中低品位贵州铝土矿石灰拜尔法溶出工艺

陈滨,肖利,唐娴敏

(湖南工业大学 冶金工程学院,湖南 株洲,412011)

摘要:采用铝硅比为5.48的贵州中低品位一水硬铝石型铝土矿进行石灰拜尔法溶出实验,系统地研究石灰添加量、母液苛碱质量浓度和溶出温度等因素对溶出过程的影响。研究结果表明:随着石灰添加量的增大,溶出赤泥铝硅比和钠硅比均呈明显的下降趋势,;后%泥的angS=本文对石灰的添加量的影响进行了详细的实验研究增大石灰添加量对降低碱耗效果十分明显。贵州中低品位铝土矿石灰拜尔法适宜的溶出条件如下:石灰添加量为10%,配料分子比为1.45,循环母液苛碱质量浓度为200 g/L左右,溶出温度为270 ℃左右,溶出时间50 min,在此溶出条件下,溶出液苛性比<1.40,赤泥铝硅比<1.20,钠硅比<0.38,氧化铝相对溶出率>95%。

关键词:一水硬铝石;中低品位铝土矿;石灰拜尔法;溶出

中图分类号:TF821 文献标志码:A 文章编号:1672-7207(2014)05-1397-06

Digestion technology of Guizhou diasporic bauxite with low and medium grades by lime Bayer process

CHEN Bin, XIAO Li, TANG Xianmin

(College of Metallurgical Engineering, Hunan University of Technology, Zhuzhou 412011, China)

Abstract: The digestion experiments of lime Bayer process using diasporic bauxite from Guizhou Province with low and medium grades (alumina-silica ratio is 5.48) were completed. The influences of lime amount, proportioning molar ratio, spent liquor’s caustic soda mass concentration, digestion temperature and digestion time on the digestion process were investigated systematically. The results show that alumina-sillicon ratio and sodium-sillicon ratio of red mud decrease obviously with increasing lime amount. Increase of lime charge will effectively reduce soda consumption. The suitable conditions for digestion of lime Bayer process is as follows: lime amount is 10% to bauxite, proportioning molar ratio is 1.45, spent liquor’s caustic soda mass concentration is controlled to about 200 g/L, digestion temperature is about 270 ℃ and digestion time is of 50 min. When adopting the above conditions in the digestion process, αk of digested solution reaches less than 1.40, alumina-silica ratio of red mud is below 1.20, sodium-silica ratio of red mud is smaller than 0.38 and relative extraction yield of alumina is above 95%.

Key words: diaspore; bauxite with low and medium grade; lime Bayer process; digestion

用于我国氧化铝生产的铝土矿大多为一水硬铝石型铝土矿,具有高铝、高硅等特点[1-2],在已探明储量中80%以上属于中低品位(铝硅比即矿石中Al2O3与SiO2的质量比<8)。近年来,我国一水硬铝石型铝土矿的品位逐年下降,矿石铝硅比的下降极大影响了现阶段我国氧化铝生产的成本。由于氧化铝产能和产量大幅增加也造成了我国矿石品位的迅速下降,生产成本持续升高[3]。由于成本较多,曾经为我国氧化铝工业做出过突出贡献的烧结法和混联法工艺面临着被淘汰的境地[4]。根据我国铝土矿的特点,开发生产成本低的氧化铝生产工艺已迫在眉睫[5-6]。铝土矿中硅含量越高,氧化铝生产过程碱耗和氧化铝损失也越大。因此,中低品位铝矿石不宜采用常规拜尔法处理[7-8]。石灰拜尔法生产氧化铝新工艺是在拜尔法的工艺基础上适当加大石灰添加量,使其主要脱硅产物由含碱的水合铝硅酸钠(钠硅渣)变成不含碱的水合铝硅酸钙(水化石榴石),以大幅降低拜尔法生产的化学碱耗,这可减小由于矿石品位下降造成碱耗升高的压力,可见,石灰拜尔法大大放宽了拜尔法工艺对铝土矿铝硅比的限制,可直接用于处理铝硅比在6左右的中低品位铝土矿[9]。石灰拜尔法技术可利用原有拜尔法系统,只需将石灰添加量提高,就可直接用拜尔法处理中低品位铝土矿[10-12],该技术可大大降低碱耗和成本,对铝土矿资源可持续发展具有重大的现实意义。贵州铝土矿资源十分丰富,我国除山西地区,贵州铝土矿资源占全国总量的17%,居第二位。矿石呈土状、半土状、碎屑状、致密块状结构构造,主要为含一水硬铝石的沉积型铝土矿矿床,与红土型铝土矿相比,具有高铝、高硅和低铁特点,中低品位居多[13],不适合采用传统拜尔法处理。石灰拜尔法较原拜尔法工艺石灰的添加量大幅增加,这会对氧化铝生产工艺过程产生新的影响。因此,针对贵州氧化铝生产的现状,以中低品位铝土矿进行石灰拜尔法溶出工艺的研究,以揭示石灰添加量等工艺条件对溶出过程的影响规律,以期对我国尤其是贵州的氧化铝工业生产具有参考价值。

