DOI: 10.11817/j.issn.1672-7207.2020.01.021

金属矿山气-水喷头雾化特性及降尘能力实验研究

蒋仲安,王亚朋,许峰

(北京科技大学 土木与资源工程学院,北京,100083)

摘要:为分析金属矿山多中段高溜井喷头雾化特性及其降尘效果,建立高溜井喷雾降尘实验平台。采用激光粒径分析仪及喷雾实验设备对新型气-水喷头雾化特性、冲击气流对喷雾捕尘能力影响规律进行研究分析。研究结果表明:气、水流量比是影响新型气-水喷头雾化效果的关键因素;当喷头工作时气、水流量比为100~150时,雾化效果最佳,最佳气压和水压区间分别为[0.4, 0.6] MPa和[0.3, 0.5] MPa,雾滴粒径分布在15~35 μm范围内;在最佳气压和水压区间内,雾化角度随气压的增加而增大,随水压先增大后减小,最大雾化角度为40°,调整气压是优化雾化角度的主要手段;溜井卸矿冲击气流对喷雾雾滴粒径影响较大,喷雾捕尘能力与冲击气流速度呈负相关。

关键词:气-水喷雾;高溜井;雾滴粒径;降尘;气水流量比

中图分类号:TD714.4 文献标志码:A

文章编号:1672-7207(2020)01-0184-09

Experimental study on atomization characteristics and dust reduction capacity of gas-water nozzles in metal mines

JIANG Zhongan, WANG Yapeng, XU Feng

(School of Civil and Resource Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: In order to analyze the atomization characteristics and dust-reducing effect of high ore pass nozzles in metal mines, a high ore pass spray dust-reducing experimental platform was established. The laser particle size analyzer and spray experiment equipment were used to study the atomization characteristics of the new gas-water nozzle and the influence law of the impact gas flow on the spray dust-collecting ability. The results show that the gas-water flow ratio is the key factor affecting the atomization effect of the new gas-water nozzle. When the ratio of gas and water flow is 100-150, the atomization effect is the best. The best pressure ranges of gas and water are [0.4, 0.6] MPa and [0.3, 0.5] MPa, respectively. In the above range of gas-water flow ratio, the droplet size distribution is in the range of 15-35 μm. The atomization angle increases with the increase of gas pressure in the optimal gas-water flow ratio range. The atomization angle first increases and then decreases with the increase of the water pressure, the maximum atomization angle is 40 °, so the adjustment of air pressure is the main means to optimize the atomization angle. The impact gas flow induced by the unloading of the ore pass has a great influence on the particle size of the spray droplets, and the spray dust-collecting ability is negatively correlated with the velocity of the impinging gas flow.

Key words: gas-water spray; high ore pass; droplet size; dust reduction; gas-water flow ratio

多中段高溜井在金属矿山运输中具有较大作用。但是,高溜井运输也导致了严重的粉尘污染问题[1-2]。在矿山粉尘治理中,除通风除尘外,喷雾降尘是控制粉尘污染较为有效的手段。传统水喷雾耗水量大,液滴粒径大,捕尘能力差。而气-水喷雾以压缩空气为动力,将水通过气-水喷头进行雾化,产生的雾滴粒径较小,提高了捕尘能力[3-4]。然而,多中段高溜井卸矿口粉尘受冲击气流的影响,粉尘运动速度较快[5-6]。现阶段对于气-水喷雾降尘的研究更多针对风流较为稳定的环境下除尘,很少应用于具有冲击气流影响的溜井卸矿口除尘。例如聂文等[7]通过改变喷雾压力,分析了喷嘴雾化特性变化规律。汲银凤等[8]通过实验对不同雾化喷头进行喷雾实验,利用雾滴粒径标定出不同喷嘴的最佳雾化气水比。显然,对于存在冲击风流的多中段溜井卸矿粉尘治理,现有水喷雾降尘参数并不能在溜井粉尘治理中完全使用。同时,气-水喷头结构在不断更新,对于金属矿山常用的新型气-水喷头雾化特性的影响因素分析较少。为提高喷雾雾化效果及除尘能力,本文作者对喷雾直径为1.5 mm的新型可调广角气-水喷头的雾化特性、风流影响下雾滴变化趋势及雾滴的捕尘能力进行实验分析,通过实验总结出新型气-水喷头的最佳气压和水压范围,雾化角随气压和水压变化的趋势,同时确定冲击风速对喷雾粒径及捕尘能力的影响程度。

