文章编号:1004-0609(2007)11-1838-06

热处理对Al-3%Ti-0.35%C细化剂组织的影响机制

刘贤斌1, 2, 赵文军1,夏天东1,刘 娜1

(1. 兰州理工大学 甘肃省有色金属新材料省部共建国家重点实验室,兰州 730050;

2. 中国科学院金属研究所, 沈阳 110016)

摘 要:研究热处理工艺对热爆法合成Al-3%Ti-0.35%C 晶粒细化剂组织的影响机制。结果表明:Ti原子的扩散是控制热处理的主要因素之一;400 ℃时脱溶反应最先发生,经过大约6 h反应基本结束;当Al3Ti满足原子计量比时,其产物形态不发生改变,而当晶界以及Al3Ti产物中存在过剩的钛元素时,则细化剂的晶界及Al3Ti产物的周边区域会有条件地发生扩散反应 ;当在600 ℃连续保温12 h以上时,脱溶反应的Al3Ti产物重新溶解,晶界处的类共晶组织会消失,经扩散反应生成含Ti颗粒物质。TiC颗粒未见变化。经400 ℃保温2 h热处理的试样的细化效果最佳。

关键词:Al-Ti-C晶粒细化剂;Al3Ti;TiC;热处理工艺

中图分类号:TG 146.1 文献标识码:A

Influence mechanism of heat treatment on microstructure of Al-3%Ti-0.35%C grain refiner

LIU Xian-bin1, 2, ZHAO Wen-jun1, XIA Tian-dong1, LIU Na1

(1. State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials, Lanzhou University of Technology, Lanzhou 730050, China;

2. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The influence mechanism of heat treatment on micro-structure of Al-3%Ti-0.35%C grain refiner prepared by thermal explosion method was researched. The results show that the Ti element diffusion is an important factor in heat treatment; the precipitation reaction is started firstly at 400 ℃ and is lasted for 6 h; when the Al3Ti particle meets the atomic computation, its configuration will hold for long. But when Ti element is superfluous at the grain boundary or border area of Al3Ti, the diffusion reaction will occur in this field at some condition. When the grain refiner holds for more than 12 h at 600 ℃, some particles that contain Ti element are obtained at the grain boundary by diffusion reaction, the eutectic-like structure and the product of precipitation reaction will disappear. The configuration of TiC particle can’t transform under the test condition. The refiner processed by the heat treatment that is held for 2 h at 400 ℃ has a good refining performance.

Key words: Al-Ti-C grain refiner; Al3Ti; TiC; heat treatment process

1986年,Banerji和Reif[1]用强力搅拌法在实验室合成了含有TiC粒子的Al-Ti-C晶粒细化剂,实验证明了Cibula[2]提出TiC粒子形核理论。10年后美国的SMC公司发布了评价Al-Ti-C晶粒细化剂细化能力的方法标准[3?4]。本世纪初,Al-Ti-C晶粒细化剂开始零星地使用,特别是AlTiC315TM晶粒细化剂[5]。Al-Ti-B晶粒细化剂仍是目前铝及铝合金最常用的晶粒细化剂。由于Al-Ti-B晶粒细化剂中的TiB2的密度大于铝液的密度,易下沉,使TiB2的细化能力丧失;铝液中微量的Zr、Cr和Mn元素及其离子也使TiB2产生“中毒”现象[6?7],使TiB2对含有上述一种或多种元素的铝合金的细化效果很差,阻碍了Al-Ti-B晶粒细化剂的应用。国内外主要针对细化剂的合成及细化机理进行研究[8?9],而关于热处理对细化剂的影响鲜有报道。本文作者在采用铝熔体热爆法合成Al-Ti-C晶粒细化剂的研究过程中发现热处理对细化剂的细化性能有影响,并就热处理工艺影响Al-3%Ti-0.35%C 晶粒细化剂的机制进行研究。

