的累积将最终导致材料的失效[2?3]。目前,对镁合金材料失效行为以及材料缺陷对镁合金性能的影响研究较多,对失效机理研究也较深入[4?6]。

对铸态镁合金进行塑性变形,不仅能够通过加工硬化改善和提高合金的力学性能,同时还可以利用塑性流变改善材料微结构的形貌和再分布状态,并部分弥合和消除铸造缺陷,可望进一步提高合金的强度。

本文作者通过压缩变形试验,结合金相观察、透射电镜和数值模拟,观察塑性变形过程中AM60B镁合金铸造缺陷(晶间缩松和缩孔)的形貌变化规律,讨论塑性流变消除镁合金铸造缺陷的微结构力学行为,为塑性变形消除镁合金铸造缺陷、提高镁合金件力学性能提供参考。

1 实验

采用金属型重力铸造方法,浇铸出矩形铸坯并加工成多块尺寸为10 mm×10 mm×10 mm的方形试样,分别用于压缩试验和金相观察。

试验过程中,将试样放入加热炉中加热到400 ℃,保温30 min,同时将压缩装置加热到400 ℃,然后以100 mm/min的变形速度进行压缩实验。第一块试样的压缩量为30%(压头下压3 mm),第二块试样的压缩量为45%(压头下压4.5 mm),第三块试样的压缩量为60%(压头下压6 mm),第四块试样的压缩量为70%(压头下压7 mm)。

将压缩前、后的试样从中间剖开,平整断面、预磨抛光和3%的硝酸酒精腐蚀后,在光学显微镜(OM)下观察不同变形量下铸造缺陷的形貌演化规律。

对试样进行切片和离子减薄,采用Tecnai20透射电镜观察缺陷界面附近的微观组织。

采用Deform塑性变形模拟软件,在400 ℃和 100 mm/min条件下对含有铸造缺陷的镁合金试样(模型)进行压缩试验,观察不同变形量下铸造缺陷(缩松与缩孔)形貌演化、应力分布及变化规律。

2 结果

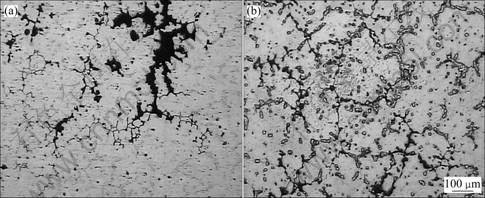

镁合金在凝固过程中,由于液态收缩和凝固收缩的产生,往往在铸件最后凝固的部位出现表面暗色、不光滑的孔洞,尺寸比较大而集中的孔洞称为集中缩孔,尺寸细小而且分散的孔洞称为分散性缩孔,简称缩松。镁合金缩松、缩孔常常存在于镁合金基体相晶界以及基体相与第二相交界处(见图1)。

由图1(a)可以看出,在镁合金铸态组织中,缩松沿着晶界呈不规则的树枝状分布,其源头常常来自缩孔处,甚至有的缩孔通过缩松首尾相连,形成网状。将组织腐蚀后进行观察(如图1(b)),则可以看出缩松常常来自第二相聚集处,树枝状的缩松与第二相首尾相连,将基体相包围。另外,大的缩孔边界呈不规则的齿状,将基体相分割开,造成镁合金材料致密度下降。

图1 铸态镁合金AM60B中的缩孔和缩松

Fig.1 Shrinkage cavity and porosity in cast AM60B magnesium alloy: (a) Shrinkage cavity; (b) Shrinkage porosity

