文章编号:1004-0609(2011)01-0102-08

电子束焊接Ti-6Al-4V合金接头的疲劳裂纹尖端微区形态

籍龙波, 胡树兵, 李行志, 陈冀彦, 肖建中

(华中科技大学 材料成形与模具技术国家重点实验室,武汉430074)

摘 要:通过对Ti-6Al-4V合金板材预制一定深度的疲劳裂纹,研究母材与焊缝区疲劳裂纹尖端的TEM显微形态。结果表明:经历疲劳循环后,位错密度大大增加,α/β相界面位错密度高,易成为位错形核的源区;在周期性疲劳载荷的作用下,位错以源区为原点呈放射状向四周发散运动;在焊缝区马氏体板条之间的细碎相之间,位错聚集严重,说明细碎相也易成为位错萌生的源区,从而成为疲劳裂纹形核的源区;在焊缝区马氏体板条宽度越窄,位错聚集密度越高,易成为疲劳裂纹萌生的位置。此外,TEM观察证实了裂纹尖端存在一定尺寸的塑性变形区。通过焊接接头分区的TEM对比分析,获得焊缝区比母材区更易萌生疲劳裂纹的相关证据。

关键词:Ti-6Al-4V合金;电子束焊接;疲劳;裂纹尖端;显微形态

中图分类号:TG 146 文献标志码:A

Morphologies at fatigue crack tip of Ti-6Al-4V electron beam welding joints

JI Long-bo, HU Shu-bing, LI Xing-zhi, CHEN Ji-yan, XIAO Jian-zhong

(State Key Laboratory of Material Processing and Die and Mould Technology,

Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: Ti-6Al-4V sheet alloy specimens were precracked in different regions of electron beam welded joints. Transmission electron microscopy (TEM) observations were carried out at fatigue crack tip of base metal and welded joint. The microstructure observations reveal that the experiencing fatigue crack growth, the dislocations which emit from α/β interfaces reach so densely that they incline to become a source of the fatigue cracks, from which the dislocations are diverged radioactively under the cyclic stress. Dislocations accumulate seriously among the fine phases which lay between two martensite lathes, indicating that these small fatigue phases tend to become the source of fatigue crack. In addition, the narrower the width of martensite lathes is, the more easily the dislocations accumulate to become the fatigue source. The plastic zone is also observed at the fatigue crack tip. By comparing the TEM images of different regions, the corresponding evidence that welded joints are more liable to become the source fatigue cracks is found.

Key words: Ti-6Al-4V alloy; electron beam welding (EBW); fatigue; crack tip; micromorphologies

钛合金最重要的特点之一是具有较高的比强度,是当代先进飞机和航空发动机的主要结构材料之一,钛合金的应用水平也成为衡量飞机先进程度的重要标志之一[1]。Ti-6Al-4V合金是一种典型的α+β型钛合金,在钛基中含稳定元素铝(6%)和钒(4%),具有比强度高、耐腐蚀性好、综合性能优等特点,在航空航天结构材料中得到了广泛的应用。在Ti-6Al-4V合金应用中,焊接是一种必不可少的手段,电子束焊接(electron beam welding,EBW)在Ti-6Al-4V合金连接中应用广泛。而目前Ti-6Al-4V钛合金电子束焊接的主要问题是由于在焊接过程中焊接区域将发生相结构转变,引起焊后接头的宏观力学性能发生变化[2],对合金的疲劳扩展行为产生较大的影响。许多学者对钛合金疲劳扩展行为进行了深入的研究[2-13]。HALL[2]的研究表明:疲劳过程为疲劳损伤的累积过程,疲劳损伤的积累导致形成滑移带,最终滑移带内材料强度下降,使裂纹加速扩展。双态组织中存在由先析β相转变而来的同位向的α条带(多晶粒构成宏观区域)[3]。 这些区域往往可作为一个单元一起变形,且在单元内变形严重处开始疲劳裂纹的萌生[4]。BANTOUNAS等[5]同样发现了50~70 μm尺度的条带区域。

