DOI: 10.11817/j.issn.1672-7207.2020.01.029

CeO2-MnOx/CF对甲苯的催化氧化性能

王玉玲,宋敏,孟凡跃

(东南大学 能源与环境学院,能源热转换及其过程测控教育部重点实验室,江苏 南京,210096)

摘要:为提高Ce基催化剂对挥发性有机物(VOCs)的催化氧化性能,采用超声辅助浸渍法制备CeO2-MnOx/CF复合氧化物催化剂,以甲苯为探针分子,考察制备条件和反应条件对催化剂甲苯催化氧化活性的影响,并采用扫描电子显微镜(SEM)、X线衍射分析仪(XRD)、全自动比表面积及孔隙分析仪(BET)等对催化剂的形貌结构进行表征。研究结果表明:CeO2-MnOx/CF催化剂比表面积高,孔容大,活性组分在载体上高度分散,双组分间具有协同催化作用;在铈锰物质的量比为2:3、活性组分负载量为14%(质量分数)、空速为22.5 L/(g·h)、甲苯初始质量浓度为1 g/L条件下,CeO2-MnOx/CF催化剂的甲苯催化氧化活性最高,228 ℃下2Ce3Mn/CF催化剂对1 g/L甲苯的催化降解率可达到90%。

关键词:铈锰复合氧化物催化剂;挥发性有机物;催化氧化;影响因素

中图分类号:X511 文献标志码:A

文章编号:1672-7207(2020)01-0261-08

Catalytic performance of CeO2-MnOx/CF for oxidation of toluene

WANG Yuling, SONG Min, MENG Fanyue

(Key Laboratory of Energy Thermal Conversion and Control of Ministry of Education, School of Energy and Environment, Southeast University, Nanjing 210096, China)

Abstract: In order to improve the catalytic oxidation performance of Ce-based catalysts for VOCs, the CeO2-MnOx catalyst supported on the carbon fiber (CF) was prepared by ultrasonic assisted impregnation method. Taking toluene as the probe molecule, the effects of preparation conditions and reaction conditions on the catalytic activity of the catalysts were investigated. The morphology and structure of the catalysts was characterized by scanning electron microscopy (SEM), X-ray diffraction analysis (XRD), fully automatic specific surface area and pore analyzer (BET). The results show that CeO2-MnOx/CF catalyst has high specific surface area, large pore volume, highly dispersed active components on the support, and synergistic catalysis between the two components. The highest catalytic activity of CeO2-MnOx/CF catalyst is obtained under the conditions of molar ratio of Ce to Mn of 2:3, active component loading of 14%(mass fraction), space velocity of 22.5 L/(g·h) and initial mass concentration of toluene of 1 g/L. The catalytic degradation rate of 2Ce3Mn/CF catalyst to 1 g/L toluene at 228 ℃ can reach 90%.

Key words: CeO2-MnOx/CF mixed oxides catalyst; VOCs; catalytic oxidation; influencing factors

随着我国经济高速发展,能源消耗持续加快,大量污染物排放到大气环境中,导致全国连续爆发灰霾等区域性大气污染事件[1]。挥发性有机污染物(VOCs)是二次气溶胶[2]、PM2.5和O3[3]形成的关键前驱体,“十三五”挥发性有机物污染防治工作方案确定了到2020年全国重点地区、重点行业VOCs污染排放总量下降10% 以上的总体控制目标,新《环境保护税法》规定19种VOCs为应税污染物,因此,VOCs的排放控制刻不容缓。VOCs净化处理技术包括吸附法[4]、吸收法[5]、冷凝法[6]和膜分离法[7]等回收性技术和生物降解法[8]、燃烧法[9]、光催化氧化法[10]、低温等离子体法[11]等销毁性技术,其中催化燃烧法无二次污染、起燃温度低、能耗小,对低浓度VOCs有良好的去除效果,全球市场占比最高。常用催化剂包括贵金属催化剂和非贵金属催化剂2类。贵金属催化剂具有起燃温度低、去除完全等优点,但成本较高,且易中毒。近年来,非贵金属催化剂因价格低廉,抗氯、抗硫性能较好而成为研究热点。稀土金属Ce具有良好的储放氧能力和氧流动性,可作为催化剂的活性组分或助剂。目前,用于VOCs催化降解的铈基催化剂主要包括Ce–M(M=Cr,Mn,Cu,Ni)和Ce–Mn–M(M=Cu,Ni,Co,Zr)[12-16]等复合氧化物催化剂,起燃温度较高,比表面积小,而VOCs需先吸附至催化剂表面再进行催化氧化,因此,将催化剂负载于VOCs吸附性能良好的载体可能有利于提高催化剂的催化活性。碳纤维(CF)热稳定性好、比表面积高、有丰富的孔隙结构,在大气有机物净化中常被用作吸附剂[4,17-18]和催化剂载体[19-20]。本文作者以CF为载体,采用超声辅助浸渍法制备铈锰复合氧化物催化剂(CeO2-MnOx/CF),考察制备条件和反应条件对其甲苯催化氧化活性的影响,并采用SEM,XRD和BET等手段对其理化性质进行表征分析。