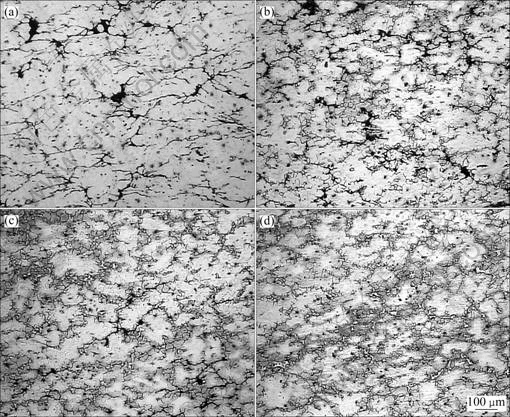

图2所示为铸态缩松、缩孔形貌在不同变形量下的形貌及组织变化。

图2 不同变形量下缩松、缩孔的形貌变化

Fig.2 Morphology evolution of shrinkage porosity and cavity with different deformations: (a) 30%; (b) 45 %;( c) 60%; (d) 70%

由图2(a)可看出,经过30%压缩变形后,沿晶界分布的网状缩松随着基体相的转动和延伸,沿垂直压力方向分布,其形状也由原来的网状变为链状,而缩孔的尺寸在压力作用下收缩变小。由图2(b)可看 出,试样经过45%压缩变形后,细小的晶间缩松通过基体相的挤压和转动已经闭合,并在界面尖端处产生细小的等轴晶粒,表明已发生再结晶。平行于压力方向的缩孔被基体相挤压成长条状,并被分割成短小孔隙,在基体相和再结晶晶粒间不规则分布。垂直于压力方向的缩孔则在压力的作用下压缩成团聚状,或随着基体相的转动而改变位向,逐渐趋于与压力方向平行。由图2(c)可看出,试样经过60%压缩变形后,大部分缩松已经消失,缩松界面上的再结晶向基体相蔓延。平行于压力方向的缩孔已经闭合,并在闭合界面产生再结晶晶粒。垂直于压力方向的团聚状缩孔在压力的作用下进一步缩小,随着基体相转动,其位向已利于闭合,并被基体相挤压成长条状。由图2(d)可看出,试样经过70%压缩变形后,大部分缩孔已经闭合,在先闭合的界面,再结晶晶粒带较明显。

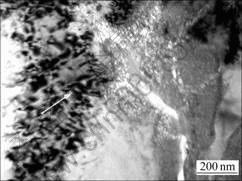

图3所示为界面附近的位错塞积。由图3可见,在界面附近(特别是靠近端部)产生大位错塞积,并伴有亚结构的出现,这说明界面周围基体畸变较严重,为再结晶晶粒的产生提供了条件。

图3 界面附近的位错塞积

Fig.3 Dislocation pileupgroup around interfaces

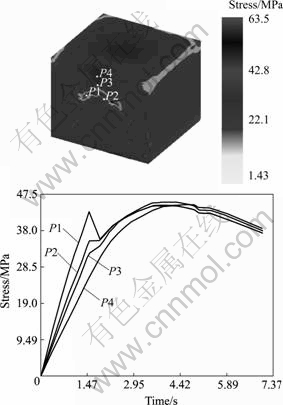

为了进一步了解试样中缩松、缩孔界面及其周围的应力分布及变化规律,采用数值模拟进行分析,结果如图4所示。

由图4可知,P1为缺陷尖端处应力测量点,P2、P3为缺陷界面应力测量点,P4为无缺陷处应力测量点。在变形初期(即界面闭合前),P1点的应力值明显大于其它三点(表明出现应力集中),该应力值随着变形的进行迅速增大,达到一峰值后跳跃式下降(表明缩松界面接触后的应力集中得以释放),之后又平稳上升至一极值,然后平稳下降,表现出镁合金塑性变形的动态再结晶应力特点。P2、P3所示点的应力在P1点应力跳跃式下降时出现一拐点,之后又平稳上升,表现出镁合金塑性变形的应力特点。P4点则始终保持镁合金塑性变形的应力特点。