1 气-水喷雾数学计算模型建立

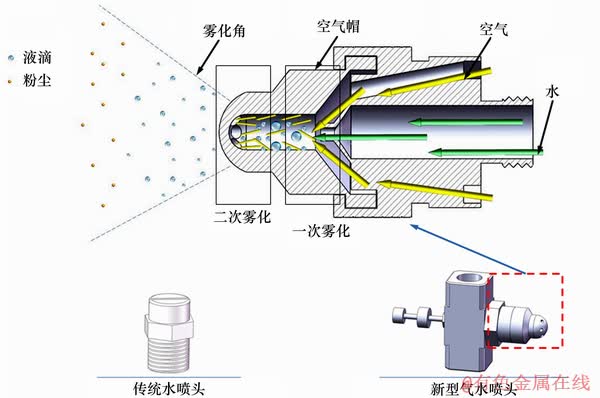

传统水喷雾是利用单相液体水作为材料和动力,完全依靠水压作用在喷头处碰撞形成雾滴,其用水量及雾滴粒径较大,捕尘效率低。而新型气-水喷雾是采用压力水和压缩空气为动力,通过喷雾头的2次雾化作用使水变成粒径较小的雾滴,更适合治理高溜井冲击气流携带的粉尘[9-10]。新型可调广角气-水喷头结构及雾化捕尘原理如图1所示。

图1 新型气-水喷头结构和雾化捕尘原理

Fig. 1 New gas-water nozzle structure and atomization principle

雾滴粒径是影响捕尘能力最主要的因素,气-水喷雾雾滴平均粒径计算公式为[11-14]:

(1)

(1)

(2)

(2)

式中: 为雾滴平均粒径,m; vr为混合室中气液两相相对流速,m/s;σ为液体的表面张力系数,10-5 N/cm; μl为液体黏性系数,Pa·s; ρl为液体的密度,g/cm3;δ为液气流量比;Ql和Qg分别为液体和空气的体积流量,m3/s;vg和vl分别为气体和液体流速,m/s; α为气液两相流速夹角。

为雾滴平均粒径,m; vr为混合室中气液两相相对流速,m/s;σ为液体的表面张力系数,10-5 N/cm; μl为液体黏性系数,Pa·s; ρl为液体的密度,g/cm3;δ为液气流量比;Ql和Qg分别为液体和空气的体积流量,m3/s;vg和vl分别为气体和液体流速,m/s; α为气液两相流速夹角。

将式(2)代入式(1)并经整理可得

(3)

(3)

在恒温恒压条件下,喷头混合腔内流体满足 Q=v·A。液体水参数σ=72×10-5 N/cm,μl=0.009 82 Pa·s及ρl=1.0 g/cm3。将上述参数代入方程(3),化简后可得

(4)

(4)

其中:Al为液体注入孔面积,m2;Ag为注气孔面积,m2。实验选用的喷头注水孔直径dl =1.5 mm,Al=1.77×10-6 m2;气孔直径dg=2.0 mm,Ag=3.14×10-6 m2;α=30°。将参数代入式(4)并化简得

(5)

(5)

由式(5)可以看出:液体和气体的体积流量是影响雾滴颗粒直径主要因素,压缩空气通过供气管线输入到喷头混合腔。在理想情况下,气体在喷头出口处速度vg可以使用圣维南公式计算:

(6)

(6)

气体质量流量Qmg使用式(6)计算可得:

(7)

(7)

其中:vg为空气出口流速,m/s;k为空气绝热指数;ρg为空气的密度,kg/m3;Qmg为空气质量流量,kg/s; ηl为注气孔流量系数,一般取0.8~0.9;Ag为注气孔总面积,m2;ph为混合室的压力;pg为供气压力。

由水泵提供的水通过管线输送到喷雾口,整个过程动力损失包括沿程阻力和局部阻力。在一般情况下,沿程阻力可以忽略,喷雾系统中局部阻力指水由1.5 mm孔径进入混合腔时存在的阻力。局部阻力损失为

(8)

(8)

其中:Δpm为局部损失,Pa;ζ为局部阻力系数,ζ=0.5;ρl为水的密度,kg/m3;vl为注水孔出口流速,m/s。Δpm=pl-ph,结合式(8)可得流体出口速度:

(9)

(9)

同理,液体质量流量Qml使用式(9)计算可得:

(10)

(10)