1 材料制备与方法

1.1 催化剂制备

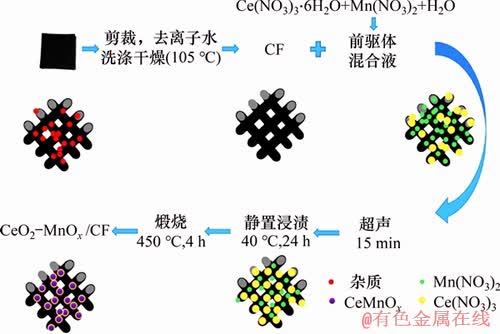

采用超声辅助等体积浸渍法,以CF为载体,Ce(NO3)3·6H2O为铈源,Mn(NO3)2(质量分数为50%)为锰源,制备铈锰复合氧化物催化剂(CeO2-MnOx/CF),具体制备流程如图1所示。先将碳纤维毡剪碎成长×宽为2 mm×2 mm,去离子水洗净后于105 ℃下干燥备用;分别称取适量金属活性组分前驱体,加入去离子水充分溶解,再加入已称量好的碳纤维,搅拌并超声处理15 min置于40 ℃水浴锅中静置浸渍24 h,105 ℃干燥12 h。将所得固体置于管式炉中,N2氛围下450 ℃煅烧4 h后,即可获得铈锰复合氧化物催化剂,并将其命名为CexMn1-xO2/CF(x=0,0.2,0.4,0.6,0.8,1.0)。单组分金属氧化物催化剂在浸渍过程中只需加入相应前驱体,其他制备步骤与复合氧化物催化剂相同。

图1 CeO2-MnOx/CF催化剂制备流程示意图

Fig. 1 Schematic diagram of preparation process of CeO2-MnOx/CF catalysts

1.2 催化剂表征

采用FEI Inspect F50型扫描电子显微镜(SEM)测定材料表面形貌,最大分辨率为1.0 nm/30 kV,加速电压为200~3×104 V;采用D8 ADVANCE型衍射仪进行X线衍射分析(XRD),测试使用Cu Kβ靶,接收狭缝为10 mm,扫描范围2θ=10°~90°,扫描速度为10 (°)/min,步长为0.02 (°)/s,管电压为40 kV,管电流为30 mA;采用Micromeritics ASAP 2020型物理吸附仪测定材料比表面积和孔结构,取适量待测样品置于测试端,预处理后,利用高纯N2作为吸附质并分别采用BET法和BJH法对催化剂的比表面积和孔结构进行检测。

1.3 催化剂活性评价

甲苯催化燃烧性能测试在内径为22 mm、长度为45 cm的固定床反应器中进行。利用液相鼓泡法由载气N2流经装有液态甲苯的玻璃鼓泡瓶带出甲苯气体,其质量浓度可通过调节载气N2流量和鼓泡瓶水浴温度控制。氧气、氮气与甲苯气体经由气体混合室混合后进入固定床催化反应器,在床层进行催化燃烧反应,床层温度由程序加热升温控制仪控制。以50 ℃为采样间隔在150~350 ℃的温度窗口内进行测试,在每一温度阶段需待系统稳定30 min后再进行采样。反应前后的气体浓度均由气相色谱仪(SP-6890)进行检测分析,测得反应前后甲苯浓度,催化剂活性采用甲苯转化率X进行评价,其计算方法如下:

