文章编号: 1004-0609(2006)03-0500-05

空心管坯的异相位电磁连铸

王哲峰1, 2, 崔建忠1, 朴凤贤2

(1. 东北大学 材料电磁过程重点实验室, 沈阳 110004;

2. 沈阳航空工业学院 航空宇航工程学院, 沈阳 110034)

摘 要: 采用异相位电磁连铸技术, 制备d290mm×35mm的铝合金空心管坯, 研究异相位电磁场对铸锭凝固组织及表面质量的影响。 结果表明: 异相位电磁场通过改变金属熔体的流动状态, 减少原子团簇上角隅的形成, 降低熔体及凝固前沿的温度梯度等机制, 可使Al熔体内产生爆发式形核, 增加晶核数量, 抑制枝晶生长, 从而可细化、 球化晶粒, 改善铸锭凝固组织, 避免裂纹的产生; 同时, 异相位电磁场通过作用于初凝壳内液态金属熔体以及初凝壳本身的电磁力, 降低了结晶器与初凝壳的接触压力、 减小了铸锭表面的摩擦并抑制了偏析瘤的形成, 从而提高铝合金空心管坯的内外表面质量。

关键词: 铝合金; 电磁铸造; 凝固组织; 表面质量 中图分类号: TG249.7

文献标识码: A

Out-phase electromagnetic continuous casting of hollow billet

WANG Zhe-feng1, 2, CUI Jian-zhong1, PIAO Feng-xian2

(1. Key Laboratory of Electromagnetic Processing of Materials,

Northeastern University, Shenyang 110004, China)

2. Institute of Aeronautical Engineering,

Shenyang Institute of Aeronautical Engineering, Shenyang 110034, China)

Abstract: Under the out-phase electromagnetic field, Al alloy hollow billet of d290mm×35mm was semi-continuously cast, the effect of out-phase electromagnetic on as-cast microstructures and surface quality were investigated. The results show that the out-phase magnetic field changes the flow of metal melt, reduces the corner, reduces the temperature gradient of melt and solidification front, which gives rise to fulminic nucleation, increases the magnitude of crystal nucleus, restraines the growth of dendritic crystal in melt aluminium, the refines crystal grain, improves solidification structure, and eliminates phenomenon of crack. Simultaneously, Lorentz force that acts on the metal melt and initial skull reduces the contact pressure between the crystallizer and the initial skull, decreases the friction of ingot surface, restrains the form of segregation burl, and improves the surface quality of Al alloy hollow billet.

Key words: aluminum alloy; electromagnetic casting; solidification structure; surface quality

EMC、 CREM、 LFEC等铝合金电磁铸造技术的迅速发展[1-6], 为后续的加工过程提供了优良的坯料, 但这些技术的发展目前还主要限于单线圈实心铸锭的生产。 针对电力、 建筑以及制冷等各行业中广泛应用的铝合金管材, 采用近终形状的电磁铸造技术将有利于减少生产工序, 提高金属利用率。 因此, 近年来, 空心管坯电磁连铸技术的研究得到业内人士的广泛重视。 杨院生等[7]研究了电磁离心铸管过程, Harada[8]、 李丘林[9]等研究了单线圈的电磁连续铸管过程, 王哲峰等[10]分析了双线圈电磁连续铸管中各种磁场的分布状态。 异相位管坯电磁连铸技术是双线圈条件下的管坯电磁连铸技术, 铸造中, 内外线圈分别施加不同相位的交变电流, 在液态金属熔池及结晶凝固区产生异相位交变电磁场, 改变液态金属的流动状态及凝固条件, 从而提高铸锭质量的连铸技术。

1 实验

实验的主要设备由内结晶器、 外结晶器、 雨淋式流槽、 水冷内/外线圈、 热顶、 内/外石墨环、 引锭座组成。

设备的结构特点:

1) 在内/外结晶器中各布置一个线圈, 两线圈产生的磁场同时作用于金属熔体。

2) 采用全内置水冷线圈(涂有利邦漆的耐高温绝缘电磁线)和非磁性不锈钢结晶器。

3) 内/外结晶器均配有热顶, 并且采用雨淋式浇注法。

作用:

1) 可按要求对两个线圈中电流强度、 相位、 频率进行分别调整, 从而达到改善铸管凝固组织以及表面质量(尤其是内表面质量)的目的, 与单线圈相比磁场分布更加复杂、 磁场调节范围更宽。