1 实验

1.1 实验原料

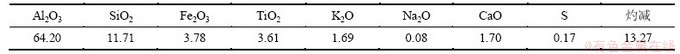

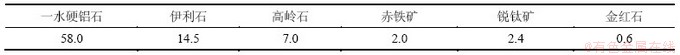

铝土矿来自贵州某地(铝硅比为5.48),经烘干,破碎后粒度分布情况为:粒径大于0.23 mm的颗粒质量分数<0.2%,粒径大于0.09 mm的颗粒质量分数<14%,将这2种粒径的颗粒混合均匀,备用,其化学成分和矿物物相组成如表1和表2所示。

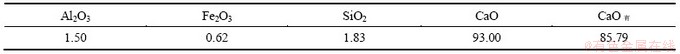

石灰经过处理后粒度小于0.15 mm,密封备用,其化学成分列如表3所示。

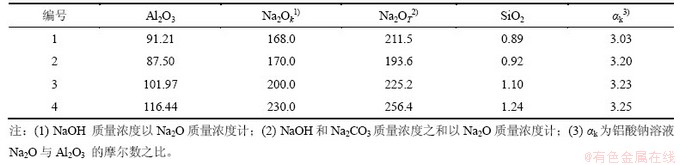

循环母液由中铝河南分公司氧化铝生产现场蒸发母液经调配而成,其化学成分如表4所示。

表1 铝土矿化学成分(质量分数)

Table 1 Chemical composition of bauxite %

表2 铝土矿的物相组成(质量分数)

Table 2 Phase composition of bauxite %

表3 石灰化学成分(质量分数)

Table 3 Chemical composition of lime %

表4 循环母液成分(质量浓度)

Table 4 Chemical composition of circulating spent liquor g·L-1

1.2 实验方法

采用熔盐浴加热的高压群釜(武汉探矿机械厂制造)进行石灰拜尔法溶出试验,溶出温度由温度控制仪控制,控温精度为±1 ℃。每个钢弹(容积150 mL) 中准确加入一定量的铝土矿和石灰,并移入100 mL 配好的循环母液,将矿浆搅匀,放入4个钢珠后加盖密封,然后放入预先控温的熔盐浴中并搅拌,在指定温度下保温溶出预定时间后取出,在冷水中强制冷却,过滤,将赤泥取出、烘干、称质量及进行化学分析。采用容量法分析滤液液相成分。

2 结果与讨论

2.1 石灰添加量对溶出过程的影响

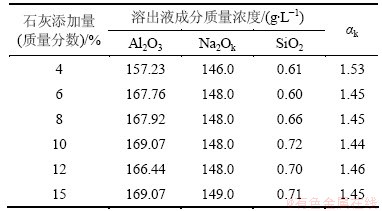

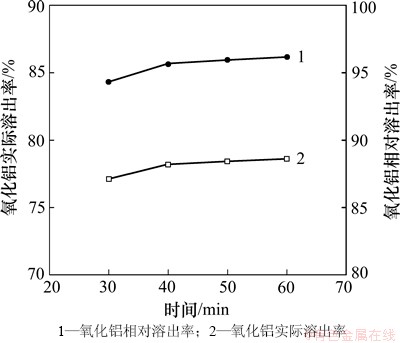

处理一水硬铝石型铝土矿时,石灰添加量(质量分数)一般为3%~5%,但石灰拜尔法则需要过量的石灰。采用1号循环母液,在配料αk为1.45、溶出温度为265 ℃、溶出时间为50 min的实验条件下,就石灰添加量对溶出过程的影响进行实验研究。溶出后液相成分如表5所示,赤泥铝硅比(氧化铝与氧化硅的质量比)、钠硅比(氧化钠与氧化硅的质量比)如图1所示。