2 新型气-水喷雾参数实验分析

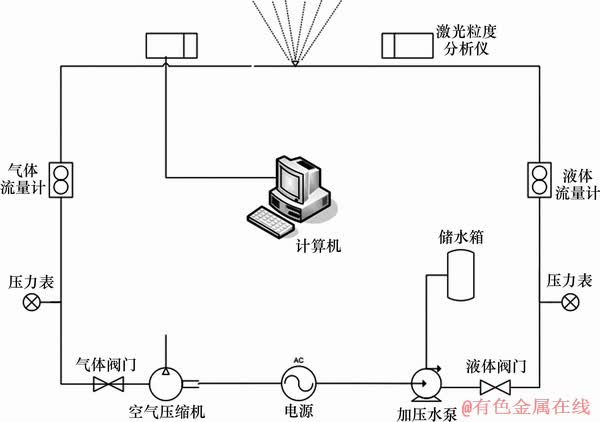

2.1 实验平台的建立

在北京科技大学安全防尘实验室现有的除尘实验设备基础上,建立新型气-水喷头雾化性能(喷射角度、雾滴粒径、雾滴轴线稳定性)实验平台。图2所示为实验平台的喷头雾化粒径测试模块,包括雾滴粒度分析仪(型号JL-3000)、空气压缩机、高压水泵、喷嘴安装三脚架、气体及液体流量计。输气及输水管线均采用直径为12 mm的空压管,空压机为实验提供压缩空气,有效可调压力范围为0~0.8 MPa;高压水泵(型号QL380A)提供压力水,压力范围为0~6.0 MPa。由空气压缩机及水泵分别用空压管连接压力表和流量计,然后通过空压管与雾化喷嘴(孔径为1.5 mm)直接相连,通过调节气压阀和水压阀,控制喷嘴的气、水流量。喷嘴采用三脚架固定,喷嘴距离粒度分析仪激光束垂直距离为0.5 m,架设高度为1.5 m。由于雾化程度反映气-水喷雾的除尘能力,而气压和水压参数是影响雾化效果主要因素[15],因此,以气压和水压参数为主进行雾化效果分析。

图2 新型气-水喷头雾化性能实验系统

Fig. 2 New gas-water atomization performance experiment system

2.2 不同参数下喷头雾化效果分析

雾滴粒径及喷射角度是衡量喷头性能即雾化效果的主要标准[16-18]。由式(5)可知:在喷头确定的情况下,气、液流量是决定雾化效果最主要的参数,而压力影响流量,因此,优先对气液压力进行分析。由于喷雾呈发散状,实验选择在喷雾轴向检测雾滴粒径分布。在进行控制变量分析时,使用卸压阀分别对气压、水压进行调节。为分析出气压与水压变化对雾化效果的影响,根据经验选取气压为0.2,0.3,0.4,0.5和0.6 MPa;选取水压为0.3,0.4,0.5,0.6,0.7和0.8 MPa,进行交叉实验。并利用激光粒度分析仪分别读取不同气压及水压配比时雾滴粒径。分析评定雾滴群的雾化质量和其雾化特性的方式较多,本文使用雾滴粒径D50及D90(D50和D90分别为累计分布50%和90%处的直径)对新型气-水喷头的雾化效果进行分析[19-20]。为使气-水喷雾在除尘过程中达到较少耗水量,同时分析气水量的变化对雾滴粒径的影响。雾滴粒径与耗气、水流量随气压及水压变化如图3所示。

图3 气压和水压变化下雾滴粒径变化

Fig. 3 Variation of droplet size under gas-water pressure changes

由图3可知:雾滴粒径在30 μm以下的比例占50%,粒径在40 μm以下的比例占90%。雾滴平均粒径可以到达24 μm,此种新型喷头雾化效果较好。矿山生产中呼吸性粉尘的空气动力学直径(AED)小于7 μm,可吸入粉尘AED小于10 μm。由于雾滴与粉尘粒径接近时粉尘容易被捕捉,因此,应通过调节气压和水压尽量将雾滴粒径缩小。对图3(a)和3(b)进行进一步分析发现,D50和D90的雾滴三维曲面图存在2个红色凹陷区α和β,区域内雾滴粒径明显比其余部分的小。其中D50约为20 μm,D90约为30 μm,雾化能力较强。红色凹陷区域α和β的气压范围为[0.4, 0.6] MPa,水压范围为[0.3, 0.5] MPa,对应水流量范围为[0.8, 1.5] L/min,气流量的范围为[110, 130] L/min。同时,由三维曲面图可看出:气压到达0.5 MPa时,继续增加气压并没有明显改变粒径,而气压过大导致压缩气体浪费。经过整理分析,最佳气、水流量比的范围为100~150。由图3(c)和3(d)可以看出:气、水流量变化呈现负相关关系。气-水流量在压力变化下相互制约,一方变大,另一方必定减小。当气压恒定时,水流量与水压呈正相关;当水压恒定时,气流量与气压呈正相关。此外,气流量随气压的增大能够持续增加,而水压的继续增大水流量增加量减缓。