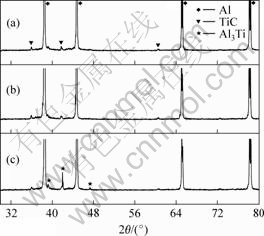

1 实验

采用铝粉、钛粉、石墨粉经球磨混合冷压压成预制块,预制块在设定的温度下进行铝熔体热爆反 应[10?11],经搅拌,静置浇铸成1 kg的Al-3%Ti-0.35%C 晶粒细化剂,将合成的细化剂分割成小样进行实 验,以研究热处理工艺对晶粒细化剂的影响。热处理工艺的关键在于保温温度和保温时间及冷却方式的选取。本研究采用表1的工艺参数进行实验。从经过热处理的试样中部锯开,制成金相试样,将制好的试样先后用MEF3型金相显微镜观察其显微组织,用EPMA?1600型电子探针观察分析其微区成分及分布, 用RigakuD/max-ⅡA 型 X 射线衍射仪分析其物相组成及变化,并依据相应的标准进行细化效果评定。

2 结果与分析

2.1 温度对Al-3%Ti-0.35%C细化剂的影响

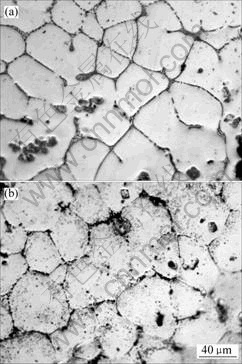

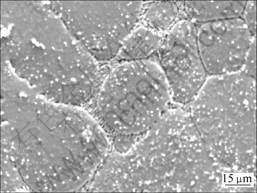

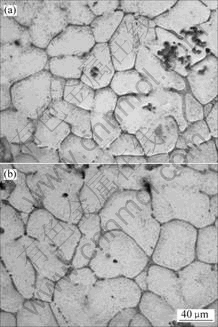

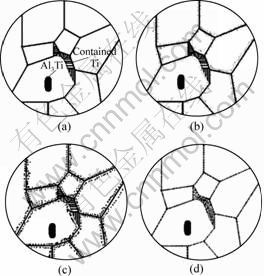

采用保温时间固定为2 h、温度递增的实验方法,以确定合适的温度参数,结果列于表1。图1所示为不同温度下保温2 h试样的显微组织。图1(a)所示为未经热处理的原样,晶界周边比较干净;随着保温温度的升高,晶界周边灰色颗粒物质的析出量是先增后减。图1(b)所示为保温温度400 ℃下试样的显微组织,其晶界周边有很多灰色颗粒析出,即为图2晶界周边的灰白色颗粒。经电子探针微区点分析,该颗粒Al与Ti的摩尔比为2.3,根据Al-Ti相图[12]以及XRD物相分析结果可知(如图3所示),细化剂中的主要物相有Al3Ti、Al和TiC,故可以确定该物质为Al3Ti。

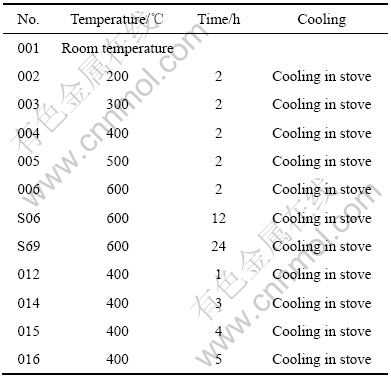

表1 热处理工艺参数

Table 1 Parameters of heat treatments

图1 不同温度下保温2 h试样的显微组织

Fig.1 Microstructures of samples held at different temperatures for 2 h: (a) Without treatment; (b) 400 ℃

图2 经400 ℃保温2 h处理的细化剂背散射显微组织

Fig.2 Microstructure of grain refiner held 2 h at 400 ℃ with EPMA

图3 经不同热处理Al-3%Ti-0.35%C细化剂的XRD谱

Fig.3 XRD patterns of Al-3%Ti-0.35%C refiner by different heat treatment processes