由表5可知:当石灰添加量为6%~10%时,可获得αk最低的溶出液;当石灰添加量为10%时,αk达到最低点1.44。

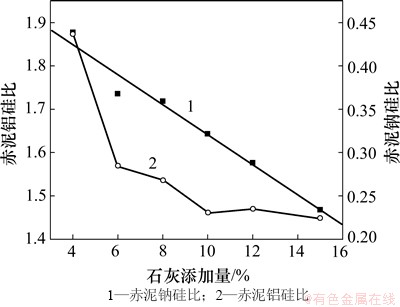

从图1可见:随着石灰添加量的增加,溶出赤泥铝硅比呈明显的下降趋势;;后%泥的angS=本文对石灰的添加量的影响进行了详细的实验研究但当石灰添加量超过10%以后,石灰添加量的增加对赤泥铝硅比影响趋小,铝硅比变化逐渐变缓;随着石灰添加量的增加,溶出赤泥钠硅比呈明显降低的趋势,且石灰添加量对溶出赤泥钠硅比的影响近似呈线性关系;当添加6%的石灰时,赤泥钠硅比为0.368,而石灰添加量增加到15%时,赤泥钠硅比降低到0.234。碱耗可以用赤泥钠硅比来定量表征[14],我国氧化铝厂钠硅比一般介于0.28~0.35。由此可知,增加石灰添加量对降低碱耗效果十分明显。

表5 石灰添加量对溶出过程的影响

Table 5 Effect of lime amount on digestion process

图1 石灰添加量对溶出过程的影响

Fig. 1 Influence of lime amount on digestion process

在氧化铝生产过程中采用拜尔法,含硅矿物在溶出过程中易转化为钠硅渣(Na2O·Al2O3·1.7SiO2·nH2O)和水化石榴石(3CaO·Al2O3·xSiO2·(6-2x)H2O)),从而随赤泥外排而损失碱和氧化铝。其中钠硅渣是引起碱耗的主要因素,而水化石榴石与钠硅渣在适宜的条件下可以相互转化,也影响碱耗[15]。通过在溶出过程中添加过量的石灰,使赤泥中的钠硅渣部分转变为水化石榴石,从而降低赤泥中Na2O含量以及生产碱耗。但是,当石灰添加量大于适宜值时,由于生成过多的水化石榴石,则会严重降低Al2O3溶出率。

综合考虑溶出液αk以及石灰添加量对赤泥铝硅比、钠硅比的影响,可选择石灰添加量为10%。

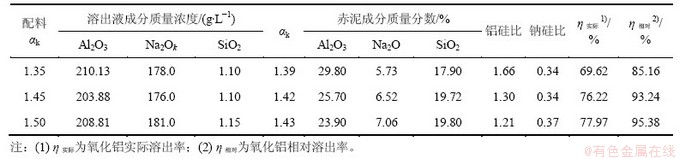

2.2 配料分子比对溶出过程的影响

采用2号循环母液,在石灰添加量为10%、溶出温度为265 ℃、溶出时间为50 min的实验条件下,配料αk对溶出过程影响的实验结果如表6所示。

由表6可知:当配料αk由1.35增至1.50时,氧化铝实际溶出率由69.62%提高至77.97%,但溶出液αk却由1.39升至1.43。配料分子比越大,即对单位质量矿石配入的碱量也就越高。由于在溶出过程溶液始终保持着更大的未饱和度,所以,溶出速度必然加快。但是这样循环效率必然降低,物料流量会增大。可见,在保证Al2O3溶出率不过分降低的前提下,制取αk尽可能低的溶出液是对溶出过程的一个重要要求,低αk还有利于后续晶种分解过程的进行。

综合考虑氧化铝溶出率及溶出液αk,配料αk以1.45为宜。

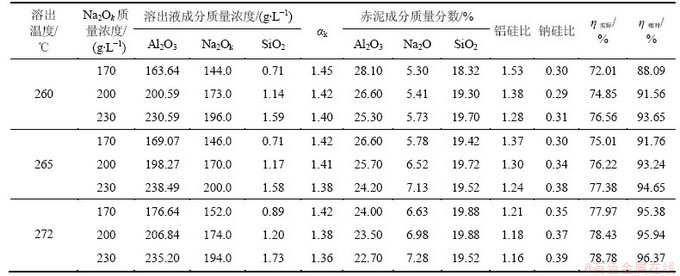

2.3 循环母液苛碱浓度、溶出温度对溶出过程的影响

分别采用2号、3号和4号循环母液,研究配料αk为1.45、石灰添加量为10%、溶出时间为50 min的实验条件下循环母液苛碱质量浓度、溶出温度对溶出过程的影响,结果如表7所示。