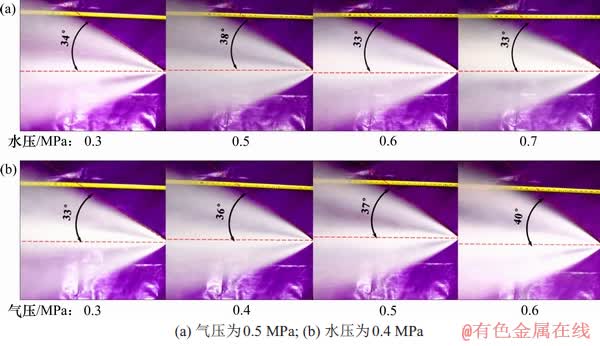

雾滴最佳粒径确保捕尘能力,喷雾角度确定了三维空间内雾滴的覆盖范围。选取最佳雾滴粒径区域α和β(气压范围为[0.4, 0.6] MPa、水压范围为[0.3, 0.5] MPa),分析区间内气压和水压变化对喷雾角度的影响。在不同气压和水压下,新型气-水喷雾雾化角度变化如图4所示。

图4 气压和水压变化对雾化角度的影响

Fig. 4 Effect of gas-water pressure changes on atomization angle

由图4可知:当气压为0.5 MPa时,水压由0.3 MPa增加到0.7 MPa,喷头雾化角度呈现出先增大后减小的趋势。喷头最大雾化角为38°,最小33°。水压增大时,供水量增加,形成雾滴较多,气压利用率较高因此雾化半径变大。当水流量过大时,气压不足以将水充分雾化,水压在雾化室内占据主要优势,雾滴粒径变大雾化角度变小。当水压为0.4 MPa时,在气压变化区间为[0.3, 0.6] MPa时,雾化角不断增大。气压增加使水在喷头处充分雾化,雾化角度不断变大。通过分析可知,气压变化是优化雾化角度最有利因素。在保证雾化粒度的前提下,适当调整气压可以增加喷雾在空间内覆盖面积,从而改善雾滴与粉尘的混合程度,提高降尘率。在最佳气、水压力配比参数区间内,根据雾化角度的变化可知,在保证气压为0.6 MPa、水压为0.5 MPa时可以达到最佳雾化角度。

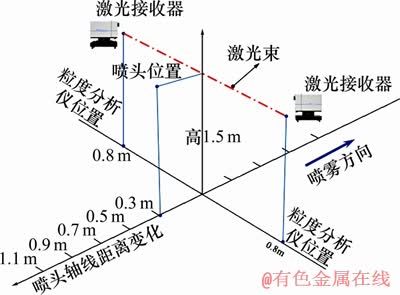

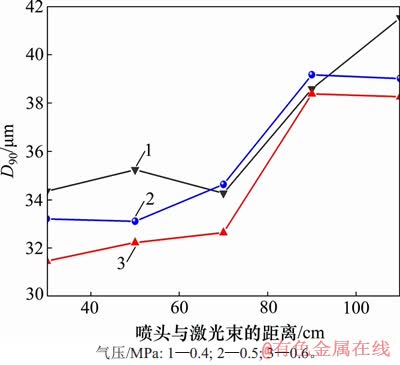

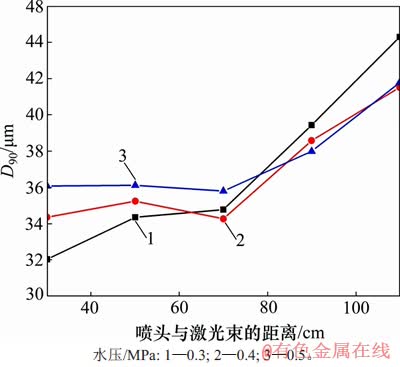

2.3 气-水压力变化对雾滴轴向稳定性分析

上述对气-水流量比的分析,得到雾滴需满足最佳捕尘粒径。雾滴由喷嘴喷出后,粒径在外界环境中的稳定性也是体现雾化效果的重要参数。为研究雾滴粒径在水平方向上的稳定性,设置间距为0.3,0.5,0.7,0.9和1.1 m 5个检测点,轴向水平移动喷雾支架,分析雾滴轴向稳定性。雾滴参数检测设置情况如图5所示。同样选取区域α和β,采用D90分析气、水压力变化对雾滴在不断运动中稳定性的影响,结果分别如图6和图7所示。

