纳米晶W-Ni-Fe复合粉末烧结过程中的致密化与

显微组织演变

曾毅,范景莲,龚星,丁飞

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:采用溶胶喷雾干燥-热还原法制备纳米晶93W-4.9Ni-2.1Fe复合粉末,利用高温热膨胀仪测定和研究纳米晶复合粉末的烧结收缩动力学曲线特征,计算纳米晶W-Ni-Fe复合粉末的固相烧结激活能,并利用金相显微镜和扫描电镜分析致密化过程中显微组织的演变规律。研究结果表明:纳米晶W-Ni-Fe复合粉末的开始收缩和剧烈收缩温度分别为900 ℃和1 120 ℃,其最大的线收缩率达0.097 %/℃;在1 200 ℃以下的固相烧结阶段,压坯便发生显著的致密化,其致密化程度可达98%以上,固相烧结的表观激活能为154.83 kJ/mol,比传统粉末烧结激活能大大降低;在固相烧结期间,W晶粒尺寸长大缓慢,在1 380 ℃以上液相烧结时W晶粒长大急剧加快。

关键词:W-Ni-Fe复合粉末;纳米晶;致密化;显微组织

中图分类号:TG146.4 文献标志码:A 文章编号:1672-7207(2011)07-1906-06

Densification and microstructure evolution of nanocrystalline W-Ni-Fe composite powders during sintering

ZENG Yi, FAN Jing-lian, GONG Xing, DING Fei

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Nanocrystalline 93W-4.9Ni-2.1Fe composite powders were synthesized by sol-spray drying and subsequent hydrogen reduction process. The characteristics of swell-shrinkage kinetic curve were investigated by high temperature dilatometer. The apparent activation energy during solid phase sintering was calculated. Additional, optical microscope and scanning electron microscope (SEM) were employed to characterize the microstructure evolution of the alloys during densification. The results show that commence shrinkage temperature and sharp shrinkage temperature of the nanocrystalline powders are 900 ℃ and 1 120 ℃ respectively. The maximum shrinkage rate is 0.097 %/℃. The densification of the nanocrystalline powders mainly occurs during the solid phase state sintering. The apparent activation energy during the solid-phase sintering stage is approximately 154.83 kJ/mol, which is much lower than that of the conventional mixed powders. The grain grows slowly during the solid phase state sintering. When the sintering temperature is above 1 380 ℃, the liquid phase sintering starts simultaneously with the rapid growth of the tungsten grains.

Key words: W-Ni-Fe composite powders; nanocrystalline; densification; microstructure

近年来,采用纳米复合粉末制备的细晶高密度合金以其优良的力学性能[1-3]以及穿甲过程中表现出的良好的“自锐化”效应[4]而受到人们的广泛关注。目前,机械合金化和喷雾干燥法是制备纳米W-Ni-Fe复合粉末比较常用的2种方法[5]。国内外研究者对利用机械合金化法制备W-Ni-Fe纳米复合粉末及其烧结行为进行了大量研究[6-8]。研究发现:机械合金化法制备的W-Ni-Fe纳米复合粉末在烧结过程中存在非晶晶化和超饱和固溶体的析出等过程,这些过程导致了纳米W-Ni-Fe复合粉末在具有很好的烧结活性。作者在前期的研究中利用喷雾干燥-热还原法制备了纳米晶W-Ni-Fe复合粉末,并发现该纳米晶W-Ni-Fe复合粉末具有比机械合金化纳米粉末更好的烧结活性[9-10],为了进一步了解喷雾干燥-热还原法制备的纳米晶W-Ni-Fe复合粉末的烧结特性,进而优化工艺,细化合金组织,提高W-Ni-Fe合金的性能,本文作者采用喷雾干燥-热还原法制备93W-4.9Ni-2.1Fe纳米复合粉末,研究93W-4.9Ni-2.1Fe纳米复合粉末烧结过程中的致密化和显微组织演化规律。

