DOI: 10.11817/j.issn.1672-7207.2016.04.010

考虑水声距的晶粒尺寸超声衰减评价模型

张晨昕1,李雄兵1, 2,宋永锋1,刘锋2,刘希玲1

(1. 中南大学 交通运输工程学院,湖南 长沙,410075;

2. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:超声衰减法评价金属材料晶粒尺寸时,会因忽略水声距设置造成系统误差而降低其评价精度。针对该问题,利用主成分分析法(PCA)对材料衰减系数测量中水声距的影响进行分析;根据PCA的数据空间降维投影特性,去除数据相关性并抑制数据噪声干扰,构建与水声距和晶粒尺寸均相关的综合衰减系数评价模型,并选取304不锈钢试块进行实验。在水声距13.8~156.9 mm范围内任取8个值,针对金相法测定晶粒粒度为72.35 μm的304不锈钢试块,对比传统衰减评价模型与该模型的评价精度,验证其有效性。研究结果表明:传统衰减法与综合模型评价对金相法结果的相对误差分别为17.55%和6.49%;综合模型可抑制水声距调整精度对晶粒尺寸评价结果的不利影响,提高金属材料晶粒尺寸超声无损评价方法的实用性和可靠性。

关键词:超声;衰减;水声距;晶粒尺寸;PCA

中图分类号:TG115.28 文献标志码:A 文章编号:1672-7207(2016)04-1151-07

Ultrasonic attenuation evaluation model of grain size considering water depth

ZHANG Chenxin1, LI Xiongbing1, 2, SONG Yongfeng1, LIU Feng2, LIU Xiling1

(1. School of Traffic and Transportation Engineering, Central South University, Changsha 410075, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Ultrasonic attenuation was investigated as a nondestructive determination method of grain-size, but the neglect of water depth setting can introduce systematic error and reduce the precision of grain-size evaluation. A synthetic model dependent on both water depth and grain-size was established based on principal component analysis (PCA), which can reduce noise as well as the dimensions of the feature vector. It can also eliminate superfluous characteristics and data correlation.304 stainless steel blocks were used to conduct the experiment. Numerical calculations were performed for the block with the grain size of 72.35 μm determined by the metallographic method when the water depth varied between 13.8 mm and 156.9 mm. The results show that the relative errors of conventional method and the proposed model are 17.55% and 6.49%, respectively, thus the presented model can inhibit the effect of water depth on grain-size evaluation and improve the applicability and reliability of ultrasonic nondestructive evaluation.

Key words: ultrasonic; attenuation; water depth; grain size; principal component analysis (PCA)

晶粒尺寸是表征金属材料微观特性的一个重要参数,它影响着材料的疲劳强度、屈服强度、韧性及塑性、蠕变抗力和抗疲劳扩展能力等机械性能[1-4],如当锻造态粉末合金在晶粒尺寸为5~10 μm时,洛氏硬度达54.8,若使热处理温度提高150 ℃,晶粒长大将导致洛氏硬度下降至34.3[5],因此,准确测量金属材料的晶粒尺寸对研究其机械性能具有重大的意义。金属材料晶粒尺寸的测量方法分为有损和无损2种。有损方法如金相法具有结果直观和检测精度高等优点,但需对材料进行破坏,且分析程序繁琐,检测效率低,因此,研究一种能准确获取材料晶粒尺寸的无损检测方法具有重大意义。常用的无损方法主要包括超声法、涡流法和X线法等。其中涡流法检测易受干扰,非线性误差大,对被测件的晶粒尺寸测量受限于表面及表面附近[6-7];X线法较常用于检测纳米级材料的晶粒尺寸[8-9],且X线对人体有害。超声无损评价方法具有穿透能力强、灵敏度高、对人体无害等优点[10-11],是目前国内外对材料进行微结构检测所普遍应用的方法之一。多晶金属材料的晶粒尺寸在很大程度上决定了声能的衰减程度,因此,可测定超声衰减系数间接评价材料的晶粒尺寸[12-13]。然而,在工程实践中,准确检测衰减系数将受到一系列苛刻的实验条件约束,如在不同水声距条件下检测,同一材料的衰减系数并非定值,故现有检测需精确调整水声距,将声束聚焦在被测对象中部,以获得可靠的衰减系数。如何剔除水声距与其他实验因素间的线性相关性,降低实验误差的干扰,并从中找出水声距对衰减测量的影响规律,是提高晶粒尺寸超声衰减评价有效性的关键。为此,本文作者研究一种水声距对超声衰减测量值影响的分析方法,利用PCA推导1个用于指导超声波衰减法精确检测不锈钢晶粒尺寸实验的综合评价模型,利用水声距设定值结合所测量的衰减系数求得精确的晶粒尺寸,以降低操作精度带来的不利影响,提高衰减法检测材料晶粒尺寸的实用性和可靠性。