相界对疲劳裂纹的扩展具有重要影响,它通过影响滑移方向从而影响裂纹扩展方向[6]。GERMAIN等[7]对αp/β相界面的研究表明,先析α相与周围β相的位向关系在变形前后因αp/β界面的匹配变形而保持一致。BOCHER和KAMAT[8]研究发现,先析α/β相界面与次生板条α/β相界面空位的运动导致解理面的交联而产生解理断裂。同时,疲劳裂纹的尖端存在一定区域的塑性变形区,塑性区尺寸对疲劳裂纹扩展具有一定程度的影响。TAKAHASHI等[9]研究发现,滑移带一般扩展至距裂纹面一定深度处,在小裂纹阶段,当裂纹长度与尖端塑性区尺寸相近时,裂纹扩展速率变缓[10]。此外,裂纹尖端的组织协调快慢[11]及裂纹尖端的应力聚集程度也会影响裂纹扩展[12]。HARDT等[13]认为板条区的宽度控制双态组织的应力聚集程度,从而影响裂纹的扩展。上述研究表明:相界面、显微组织尺寸、裂纹尖端塑性区等因素对疲劳裂纹扩展具有重要影响。但对疲劳裂纹尖端显微形态的研究并不深入。本文作者从显微形态入手,着重对Ti-6Al-4V母材与电子束焊接接头的裂纹尖端形态进行对比分析,探讨显微组织对疲劳裂纹扩展的影响,力求建立微观结构与裂纹扩展特性之间关系,为深入研究显微组织对电子束焊接Ti-6Al-4V合金疲劳行为的影响提供理论依据。

1 实验

1.1 实验材料

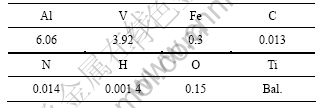

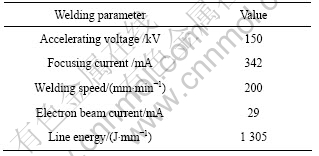

钛合金样品采用Ti-6Al-4V热轧板材,其化学成分如表1所列。采用电子束焊接,焊接试样尺寸为200 mm×180 mm×20 mm,焊缝垂直于轧向,位于试样中间,焊接工艺参数如表2所列。焊后热处理温度为650 ℃,保温4 h。电子束焊接设备采用北京航空制造工程研究所研制的ZD150-15A型和ZD150-30A型高压电子束焊机。

表1 Ti-6Al-4V钛合金的化学成分

Table 1 Chemical composition of Ti-6Al-4V alloy (mass fraction, %)

表2 Ti-6Al-4V合金焊接工艺参数

Table 2 Welding parameters of Ti-6Al-4V alloy

1.2 实验方法

1.2.1 疲劳裂纹扩展

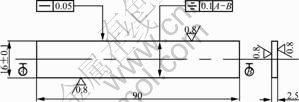

试样制备方法如下:沿平行于焊缝的方向取疲劳试样,加工成光滑的疲劳试样。试样宽度为16 mm,去除焊缝余高和上、下部各2 mm,以去除几何应力集中和熔合线气孔等疲劳裂纹萌生因素。疲劳试样尺寸如图1所示,取样位置如图2所示。

图1 Ti-6Al-4V疲劳试样形状与尺寸

Fig.1 Shape and size of fatigue specimen of Ti-6Al-4V alloy(Unit: mm)

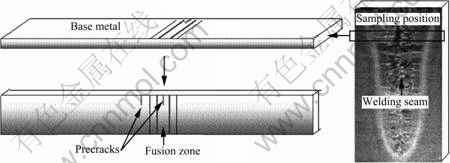

采用5%HF+12%HNO3+83%H2O溶液浸蚀焊接接头的不同区域,以便分区预制裂纹。为了进行对比研究,分别在母材与焊缝中心预制裂纹,预制缺口深度为0.2 mm。动态疲劳试验在SHIMADZU EA-10型电液伺服低周疲劳实验机上进行。采用拉-拉加载方式、加载频率f=5 Hz、应力比R= 0.1、正弦波形、最大疲劳应力σmax=392 MPa。每隔一定的加载循环次数后测定裂纹长度,当裂纹长度为a=0.5 mm时,停止疲劳 加载。