2.2 时间对Al-3%Ti-0.35%C细化剂的影响

采用保温温度为400 ℃、保温时间递增的实验方法,以确定合适的时间参数。图4所示为在400 ℃保温不同时间试样的显微组织。保温2 h处理后试样的显微组织如图1(b)所示。保温4 h后,晶界周边区域有大量的Al3Ti颗粒析出,如图4(a)所示;保温6 h后,试样中晶界周边区域的析出量最多。本文作者认为,试样在400 ℃保温6 h后,脱溶反应基本结束。

图4 在400 ℃保温不同时间试样的显微组织

Fig.4 Microstructures of samples held at 400 ℃ for different times: (a) 4 h; (b) 6 h

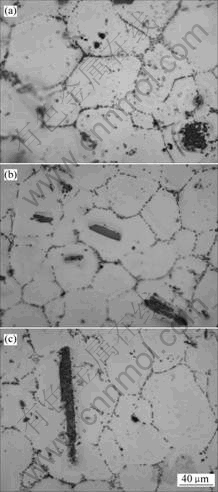

图5(a)所示为在600 ℃保温12 h试样的显微组织。由图可见,晶界周边有大颗粒状物质,随着保温时间的延长,原晶界周边的大颗粒物质开始溶解于基体中。如图5(b)所示,晶界明显被团聚大颗粒状物质分开。从电子探针钛元素面扫描分析可知,晶界区域的Ti含量明显高于基体的Ti含量,如图6(a)所示。据Al-Ti相图[12]及Al、C、Ti元素面扫描分析,背散射电子成像原理可以推断,晶界颗粒物质为含Ti的颗粒物。同时在图5(b)中间部位还有一制备细化剂时形成的块状Al3Ti,而在图5(c)中也有一制备细化剂时形成的棒状Al3Ti,且在棒状Al3Ti周边有细小的颗粒物质生成。

图5 在600 ℃保温不同时间试样的显微组织

Fig.5 Microstructures of samples held at 600 ℃ for different times: (a) 12 h; (b) 24 h; (c) 24 h

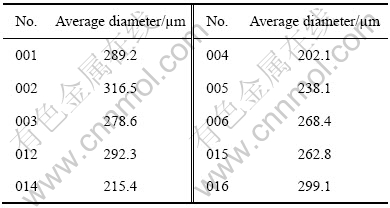

2.3 晶粒细化剂的细化效果评定

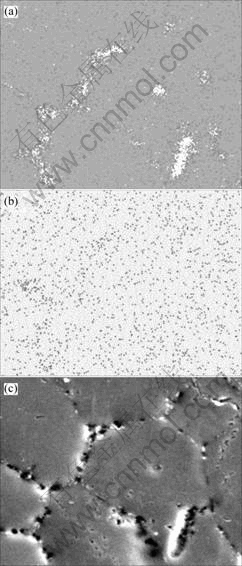

本研究的目标是提高细化剂的细化能力,因此评判标准就是细化工业纯铝的平均直径,按GB/T 3246.1—2000[13]平面晶粒计算法进行晶粒度评定。表2为经不同热处理的细化剂细化工业纯铝的平均直径(Ti添加量的质量分数为0.01%),从表中可以看出,在400 ℃保温2 h的细化剂的细化效果最好。从图6(b)可知,细化剂中的C以细小的TiC颗粒形式存在,这是被广泛认可的异质粒子形核质点;经热处理生成的细小的Al3Ti颗粒也可以很好地细化晶粒,但还需要适当的配合,才能达到较为理想的细化效果。

表2 经不同热处理的细化剂细化的工业纯铝的平均直径

Table 2 Average diameter of solidified Al samples refined by refiners after different heat treatments

图6 在600 ℃保温时间24 h试样的电子探针面分析

Fig.6 Mapping analyses of refiner held at 600 ℃ for 24 h with EPMA: (a) Ti element; (b) C element; (c) COMP?BE