2) 水冷线圈使线圈与熔体的距离更近、 非磁性不锈钢结晶器使磁感强度在结晶器上的损失减小, 这些都使线圈产生的磁场更有效地作用在铝合金熔体上。

图1 电磁铸造过程半剖示意图

Fig.1 Schematic illustration of semi-section of electromagnetic casting process

3) 内/外结晶器都装有热顶, 能使铝熔体充分流动, 减少熔体的径向温差; 淋式浇注法使管坯周向温度更加均匀, 从而能够铸造出更优质的管坯。

实验采用6063铝合金, 其化学成分为: 0.2%~0.6%Mg, 0.45%~0.9%Si, 〈0.35%Fe, 其它含量(Mn、 Cu、 Cr、 Zn、 Ti)均小于0.1%、 余量为Al。 实验时, 将金属熔化后在中间包除气、 除渣, 待温度达到730℃进行浇注, 同时施加电磁场。 产生异相位磁场的电流为50Hz、 100A的工频交变电流, 内/外线圈相位差为90°。 线圈为内线圈120匝, 内、 外直径分别为60、 180mm, 外线圈30匝, 内、 外直径分别为340、 360mm, 高度均为60mm。

2 结果与分析

2.1 凝固组织

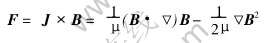

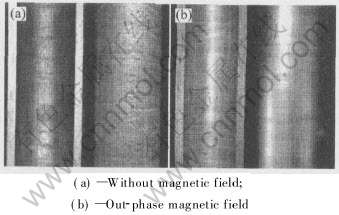

图2和3所示分别为铸管的宏观及微观组织照片。 由图可知, 无磁场时铸锭中具有发达的枝晶组织, 铸管壁厚中部是粗大的等轴晶, 这对管材性能有很大的负面影响, 实际生产中常出现如图2(c)所示的裂纹。 施加异相位磁场后, 枝晶被打碎、 熔断, 晶粒得到显著的细化、 球化, 中部和边部的晶粒大小已基本接近, 裂纹消失。 能够获得这些效果, 主要有以下原因[11-14]: 异相位磁场作用下金属熔体中存在感生电流, 同时感生电流与磁场作用产生洛伦兹力F,

式中 μ为相对磁导率;  项为洛伦兹力的有旋分量, 是由磁感强度矢量向对称轴倾斜而产生的。 它对金属熔体起到搅拌作用, 使熔体流动速度加快, 熔池中的熔体温度变得比较均匀, 这样可以在熔池的较大范围内存在“能够形核的原子团簇”或初晶坯, 由于他们均有与液相合适的相位, 良好的润湿, 因此随着铸锭的移动在较小的过冷度下, 即可形成爆发式的形核, 增加晶粒数量, 细化晶粒。 金属熔体中的能够形核的较大原子团簇是由尺寸相差悬殊的中、 小原子团簇结合而成, 这些较大原子团簇虽然形状各异但都具有比较突出的角隅, 这些角隅就是形成枝晶的起点。 异相位磁场可以增加原子团簇的能量, 使突出角隅上的原子更易于游离, 抑制或减少了枝晶起点的形成, 使晶粒近似按等轴方向发展。 在形成初凝壳的上部, 熔体接触结晶器, 会凝结成大量的原子团或初晶胚, 他们被快速流动的熔体带入熔池中增加形核核心。 通过对异相位电磁连铸过程熔体流动场的模拟计算可知, 熔体流动的相对速度快且流动方向与枝晶生长方向夹角大, 因此熔体流动对枝晶的冲刷、 熔断作用强, 抑制枝晶生长, 同时增加形核核心。 由于集肤效应, 感生电流多是集中于铸锭的表面, 因此异相位磁场产生的焦耳热也集中于边部, 这恰好降低了铸管壁厚中部与边部的温差(一般壁厚中部的温度总是高于边部), 而且使结晶器壁上的晶核、 初晶坯更加易于游离。 电磁力的脉动分量, 能引发两相区中晶间熔体产生受迫振荡, 改变晶间熔体的流动方式, 减小凝固前沿的温度梯度和成分过冷, 从而避免枝晶过分长大, 起到细化晶粒和提高等轴晶比例的作用。 两相区温度高、 范围大, 不利于枝晶的生长, 并给形核过程提供了充足的孕育时间。 晶粒相互碰撞、 摩擦, 使枝晶生长困难, 晶粒成近球状。 晶粒的自旋转运动使晶粒生长表现出各向同性。