图4 缩松、缩孔在塑性变形过程中的应力变化

Fig.4 Stress evolution of shrinkage porosity and cavity in plastic deformation

由此可见,在塑性变形过程中,缺陷界面周围的应力分布及变化是复杂的,它与界面周围的应力、应变密切相关。

3 分析与讨论

3.1 镁合金铸造缺陷产生机理

铸件的缩孔主要是由金属凝固收缩引起的液面下降和压力下降形成,溶质成分富集以及过饱和气体的析出也促进缩孔的形成。与缩孔形成的原因相似,缩松也是由于金属凝固收缩和过饱和气体的析出而形成的。

镁合金的结晶温度范围较宽,一般是以糊状凝固方式进行凝固。当金属从液态转变为固态时,体积发生收缩。随着型壁传热作用不断地进行,型内液体金属温度不断降低。当铸件表面温度降低至凝固温度时,铸件就开始凝固形成一个个小晶体,发生体积收缩,此时剩余可流动液体将对收缩部分进行自动补缩。随着凝固的进行,凝固的晶体呈枝晶状,熔体可以在枝晶间流动,当固相约占70%(体积分数)时,分枝较多的树枝晶互相搭接形成骨架,枝晶间未凝固的液体被枝晶分割和封闭为一个个互不相通的小熔池。当这些被分割开的枝晶间的液体凝固收缩时,由于金属的液态收缩和凝固收缩值之和大于固态收缩,出现的细小孔洞得不到液体的补充,便会在最后凝固的地方形成微小缩孔[7?8],如图1所示。

3.2 镁合金铸造缺陷塑性变形弥合与修复过程

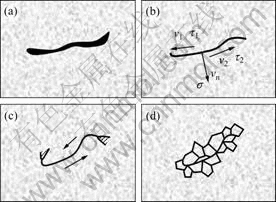

根据单极空洞效应理论模型及不连续面变形过程中的应力、应变速率分布规律,镁合金铸造缺陷在塑性变形过程中的弥合与修复过程如图5所示。

图5 镁合金铸造缺陷弥合力学过程示意图

Fig.5 Dynamical process schematic of cast imperfection closing for Mg alloy: (a) Casting imperfection; (b) Interface closing; (c) Stress concentrating; (d) Dynamic recrystallization (σ—Normal stress; vn—Normal velocity; τ1, τ2—Tangential stress; v1, v2—Tangential velocity)

李国琛等[9]报道了利用最大塑性功原理以及Rayleigh- Ritz方法,对连续介质中空洞模型在远处应变场和平均法向应力作用下的流动场进行近似求解的方法,并得出估算空洞平均半径a的变化的公式:

式中: 为空洞的瞬时半径,

为空洞的瞬时半径, 和

和 分别为远处的平均应力和等效应力,

分别为远处的平均应力和等效应力, 为远处的简单拉伸应变率。且有:

为远处的简单拉伸应变率。且有:

在镁合金的压缩变形过程中,拉伸应变率变为压缩应变率(均为正值),而所受的应力方向刚好与拉伸时相反,因此 取负值,而

取负值,而 恒为正值。因此,式(1)中的瞬时半径

恒为正值。因此,式(1)中的瞬时半径 与

与 成反比关系。

成反比关系。

随着压缩变形的进行,压缩应变率 越来越大,

越来越大, 的值也越来越大,因此,空洞瞬时半径

的值也越来越大,因此,空洞瞬时半径 随着变形的进行越来越小(缺陷体积在压缩过程中不断受挤收缩),并最终使缺陷界面闭合(见图5(b))。闭合后的缺陷界面并没有形成良好的结合,随着变形的进行,缺陷界面还会发生迁移并消失。

随着变形的进行越来越小(缺陷体积在压缩过程中不断受挤收缩),并最终使缺陷界面闭合(见图5(b))。闭合后的缺陷界面并没有形成良好的结合,随着变形的进行,缺陷界面还会发生迁移并消失。