(1)

(1)

式中: 为甲苯进口质量浓度,mg/L;

为甲苯进口质量浓度,mg/L; 为甲苯出口质量浓度,mg/L。

为甲苯出口质量浓度,mg/L。

2 结果与讨论

2.1 制备条件对催化剂活性的影响

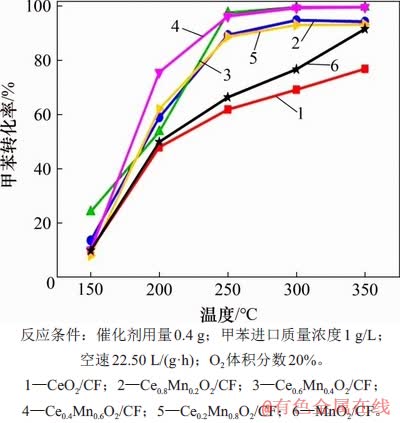

2.1.1 不同铈锰物质的量比对催化剂活性的影响

活性组分是催化剂的核心部分,选择合适的活性组分复合比例,不仅可以提高催化剂的催化活性,而且能节约成本。图2所示为不同铈锰物质的量比对催化剂催化活性的影响曲线。由图2可知:单组分催化剂的甲苯转化率较低,且MnO2/CF活性(t50=194 ℃,t90=345 ℃)略高于CeO2/CF活性(t50=208 ℃,t90 > 350 ℃,t50和t90分别为甲苯转化率为50%和90%时所对应的反应温度);铈锰复合氧化物催化剂的甲苯催化氧化活性(t90)从大到小依次为:Ce0.4Mn0.6O2/CF(228 ℃), Ce0.6Mn0.4O2/CF(241 ℃),Ce0.8Mn0.2O2/CF(256 ℃),Ce0.2Mn0.8O2/CF(265 ℃),均显著比单组分催化剂的高,说明适当掺杂锰元素,可使催化剂具有更高的深度氧化能力,但当铈锰物质的量比低于2:3后,催化剂甲苯催化氧化活性反而下降。Ce0.4Mn0.6O2/CF的甲苯催化氧化活性比贵金属催化剂Au[21]和Mn-Ce系列催化剂的高[22-23],因此,选择Ce0.4Mn0.6O2/CF进行后续研究。

图2 不同铈锰物质的量比对催化剂活性的影响

Fig. 2 Effect of different molar ratios of Ce to Mn on catalyst activity

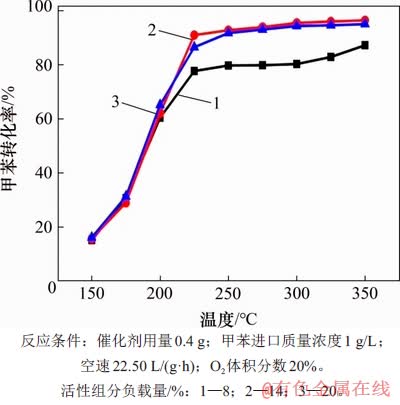

2.1.2 活性组分负载量对催化剂活性的影响

活性组分负载量是影响催化剂反应性能的重要因素。图3所示为不同活性组分负载量对催化剂活性的影响曲线。由图3可知:在不同温度范围内,活性组分负载量对甲苯转化率的影响幅度不同。在150~200 ℃区间内,3种不同活性组分负载量的Ce0.4Mn0.6O2/CF催化剂对甲苯的催化氧化活性无显著差异;随着反应温度升高,3种活性组分负载量催化剂的甲苯转化率均有所增加,其从大到小依次为:14%Ce0.4Mn0.6O2/CF,20%Ce0.4Mn0.6O2/CF,8%Ce0.4Mn0.6O2/CF,可见活性组分负载量存在极限值。活性组分负载量增加,催化剂表面活性位点增多,可促进活性组分与甲苯分子的充分接触,提高催化剂的甲苯催化氧化性能;当负载量超过14%时,催化剂表面活性组分堆积,分散度降低,同时阻碍了表面吸附点,吸附性能降低,反应气体与活性组分不能够充分接触并反应,进而导致催化剂活性无明显变化甚至降低。由此可见,合适的活性组分负载量有利于提高Ce0.4Mn0.6O2/CF催化剂的甲苯催化氧化活性,出于经济有效的考虑,选择14% Ce0.4Mn0.6O2/CF催化剂进行后续研究。