3 热处理工艺对Al-3%Ti-0.35%C晶粒细化剂的组织影响机理讨论

3.1 低温下的热处理机理讨论

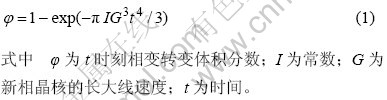

本研究对铝熔体热爆法制备的1 kg Al-3%Ti- 0.35%C晶粒细化剂进行热处理实验。由于铝熔体热爆法为一种非平衡合成技术,加之浇铸后的凝固速度较快,所以Ti在铝基体中处于过饱和状态,热处理初期对于晶粒细化剂而言为固溶处理,属扩散型相变[14],满足Johnson-Mehl方程,即:

选定不同的温度参数,可以绘出“TTT曲线”[14],运用“TTT曲线”可以解释温度对Al-3%Ti-0.35%C细化剂的影响机制。在20~400 ℃之间,随着温度的增大,晶界周边的Al3Ti析出量增大,因温度升高,Ti的扩散能力增大,可以逾越扩散能垒,容易发生脱溶反应;而在400~600 ℃之间,随着温度的升高,形核孕育期加长,转变时间变长;从400 ℃保温不同时间的试样的显微组织可以看出,随着保温时间的延长,晶界周边的Al3Ti析出量呈增多趋势,可认为在400 ℃保温6 h左右,脱溶过程基本结束。

α-Ti在500 ℃保温50 h后,扩散的距离大约为0.8 ?m。α-Ti在500 ℃的自扩散系数约为10?19 m2/s[15],Al为4.3×10?14 m2/s,C在α-Fe中约为10?13 m2/s[16],互扩散的扩散系数会变大一些。由图6(a)可看出晶界富Ti,晶界的原子分布相对无序松散,因此扩散激活能低一些,比在固溶体中进行扩散要容易很多。实验结果表明,Al3Ti析出物是在晶界周边,这表明析出物是由晶界及基体的Ti元素扩散控制的。故在热处理初期,Ti原子的扩散是主要控制因素。

3.2 高温下的热处理机理讨论

凝固时,依选分结晶原理,溶质原子Ti从凝固界面连续排入边界层液体[16],最后在晶界凝固。这也形成了上面试样可以观察到的类共晶组织[16],见图1(a)所示的左上角晶界。依据现有的数据和原子衬度成像原理及经验推测,这种类共晶组织为α(Al)和含Ti化合物(也可能是Ti颗粒)。经600 ℃连续保温12 h,类共晶组织消失。

从不同热处理后Al-3%Ti-0.35%C细化剂的XRD谱可以看出(图3):细化剂的主要物相为Al、少量的Al3Ti和TiC;经400 ℃保温2 h后试样中的Al3Ti含量明显增多,证明在600 ℃以下进行热处理时,体系主要发生从过饱和Al基体析出Al3Ti的反应;根据文献[17?18]的报道及本研究XRD谱可见,在所选的温度范围内,TiC的形态及相对量是不会发生改变,3个样品的TiC峰值基本都没有变化;经600 ℃保温24 h后试样中的Al3Ti含量基本与未处理试样的相同,出现回归现象[14]。由于经脱溶反应生成的Al3Ti颗粒周围可能没有足够的Ti来支持Al3Ti颗粒的长大,当Al3Ti颗粒尺寸小于其热力学稳定的临界半径值时[16],Al3Ti颗粒处于热力学不稳定状态,在随后的更高更长时间热处理会重新溶解。

依据现有的图片数据及上面的分析表明,随着保温时间的延长,类共晶组织内部发生了扩散反应,在自由能减少的驱动下,富钛的晶界里发生了团聚扩散反应,生成了一些含Ti的颗粒物质。