图5 雾滴轴线稳定性检测

Fig. 5 Droplet stability test

图6 气压变化对雾滴稳定性的影响

Fig. 6 Effect of pressure change on droplet stability

由图6可知:当水压为0.4 MPa时,随着气压不断增大,雾滴粒径逐渐减小;在距离喷头 [30,70] cm范围时,雾滴处于稳定状态,粒径变化较小。当气压为0.5 MPa和0.6 MPa时,雾滴远离喷头90 cm后,粒径逐渐稳定在38~39 μm,不随距离增大而增大。由图7可知:当气压为0.4 MPa时,水压的变化对雾滴粒径稳定性的影响不大。综上可知:水压的变化对喷嘴的雾化效果影响不明显,调节气压是维持雾滴稳定及保证雾滴粒径较小的主要手段。

图7 水压变化对雾滴稳定性的影响

Fig. 7 Effect of water pressure change on droplet stability

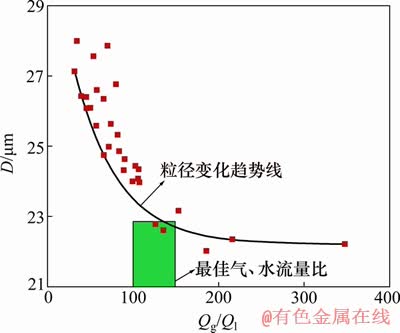

2.4 体积流量比对雾滴粒径影响分析

当气、水流量范围分别为[110, 130] L/min和[0.8, 1.5] L/min时,雾滴平均粒径小于30 μm。气、水流量是影响雾滴粒径变化主要原因,但同时涉及气压、水压的分析离散性太强。因此,引入气、水流量比(Qg/Ql)分析其对雾滴粒径变化影响。图8所示为气、水流量比与雾滴平均粒径关系图。

图8 雾滴平均粒径随气、水流量比变化

Fig. 8 Average particle size of droplet changes with flow ratio of gas to water

由图8可知:雾滴粒径与气、水流量呈反比,气、水流量比在[100, 150]范围雾滴平均粒径小于23.5 μm;当气、水流量比小于100时,对雾滴粒径的影响较大;当气、水流量比为[100, 200]时,雾滴受气水流量比的影响较小;当气、水流量比大于200时,雾滴粒径基本稳定。平均雾化粒径拟合出的最佳气、水流量比与实验中气液压力比确定的最佳气、水流量比相吻合。

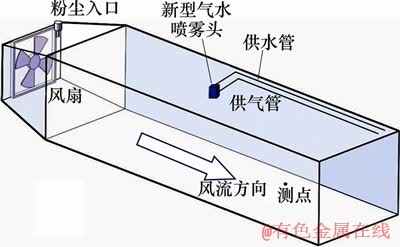

3 冲击气流对捕尘能力影响的实验分析

矿山运输系统其他部位采用气-水喷雾降尘时,环境风流稳定且风速较小,不会对降尘效果产生影响。而多中段溜井卸矿时,粉尘由矿石下落产生的冲击性气流带入联络巷污染作业环境,具有粉尘运移速度快的特点。溜井口冲击风速相对较大,影响了粉尘与雾滴的均匀混合。因此,建立如图9所示喷雾降尘实验巷道分析冲击气流对雾滴粒径及捕尘效率的影响。矩形高溜井联络巷长、宽和高分别为6.0 m、1.5 m和1.2 m,断面积为1.8 m2;除尘实验采用图2所示的气-水喷雾设备。进行多中段溜井卸矿时,冲击气流携带粉尘由不同中段溜井口喷出。由于受现有巷道模型的限制,不能实现从巷道底部产尘,因此,采用巷道端头设置64 m3/min的扬尘风扇配合粉尘扩散器模拟产尘源。为区分出喷雾对呼吸性粉尘及可吸入粉尘的降尘能力,采用4.0,6.5,8.0,13.0和18.0  m 5种粒度铜矿石粉,配比出粉尘材料。将喷雾头布置在距离风扇2 m处,安装角度为指向产尘源30°方向的位置。分别采用粉尘浓度测试仪及粒度分析仪检测出巷道内降尘前后粉尘浓度及粉尘粒径分布。

m 5种粒度铜矿石粉,配比出粉尘材料。将喷雾头布置在距离风扇2 m处,安装角度为指向产尘源30°方向的位置。分别采用粉尘浓度测试仪及粒度分析仪检测出巷道内降尘前后粉尘浓度及粉尘粒径分布。