缺陷界面的迁移及消失过程,可以用不连续界面在均质连续体中的迁移过程进行解释。

由均质连续体内不连续界面在塑性变形过程中的运动许可条件可知[10]:连续介质在不连续面上应分别满足质量、动量和能量守恒。即:不连续曲面两侧法向速度(vn)必须连续(可理解为大小相等、方向相同),而不连续曲面的切向速度(v1、v2)可以产生不连续(可理解为大小不同、方向相反)而不影响质量守恒;同时,为了满足动量守恒和质量守恒,不连续面两侧的法向应力σ不应间断,但两侧的剪应力τ1和τ2可以间断(见图5(b))。

随着变形量的增加,压力增大,缩松界面尖端的应力高度集中[11?12](见图4和图5(c)),当应力超过材料的极限应力时,该处镁合金基体相将先于其它部位发生晶内滑移[13?15],滑移在界面上受阻即产生位错塞积(见图3)。

另外,压缩变形将导致界面两侧的晶粒发生转动。由于垂直界面的法向速度必须连续,而切向速度可以不连续,界面的切向将发生切变而使界面附近局部区域发生扭曲,局部的扭曲将造成畸变,从而成为动态再结晶优先形核的地方。当温度较高时,在界面附近容易发生非基面滑移和交滑移而使扭曲区域扩大,并释放局部应力集中(见图4)。

随着应变的增大,在扭曲的界面附近通过动态回复形成亚晶,并最终通过亚晶界的迁移和亚晶的合并长大而围绕界面形成再结晶新晶粒(见图5(d))[16?20]。

由以上分析可知,镁合金铸造缺陷弥合过程可归纳为:缺陷体积压缩→界面尖端的应力高度集中→界面闭合→界面两侧基体相切变→界面附近动态回复形成亚晶→亚晶界的迁移和亚晶的合并长大→形成新的动态再结晶晶粒→界面消失(缺陷弥合)。

4 结论

1) 在镁合金铸态组织中,缩松沿着晶界呈不规则的树枝状分布,其源头常常来自缩孔处,甚至有的缩孔通过缩松首尾相连,形成网状。将组织腐蚀后进行观察,可看出缩松常常来自第二相聚集处,树枝状的缩松与第二相首尾相连,将基体相包围。

2) 数值模拟结果显示:在塑性变形过程中,缺陷界面周围的应力分布及变化及其复杂,它与界面周围的应力、应变密切相关。

3) 金相及TEM观察显示:界面附近(特别是靠近端部)易产生大量位错,并伴有亚结构的出现,说明界面周围基体畸变较严重,是再结晶晶粒优先形核的地方。

4) 镁合金铸造缺陷经缺陷体积压缩→界面闭合→界面两侧基体相切变→界面附近动态回复形成亚晶→亚晶界的迁移和亚晶的合并长大→形成新的动态再结晶晶粒→界面消失等过程后得以部分弥合。

REFERENCES

[1] 坎贝尔J E. 断裂力学在选材方面的应用[M]. 汪一麟, 邵本逑, 译. 北京: 冶金工业出版社, 1932.

[2] LEE C D. Effect of grain size on the tensile properties of magnesium alloy[J]. Mater Sci Eng A, 2007, 459: 355?360.

[3] GALL K, BIALLAS G, MAIER H J, GULLETT P, HORSTEMEYER M F, MCDOWELL D L, FAN Jing-hong. In-situ observations of high cycle fatigue mechanisms in cast AM60B magnesium in vacuum and water vapor environments[J]. International Journal of Fatigue, 2004, 26: 9?70.

[4] SAJURI Z B, MIYASHITA Y, HOSOKAI Y, MUTOH Y. Effects of Mn content and texture on fatigue properties of as-cast and extruded AZ61 magnesium alloys[J]. International Journal of Mechanical Sciences, 2006, 48: 198?209.

[5] MAYER H, PAPAKYRIACOU M, ZETTL B, STANZL- TSCHEGG S E. Influence of porosity on the fatigue limit of die cast magnesium and aluminium alloys[J]. International Journal of Fatigue, 2003, 25: 245?256.