图3 不同活性组分负载量对催化剂活性的影响

Fig. 3 Effect of different active component loadings on catalyst activity

2.2 反应条件对催化剂活性的影响

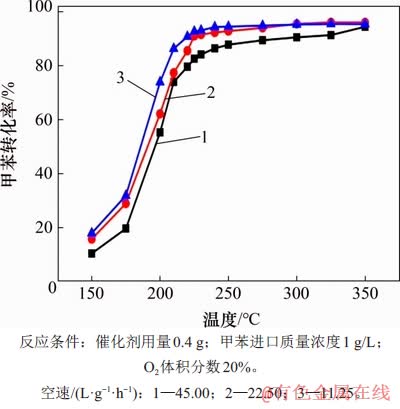

2.2.1 空速对催化剂活性的影响

图4所示为不同空速对Ce0.4Mn0.6O2/CF催化剂催化活性的影响曲线。空速大小反映了反应时间的长短。空速过大,催化剂的处理能力提高,但气固相接触不充分,反应不完全,催化剂活性降低;空速过小,催化剂活性提高,但处理量下降也会导致实际应用成本上升。因此,选择合适的空速至关重要。由图4可知:甲苯在同一温度下的转化率随空速的增加而不断降低;当空速由11.25L/(g·h) (t90=216 ℃)增大至22.50 L/(g·h )(t90=228 ℃)时,催化剂处理甲苯完全转化温度t90升高了约7 ℃,依然能保证催化剂与甲苯充分接触,在较低温度下实现甲苯的高效去除;随着空速继续增大至45.00 L/(g·h)(t90=300 ℃),催化剂处理甲苯完全转化温度t90升高了约72 ℃,与低空速下对应的t90相差较大。这是因为在此空速条件下,甲苯分子在催化剂床层停留时间短,催化氧化反应不充分,部分甲苯分子尚未被吸附至催化剂表面并发生反应就离开了催化剂床层,导致催化剂降解甲苯的效率降低,甲苯完全去除所需要的温度增加。为了保证催化剂较高的处理能力和较低的应用成本,选择11.25 L/(g·h)作为后续研究的空速。

图4 不同空速对催化剂活性的影响

Fig. 4 Effect of different space velocities on catalyst activity

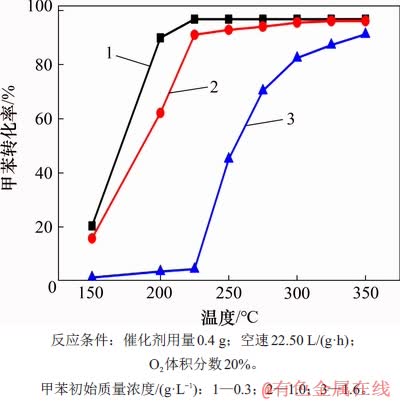

2.2.2 甲苯初始质量浓度对催化剂活性的影响

在实际工业排放的有机废气中,VOCs质量浓度变化范围较大,而催化剂对不同质量浓度VOCs的催化降解性能有显著差异。图5所示为不同甲苯初始质量浓度对铈锰复合氧化物催化剂甲苯催化氧化活性的影响。由图5可知:甲苯在同一温度下的转化率随初始质量浓度的增加而不断降低,但在不同温度范围内,甲苯初始质量浓度对转化率的影响幅度有显著差异;在低温区间内(< 225 ℃),甲苯初始质量浓度增加导致其转化率迅速下降,如当反应温度为200 ℃时,0.3,1.0和1.6 g/L初始质量浓度条件下对应的甲苯转化率分别为89.91%,62.16%和3.52%;当温度高于225 ℃时,在0.300~1.0 g/L范围内,甲苯初始质量浓度增加对其转化率影响不大,250 ℃下甲苯转化率比90%时的高;当甲苯初始质量浓度继续增加至1.6 g/L时,转化率下降,350 ℃方可达到90%以上。总体而言,Ce0.4Mn0.6O2/CF催化剂对高浓度甲苯仍具有较高的催化活性,适用于工业上高浓度有机废气的净化处理。