图9 喷雾和粉尘抑制的实验平台

Fig. 9 Experimental platform for spray and dust suppression

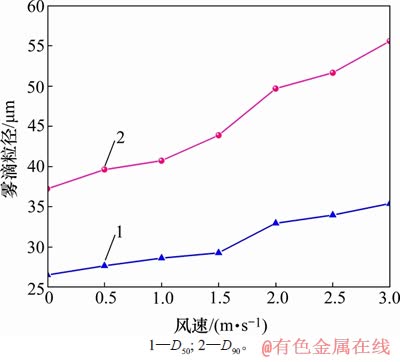

3.1 冲击气流对雾滴粒径的影响

溜井口卸矿粉尘治理与普通巷道内弥漫粉尘治理不同,喷雾对卸矿粉尘治理时受风速影响较大,因此,研究风速对雾滴粒径的影响及不同风速下除尘能力意义较大。选取最佳气、水流量比为126(气压为0.5 MPa,水压为0.4 MPa),同时改变正向风速为0,0.5,1.0,1.5,2.0,2.5和3.0m/s,监测雾滴粒径变化。在不同风速下检测雾滴粒径(D50和D90)及分布情况,分析风速对雾滴粒径的影响,如图10所示。

图10 不同风速下雾滴粒径变化

Fig. 10 Variation of droplet size at different wind speeds

由图10可知:在不同雾滴粒径分析标准下,随着巷道内风速增加,雾滴粒径均表现出增大趋势。风速增大增加了雾滴之间的相互碰撞,使雾化后的液滴互相捕捉,导致雾滴质量的积累,从而雾滴粒径增加。当风速小于1.5 m/s时,雾滴粒径变化较平缓,D50增量为3 μm左右,D90增量为6 μm左右。因此,当巷道内风速小于1.5 m/s时,对于雾滴的变化影响不大,可以保证雾化效果。

3.2 冲击气流对捕尘率的影响

经现场监测,溜井联络巷内正常风速为0.5 m/s左右。为模拟现场真实环境,开启风机使巷道达到正常风量,粉尘分布均匀后开启喷雾,监测喷雾后粉尘质量浓度。为分析卸矿后冲击性风速对喷雾降尘效果的干扰,采用同样的实验步骤,分别对风速为0.5,1.0,1.5,2.0和2.5 m/s时喷雾后粉尘质量浓度进行监测,监测结果如表1所示。

表1 不同风速下气-水喷雾捕尘率

Table 1 Gas-water spray dust collection at different wind speeds

由表1可知:喷雾前后全尘质量浓度的降低程度比呼吸性粉尘的质量浓度降低程度大;最佳全尘降尘率为65.65%,呼吸性粉尘降尘率最佳为33.46%。呼吸性粉尘相比全尘粒径较小,不易在空气中产生自由沉降,喷雾对其捕捉能力有限。全尘及呼吸性粉尘的降尘率均呈现出先增大后减小的趋势,这与风流对雾滴粒径影响的规律基本一致。经分析可知:当风速小于1.5 m/s时,喷雾雾滴粒径变化较小;风速的存在提高了粉尘与雾滴之间的混合程度,进而增大了雾滴对粉尘捕捉概率,因此,降尘率增加。当风速大于1.5 m/s时,雾滴粒径受风速的影响急剧增大;同时,当风速较大时降低了粉尘与雾滴的接触时间,使喷雾降尘能力快速减弱。通过分析风速对雾滴粒径及降尘率的影响,可知巷道内冲击风速小于1.5 m/s时,喷雾降尘能力最强。

4 结论

1) 在气压、水压及雾滴粒径这3个变量中,当气-水喷头供气压范围为[0.4,0.6] MPa、供水压范围为[0.3,0.5] MPa时,确定出的三维空间为最佳雾化效果区域。新型气-水喷头最佳气、水流量比为100~150,雾滴粒径可达30 μm以下。