项为洛伦兹力的有旋分量, 是由磁感强度矢量向对称轴倾斜而产生的。 它对金属熔体起到搅拌作用, 使熔体流动速度加快, 熔池中的熔体温度变得比较均匀, 这样可以在熔池的较大范围内存在“能够形核的原子团簇”或初晶坯, 由于他们均有与液相合适的相位, 良好的润湿, 因此随着铸锭的移动在较小的过冷度下, 即可形成爆发式的形核, 增加晶粒数量, 细化晶粒。 金属熔体中的能够形核的较大原子团簇是由尺寸相差悬殊的中、 小原子团簇结合而成, 这些较大原子团簇虽然形状各异但都具有比较突出的角隅, 这些角隅就是形成枝晶的起点。 异相位磁场可以增加原子团簇的能量, 使突出角隅上的原子更易于游离, 抑制或减少了枝晶起点的形成, 使晶粒近似按等轴方向发展。 在形成初凝壳的上部, 熔体接触结晶器, 会凝结成大量的原子团或初晶胚, 他们被快速流动的熔体带入熔池中增加形核核心。 通过对异相位电磁连铸过程熔体流动场的模拟计算可知, 熔体流动的相对速度快且流动方向与枝晶生长方向夹角大, 因此熔体流动对枝晶的冲刷、 熔断作用强, 抑制枝晶生长, 同时增加形核核心。 由于集肤效应, 感生电流多是集中于铸锭的表面, 因此异相位磁场产生的焦耳热也集中于边部, 这恰好降低了铸管壁厚中部与边部的温差(一般壁厚中部的温度总是高于边部), 而且使结晶器壁上的晶核、 初晶坯更加易于游离。 电磁力的脉动分量, 能引发两相区中晶间熔体产生受迫振荡, 改变晶间熔体的流动方式, 减小凝固前沿的温度梯度和成分过冷, 从而避免枝晶过分长大, 起到细化晶粒和提高等轴晶比例的作用。 两相区温度高、 范围大, 不利于枝晶的生长, 并给形核过程提供了充足的孕育时间。 晶粒相互碰撞、 摩擦, 使枝晶生长困难, 晶粒成近球状。 晶粒的自旋转运动使晶粒生长表现出各向同性。

图2 铸管的宏观组织及裂纹

Fig.2 Macrostructures and crack of cast tube

图3 铸管的微观组织

Fig.3 Microstructures of cast tube

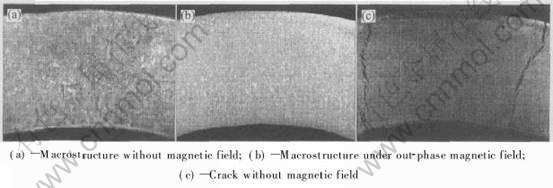

2.2 表面质量

图4所示为无磁场及异相磁场铸造条件下空心管的表面质量。 可以看出, 双线圈异相位磁场条件下铸锭内外表面均好, 偏析瘤得到了有效的抑制, 表面平整光洁; 无磁场时内外表面的偏析瘤严重, 表面凸凹不平, 质量不好。 通过实验及模拟计算可知, 异相磁场条件下, 内石墨环处的初凝壳及其附近液态金属受到较大的沿径向向外的电磁推力。 此力部分地抵消了液态金属对初凝壳的静压力, 使初凝壳与内石墨环接触压力减小; 另一方面使初凝壳中, 因内部过热熔体重溶的枝晶间低熔点物质, 不至于在熔体静压力作用下渗出凝壳, 形成偏析瘤。 此外, 此力使初凝壳具有与芯石墨环分离的趋势, 减少了凝固收缩的接触压力, 还使一次冷却强度降低, 形成较薄的具有一定塑性的凝壳, 避免出现因强烈的凝固收缩使铸锭与芯直接抱死的“抱芯”现象; 也可使摩擦力降低, 导致凝壳与石墨环之间容易出现空隙, 减少摩擦距离, 实现连铸空心管内表面的“软接触”, 提高铸锭的内表面质量。 至于电磁场提高空心管的外表面质量的原因与电磁连铸实心锭[3, 15, 16]的情况相同。

图4 铸管的内、 外表面

Fig.4 Inner and outer surfaces of cast tube

3 结论

1) 异相位管坯电磁连铸中, 磁场通过改变金属熔体的流动状态, 减少角隅的形成, 降低熔体及凝固前沿的温度梯度等机制, 可增加形核数量, 抑制枝晶生长, 从而达到细化、 球化晶粒, 改善铸锭凝固组织, 避免裂纹的目的。

2) 异相位磁场通过作用于初凝壳内液态金属熔体以及初凝壳本身的电磁力, 提高铸锭的表面质量。

REFERENCES

[1]Richter R T, Martin E J. Cause and prevention of explosions involving DC and EMC casting of aluminum sheet ingot[J]. Japan Institute of Metals, 2004, 56(11): 10-23.

[2]Kim S W, Hao H. Microstructure and fatigue characteristics of direct chill cast and electromagnetic cast 2024 Al alloy ingots[J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2003, A34(7): 1537-1542.

[3]张勤, 路贵民, 崔建忠. CREM法半连铸铝合金初凝壳与磁场强度的关系[J]. 中国有色金属学报, 2002, 12(1): 48-51.

ZHANG Qin, LU Gui-min, CUI Jian-zhong. Relationship between electromagnetic intensity and initial solidified shell height of aluminum alloy produced by CREM process[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(1): 48-51.