图5 不同甲苯初始质量浓度对催化剂活性的影响

Fig. 5 Effect of different initial mass concentrations of toluene on catalyst activity

3 表征分析

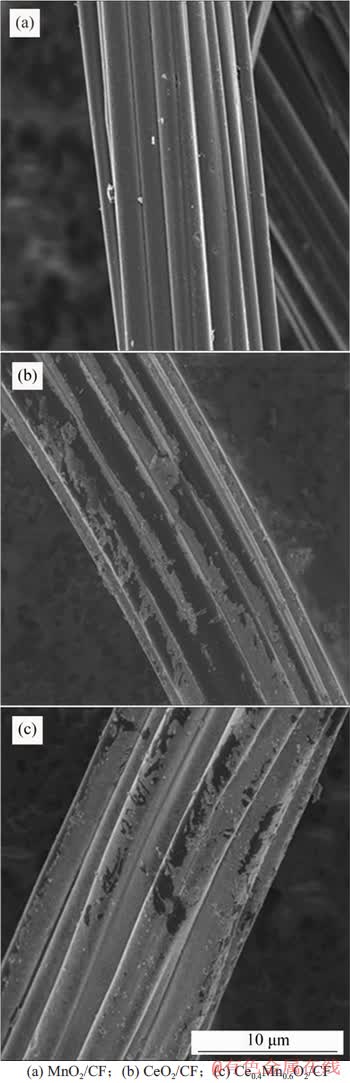

3.1 SEM分析

采用扫描电子显微镜(SEM)分析铈锰复合氧化物催化剂的表面形貌结构,结果如图6所示。从图6可以观察到载体CF纤维条直径为1~2 μm,且基本保持均匀,表面具有丰富的孔隙结构,纤维条上的沟壑纹路增大了CF的比表面积,有利于甲苯分子的传递和吸附,而活性组分则呈片层状沉积裹覆于CF的纤维条表面,说明活性组分负载成功且高度分散。从整体范围来看,CF表面有一些白色凸起物,究其原因可能是在等体积浸渍制备材料过程中,浸渍液含量相对较少,与载体CF混合吸附时活性组分前驱体不能均匀分散,瞬时吸附量较大造成局部过量,经超声辅助处理后活性组分前驱体分散度增加,但仍有少部分活性组分前驱体局部轻微过量,导致CF表面活性组分出现局部轻微堆积现象。

图6 CeO2-MnOx/CF催化剂的SEM图

Fig. 6 SEM images of CeO2-MnOx/CF catalysts

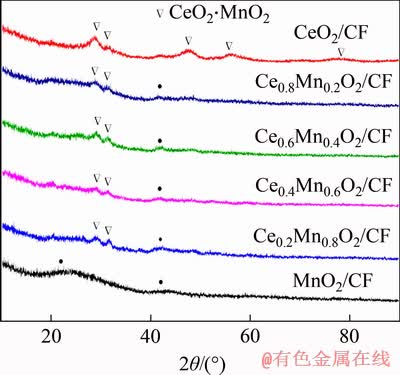

3.2 XRD分析

采用X线衍射(XRD)分析铈锰复合氧化物催化剂的晶体结构,结果如图7所示。由图7可知:对于CeO2/CF,28.6°,33.1°,47.5°,56.3°和79.1°处的特征峰归属于典型的CeO2萤石状结构,分别对应于其(111),(200),(220),(311)和(331)(JCPDS 34-0394)晶面。MnO2/CF在22.2°和43.5°处的特征峰分别对应于MnO2的(101)和(401)(JCPDS 44-0142)晶面。复合氧化物催化剂中,CeO2在47.5°,56.3°和79.1°处的特征峰消失,28.6°和33.1°处的特征峰位置向右发生轻微偏移,说明MnO2和CeO2之间发生了强烈相互作用。研究表明,在Mn-Ce氧化物催化剂[24]上,晶体结晶度越低,特征峰强度越弱甚至不存在。Ce0.4Mn0.6O2/CF表面MnO2和CeO2的所有特征峰均基本消失,说明Ce0.4Mn0.6O2/CF表面负载的活性组分为非晶结构,这可能是Mn物种进入CeO2晶格,通过强相互作用,形成无定型CeMnOx固溶体,引起其晶体紊乱所致。Ce0.4Mn0.6O2/CF表面高度分散的CeMnOx固溶体,可增加表面氧物种的数量及氧的流动性,从而显著提高复合氧化物催化剂的氧化还原性能,这与催化剂活性评价中Ce0.4Mn0.6O2/CF催化剂甲苯催化氧化活性最高的实验结果相一致。