图2 取样及预制裂纹位置示意图

Fig.2 Schematic illustration of sampling and precrack position

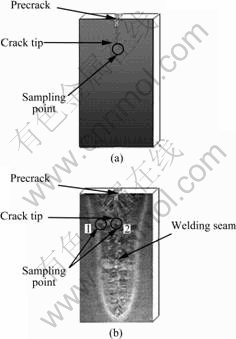

1.2.2 TEM试样制备

疲劳循环后,母材试样裂纹尖端TEM取样如图3(a)所示,焊缝区裂纹尖端TEM取样如图3(b)中位置2所示;焊缝区裂纹边缘TEM取样如图3(b)中位置1所示,每组试验样品各取5个试样。TEM分析在Tecnai G2 20型透射电镜上进行。

图3 母材与焊缝TEM取样位置及标号

Fig.3 Sampling location and labeling of foil for TEM test in base metal (a) and welded joint (b)

2 结果与分析

2.1 金相组织观察

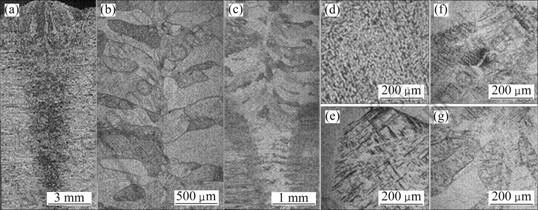

图4(a)所示为焊接接头的宏观形貌。焊缝上部的

柱晶尺寸较大,焊缝中部柱晶尺寸较为均匀。图4(b)所示为焊接接头中部区域的柱晶形态。可以看到,柱晶生长方向与焊缝中心成一定角度。图4(c)所示为焊缝下部的形貌,焊缝下部随焊缝宽度的减小,柱晶尺寸迅速减小。图4(d)所示为Ti-6Al-4V母材的显微组织。Ti-6Al-4V钛合金为典型的α+β双态组织,α相为亮相,而β相为暗相,β相分布于α相之间,且在一定区域α相呈条带状,分布位向相互平行。图4(e)、(f)和(g)所示分别为焊缝上部、中部和下部显微组织。可以看到,马氏体层片在逐渐变细。

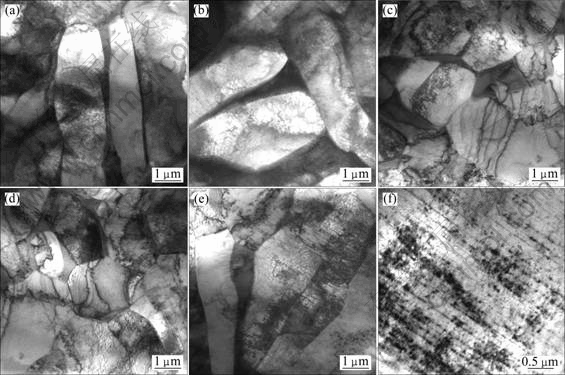

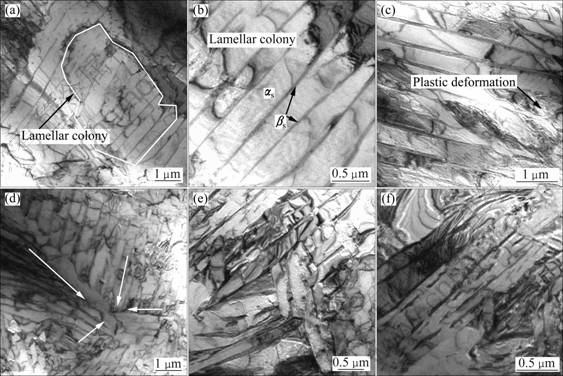

2.2 母材裂纹尖端显微形态

图5所示为母材裂纹尖端的TEM显微形态。Ti-6Al-4V合金为双态合金,亮色的α相之间为暗色 的β相(见图5(a)和(b))。图5(c)所示为位错在等轴相区分布状况,α相位错线分布较为有序,呈发射状。尺寸较小的等轴α相中位错密度明显高于尺寸较大的相(见图5(d))。图5(e)中一些板条相内位错聚集,细部形态如图5(f)所示。从图5的分析来看,位错在母材中尺寸较大的α相中密度较小。