1 实验

按93W-4.9Ni-2.1Fe的化学成分比将钨酸铵、硝酸镍晶体、硝酸铁晶体配置喷雾干燥前驱体胶体溶液,并加入一定量的聚乙二醇来增加溶液的分散度。所得前驱体溶液经喷雾干燥后制得(W,Ni,Fe)复合氧化物粉末,然后在氢气气氛中于450 ℃保温90 min+ 750 ℃保温90 min两步还原,得到纳米晶W-Ni-Fe复合粉末,其钨晶粒大小在40~50 nm之间[11]。将所得纳米复合粉末经普通模压成型,压坯为标准工字形拉伸样及5 mm×5 mm×10 mm的长方体热膨胀试样,压制压力为300 MPa。所得样品的生坯的相对密度分别为50%和53%。为了保存合金烧结过程中的组织形貌,将拉伸试样置于钼丝炉中氢气气氛下,以相同的推舟速度于 900~1 460 ℃之间的不同温度下分别保温15~60 min后直接淬火冷却(水淬)制得烧结样品;将长方体压坯于高温热膨胀仪中进行升温,升温速率为5 ℃/min,升温范围为25~1 350 ℃,采取氩气保护。合金的密度在精度为10-4 g的BS210S电子分析天平上用排水法测定。采用日本JEOL公司的JSM-5600LV型扫描电镜观察试样的组织形貌,并用SEM自带软件测定钨晶粒大小。用TC-436型氮/氧分析仪测定粉末的氧含量。

2 结果与分析

2.1 喷雾干燥纳米粉末的致密化

图1给出了压坯密度与烧结温度和烧结时间的关系。从图1可以看出:在900 ℃时,随烧结时间的延长,密度迅速增加,当温度升高时,致密化过程显著加快。在900 ℃保温15 min后压坯相对密度仅为66.3%,而在1 100 ℃以下保温15 min,合金的相对密度就达到了97.2%。随着时间的延长,合金的密度进一步增加,在1 100 ℃烧结60 min后合金接近全致密。

图1 压坯在不同温度下烧结后相对密度与时间的关系

Fig.1 Relative sintering densities of compacts as function of sintering temperature at different holding time

为更准确地描述烧结温度对致密化过程的影响,图2给出压坯在不同温度下烧结1 h后合金相对密度的变化规律。从图2可以看出:在900 ℃到1 100 ℃之间密度急剧增大,致密化过程加快。在1 200 ℃时,相对密度达到最大值,已接近全致密。但在随后的烧结过程中,压坯出现了膨胀现象。究其原因,是由于纳米粉表面极易吸氧,根据W-O平衡相图可知:在 1 700 ℃时,氧在钨中的饱和溶解度为0.000 6。而TC-436型氮/氧分析仪检测结果表明,采用溶胶-喷雾干燥-两步还原所得的粉末中氧含量为0.25%,此氧含量远远超出了氧在钨中的最大溶解度。这些剩余的氧可能以稳定的WOn的形式包围在钨颗粒的表面,由于纳米粉末的致密化速度相当快,一部分氧在升温过程中没有来得及被还原,压坯已经达到了很高的密度,而随着温度的升高,这些氧化物的挥发及被还原形成的水蒸气的挥发都会造成密度降低。

图2 压坯在不同烧结温度下烧结1 h后的相对密度

Fig.2 Relative density of compact after being sintered at different temperatures for 1 h

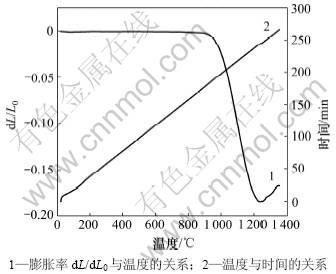

图3所示是利用高温热膨胀仪测得的纳米W-Ni-Fe复合粉末的烧结收缩动力学曲线。从图3可以看出:在25~800 ℃阶段,合金压坯基本不发生收缩;当温度为900 ℃时压坯开始收缩,在1 000~1 150 ℃时压坯剧烈收缩,随后收缩开始减慢。在1 240 ℃时合金收缩达到极大值,高于1 240 ℃时合金出现膨胀现象,这里的剧烈收缩温度段,以及出现了膨胀的现象在上述的密度变化规律中已得到了一定的反映。

图3 纳米晶93W-4.9Ni-2.1Fe恒速升温过程的热膨胀曲线

Fig.3 Dilatometry curves for constant-heating-rate sintering of nanocrystalline 93W-4.9Ni-2.1Fe composite powder

为了准确求出剧烈收缩对应的温度,按图3的试验数据将收缩量(dL/L0)对温度(T)求导,可得收缩速率与温度的关系如图4所示。

从图4可看出:其最大收缩速率对应的烧结温度为1 120 ℃,最大收缩速率为0.097 %/℃。而对于传统93W-Ni-Fe合金而言,其开始收缩温度为1 290 ℃,比纳米晶复合粉末高约390 ℃;剧烈收缩温度约为 1 453 ℃,高于纳米晶复合粉末335 ℃;普通混合粉末的最大收缩速率只有0.03 %/℃[12],远低于纳米晶复合粉末的最快收缩速率。