图7 CeO2-MnOx/CF催化剂的XRD图

Fig. 7 XRD patterns of CeO2-MnOx/CF catalysts

3.3 BET分析

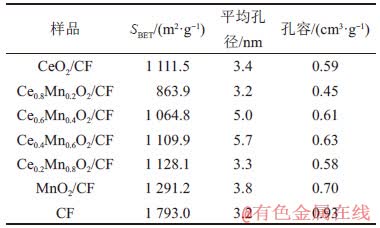

不同铈锰物质的量比制备的样品的比表面积及孔径结构见表1。CF的比表面积和孔容远比纯CeO2和MnO2的大,负载复合氧化物后,活性组分覆盖于CF表面,堵塞孔道,比表面积和孔容也随之减小,但仍远高于同类催化剂[22-23]。样品比表面积从大到小依次为:Ce0.2Mn0.8O2/CF, Ce0.4Mn0.6O2/CF,Ce0.6Mn0.4O2/CF,Ce0.8Mn0.2O2/CF,随着锰掺杂量的增加,铈锰复合氧化物催化剂比表面积逐渐增大,孔容和孔径则呈先增大后减小的趋势。比表面积测试与催化效果一致,Ce0.4Mn0.6O2/CF催化效果最优,同时比表面积(1 109.9 m2/g)也较高,孔容和孔径最大,分别为5.7 nm和0.63 cm3/g;Ce0.2Mn0.8O2/CF比表面积最高,但孔容和孔径较小。可见催化剂催化效果受其比表面积和孔径结构影响,高比表面积和大孔容有利于活性组分的高度分散和甲苯分子的传递吸附,因而,Ce0.4Mn0.6O2/CF催化剂的甲苯催化氧化活性最强。

表1 CeO2-MnOx/CF 催化剂的比表面积、孔径和孔容

Table 1 Surface area, pore diameter and pore volume of CeO2-MnOx/CF catalysts

由CeO2-MnOx/CF系列催化剂的表征结果推测可知,甲苯催化氧化反应发生在催化剂表面吸附的甲苯分子和活性组分晶格氧之间,且甲苯的催化氧化分为2步:第一步,甲苯在催化剂表面CeMnOx固溶体的氧空位上发生吸附而被活化,而后在活性氧物种的作用下开环裂解成相应的直链有机物并最终转化为CO2和H2O,与此同时,CeMnOx固溶体的氧空位被甲苯分子所还原;第二步,气相氧在CeMnOx固溶体的氧空位上吸附、解离并将氧空位重新氧化恢复至起始状态,形成消耗-补给过程,从而完成Ce4+/Ce3+和Mn4+/Mn3+间的催化循环过程,实现催化剂的再生,然后参与到下一个催化循环当中,因此,甲苯在CeO2-MnOx/CF系列催化剂上的催化氧化过程符合Marsevan-Krevelen (M-VK)机理。

4 结论

1) 催化剂催化效果受其比表面积和孔径结构影响。Ce0.4Mn0.6O2/CF催化剂的高比表面积、大孔容及表面丰富的孔隙结构有利于甲苯分子的传递吸附和活性组分的高度分散,使甲苯分子能够与活性位点充分接触并反应;也可促进催化剂中气相氧和表面氧的流动,氧化还原性能提高,因此,Ce0.4Mn0.6O2/CF催化剂的甲苯催化活性最强。

2) 2种金属氧化物间具有协同催化作用。MnO2进入CeO2晶格,并发生强相互作用,形成高度分散的CeMnOx固溶体,增加了CeO2-MnOx/CF的深度氧化能力,氧化还原性能显著提高。

3) 铈锰物质的量比、活性组分负载量、空速、甲苯初始质量浓度等影响因素中,甲苯初始质量浓度对CeO2-MnOx/CF催化剂催化效果的影响最大,且不同温度范围内,其对转化率的影响幅度有显著差异。

参考文献:

[1] 蒋锦晓, 何建波, 陈彬, 等. 城市不同源雾霾颗粒物健康风险差异评估比较[J]. 中国环境科学, 2019, 39(1): 379-385.