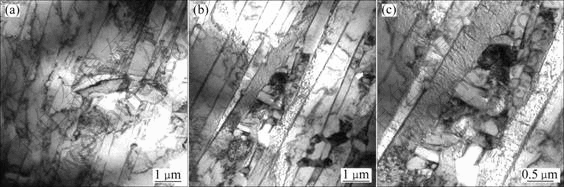

对裂纹尖端变形较严重的区域进行分析。图6(a)中,α相在一定程度上扭曲,而β相也在一定程度上弯曲,说明此处在裂纹尖端的塑性变形区内。在疲劳裂纹前端都存在一定尺寸的塑性变形区。 JINKEUN等[14]对塑性区与显微组织关系的研究表明,塑性区大小与显微组织之间有密切的关系。图6(b)中暗色区域为β相,α/β相界面处位错密度较高。CASTANY等[15]与ZUO等[16]的研究表明,位错总是首先萌生于α/β相界面。因此,在相界处比相内的位错聚集程度要明显得多。当相界位错聚集到一定程度时便向相内运动和聚集 (见图6(c))。

在图6(d)中,等轴α相区位错汇集成线,形态如

图4 Ti-6Al-4V合金焊接接头、母材、焊缝上部、焊缝中部和焊缝下部的形貌

Fig.4 Morphologies of Ti-6Al-4V alloy in welded joint ((a), (b), (c)), base metal (d), upper part of welding seam (e), middle part of welding seam (f) and lower part of welding seam (g) in welded joint

图5 Ti-6Al-4V合金中母材α、β相形态及裂纹尖端位错形态

Fig.5 Morphologies of α, β phases (a), (b) and dislocations ((c)-(f)) at crack tip of Ti-6Al-4V alloy in base metal

波浪状;在位错形态之间,相界模糊,并有一定程度的变形,在疲劳循环应力作用下,裂纹尖端产生一定区域的塑性变形[11],位错线呈弧形发散(见图6(e))。在图6(f)中,位错密度很高,大量位错呈弧形发散,位错在周期性应力作用下运动,但在某些组织或缺陷作用下位错会在局部发生缠结。这些现象表明,在循环应力作用下,位错首先在相界形成,并向相内运动;位错运动与显微组织交互作用影响材料的疲劳行为。

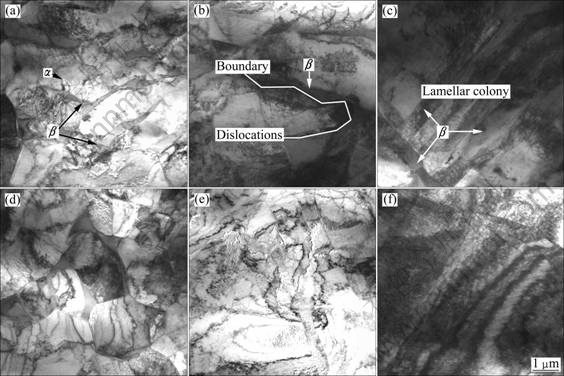

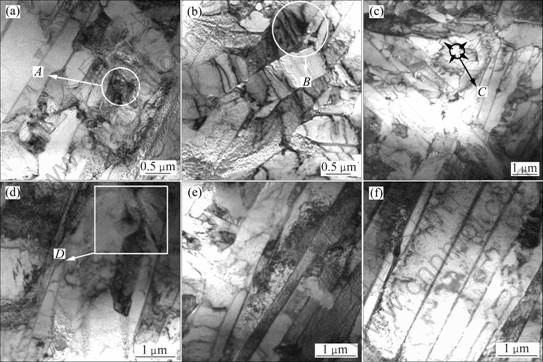

2.3 焊缝区裂纹尖端与边缘显微形态对比

在焊缝区的两组试样中,一组为焊缝中心(裂纹 尖端),另一组为焊缝边缘(裂纹边缘)。图7所示为 裂纹边缘相的TEM像。电子束焊接后形成马氏体,马氏体呈板条或针状。在图7(a)中出现了板条群状态,

图6 母材裂纹尖端塑性变形形态、β相内位错形态、相界处位错形态及高密度位错形态

Fig.6 Morphologies of plastic deformation(a), dislocation in β phase(b), dislocation in phase boundary(c), and high density dislocation ((d)-(f)) at crack tip in base metal