3.3 细化剂组织转变机制

综上所述,Ti原子扩散是控制热处理初期的主要因素,随着保温时间的延长(600 ℃),晶界原子的扩散能力进一步提高,在自由能的驱动下,发生团聚扩散反应,生成了一些含Ti的颗粒物质。图7所示为热处理时Al-3%Ti-0.35%C细化剂的组织转变过程的示意图(没有将细小的TiC画出)。开始进行热处理不久,晶界析出很小的Al3Ti颗粒(见图7(b));随着时间的延长,Al3Ti颗粒长大(见图7(c)),随后会出现回归现象,这个过程主要由固溶体中的Ti扩散来控制。当温度为600 ℃,保温时间进一步增大到12 h以上时,晶界中的Ti、C等元素发生扩散反应所需的能量和浓度基本具备,团聚扩散反应发生,生成了一些含Ti的颗粒物质,使得晶界割裂(见图7(d))。

图7 热处理时Al-3%Ti-0.35%C细化剂的组织转变过程示意图

Fig.7 Sketch map for transformation of microstructure of Al-3%Ti-0.35%C refiner during heat treatment

4 结论

1) Al-Ti-C晶粒细化剂的脱溶反应最先发生的温度是400 ℃,反应持续约6 h;反应的控制因素主要是Ti原子的扩散,在晶界周边区域过饱和固溶体发生脱溶析出Al3Ti颗粒;但在600 ℃保温12 h后,脱溶反应析出的Al3Ti颗粒会重新溶解。

2) 当Al3Ti产物满足计量比的情况,其形态是不发生改变的,而当产物中有过剩的Ti元素时,会发生扩散反应,使得其形貌发生改变,而TiC颗粒在本实验条件下,没有发生变化。

3) Al-Ti-C晶粒细化剂中的类共晶组织在反应时间很短和低于600 ℃的条件下是很难消除,而当保温温度为600℃,保温时间大于12 h时,基本可以消除,形成含Ti的颗粒物质。

REFERENCES

[1] Banerji A, Reif W. Development of Al-Ti-C grain refiners containing TiC[J]. Metallurgical Transactions A, 1986, A17: 2127?2137.

[2] Cibula A. The mechanism of grain refinement of sand casting in aluminum alloys[J]. J Inst Metals, 1949/1950, 76: 321?360

[3] Whitehead A J, Cooper P S, McCarthy R W. An evaluation of metal cleanliness and grain refinement of 5182 aluminum alloy DC cast ingot using Al-3%Ti-0.15%C and Al-3%Ti-1%B grain refiners[C]//The 128th TMS Annual Meeting & Exhibition. San Diego: Shieldalloy Metallurgical Corporation, 1999: 1?7.

[4] Detomi A M, Messias A J, Majer S. The impact of TiCAlTM and TiBAlTM grain refiners on cathouse processing[C]//130th Annual International Meeting & Exhibition. New Orleans Louisiana: Shieldalloy Metallurgical Corporation, 2001: 1?8.

[5] Granger D A. The development of a commercial Al-3%Ti-0.15%C grain refining master alloy[C]//The 126th TMS Annual Meeting & Exhibition, Orlando Florida: Shieldalloy Metallurgical Corporation, 1997: 1?6.

[6] 张柏清, 马洪涛, 李建国, 方鸿生. Al-Ti-C中间合金细化剂的组织及其细化性能[J]. 金属学报, 2000, 36(4): 341?345.

ZHANG Bai-qing, MA Hong-tao, LI Jian-guo, FANG Hong-sheng. Study on the microstructures and grain refining performance of Al-Ti-C grain refining master alloys[J]. Acta Metallurgica Sinica, 2000, 36(4): 341?345.

[7] 严有为, 刘生发, 范晓明, 傅正义, 魏伯康. 自蔓延高温合成Al-TiC 晶粒细化剂及其晶粒细化效果[J]. 中国有色金属学报, 2002, 12(5): 977?981.

YAN You-wei, LIU Sheng-fa, FAN Xiao-ming, FU Zheng-yi, WEI Bo-kang. SHS of Al-TiC grain refiner and their grain refining performances for commercially pure aluminum[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(5): 977?981.