JIANG Jinxiao, HE Jianbo, CHEN Bin, et al. Comparison and assessment of haze particles health risks from different sources in City[J]. China Environmental Science, 2019, 39(1): 379-385.

[2] 陈文泰, 邵敏, 袁斌, 等. 大气中挥发性有机物(VOCs)对二次有机气溶胶(SOA)生成贡献的参数化估算[J]. 环境科学学报, 2013, 33(1): 163-172.

CHEN Wentai, SHAO Min, YUAN Bin, et al. Parameterization of contribution to secondary organic aerosol(SOA) formation from ambient volatile organic compounds (VOCs)[J]. Acta Scientiae Circumstantiae, 2013, 33(1): 163-172.

[3] 闫雨龙, 彭林. 山西省人为源 VOCs排放清单及其对臭氧生成贡献[J]. 环境科学, 2016, 37(11): 4086-4093.

YAN Yulong, PENG Lin. Emission inventory of anthropogenic VOCs and its contribution to ozone formation in Shanxi Province[J]. Environmental Science, 2016, 37(11): 4086-4093.

[4] 许伟, 刘军利, 孙康. 活性炭吸附法在挥发性有机物治理中的应用研究进展[J]. 化工进展, 2016, 35(4): 1223-1229.

XU Wei, LIU Junli, SUN Kang. Application progresses in the treatment of volatile organic compounds by adsorption on activated carbon[J]. Chemical Industry and Engineering Progress, 2016, 35(4): 1223-1229.

[5] 孟凡飞, 王海波, 刘志禹, 等. 工业挥发性有机物处理技术分析与展望[J]. 化工环保, 2019, 39(4): 387-395.

MENG Fanfei, WANG Haibo, LIU Zhiyu, et al. Analysis and prospect on treatment technologies of industrial volatile organic compounds[J]. Environmental Protection of Chemical Industry, 2019, 39(4): 387-395.

[6] 景海波, 汪城, 黄维秋, 等. 集成催化燃烧和氨水吸收制冷的油气冷凝吸附回收系统[J]. 环境工程学报, 2018, 12(2): 382-387.

JING Haibo, WANG Cheng, HUANG Weiqiu, et al. Oil vapor recovery system with integrated condensation, adsorption, catalytic combustion and ammonia absorption refrigeration[J]. Chinese Journal of Environmental Engineering, 2018, 12(2): 382-387.

[7] OZTURK B, KURU C, AYKAC H, et al. VOC separation using immobilized liquid membranes impregnated with oils[J]. Separation and Purification Technology, 2015, 153: 1-6.

[8] ZHANG Shihan, YOU Juping, KENNES C, et al. Current advances of VOCs degradation by bioelectrochemical systems: A review[J]. Chemical Engineering Journal, 2018, 334: 2625-2637.

[9] 户英杰, 王志强, 程星星, 等. 燃烧处理挥发性有机污染物的研究进展[J]. 化工进展, 2018, 37(1): 319-329.

HU Yingjie, WANG Zhiqiang, CHENG Xingxing, et al. Recent progress in the removal of volatile organic compounds by combustion[J]. Chemical Industry and Engineering Progress, 2018, 37(1):319-329.

[10] 芮泽宝, 杨晓庆, 陈俊妃, 等. 光热协同催化净化挥发性有机物的研究进展及展望[J]. 化工学报, 2018, 69(12): 4947-4958.

RUI Zebao, YANG Xiaoqing, CHEN Junfei, et al. Photo-thermal synergistic catalysis for VOCs purification: current status and future perspectives[J]. Journal of Chemical Industry and Engineering, 2018, 69(12): 4947-4958.

[11] 鲁美娟, 汪怀建, 黄荣,等. 催化剂对等离子体协同催化降解挥发性有机物影响的研究进展[J]. 环境污染与防治, 2018, 40(1): 88-94.