1 方法

超声衰减根据成因可分为扩散、吸收和散射,其中,散射衰减在多晶金属中起主导作用。一般地,若衰减系数与晶粒尺寸的z次幂呈正比,则它也正比于检测频率的z+1次幂[14]:

(1)

(1)

式中:α为衰减系数;D为晶粒尺寸;f为探头主频率;k为由材料不均匀程度决定的常数。由式(1)可知:在传统超声衰减研究中,衰减系数α与试块晶粒尺寸Dz呈正比,且当检测频率f一定时,衰减系数α仅与晶粒尺寸D相关。故传统衰减评价模型可表示为

(2)

(2)

其中:C0为常数;在衰减系数的实际测量中,水声距W与α呈多项式曲线关系,可假设α最高可与 和

和 相关,建立衰减系数与晶粒尺寸、水声距均相关的初始非线性回归模型:

相关,建立衰减系数与晶粒尺寸、水声距均相关的初始非线性回归模型:

(3)

(3)

其中:C1为常数。对于高维空间回归模型,若直接拟合计算,则其结果将引入各维数据的相关性及原始数据的噪声干扰,而PCA作为一种常用的回归模型前处理方法,可实现对多维数据的降维以及消除统计大量数据的干 扰[15]。

将变量(D,D2,…, ,W,W2,…,

,W,W2,…, )记作

)记作 ,每个变量有n个观测样本,由此可构建线性化数据矩阵

,每个变量有n个观测样本,由此可构建线性化数据矩阵 ;同时,为消除各被测量因量纲不同而取值分散程度差异大的影响,将被测变量标准化,即

;同时,为消除各被测量因量纲不同而取值分散程度差异大的影响,将被测变量标准化,即

(4)

(4)

式中:Ln为n维单位列矢量; ;

; 。此时,标准化矩阵

。此时,标准化矩阵 。设xi为矩阵X的第i行数据,首先求其协方差矩阵:

。设xi为矩阵X的第i行数据,首先求其协方差矩阵:

(5)

(5)

X可分解如下:

(6)

(6)

其中: 表示X的模型值;E为建模误差。

表示X的模型值;E为建模误差。

(7)

(7)

(8)

(8)

式中:ti为得分矢量;pi为负荷矢量;l为主元数量;Z为主元得分矩阵;P为主元负荷矩阵;Z*为残差得分矩阵;P*为残差负荷矩阵[16]。通过计算主元累计贡献率Ql来确定最终的主元数目l:

(9)

(9)

其中:Λi为R的特征值,且 ;QC为主元累计贡献率控制值,一般取值为0.85~0.95[17]。

;QC为主元累计贡献率控制值,一般取值为0.85~0.95[17]。

利用PCA处理后的数据,对所得的主元得分矩阵进行多元回归可得

(10)

(10)

其中: ,为主元回归模型系数矩阵;C2为常数。

,为主元回归模型系数矩阵;C2为常数。

将原始被测量代入各个元主元后,即可得到消除了原始变量间相关性并降噪后的综合衰减系数评价 模型:

(11)

(11)

(12)

(12)