2) 在最佳气压和水压范围,雾化角度随气压的增大而增大,最大雾化角度为40°;雾化角度随水压的增大先增大后减小最后趋于稳定,最大雾化角度为38°。气压变化相对水压变化对雾化角的影响更大,现场可以根据实际情况调整气压优化雾化角度。

3) 溜井卸矿产生的冲击气流对雾滴粒径影响较大,雾滴粒径随风速的增大而增大。风速与雾滴捕尘能力呈反比,随着风速增大,捕尘能力呈现出先增大后急剧减小的趋势。喷雾全尘最大降尘率为65.65%,呼吸性粉尘最大降尘率为33.46%。

参考文献:

[1] 王明. 高溜井粉尘产运机理与时空分布特征及控制技术研究[D]. 北京: 北京科技大学土木与资源工程学院, 2017: 1-145.

WANG Ming. Study on the mechanism and temporal and spatial distribution of high ore pass dust and its control technology[D]. Beijing: University of Science and Technology Beijing. School of Civil and Resource Engineering, 2017:1-145.

[2] 蒋仲安, 王明, 陈举师, 等. 气水喷嘴雾化特征与降尘效果分析[J]. 哈尔滨工业大学学报(社会科学版), 2017, 49(2): 151-157.

JIANG Zhongan, WANG Ming, CHENG Jushi, et al. Atomization characteristics and dust suppression mechanism of a gas-water nozzle[J]. Journal of Harbin Institute of Technology(Social Sciences Edition), 2017, 49(2): 151-157.

[3] 王鹏飞, 谭烜昊, 刘荣华, 等. 出口直径对内混式空气雾化喷嘴雾化特性及降尘性能的影响[J]. 煤炭学报, 2018, 43(10): 167-175.

WANG Pengfei, TAN Xuanhao, LIU Ronghua, et al. Effect of outlet diameter on atomization characteristics and dust reduction performance of internal mixing air atomizing nozzle[J]. Journal of China Coal Society, 2018, 43(10): 167-175.

[4] 赵晓亮, 齐庆杰, 葛少成, 等. 气泡雾化喷嘴在受限空间雾化特性的实验研究[J]. 辽宁工程技术大学学报(自然科学版), 2018, 37(2): 290-296.

ZHAO Xiaoliang, QI Qingjie, GE Shaocheng, et al. Experimental investigation of spray characteristic of effervescent atomization nozzle in confined space[J]. Journal of Liaoning Technical University(Natural Science), 2018, 37(2): 290-296.

[5] 陈记合, 蒋仲安, 王明, 等. 卸矿站风流流场及粉尘浓度分布规律的数值模拟[J]. 科学技术与工程, 2018, 18(9): 210-214.

CHEN Jihe, JIANG Zhongan, WANG Ming, et al. Numerical simulation of air flow field and dust concentration distribution in unloading station[J]. Science and Technology and Engineering, 2018, 18(9): 210-214.

[6] 蒋仲安, 陈记合, 王明, 等. 卸矿站粉尘浓度影响因素的数值模拟研究[J]. 煤炭学报, 2018, 43(S1): 185-191.

JIANG Zhongan, CHEN Jihe, WANG Ming, et al. Numerical simulation study on influence factors of dust concentration in unloading station[J]. Journal of China Coal Society, 2018, 43(S1): 185-191.

[7] 聂文, 彭慧天, 晋虎, 等. 喷雾压力影响采煤机外喷雾喷嘴雾化特性变化规律[J]. 中国矿业大学学报, 2017, 46(1): 41-47.

NIE Wen, PENG Huitian, JIN Hu, et al. The effect of spray pressure on atomization characteristics of external spray nozzle on coal mining machine[J]. Journal of China University of Mining & Technology, 2017, 46(1): 41-47.

[8] 汲银凤, 陈举师, 张波, 等. 气水喷嘴雾化特性实验研究[J]. 中国安全生产科学技术, 2017, 13(12): 27-32.

JI Yinfeng, CHEN Jushi, ZHANG Bo, et al. Experimental research on atomization characteristics of air-water nozzle[J]. Journal of Safety Science and Technology, 2017, 13(12): 27-32.

[9] 孙中圣, 沈政, 李小宁. 气力式油雾器雾化性能影响因素试验研究[J]. 中南大学学报(自科学版), 2018, 49(3): 600-605.