图7 焊缝区裂纹边缘的相及塑性变形显微形态

Fig.7 Morphologies of phase ((a),(b)) and plastic deformation ((c)-(f)) at crack tip edge in welded joint

在板条之间的暗色细条为β相(见图7(b))。在板条群外围,有波浪状的位错组态,虽然其密度不高,但形态十分明显。在裂纹边缘,板条束产生一定程度的塑性变形(见图7(c)),相结构在一定程度上被扭曲。图7(d)所示为板条束方向结合处。从图7(d)可以看到,4个方向分布的板条束在此聚集成一点。图7(e)和(f)所示为塑性变形的显微形态,两相都在不同程度上被扭曲,相界也产生变形。这表明,在裂纹的边缘同样存在塑性变形,且在疲劳循环后被保存下来。裂纹的扩展前沿有弹塑性变形区,而当裂纹穿过后,弹性变形被释放,塑性变形保留在合金中。

图8所示为焊缝区裂纹尖端的相形态。与裂纹 边缘相比,此处针状结构更加明显(见图8(a))。值得一提的是,在马氏体板条之间存在一定数量尺寸较小、细碎状的等轴相,这些相依附于马氏体多点形核(见 图8(b))。在电子束焊接冷却过程中,热应力导致马氏体板条尖端破碎,成为二次形核的核心。由于细碎 相处于马氏体板条之间,空间受限,故尺寸较小(见 图8(c))。

细碎相之间的位错密度要高于马氏体板条内的 位错密度,说明这些细碎相之间的区域应力集中较高。较高的应力集中表明马氏体束的协调变形能力下降,

图8 焊缝区裂纹尖端的马氏体与马氏体细碎相形态

Fig.8 Morphologies of martensite (a) and fine phases among martensite lathes ((b), (c)) at crack tip in welded joint

图9 焊缝区裂纹尖端不规则马氏体板条、细碎相、马氏体板条结合处、细马氏体束处塑性变形及马氏体板条位错形态

Fig.9 Morphologies of irregular martensite (a), fine phases among martensite lathes (b), juncture of martensite lathes (c), plastic deformation in narrow martensite lathes (d) and dislocations in martensite lathes ((e),(f)) at crack tip in welded joint

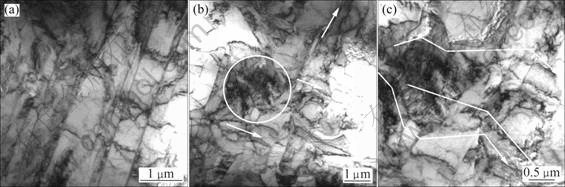

图10 焊缝区裂纹尖端位错形态(发散运动, 聚集及从聚集处向外运动)

Fig.10 Morphologies of dislocation at crack tip in welded joint: (a) Divergent motion; (b) Accumulation; (c) Motion form accumulated point to outward

容易发展成为裂纹源。由图9可知,焊缝区有些区域并不是规则的马氏体板条,还存在一些等轴状的α相。图9(a)所示为马氏体边缘等轴状与柱状的α相形态。在其边界上,有位错呈弧形分布形态,边界某处的位错密度比相内的位错密度高,并在一定区域聚集成团(见图9(a)中A区)。图9(b)所示为等轴α相形态,在相内位错线呈规律分布,在相间存在细碎相(见图9(b)中B区),细碎相之间位错大量聚集。图9(c)所示为几个方向马氏体束的结合处,结合处中心有圆形位错发散的形态(见图9(c)中C区),表明马氏体束交界处位错容易萌生。图9(d)所示为两细片马氏体之间的α相形态,在一些区域(见图9(d)中D区),受循环应力作用,一些层片较细的束发生严重的塑性变形。这表明,在裂纹的尖端,越细小的组织越可能成为疲劳过程中的“弱化区”,这些“弱化区”在循环应力作用下,细碎相发生塑性变形,导致驻留滑移带的软化,从而加速裂纹扩展。在较细的马氏体束内的位错密度高于较厚的马氏体束的位错密度(见图9(e)和(f))。SHADEMAN等[17]发现,Ti-6Al-4V板条的组织粗大,抗裂纹扩展能力上升。通过对塑性区大小的计算,JINKEUN等[14]认为,在应力强度因子范围?K较小时,影响裂纹扩展速率最重要的因素是α板条的宽度,板条宽度越小,裂纹扩展速率越大。ZUO等[16]的研究表明:较细的α板条充当的作用就像一条晶界,在此处裂纹更容易萌生。在循环应力的作用下,位错在合金的“软点”萌生,并呈发射状运动(见图10)。对裂纹边缘与裂纹尖端的TEM像进行对比研究发现,细小的板条更容易发展成为位错萌生的源点,裂纹尖端的位错密度要远大于裂纹边缘的位错密度,且裂纹尖端应力集中,塑性变形程度也更高。焊缝区由于焊接过程中的热应力作用,一些马氏体被碎化成为细碎相,细碎相边界成为疲劳裂纹源。