2 实验及模型计算

2.1 试块制备与金相法检测

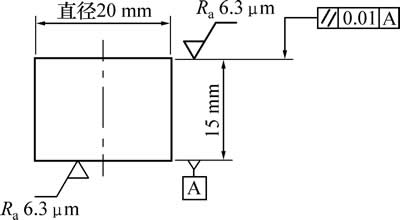

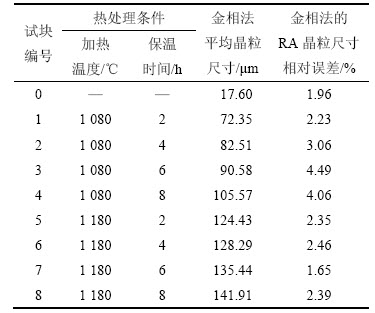

选用牌号为06Cr19Ni10的304不锈钢制备试块,为使超声检测时不产生侧壁干扰[18],设计几何尺寸如图1所示。使用CM公司1610BL型高温炉对同批制备的9个试块进行不同温度与保温时间的热处理,使其具有晶粒尺寸梯度的同时保持基本相同的扩散速率与晶界偏析,接着对所有试块进行1次去应力退火,再用金相法测量平均晶粒尺寸:对热处理后的试块进行磨样和抛光;配制化学成分(质量分数)为20% HF+ 10% HNO3+ 70% H2O的腐蚀液进行20 min腐蚀[19];在Leica公司DM4000M型金相显微系统中进行金相观察和图样采集,各试块金相如图2所示。根据GB 6394—2002“金属平均晶粒尺寸测定方法”计算晶粒尺寸。晶粒尺寸统计结果及误差如表1所示。

图1 试块几何尺寸

Fig. 1 Dimension of test block

2.2 超声数据获取与初步分析

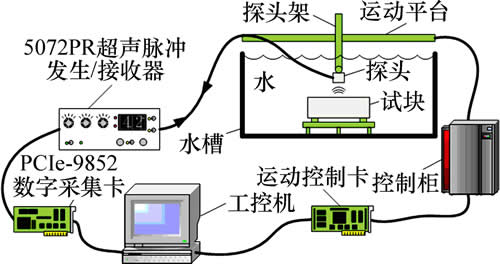

采用Olympus 5072PR 超声脉冲信号发生/接收器与聚焦探头连接进行脉冲信号的收发;使用DMC2610 PCI总线6轴运动控制卡和运动平台,调整控制探头垂直于被测表面上下运动,对9个不同晶粒尺寸试块依次取8组水声距;使用ADLINK PCIe-9852 高速数据采集卡,采用VC++与Matlab混合编程对采集到的267组数据进行处理,得到采样间隔为5 ns的A波数据,并由此计算出水声距和衰减系数。超声检测系统如图3所示。

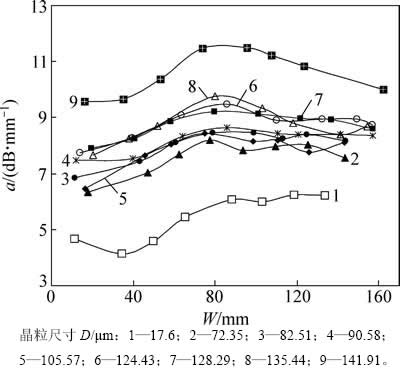

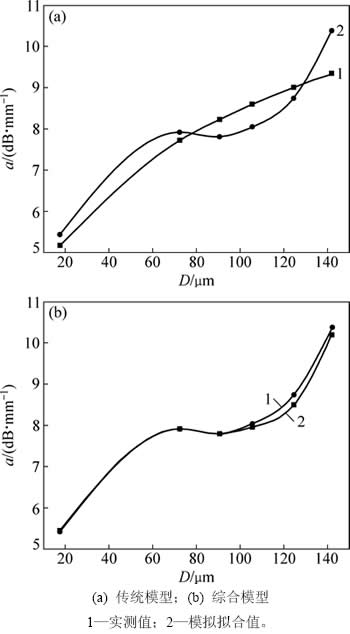

选用型号为GE-IAP10.6.3的探头,其中心频率为10 MHz,改变水声距W对各试块测量超声衰减系数α,样本容量为72。针对不同晶粒尺寸的各个试块进行测量,水声距和衰减的关系如图4所示。

图2 各试块金相图

Fig. 2 Metallographical images of test blocks

表1 试块热处理条件与金相法晶粒尺寸

Table 1 Heat treatment and metallographical grain size

图3 超声信号采集系统示意图

Fig. 3 Diagram of ultrasonic data acquisition system

由图4易见水声距W对衰减值a有显著的影响;水声距一定时,衰减系数与晶粒尺寸整体上呈正相关,但在晶粒尺寸D为82.51~105.57 μm及124.43 ~135.44 μm区间时,该正相关性减小且衰减系数分布相对集中。同时,由图4还可见衰减随水声距的变化呈高次多项式函数的波动趋势,且采用枚举法,对每条曲线都采用4次拟合时,相关系数首次均大于0.95,即采用最高4次的多项式非线性回归模型就足够拟合,即此时式(4)中m1=4;实验条件满足瑞利散射,故取m0=3[14]。

图4 水声距-衰减关系图

Fig. 4 Relationship between water depth and attenuation

2.3 模型计算

为使晶粒尺寸的区分度尽可能地大,现根据表1筛选出0号、1号、3号、4号、5号和8号试块6组实验数据进行计算。根据式(2)可知传统衰减系数评价模型中lnα与lnD呈线性关系,结合6个试块的衰减系数自然对数平均值 和晶粒尺寸自然对数平均值