LU Meijuan, WANG Huaijian, HUANG Rong, et al. Research of effect of catalyst on the VOCs degradation using plasma-assisted catalysis technology[J]. Environmental Pollution & Control, 2018, 40(1): 88-94.

[12] YANG Peng, SHI Zhinan, YANG Shanshan, et al. High catalytic performances of CeO2-CrOx catalysts for chlorinated VOCs elimination[J]. Chemical Engineering Science, 2015, 126: 361-369.

[13] SHU Yajie, HE Miao, JI Jian, et al. Synergetic degradation of VOCs by vacuum ultraviolet photolysis and catalytic ozonation over Mn-xCe/ZSM-5[J]. Journal of Hazardous Materials, 2019, 364: 770-779.

[14] ZHU Xinbo, GAO Xiang, QIN Rui, et al. Plasma-catalytic removal of formaldehyde over Cu–Ce catalysts in a dielectric barrier discharge reactor[J]. Applied Catalysis B: Environmental, 2015, 170/171: 293-300.

[15] ZHANG Xue, WU Dongfang. Ceramic monolith supported Mn–Ce–M ternary mixed-oxide (M=Cu, Ni or Co) catalyst for VOCs catalytic oxidation[J]. Ceramics International, 2016, 42(15): 16563-16570.

[16] 潘红艳, 张煜, 林倩, 等. 催化燃烧VOCs用非贵金属催化剂研究新进展[J]. 化工进展, 2011, 30(8): 1726-1732.

PAN Hongyan, ZHANG Yu, LIN Qian, et al. Advance in non-noble metal catalysts for catalytic combustion of volatile organic compounds[J]. Chemical Industry and Engineering Progress, 2011, 30(8): 1726-1732.

[17] GIRAUDET S, BOULINGUIEZ B, LE CLOIREC P. Adsorption and electrothermal desorption of volatile organic compounds and siloxanes onto an activated carbon fiber cloth for biogas purification[J]. Energy & Fuels, 2014, 28(6): 3924-3932.

[18] YI Fenyun, LIN Xiaodan, CHEN Shuixia, et al. Adsorption of VOC on modified activated carbon fiber[J]. Journal of Porous Materials, 2009, 16(5): 521-526.

[19] WEI Yuexing, SONG Min, YU Lei, et al. Promotion effect of SiO2 on the catalytic performance of Ni/CF for biomass derived gas reforming[J]. Industrial & Engineering Chemistry Research, 2018, 57(32): 10851-10858.

[20] GAO Ruiqi, SONG Min, WEI Yuexing, et al. CO2 reforming of methane over Ni/carbon fibers-La2O3 catalyst: effects of ultrasound-assisted method and La2O3 doping on catalytic properties and activity[J]. Waste and Biomass Valorization, 2019, 10(12): 3897-3905.

[21] CARABINEIRO S A C, CHEN X, MARTYNYUK O, et al. Gold supported on metal oxides for volatile organic compounds total oxidation[J]. Catalysis Today, 2015, 244: 103-114.

[22] CHEN Jin, CHEN Xi, CHEN Xi, et al. Homogeneous introduction of CeOy into MnOx-based catalyst for oxidation of aromatic VOCs[J]. Applied Catalysis B: Environmental, 2018, 124: 825-835.

[23] TANG Wenxiang, WU Xiaofeng, LIU Gang, et al. Preparation of hierarchical layer-stacking Mn-Ce composite oxide for catalytic total oxidation of VOCs[J]. Journal of Rare Earths, 2015, 33(1): 62-69.

[24] ARENA F, TRUNFIO G, NEGRO J, et al. Basic evidence of the molecular dispersion of MnCeOx catalysts synthesized via a novel “Redox-precipitation” route[J]. Chemistry of Materials, 2007, 19: 2269-2276.

(编辑 杨幼平)

收稿日期: 2019 -04 -02; 修回日期: 2019 -05 -29

基金项目(Foundation item):国家重点研发项目(2018YFB0605200) (Project(2018YFB0605200) supported by the National Key Research and Development Program of China)

通信作者:宋敏,博士,副教授,从事气体污染物(VOCs/重金属)联合脱除技术研究;E-mail:minsong@seu.edu.cn