[6] LU Y, TAHERI F, GHARGHOURI M. Study of fatigue crack incubation and propagation mechanisms in a HPDC AM60B magnesium alloy[J]. Journal of Alloys and Compounds, 2008, 466: 214?227.

[7] 贾宝仟, 柳百成. 铸件缩松缩孔判据G/T1/2的理论基础及应用[J]. 铸造, 1996, 4: 13?15.

JIA Bao-qian, LIU Bai-cheng. Theoretical derivation of criterion G/T1/2 for predicting the shrinkage cavity and porosity in castings and its application[J]. Foundry, 1996, 4: 13?15.

[8] LAURENT V, RIGAUT C. Experimental and numerical study of criteria functions for predicting micro porosity in cast aluminum alloys[J]. AFS Transaction, 1992, 100: 647?655.

[9] 李国琛, M.耶纳. 塑性大应变微结构力学[M]. 北京: 科学出版社, 2003.

LI Guo-chen, YENA M. Micro-structural mechanics of large plastic strain[M]. Beijing: Science Press, 2003.

[10] 赵德文. 连续体成形力数学解法[M]. 沈阳: 东北大学出版社, 2003.

ZHAO De-wen. Mathematical solution for forming force of nonindividual body[M]. Shenyang: Northeast University Press, 2003.

[11] 匡震邦, 马法尚. 裂纹端部场[M]. 西安: 西安交通大学出版社, 2001.

KUANG Zhen-bang, MA Fa-shang. Crack tip fields[M]. Xi’an: Xi’an Jiaotong University Press, 2001.

[12] 许金泉. 界面力学[M]. 北京: 科学出版社, 2006.

XU Jin-Quan. Interface mechanics[M]. Beijing: Science Press, 2006.

[13] NAVE M D, BARNETT M R. Microstructures and textures of pure magnesium deformed in plane-strain compression[J]. Scripta Materialia, 2004, 51: 881?885.

[14] BARBAGALLO S, CAVALIERE P, CERRI E. Compressive plastic deformation of an AS21X magnesium alloy produced by high pressure die casting at elevated temperatures[J]. Mater Sci Eng A, 2004, 367: 9?16.

[15] XIA Ming-xu, ZHENG Hong-xing, YUAN Sen, LI Jian-guo. Recrystallization of preformed AZ91D magnesium alloys in the semisolid state[J]. Materials and Design, 2005, 26: 343?349.

[16] WANG R M, ELIEZER A, GUTMAN E. Microstructures and dislocations in the stressed AZ91D magnesium alloys[J]. Mater Sci Eng A, 2002, 344: 279?287.

[17] ???EKA L, GREGERA M, PAWLICAA L, DOBRZA?SKIB L A, TA?SKIB T. Study of selected properties of magnesium alloy AZ91 after heat treatment and forming[J]. Journal of Materials Processing Technology, 2004, 157/158: 466?471.

[18] GOURDET S, MONTHEILLET F. An experimental study of the recrystallization mechanism during hot deformation of aluminium[J]. Mater Sci Eng A, 2000, 283: 274?288.

[19] KANICHI H, KUNIO M. Deformation behavior and forging of magnesium wrought alloy[J]. Materials Science Forum, 2003, 426/432: 557?562.

[20] WATANABE H, MUKAI T, MABUCHI M, HIGASHI K. Super plastic deformation mechanism in power metallurgy magnesium alloys and composites[J]. Acta Mater, 2001, 49: 2027?2037.

基金项目:重庆市科技攻关计划资助项目(CSTC2008AB4111;CSTC2007AA4008)

收稿日期:2008-10-13;修订日期:2009-04-30

通讯作者:曹韩学,讲师,博士;电话:023-65112626;E-mail: chxchx2001@126.com

(编辑 李向群)