和晶粒尺寸自然对数平均值 ,用最小二乘法可得式(2)中相关系数z=0.283 1,常数C0=0.831 9,解得传统衰减系数评价模型的表达式为

,用最小二乘法可得式(2)中相关系数z=0.283 1,常数C0=0.831 9,解得传统衰减系数评价模型的表达式为

(13)

(13)

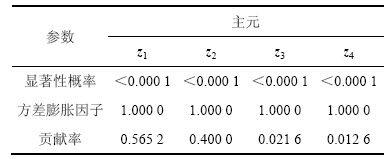

同时,对上述6组数据进行PCA处理,可得X的主元得分矩阵 。主元得分系数特征包括显著性概率、方差膨胀因子及贡献率,其计算结果如表2所示。

。主元得分系数特征包括显著性概率、方差膨胀因子及贡献率,其计算结果如表2所示。

表2 主元得分系数各特征值

Table 2 Eigenvalues of principal component weight coefficient

由表2可看出:各主元显著性概率均小于0.000 1,即主元得分系数显著;各个主元的方差膨胀因子均小于10,可判断各主元间均不相关;按贡献率最大原则选择前4个主元,累计贡献率为0.995 0,可视为完全表征原始数据信息。将所选的4个主元代入式(10)进行计算,可得各个主元回归模型的系数矩阵:

(14)

(14)

进一步计算出消除了D和W的量纲及取值差异程度影响的衰减系数α关于D和W的综合评价模型:

(15)

(15)

3 有效性分析

为验证晶粒尺寸和水声距均相关的综合衰减系数评价模型的有效性,将该模型与仅考虑晶粒尺寸相关的传统衰减系数模型进行对比。从相同晶粒尺寸的每组初始样本数据中,选出衰减系数最接近该组衰减系数平均值的1个样本个体,由此可获取9个个体数据来构成2种模型的对比样本。

首先从对比样本中选取参与模型推导的6个个体数据,分别代入2种模型求出衰减系数计算值,对比衰减系数实测值以验证其准确性,如图5所示。

经计算可得传统评价模型和综合评价模型的拟合相关系数分别为0.931 0和0.998 8。传统模型计算的衰减系数随晶粒尺寸的变化而呈幂函数递增规律变化,但衰减系数的实际测量值仅在整体上与晶粒尺寸呈正相关;而同时考虑水声距和晶粒尺寸的综合模型所计算出衰减系数能很好地追踪真实测量值的局部波动,可见衰减实测值局部波动是由水声距取值引起的,综合考虑水声距及晶粒尺寸对衰减系数的影响可提高评价模型的准确性。

图5 2种模型拟合衰减系数对比

Fig. 5 Comparison of fitting attenuation coefficient of two models

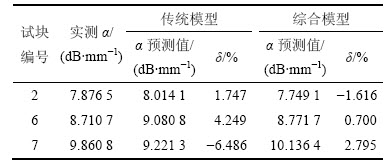

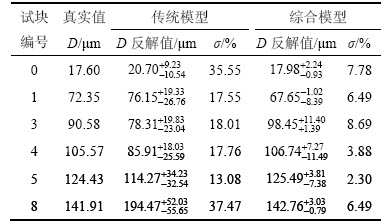

选取对比样本中不参与模型参数计算的3个样本个体,预测它们对应的3个试块的衰减系数以分析2种模型的预测性,结果如表3所示。从表3可见:综合模型对2号、6号和7号这3个试块的衰减系数预测值的相对误差δ均比传统模型的小;对于6号试块,传统模型的预测的衰减系数相对误差为4.249%,约为综合评价模型的6倍。可见综合评价模型对衰减系数的预测性能优于传统评价模型。

表3 2种模型预测衰减系数的性能对比

Table 3 Comparison of performance of two models’ predicting attenuation coefficients