由上述分析可知:纳米复合粉末的致密化特征与普通混合粉末的液相烧结致密化不同,其在烧结时,在升温阶段就产生了大部分的致密化,而且开始收缩和快速收缩所对应的温度均大幅度降低。根据Wang等[13-14]提出的粉末固相烧结模型,烧结收缩速率方程可以分解为与温度T、晶粒尺寸d及相对密度ρ有关的函数:

(1)

(1)

其中:A=CγΩ2/3/R;d为晶粒尺寸; 为密度的函数;C为常数;A为与d,T或ρ无关的一个材料参量;γ为表面能;Ω为摩尔体积;R为摩尔气体常数;T为热力学温度;Q为激活能;n取决于烧结过程中的物质运输机制。

为密度的函数;C为常数;A为与d,T或ρ无关的一个材料参量;γ为表面能;Ω为摩尔体积;R为摩尔气体常数;T为热力学温度;Q为激活能;n取决于烧结过程中的物质运输机制。

图4 纳米晶93W-4.9Ni-2.1Fe恒速升温过程中收缩速率与温度的关系

Fig.4 Relationship between shirinkage rate and temperature for 93W-4.9Ni-2.1Fe during constant-heating-rate sintering

将该式进行简化,假设样品在收缩时各向均匀收缩,则可以利用烧结收缩动力学曲线得到样品的相对密度的表示方法:

(2)

(2)

对于恒速升温烧结过程,致密化速率写为:

(3)

(3)

把式(3)代入式(1)同时对两边取对数可得到:

(4)

(4)

而对于该式右部分 在小的温度范围内可视为恒量,因此,可以根据烧结收缩动力学数据与已知的生坯密度

在小的温度范围内可视为恒量,因此,可以根据烧结收缩动力学数据与已知的生坯密度 作出式(4)等号左边部分与1/T的关系曲线,而该曲线的斜率便是烧结的激活能。选取其迅速致密化的温度范围为950~1 100 ℃,其计算结果如图5所示。经计算,该直线的斜率为154.85 kJ/mol,即所计算的致密化表观激活能。该激活能比普通粉末该温度区间的固相烧结激活能 (387 kJ/mol) [15]低很多。根据经典烧结理论,粉末的烧结激活能是流动、扩散和物理化学反应3个激活能的综合反应,而对于纳米晶W-Ni-Fe复合粉末固相烧结而言,扩散是其固相阶段致密化的主要因素,采用喷雾干燥法制备的纳米复合粉末,颗粒细小、分散性高,其颗粒表面具有很高的比表面能及高密度的悬空键,这可能使得原子的扩散能垒大大降低,因此,使得压坯在900~1 100 ℃的升温阶段便产生了剧烈收缩。

作出式(4)等号左边部分与1/T的关系曲线,而该曲线的斜率便是烧结的激活能。选取其迅速致密化的温度范围为950~1 100 ℃,其计算结果如图5所示。经计算,该直线的斜率为154.85 kJ/mol,即所计算的致密化表观激活能。该激活能比普通粉末该温度区间的固相烧结激活能 (387 kJ/mol) [15]低很多。根据经典烧结理论,粉末的烧结激活能是流动、扩散和物理化学反应3个激活能的综合反应,而对于纳米晶W-Ni-Fe复合粉末固相烧结而言,扩散是其固相阶段致密化的主要因素,采用喷雾干燥法制备的纳米复合粉末,颗粒细小、分散性高,其颗粒表面具有很高的比表面能及高密度的悬空键,这可能使得原子的扩散能垒大大降低,因此,使得压坯在900~1 100 ℃的升温阶段便产生了剧烈收缩。