2.4 母材与焊缝区裂纹尖端显微形态对比研究

疲劳裂纹在应力强度因子范围?K较小时,扩展差异与其显微组织及不同尺寸裂纹扩展的阻力机制有关:在小裂纹扩展阶段,裂纹受到前端滑移线的影响沿滑移线向前扩展,晶粒的边界对显微小裂纹的扩展形成强大的阻力。母材区组织为晶粒较小且均匀的等轴晶,而焊缝区组织则为粗大的柱晶及针状马氏体。细小的等轴晶具有更好的协调变形能力,能提高钛合金的滑移变形抗力,抑制循环滑移的形成和开裂,产生的滑移线细短;针状马氏体的位错滑移程则远大于等轴晶的位错滑移程,因此,产生的位错较长。从TEM像可以发现,在母材的等轴α相中,位错运动较为有序;而在焊缝区马氏体内位错线的宽度及分叉更加明显。

在Ti-6Al-4V合金中,hcp型的α相比bcc型的β相脆性更大。因此,滑移首先在β相中启动,位错在α/β边界与初生α相上聚集,如果组织粗大,则滑移长度变大,这就需要增加裂纹尖端位错的聚集密 度[16]。因此,有较长α/β边界的地方往往更易萌生裂纹。经过退火后的母材组织比较均匀(见图4(d)),从一定程度上降低了裂纹萌生源的可能性;电子束焊接后马氏体组织中具有长α/β边界区域较多,且焊缝中心的板条宽度不十分均匀,细长的板条束就成为裂纹萌生的地方。

3 结论

1) 疲劳裂纹尖端微观形态研究表明:经历疲劳循环后,位错密度大大增加,α/β相界面位错密度较高,易成为位错形核的源区;在周期性疲劳载荷作用下,位错呈放射状向四周运动。

2) 焊缝区马氏体板条之间的细碎相易成为疲劳裂纹形核的“软点”,焊缝区较窄的马氏体板条易成为疲劳裂纹萌生的源区。

3) 疲劳裂纹尖端存在一定尺寸的塑性变形区,裂纹尖端承受的应力和应变比裂纹边缘承受的应力和应变更加复杂。

4) 与母材组织相比,焊缝区组织不均匀,裂纹萌生“软点”增加,抗疲劳裂纹扩展能力降低。

References

[1] 陈芙蓉, 霍立兴, 张玉凤. 电子束焊接技术及其接头质量评定[J]. 焊接, 2001, 11: 21-24.

CHEN Fu-rong, HUO Li-xing, ZHANG Yu-feng. Electron beam welding and its joint quality assessment[J]. Welding and Joining, 2001, 11: 21-24.

[2] HALL J A. Fatigue crack initiation in alpha-beta titanium alloys[J]. International Journal of Fatigue, 1997, 19(1): S23-S37.

[3] GERMAIN L, GEY N, HUMBERT M, BOCHER P, JAHAZI M. Analysis of sharp microtexture heterogeneities in a bimodal IMI 834 billet[J]. Acta Materialia, 2005, 53(13): 3535-3543.

[4] LEBIAVANT K, POMMIERAND S, PRIOUL C. Local texture and fatigue crack initiation in a Ti-6Al-4V titanium alloy[J]. Fatigue and Fracture of Engineering Materials and Structures, 2002, 25(6): 527-545.