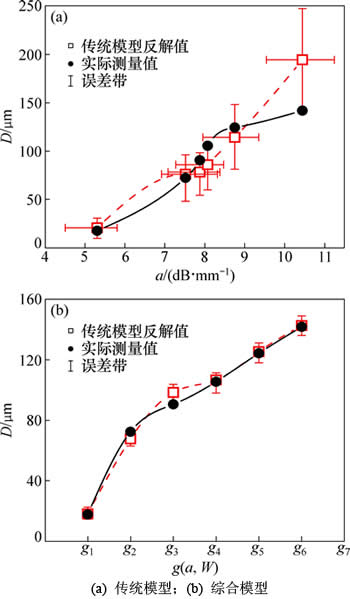

接着选用0号、1号、3号、4号、5号和8号试块的衰减系数和水声距,分别采用传统模型和综合评价模型进行晶粒尺寸反解。由传统模型式(13)反解得到的晶粒尺寸及误差带如图6(a)所示。对于综合模型,可视为解隐函数 f (D):

f (D)=α-g(W)-C1=h(α,W) (16)

设第i号试块对应的h(α,W)为hi,hi与反解的晶粒尺寸及误差带如图6(b)所示。

2种模型的反解值、误差带和均方误差率σ见表4。

表4 2种模型晶粒尺寸反解值

Table 4 Computing grain sizes of two models

图6 2种模型反解晶粒尺寸对比

Fig. 6 Comparison of grain-sizes of two models

从表4可知:传统模型对6个试块反解晶粒尺寸的均方误差率均值高达23.24%,而采用综合模型的均方误差率均值仅为5.94%,可见综合模型较传统模型的可靠性显著提高。

4 结论

1) 分析了影响晶粒尺寸超声衰减无损测量精度的因素,利用PCA方法研究了水浸式聚焦探头测量材料衰减系数过程中水声距对测量结果的影响,建立了含晶粒尺寸和水声距的衰减系数新评价模型。

2) 在同一晶粒尺寸下,当水声距在13.8~156.9 mm内变化时,衰减系数的测量值呈现波动变化;在同一水声距下,衰减系数与晶粒尺寸整体上呈正相关,但在晶粒尺寸为82.51~105.57 μm及124.43 ~135.44 μm时,该正相关性减小且衰减系数分布相对集中。

3) 所提出的衰减系数综合评价模型的准确性及稳定性均优于传统模型评价模型,它能在更大范围内通过晶粒尺寸和水声距预测衰减系数,并可利用实测的衰减系数反解得到消除水声距影响的较精确的材料晶粒尺寸,有效抑制了水声距调整精度对晶粒尺寸评价结果的不利影响。

参考文献:

[1] CUI C Y, OSADA T, HARADA H. Enhanced mechanical properties in a new Ni-Co base superalloy by controlling microstructure[J]. Materials Science and Engineering A, 2011, 528(16/17): 5465-5469.

[2] 刘宏, 郭荣新, 李莎, 等. 非晶态Ni-W-P镀层退火晶化和激光晶化组织结构的演变[J]. 中国有色金属学报, 2011, 21(8): 1936-1943.

LIU Hong, GUO Rongxin, LI Sha, et al. Microstructures evolution of electroless amorphous Ni-W-P coating during laser and annealing crystallization[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1936-1943.

[3] LI Jinzhu, NONG Deng, ZHENG Kaihong, et al. Microstructure and mechanical properties of AZ31 alloy ingot fabricated by semi-continuous casting[J]. Journal of Central South University, 2014, 21(8): 2984-2990.

[4] LEHTO P, REMES H, SAUKKONEN T, et al. Influence of grain size distribution on the Hall-Petch relationship of welded structural steel[J]. Mat Sci Eng A, 2014, 592: 28-39.

[5] 刘东华, 刘咏, 赵大鹏, 等. 锻态粉末液晶铁基合金的显微组织和力学性能[J]. 中南大学学报(自然科学版), 2010, 41(2): 455-459.

LIU Donghua, LIU Yong, ZHAO Dapeng, et al. Microstructure and mechanical properties of hot-forged powder metallurgy Fe-based alloys[J]. Journal of Central South University (Science and Technology), 2010, 41(2): 455-459.

[6] ZERGOUG M, LEBAILI S, BOUDJELLAL H, et al. Relation between mechanical microhardness and impedance variations in eddy current testing[J]. Nondestructive Test and Evaluation International, 2004, 37(1): 65-72.

[7] Review of progress in quantitative nondestructive evaluation[M]. New York: American Institute of Physics, 2009: 742.

[8] INAMI T, KOBIYAMA M, OKUDA S, et al. Grain size measurement of nanocrystalline gold by X-ray diffraction method[J]. Nano Structured Materials, 1999, 12(5): 657-660.

[9] 陈冷, 毛卫民, 杨平, 等. 基于 X 射线二维衍射图像的晶粒尺寸在线检测方法[J]. 中国体视学与图像分析, 2004, 9(3): 163-168.