由表7可见:当其他条件相同时,母液苛碱质量浓度越高,溶出液αk越低,氧化铝溶出率越高;母液苛碱质量浓度越高,Al2O3的未饱和程度就越大,铝土矿中Al2O3的溶出速度就会越快,而且能得到分子比低的溶出液。质量浓度高的铝酸钠溶液,其饱和蒸汽压低,设备承受的压力也较低。但母液苛碱质量浓度若过高则会使得后面蒸发工序的负担和困难增大,所以,从整个流程权衡,母液苛碱质量浓度只宜保持适当的数值。综合考虑蒸发能耗及矿石溶出性能,循环母液苛碱质量浓度选200 g/L左右为宜。

从表7还可见:当母液苛碱质量浓度相同时,随着溶出温度的升高,氧化铝溶出率随之升高。在相对较低的溶出温度(260 ℃)下,质量浓度相对较低的循环母液(Na2Ok质量浓度170 g/L)的氧化铝实际溶出率比质量浓度高的(Na2Ok质量浓度为230 g/L)低4.55%,溶出液αk高0.05;随着溶出温度的上升,这种差别缩小;在272 ℃的溶出温度下,苛碱质量浓度相对较低(Na2Ok质量浓度为170 g/L)的氧化铝实际溶出率比质量浓度高的(Na2Ok质量浓度为230 g/L)溶出率相差不足1%。因此,铝土矿溶出过程最主要的影响因素是溶出温度,在较高溶出温度下,可选择较低的母液苛碱质量浓度,从而缩小溶出液与循环母液苛碱质量浓度差,大大降低母液蒸发的难度和负荷。

采用石灰拜尔法工艺的前提是具有拜尔法强化溶出技术。只有采用强化溶出技术,才能保证溶出赤泥中一水硬铝石的残余量趋近于0,同时,生成的水化石榴石分子中SiO2的饱和系数x有较大的值,从而确保得到铝硅比和钠硅比较低的溶出赤泥,大幅降低化学碱耗,并尽可能减少氧化铝损失。20世纪90年代,中铝河南分公司已成功引进德国管道化溶出技术,并经不断改善,现已逐步适应我国一水硬铝石矿的特性;我国针对一水硬铝石型铝土矿还自主开发了管道化预热—停留罐强化溶出技术,在运行期间可使矿浆的溶出温度达到265~270 ℃,从而使得拜尔法赤泥均衡稳定的低铝硅比(1.3~1.5)有保证[16],这也使生产过程温度的控制有了充足的保障。所以,在采用石灰拜尔法的生产氧化铝过程中,为获得较好的溶出效果,在生产条件许可的情况下,应尽可能采用高的溶出温度。贵州矿石最佳溶出温度可考虑为270 ℃左右。

表6 配料αk对溶出过程的影响

Table 6 Effect of proportioning molar ratio on digestion process

表7 循环母液苛碱质量浓度、溶出温度对溶出过程的影响

Table 7 Effect of circulating spent liquor’s caustic soda mass concentration and digestion temperature on digestion process

2.4 溶出时间对矿石氧化铝溶出率的影响

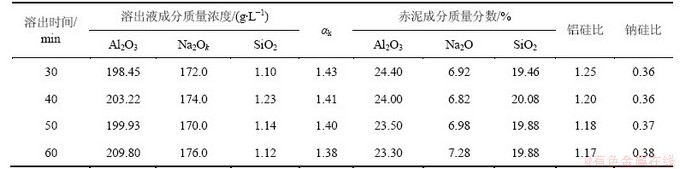

采用3号循环母液,配料αk为1.45,石灰添加量为10%,溶出温度为272 ℃的实验条件下,研究溶出时间对溶出过程的影响,结果如表8和图2所示。

从表8和图2可见:当溶出温度相同时,随着溶出时间的延长,溶出液αk和赤泥铝硅比有小幅度下降,而赤泥钠硅比则缓慢增大;而溶出时间对铝土矿氧化铝溶出率的影响不明显。国内科技工作者对一水硬铝石型铝土矿溶出动力学的研究表明[17]:当温度为224~242 ℃时,表观活化能为89.5 kJ/mol,反应为动力学控制区;而当温度提高到242~268 ℃时,表观活化能降至44.4 kJ/mol,此时传质步骤逐渐占有重要的地位,对反应速度产生不可忽略的影响,因此,溶出时间对溶出率的影响相对减弱。溶出时间取50 min为宜。