图5 纳米晶复合粉末固相烧结激活能

Fig.5 Activation energy of nanocrystalline powders during solid state sintering

2.2 烧结体显微组织的演化

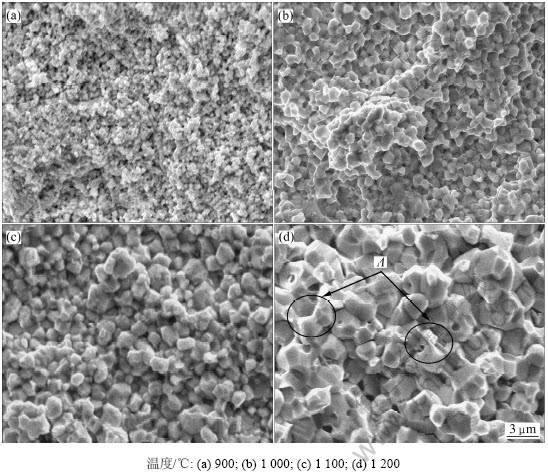

图6所示为压坯在900~1 200 ℃之间粉末保温30 min后淬火的显微组织形貌。从图6可以看出:在900 ℃保温1 h后,材料中还存在大量的连通孔隙,其中的颗粒十分细小,并且相互聚集。而随着烧结温度的升高,在1 000 ℃保温30 min后,颗粒发生了迅速长大,压坯的密度也大大提高,W颗粒相互接触,形成了紧密的W颗粒骨架。

图7所示为不同温度下烧结30 min后的烧结体显微组织。从图7(a)可以看出:原来的连通孔隙已经基本消失,只存有少量的闭孔存在,材料发生了显著的致密化。而随着温度的升高,相互接触的W颗粒形成烧结颈(如图6(d)中A所示),进一步发生颗粒之间的合并长大,同时一些闭孔消失,密度进一步提高。 当温度超过1 380 ℃以后,合金开始进入液相烧结阶段,如图7(d)所示,在1 420 ℃保温30 min后,W颗粒由于溶解-析出机制的作用,产生了显著的球化。同时液相往W晶粒间的流动导致的颗粒重排使得W-W颗粒的接触度大大降低,使得组织更为均匀。

图6 不同温度下烧结30 min后合金的断口形貌

Fig.6 Fractographs of alloy after being sintered at different sintering temperatures for 30 min

图7 不同烧结温度下烧结30 min后合金的显微组织

Fig.7 Microstructures of alloy after being sintered at different temperatures for 30 min

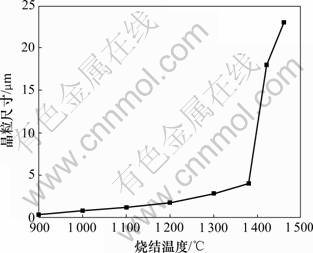

图8所示是不同烧结温度下保温1 h后晶粒尺寸的变化。从图8可以看出:纳米晶粉末的晶粒长大可分为2个阶段。在固相烧结阶段,随着烧结温度的升高,W晶粒逐渐增加,特别是在1 200 ℃以上晶粒迅速长大,在1 380 ℃保温1 h后其晶粒长大到3~5 μm,是原来的80~100倍。在该阶段,W晶粒主要依靠晶粒的聚集再结晶而发生长大,特别是材料在 1 100 ℃以上烧结时,材料发生了显著的致密化,孔隙大大减少,降低了晶界运动的阻力,使得晶粒长大速度大大增加。W晶粒长大的第2阶段发生在液相生成以后,随着液相的出现,W颗粒的溶解-析出机制迅速进行,由于W在液相中的扩散速率快,使得W晶粒在短时间内迅速发生晶粒长大,在1 420 ℃保温1 h后其晶粒可达15~20 μm。

图8 晶粒尺寸与烧结温度的关系

Fig.8 Relationship between grain size and sintering temperature

3 结论

(1) 喷雾干燥-热还原法制备的纳米晶W-Ni-Fe复合粉末开始收缩温度和剧烈收缩温度分别为900 ℃和1 120 ℃,分别比传统粉末低390 ℃和335 ℃,最大收缩率达0.097 %/℃。

(2) 纳米晶W-Ni-Fe复合粉末主要的致密化阶段发生在1 000~1 200 ℃之间,该阶段的致密化激活能为154.83 J/mol,远低于普通混合粉末在该阶段的致密化激活能。

(3) W晶粒在1 000 ℃以下长大并不明显,在1 000 ℃以上,随着烧结温度的增加,晶粒长大速率逐渐加快。当温度超过1 380 ℃进入液相烧结后,W发生剧烈长大。

参考文献

[1] 范景莲. 钨合金及其制备新技术[M]. 北京: 冶金工业出版社, 2006: 17-18.

FAN Jing-lian. Tungsten alloys and its new technique[M]. Beijing: Metallurgy Industry Publishing Company, 2006: 17-18.

[2] German R M, Olevsky E. Strength predictions for bulk structures fabricated from nanoscale tungsten powders[J]. International Journal of Refractory Metals and Hard Materials, 2005, 23(1): 77-84.

[3] Ryu H J, Hong S H, Baek W H. Microstructure and mechanical properties of mechanically alloyed and solid-state sinterd tungsten heavy alloys[J]. Mater Sci Eng A, 2000, 291: 91-96.