[5] BANTOUNAS I, LINDLEY T C, RUGG D, DYE D. Effect of microtexture on fatigue cracking in Ti-6Al-4V[J]. Acta Materialia, 2007, 55(16): 5655-5665.

[6] 马英杰, 刘建荣, 雷家峰, 刘羽寅, 杨 锐. TC4ELI合金疲劳裂纹尖端塑性区对裂纹扩展的影响[J]. 中国有色金属学报, 2009, 19(10): 1789-1794.

MA Ying-jie, LIU Jian-rong, LEI Jia-feng, LIU Yu-yin, YANG Rui. Influence of fatigue crack tip plastic zone on crack propagation behavior in TC4ELI alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(10): 1789-1794.

[7] GERMAIN L, GEY N, HUMBERT M, VO P, JAHAZI M, BOCHER P. Texture heterogeneities induced by subtransus processing of near α titanium alloys[J]. Acta Materialia, 2008, 56(16): 4298-4308.

[8] BOCHER P, KAMAT S V. Dynamic fracture toughness of a near alpha titanium alloy Timetal 834[J]. Journal of Alloys and Compounds, 2010, 491(1/2 ): 237-241.

[9] TAKAHASHI Y, TANAKA M, HIGASHIDA K, YAMAGUCH K, NOGUCHI H. An intrinsic effect of hydrogen on cyclic slip deformation around a {110} fatigue crack in Fe-3.2wt.%Si alloy[J]. Acta Materialia, 2010, 58(6): 1972-1981.

[10] KORSUNSKY A M, SONG X, BELNOUE J, JUN T, HOFMANN F, DE MATOS P F P, NOWELL D, DINI D, APRICIO-BLANCO O, WALSH M J. Crack tip deformation ?elds and fatigue crack growth rates in Ti-6Al-4V[J]. International Journal of Fatigue, 2009, 31(11/12): 1771-1779.

[11] 李士凯, 惠松骁, 叶文君, 于 洋, 熊柏青. 微观组织对TA15ELI 钛合金损伤容限性能的影响[J]. 中国有色金属学报, 2007, 17(7): 1119-1123.

LI Shi-kai, HUI Song-xiao, YE Wen-jun, YU Yang, XIONG Bai-qing. Effects of microstructure on damage tolerance properties of TA15ELI titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1119-1123.

[12] BOCHER P, KUMAR V. Effect of temperature and hold time on internal hardening behavior of a near α titanium alloy under cyclic deformation[J]. Materials and Design, 2010, 31(6): 2716-2724.

[13] HARDT S, MAIER H J, CHRIST H J. High-temperature fatigue damage mechanisms in near α titanium alloy IMI834[J]. International Journal of Fatigue, 1999, 21(8): 779-789.

[14] JINKEUN O, KIM N J, LEE S H, LEE E W. Correlation of fatigue properties and microstructure in investment cast Ti-6Al-4V welds[J]. Materials Science and Engineering A, 2003, 340(1/2): 232-242.

[15] CASTANY P, PETTINARI-STURMEL F, CRESTOU J, DOUIN J, COUJOU A. Experimental study of dislocation mobility in a Ti-6Al-4V alloy[J]. Acta Materialia, 2007, 55(18): 6284-6291.

[16] ZUO J H, WANG Z G, HAN E H. Effect of microstructure on ultra-high cycle fatigue behavior of Ti-6Al-4V[J]. Materials Science and Engineering A, 2008, 473(1/2): 147-152.

[17] SHADEMAN S, SINHA V, SOBOJEJO A B O, SOBOJEJO W O. An investigation of the effects of microstructure and stress ratio on fatigue crack growth in Ti-6Al-4V with colony α/β microstructures[J]. Mechanics of Materials, 2004, 36(1/2): 161-175.

(编辑 陈卫萍)

基金项目:国家磁约束核聚变能研究专项基金资助项目(2010GB109000);华中科技大学材料成形与模具技术国家重点实验室自主课题(09-10)

收稿日期:2010-04-15;修订日期:2010-11-28

通信作者:胡树兵,教授;电话: 027-87540057;E-mail:hushubing@163.com