CHEN Leng, MAO Weiming, YANG Ping, et al. A method of onl ine grain size measurement based on x-ray two-dimensional diffraction frame[J]. Chinese Journal of Stereology and Image Analysis, 2004, 9(3): 163-168.

[10] BADIDI BOUDA A, LEBAILI S, BENCHAALA A. Grain size influence on ultrasonic velocities and attenuation[J]. NDT & E International, 2003, 36(1): 1-5.

[11] DU H, LONSDALE C, OLIVER J, et al. Evaluation of railroad wheel steel with lamellar duplex microstructures using diffuse ultrasonic backscatter[J]. Nondestruct Evalution, 2013, 32(4): 331-340.

[12] LI A, ROBERTS R, FRANK J M, et al. Study of the effect of microstructure on ultrasonic signal attenuation[J]. Review of Progress in Quantitative Nondestructive Evaluation, 2001, 557(1): 1322-1329.

[13] LI Xiongbing, SONG Yongfeng, LIU Feng, HU Hongwei, NI Peijun. Evaluation of mean grain size using the multi-scale ultrasonic attenuation coefficient[J]. Nondestructive Test and Evaluation International, 2015, 72: 25-32.

[14] 美国无损检测学会.美国无损检测手册: 超声卷[M]. 美国无损检测手册译审委员会. 上海: 世界图书出版社, 1996: 617-618.

American Society of Nondestructive Testing. American nondestructive testing handbook: ultrasonic testing[M]. Translation Audit Committee of American Nondestructive Testing Handbook. Shanghai: World Publishing Press, 1996: 617-618.

[15] OCHOA A,  J, HERNANDEZ A, et al. PCA-based classification for 3Dultrasonic reflectors[C]//2007 IEEE International Symposium on Intelligent Signal Processing. Alcala de Henares, Spain: IEEE, 2007: 609-614.

J, HERNANDEZ A, et al. PCA-based classification for 3Dultrasonic reflectors[C]//2007 IEEE International Symposium on Intelligent Signal Processing. Alcala de Henares, Spain: IEEE, 2007: 609-614.

[16] 姜万录, 吴胜强, 刘思远. 指数加权动态核主元分析法及其在故障诊断中应用[J]. 机械工程学报, 2011, 47(3): 63-68.

JIANG Wanlu, WU Shengqiang, LIU Siyuan. Exponentially weighted dynamic kernel principal component analysis alogrithm and application in fault diagnosis[J]. Journal of Mechanical Engineering, 2011, 47(3): 63-68.

[17] 余建波. 基于智能学习模型的制造过程质量控制理论与方法论研究[D]. 上海: 上海交通大学机械与动力工程学院, 2009: 53-55.

YU Jianbo. Studying of manufacturing process quality control theory and methodology based on intelligent learning model[D]. Shanghai: Shanghai Jiaotong University. School of Mechanical Engineering, 2009: 53-55.

[18] 林莉. 合金钢显微组织超声无损表征研究[D]. 大连: 大连理工大学材料学院, 2003: 27-30.

LIN Li. Ultrasonic nondestructive characterization of microstructure of alloy steel[D]. Dalian: Dalian University of Technology. Department of Materials Engineering, 2003: 27-30.

[19] 董加坤. 制作奥氏体不锈钢金相试样的高效侵蚀剂配方及使用方法[J]. 金属热处理, 2011, 36(5): 133-135.

DONG Jiakun. Formulation and operation method of a high effective etchant for preparing austenitic stainless steel metallographic sample[J]. Heat Treatment of Metals, 2011, 36(5): 133-135.

(编辑 陈灿华)

收稿日期:2015-04-10;修回日期:2015-06-22

基金项目(Foundation item):国家高技术研究发展规划(863计划)项目(2012AA03A514);国家自然科学基金资助项目 (61271356,51575541);中国博士后科学基金资助项目(2014M562126);中南大学中央高校基本科研业务费专项资金资助项目(2015zzts209) (Project (2012AA03A514) supported by the High Technology Research and Development Program of China (863 Program); Projects (61271356, 51575541) supported by the National Natural Science Foundation of China; Project (2014M562126) supported by the Postdoctoral Science Foundation of China; Project (2015zzts209) supported by the Fundamental Research Funds for the Central Universities of Central South University)

通信作者:李雄兵,博士,副教授,从事超声自动检测研究;E-mail:lixb213@csu.edu.cn