[8] Iqbal N, van Dijk N H, Offerman S E, Geerlofs N, Moret M P, Katgerman L, Kearley G J. In situ investigation of the crystallization kinetics and the mechanism of grain refinement in aluminum alloys[J]. Mater Sci Eng A, 2006, A416: 18?32.

[9] Zhang M X, Kelly P M, Easton M A. Crystallographic study of grain refinement in aluminum alloys using the edge-to-edge matching model[J]. Acta Materialia, 2005, 53: 1427?1438.

[10] 李英龙, 温景林, 陈彦博, 曹富荣, 占国灿. SHS技术制备的Al-3Ti-0.15C晶粒细化剂[J]. 中国有色金属学报, 2004, 14(2): 179?183.

LI Ying-long, WEN Jing-lin, CHEN Yan-bo, CAO Fu-rong,ZHAN Guo-chan. Al-3Ti-0.15C grain refiner prepared by SHS[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 179?183.

[11] 赵文军, 刘贤斌, 候运丰, 夏天东. 成分对热爆法合成Al-Ti-C的组织及细化效果的影响[J]. 铸造技术, 2007. 28(3): 354?358.

ZHAO Wen-jun, LIU Xian-bin, HOU Yun-feng, XIA Tian-dong. Effect of component on the grain refining performances and micro-structure of Al-Ti-C prepared by thermal explosion method[J]. Foundry Technology, 2007, 28(3): 354?358.

[12] 潘复生, 张丁非. 铝合金及其应用[M]. 北京: 化学工业出版社, 2006: 103.

PAN Fu-sheng, ZHANG Ding-fei. Aluminum alloy and its application[M]. Beijing: Chemical Industry Press, 2006: 103.

[13] GB/T 3246.1—2000. 变形铝及铝合金制品组织检验方法[S].

GB/T 3246.1—2000. Wrought aluminum and aluminum alloys products inspection method for structure[S].

[14] 徐 洲, 赵连城. 金属固态相变原理[M]. 北京: 科学出版社, 2005: 156?157.

XU Zhou, ZHAO Lian-cheng. Theory on transformation in solid metal[M]. Beijing: Science Press, 2005: 156?157.

[15] Leyens C, Peters M. 钛与钛合金[M]. 北京: 化学工业出版社, 2005: 6?7.

Leyens C, Peters M. Titanium and titanium alloys[M]. Beijing: Chemical Industry Press, 2005: 6?7.

[16] 石德珂. 材料科学基础[M]. 北京: 机械工业出版社, 2002: 196?199.

SHI De-ke. Foundation of material science[M]. Beijing: China Machine Industry Press, 2002: 196?199.

[17] 张尚洲, 王青江, 刘羽寅, 杨 锐. Ti-60合金双态组织时效过程中碳化物的溶解行为[J]. 金属学报, 2005, 41(9): 969?973.

ZHANG Shang-zhou, WANG Qing-jiang, LIU Yu-yin, YANG Rui. Dissolution behavior of carbide in Ti-60 titanium alloys with bimodal microstructure during ageing[J]. Acta Metallurgica Sinica, 2005, 41(9): 969?973.

[18] 金云学, 曾松岩, 王宏伟. Ti-15Al-7C合金热处理过程中碳化物形态变化研究[J]. 稀有金属材料与工程, 2002, 31(5): 358?362.

JIN Yun-xue, ZENG Song-yan, WANG Hong-wei. Changes of carbides morphology in the alloy during heat treatment[J]. Rare Metal Materials and Engineering, 2002, 31(5): 358?362.

基金项目:国家高技术研究发展计划资助项目(2003AA33X050)

收稿日期:2007-05-09;修订日期:2007-08-22

通讯作者:夏天东,教授,博士;电话:0931-29737179;E-mail: xiatid@lut.cn

(编辑 陈爱华)