SUN Zhonsheng, SHEN Zheng, LI Xiaoning. Experimental study on influence factors of atomization performance of air-blast lubricator[J]. Journal of Central South University(Science and Technology), 2018, 49(3): 600-605.

[10] 曹建明, 朱辉, 郭广祥, 等. 空气助力改善液滴雾化质量的研究[J]. 实验流体力学, 2013, 27(1): 56-60, 87.

CAO Jianming, ZHU Hui, GUO Guangxiang, et al. Study on air assistant to improve quality of droplet atomization[J]. Journal of Experiments in Fluid Mechanics, 2013, 27(1): 56-60, 87.

[11] ZAREMBA M, WEIβ L, MALY M, et al. Low-pressure twin-fluid atomization: effect of mixing process on spray formation[J]. International Journal of Multiphase Flow, 2017, 89: 277-289.

[12] 曹建明. 液体喷雾学[M]. 北京: 北京大学出版社, 2013, 179-184.

CAO Jianming. Liquid sprays[M]. Beijing: Peking University Press, 2013: 179-184.

[13] 章明川, 吕勇, 王峻晔, 等. Y型喷嘴内部气液两相流动及液膜雾化的数学模型[J]. 燃烧科学与技术, 2000, 6(3): 205-209.

ZHANG Mingchuan, LU Yong, WANG Junye, et al. Mathematical modeling on the gas-liquid two phase flowin the Y-jet nozzle and Its atomization process[J]. Journal of Combustion Science and Technology, 2000, 6(3): 205-209.

[14] MA Rui, DONG Bo, YU Zhongqiang, et al. An experimental study on the spray characteristics of the air-blast atomizer[J]. Applied Thermal Engineering, 2015, 88(12): 149-156.

[15] 王鹏飞, 谭烜昊, 刘荣华, 等. 供水压力对气水喷雾雾化特性及降尘效果的影响[J]. 应用基础与工程科学学报, 2018, 26(6): 1348-1359.

WANG Pengfei, Tan Xuanhao, LIU Ronghua, et al. Effect of water supply pressure on atomization characteristics of gas-water spray and dust-reducing effect[J]. Journal of Applied Basic and Engineering Science, 2018, 26(6): 1348-1359.

[16] 王鹏飞, 刘荣华, 王海桥, 等. 煤矿井下气水喷雾雾化特性实验研究[J]. 煤炭学报, 2017, 42(5): 1213-1220.

WANG Pengfei, LIU Ronghua, WANG Haiqiao, et al. Atomization characteristics of air-water spray in underground coal mine[J]. Journal of China Coal Society, 2017, 42(5): 1213-1220.

[17] 句海洋, 凌标灿, 彭驰, 等. 综掘工作面机载气水两相喷雾装置的应用[J]. 煤炭工程, 2015, 47(4): 131-133.

JU Haiyang, LING Biaocan, PENG Chi, et al. Application of water air two-phase spray device on coal shearer in fully mechanized tunneling working site[J]. Coal Engineering, 2015, 47(4): 131-133.

[18] 桂哲, 刘荣华, 王鹏飞, 等. 供水压强对气水喷雾雾化粒度的影响[J]. 矿业工程研究, 2016, 31(3): 21-25.

GUI Zhe, LIU Ronghua, WANG Pengfei, et al. Influence of water supply pressure over atomization article size by air-water spray[J]. Mineral Engineering Research, 2016, 31(3): 21-25.

[19] PROSTANSKI D. Use of air-and-water spraying systems for improving dust control in mines[J]. Journal of Sustainable Mining, 2013, 12(2): 29-34.

[20] 许满贵, 刘欣凯, 文新强. 煤矿综掘工作面高效喷雾降尘系统[J]. 湖南科技大学学报(自然科学版), 2015, 30(2): 1-7.

XU Mangui, LIU Xinkai, WEN Xinqiang. Full-mechanized excavation face efficient sprinkler & dust fall system[J]. Journal of Hunan University of Science & Technology(Natural Science Edition), 2015, 30(2): 1-7.

(编辑 杨幼平)

收稿日期: 2019 -05 -09; 修回日期: 2019 -06 -24

基金项目(Foundation item):国家自然科学基金资助项目(51874016)(Project(51874016) supported by the National Natural Science Foundation of China)

通信作者:王亚朋,博士研究生,从事通风和粉尘控制研究; E-mail: 18306422116@163.com