[4]Vivès C. Electromagnetic refining of aluminum alloys by the CERM process (part Ⅰ): working principle and metallurgical results[J]. Metallurgical Transactions B, 1989, 20B: 623-629.

[5]Vivès C. Electromagnetic refining of aluminum alloys by the CREM process (part Ⅱ): Specific practical problems and their solutions[J]. Metallurgical Transactions B, 1989, 20B: 631-643.

[6]董杰, 崔建忠. 7A60超高强铝合金的低频电磁铸造(Ⅰ)—直径0.2m锭坯的铸态组织[J]. 中国有色金属学报, 2003, 13(6): 1494-1499.

DONG Jie, CUI Jian-zhong. Super-high strength 7A60 A1 alloy by low frequency electromagnetic cast(Ⅰ)—As-cast structures of billets with diameter of 0.2m[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1494-1499.

[7]杨院生, 刘清民, 焦育民, 等. 液态金属电磁离心凝固的力场分析[J]. 金属学报, 1994, 30(5): B208-B212.

YANG Yuan-sheng, LIU Qing-min, JIAO Yu-ming, et al. Force field analysis on liquid metal during electromagnetic centrifugal solidification[J]. Acta Metall Sinica, 1994, 30(5): B208-B212.

[8]Harada H, Anazai E, Takeuchi E. Continuous casting of hollow billets[J]. Canadian Metallurgical Quarterly, 2000, 39(3): 307-318.

[9]李丘林, 李廷举, 金俊泽, 等. 空心管坯热顶电磁连铸工艺的研究[J]. 稀有金属材料工程, 2004, 33(4): 429-431.

LI Qui-lin, LI Ting-ju, JIN Jun-ze, et al. Research on hot-top electromagnetic continuous casting of hollow billets[J]. Rare Metal Materials and Engineering, 2004, 33(4): 429-431.

[10]王哲峰, 崔建忠. 铝合金空心管坯电磁铸造中磁场分布的数值模拟[J]. 东北大学学报, 2005, 26(3): 244-247.

WANG Zhe-feng, CUI Jian-zhong. Numerical simulation of magnetic field distribution during electromagnetic casting of Al-alloy hollow billets[J]. Journal of Northeastern University, 2005, 26(3): 244-247.

[11]张勤, 崔建忠. 磁场强度对半连铸铝合金液穴形状及凝固组织的影响[J]. 金属学报, 2002, 38(9): 956-960.

ZHANG Qin, CUI Jian-zhong. Effects of electromagnetic intensity on the sump shapes and structures of aluminum alloy produced by CREM process[J]. Acta Metall Sinica, 2002, 38(9): 956-960.

[12]刘让苏, 董科军, 刘凤翔, 等. 液态金属Al凝固过程中大团簇结构的形成与演变机理[J]. 中国科学G辑, 2004, 34(5): 549-559.

LIU Rang-su, DONG Ke-jun, LIU Feng-xiang, et al. Formation and evolution of cluster during solidification process of liquid metal Al[J]. Science in China G, 2004, 34(5): 549-559.

[13]刘让苏, 刘凤翔, 董科军, 等. 液态金属Al快速凝固过程中团簇结构的形成特性[J]. 化学物理学报, 2004, 17(6): 722-728.

LIU Rang-su, LIU Feng-xiang, DONG Ke-jun, et al. Formation characteristics of cluster during rapid solidification process of liquid metal Al[J]. Chinese Journal of Chemical Physics, 2004, 17(6): 722-728.

[14]张北江, 崔建忠. 电磁场频率对电磁铸造7075铝合金微观组织的影响[J]. 金属学报, 2002, 38(2): 215-218.

ZHANG Bei-jiang, CUI Jian-zhong. Effect of frequency on microstructure of electromagnetic casting 7075 aluminum alloy[J]. Acta Metall Sinica, 2002, 38(2): 215-218.

[15]Vives C. Experimental study of continuous electromagnetic casting of aluminum alloys[J]. Metallurgical transactions B, 1985,16B: 377-284.

[16]张勤,崔建忠. 液穴形状及铸锭表面质量随磁场强度的变化规律[J]. 东北大学学报, 2002, 23(7): 671-674.

ZHANG Qin, CUI Jian-zhong. Evolutions of sump shape and ingot surface quality of Al-7075 alloy manufactured under electromagnetic field with different intensity[J]. Journal of Northeastern University, 2002, 23(7): 671-674.

基金项目: 国家高技术研究发展计划资助项目 (2001AA332030)

收稿日期: 2005-07-11; 修订日期: 2005-12-12

作者简介: 王哲峰(1970-), 男, 博士研究生

通讯作者: 崔建忠, 教授; 电话: 13514286803; E-mail: zhefeng_w@126.com

(编辑陈爱华)