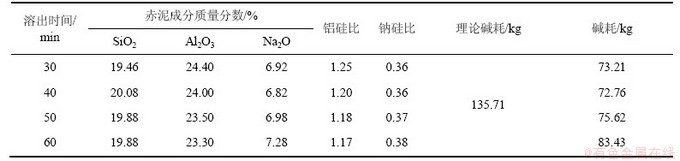

2.5 溶出过程的碱耗

在272 ℃的溶出温度下,使用3号循环母液对铝土矿进行溶出,其碱耗(按每生产1 t氧化铝消耗的氧化钠计)等实验结果如表9所示。

图2 溶出时间对溶出过程溶出率的影响

Fig. 2 Influence of digestion time on extractive yield of Al2O3 in digestion process

从表9可知:当溶出时间为30~50 min时,赤泥铝硅比<1.26,钠硅比<0.38,碱耗均低于76 kg Na2O-tAl2O3,大大低于传统拜尔法高压溶出过程的理论碱耗,这表明石灰拜尔法确实能明显降低生产过程的化学碱耗。此外,由于赤泥中碱含量的降低,赤泥则可能用于进一步综合利用,如烧制水泥或作为建筑材料等,从而实现氧化铝生产过程的废渣零排放。

表8 溶出时间对溶出过程的影响

Table 8 Effect of digestion time on digestion process

表9 溶出实验结果

Table 9 Experimental results of digestion process

3 结论

(1) 随着石灰添加量的增加,溶出赤泥铝硅比呈明显的下降趋势;;后%泥的angS=本文对石灰的添加量的影响进行了详细的实验研究但当石灰添加量超过10%以后,石灰添加量的增加对赤泥铝硅比影响趋小,铝硅比变化逐渐变缓。随着石灰添加量的增加,溶出赤泥钠硅比呈明显降低的趋势,且石灰添加量对溶出赤泥钠硅比的影响近似呈线性关系。增加石灰添加量对降低碱耗效果十分明显;为获得较好的溶出效果,应尽可能采用高的溶出温度;当温度提高到一定程度后,反应的控制步骤逐渐转入扩散过程控制,因此,溶出时间对溶出率的影响相对减弱。

(2) 贵州中低品位铝土矿石灰拜尔法适宜的溶出条件如下:石灰添加量为10%,配料分子比为1.45,循环母液苛性碱质量浓度为200 g/L左右,溶出温度为270 ℃左右,溶出时间为50 min,在此条件下,溶出液苛性比值αk<1.40,赤泥铝硅比<1.20,钠硅比<0.38,氧化铝相对溶出率>95%。

(3) 石灰拜尔法处理过程碱耗大大低于传统拜尔法高压溶出过程的理论碱耗,表明采用该方法能明显降低生产过程的碱耗。

参考文献:

[1] 刘桂华, 张明, 肖伟, 等. 高铁一水硬铝石型铝土矿的低钙比烧结[J]. 中国有色金属学报, 2008, 18(10): 1903-1908.

LIU Guihua, ZHANG Ming, XIAO Wei, et al. Sintering process of diasporic bauxite with high iron content at low ratio of lime to silica for alumina production[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(10): 1903-1908.

[2] 吴玉胜, 刘墨. 苛碱浓度对种分产品粒度变化规律的影响[J]. 沈阳工业大学学报, 2012, 34(2): 159-163.

WU Yusheng, LIU Mo. Effect of caustic sodium concentration on variation rule in particle size of crystal seed precipitation product[J]. Journal of Shenyang University of Technology, 2012, 34(2): 159-163.

[3] 张伦和. 铝土矿资源合理开发与利用[J]. 轻金属, 2012(2): 3-11.

ZHANG Lunhe. Reasonable development and utilization of bauxite resource[J]. Light Metals, 2012(2): 3-11.

[4] 张佰永, 王鹏. 低铝硅比时代的中国氧化铝工艺选择[J]. 轻金属, 2011(7): 36-39.

ZHANG Baiyong, WANG Peng. Selection for Chinese alumina process in the times of low A/S ratio[J]. Light Metals, 2011(7): 36-39.