[4] Wei Q, Ramesh K T. Plastic flow localization in bulk-tungsten with ultrafine microstructure[J]. Appl Phys lett, 2005, 86(10): 101907-101909.

[5] 范景莲, 黄伯云, 张传福. 纳米钨合金粉末的制备技术与烧结技术[J]. 硬质合金, 2001, 18(12): 226-231.

FAN Jing-lian, HUANG Bai-yun, ZHANG Chuan-fu, Preparation and sintering technique of nanoscale tungsten alloy powders[J]. Cemented Carbide, 2001, 18(12): 226-231.

[6] Jang J S C, Fwu J C, Chang L J. Study on the solid-phase sintering of nano-structured heavy tungsten alloy powder[J]. Journal of alloys and compounds, 2007, 434/435(12): 367-370.

[7] Aning A O, Whang Z. Tungsten solution kinetics and amrphization of nickel in mechanically alloyed Ni-W alloys[J]. Acta Metal Mater, 1993, 10(1): 57-59.

[8] 范景莲, 黄伯云, 张传福. 机械合金化纳米钨合金粉末常压烧结下的致密化与晶粒长大[J]. 中南工业大学学报: 自然科学版, 2001, 32(4): 390-394.

FAN Jing-lian, HUANG Bai-yun, ZHANG Chuan-fu. Densification and grain growth of nano-structured tungsten alloy powders during pressureless sintering[J]. Chinese Journal of Central South University of Technology: Natural Science, 2001, 32(4): 390-394.

[9] 马运柱, 黄伯云, 熊翔. 稀土钇对纳米粉90W-7Ni-3Fe合金烧结特性的影[J]. 中国有色金属学报, 2005, 15(6): 882-887.

MA Yun-zhu, HUANG Bo-yun, XIONG Xiang. Influence of rare earth Y on sintering properties of nano-powder 90W-7Ni-3Fe alloy[J]. The Journal of Chinese Nonferrous Metal, 2005, 15(6): 882-887.

[10] 祁美贵, 范景莲, 张骁, 等. 微量Y2O3 对细晶W-Ni-Fe粉末烧结行为和显微组织的影响[J]. 中国有色金属学报, 2009, 19(4): 656-661.

QI Mei-gui, FAN Jing-lian, ZHANG Xiao, et al. Influence of trace Y2O3 on sintering behavior and microstructure of fine grain W-Ni-Fe powders[J]. The Journal of Chinese Nonferrous Metals, 2009, 19(4): 656-661.

[11] 祁美贵. 细晶93W-4.9Ni-2.1Fe微细结构与力学行为研究[D]. 长沙: 中南大学粉末冶金研究院, 2009: 22-23.

QI Mei-gui, Investigate on the microstructure and mechanical behavior of fine grained 93W-4.9Ni-2.1Fe alloys[D]. Changsha: Central South University. Powder Metallurgy Research Institute, 2009: 22-23.

[12] 王峻, 张丽英, 郭志猛, 等. 超细晶粒W-Ni-Fe合金收缩动力学特征[J]. 北京科技大学学报, 2002, 24(2): 107-110.

WANG Jun, ZHANG Li-ying, GUO Zhi-meng, et al. Shrinkage kinetics during sintering W-Ni-Fe heavy alloy with ultrafine grain[J]. Chinese Journal of University of Science and Technology Beijing, 2002, 24(2): 107-110.

[13] Wang J, Raj R. Activation energy for the sintering of two-phase alumina/zirconia ceramics[J]. J Am Ceram Soc, 1991, 74(8): 1959-1963.

[14] Wang J, Raj R. Estimate of the activation energies for boundary diffusion from rate-controlled sintering of pure alumina and alumina doped with zirconia and titania[J]. J Am Ceram Soc, 1990, 73(5): 1172-1175.

[15] Park S J, Martin J M, Guo J F, et al. Densification behavior of tungsten heavy Alloy based on master sintering curve concept[J]. Metallurgical and Materials Transactions A, 2006(37): 2837-2947.

(编辑 陈爱华)

收稿日期:2010-07-27;修回日期:2010-09-27

基金项目:国家自然科学基金资助项目(50674106);国家杰出青年基金资助项目(50925416);国家自然科学基金创新群体资助项目(50721003)

通信作者:范景莲(1967-),女,湖南澧县人,教授,博士,从事细晶钨钼材料的研究;电话:0731-88836652;E-mail: fjl@csu.edu.cn