[5] 杨海洋, 陈建宏. 铝土矿资源安全与供给保障的战略分析[J]. 资源环境与工程, 2008, 22(6): 628-633.

YANG Haiyang, CHEN Jianhong. Strategic analysis on the bauxite resources security and supply control[J]. Resources Environment & Engineering, 2008, 22(6): 628-633.

[6] 刘建新. 适应我国铝土矿特点的氧化铝生产工艺技术探讨[J]. 轻金属, 2010(10): 13-16.

LIU Jianxin. Discussion on the a lumina production process adapted to the features of bauxite in China[J]. Light Metals, 2010(10): 13-16.

[7] 王少娜, 郑诗礼, 张懿. 亚熔盐溶出一水硬铝石型铝土矿过程中赤泥的铝硅行为[J]. 过程工程学报, 2007, 7(5): 967-972.

WANG Shaona, ZHENG Shili, ZHANG Yi. Behavior of Al and Si in red mud from leaching process of diaspore bauxite with NaOH sub-molten salt[J]. The Chinese Journal of Process Engineering, 2007, 7(5): 967-972.

[8] 彭志宏, 王浩宇, 刘桂华, 等. 二氧化硅在铝酸钠溶液中的反应行为[J]. 矿冶工程, 2009, 29(6): 57-60.

PENG Zhihong, WANG Haoyu, LIU Guihua, et al. Reaction behavior of silica in sodium aluminate solution[J]. Mining and Metallurgical Engineering, 2009, 29(6): 57-60.

[9] 厉衡隆, 顾松青. 铝冶炼生产技术手册(上册)[M]. 北京: 冶金工业出版社, 2011: 801-802.

LI Henglong, GU Songqing. Technology handbook of aluminum production (Ⅰ)[M]. Beijing: Metallurgical Industry Press, 2011: 801-802.

[10] Solymaer K, Zoeldi J. Lime in the Bayer process[C]// The 122nd Annual Meeting and Exhibition: Light Metals Proceedings. Warrendale: TMS Light Metals, 1993: 185-194.

[11] Xu B A, Giles D E, Ritchie I M. Reactions of lime with aluminate-containing solutions[J]. Hydrometallurgy, 1997, 44(6): 231-244.

[12] Whittington B I. The chemistry of CaO and Ca(OH)2 relating to the Bayer process[J]. Hydrometallurgy, 1996, 43(1): 13-35.

[13] 穆童. 贵州铝土矿品位变化趋势及对策[J]. 中国金属通报, 2012(38): 36-37.

MU Tong. The countermeasure and variation trend of quality of bauxite from Guizhou province[J]. Bulletin of the Chinese Metals, 2012(38): 36-37.

[14] 陈文汨, 黄伟光, 陈学刚. 改变石灰添加点降低铝土矿拜尔法溶出碱耗的研究[J]. 轻金属, 2008(5): 9-12.

CHEN Wenmi, HUANG Weiguang, CHEN Xuegang. Study of lime adding points to reduce consumption of caustic soda in Bayer digestion of bauxite[J]. Light Metals, 2008(5): 9-12.

[15] Barnes M C, Addai-Mensah J, Gerson A R. The kinetics of desilication of synthetic spent Bayer liquor seeded with cancrinite and cancrinite/sodalite mixed-phase crystals[J]. Journal of Crystal Growth, 1999, 200: 251-264.

[16] 曹彦卓, 董放战. 石灰拜尔法溶出工艺的探讨[J]. 中国有色冶金, 2008(4): 13-16.

CAO Yanzhuo, DONG Fangzhan. Study on lime Bayer process dissolution[J]. Chinese Non-ferrous Metallurgy, 2008(4): 13-16.

[17] 毕诗文, 于海燕, 杨毅宏, 等. 拜尔法生产氧化铝[M]. 北京: 冶金工业出版社, 2007: 40-41.

BI Shiwen, YU Haiyan, YANG Yihong, et al. Alumina production by Bayer process[M]. Beijing: Metallurgical Industry Press, 2007: 40-41.

(编辑 邓履翔)

收稿日期:2013-06-11;修回日期:2013-08-12

基金项目:国家自然科学青年基金资助项目(51208193);湖南省教育厅资助项目(09C342)

通信作者:陈滨(1976-),男,江西高安人,博士,从事氧化铝生产工艺及其理论研究;电话:0731-22183465;E-mail: csuchenbin@sohu.com