DOI: 10.11817/j.issn.1672-7207.2016.05.011

装载机转向液压系统的热平衡分析与比较

王剑鹏1,秦四成1,杨立光2,石有胜1

(1. 吉林大学 机械科学与工程学院,吉林 长春,130022;

2. 水利部长春机械研究所,吉林 长春,130012)

摘要:基于集中参数法建立装载机液压转向系统的传热仿真模型,并对高速跑车试验工况进行仿真分析。针对50型轮式装载机几种典型作业方式,对同轴流量放大转向系统和流量放大转向系统2种配置的装载机利用传热模型分别进行热平衡仿真计算,并计算2种转向液压系统的功率损失。研究结果表明:仿真与试验结果一致,证明模型准确可信。目前装载机热平衡工业性试验中普遍采用的I形铲装循环工况,并不是装载机液压系统最大热负荷工况。同轴流量放大转向液压系统装载机在T形作业中热平衡温度与环境温差最高为74.3 ℃;流量放大转向液压系统装载机在V形作业中热平衡温度与环境温差最高为62.64 ℃。

关键词:转向液压系统;传热;仿真;装载机

中图分类号:TH243 文献标志码:A 文章编号:1672-7207(2016)05-1527-06

Analysis and comparison for thermal balance of steering hydraulic system of loader

WANG Jianpeng1, QIN Sicheng1, YANG Liguang2, SHI Yousheng1

(1. College of Mechanical Science and Engineering, Jilin University, Changchun 130022, China;

2. Changchun Research Institute of Mechanical Engineering of Water Resources Ministry, Changchun 130012, China)

Abstract: Based on the lumped parameter method to establish simulation model of heat transfer in the loader full hydraulic steering system,high-speed car test conditions were simulated. For several typical mode of operation,the thermal balance simulation of two kinds of steering hydraulic system was done by using heat transfer model. The loss of two hydraulic steering systems was compared. The results show that the results validated the simulation model is accurately credible. At present, the I-shaped shovel loading cycle is widely used in the thermal balance industrial test of loader, which is not the maximum heat load condition of the hydraulic system of loader. The thermal balance temperature and the ambient temperature difference of the coaxial flow amplifying steering hydraulic system loader in the T-shaped operation is 74.3 ℃; the thermal balance temperature and the ambient temperature difference between the flow amplification and steering hydraulic system loader in the V-shaped operation is 62.64 ℃.

Key words: steering hydraulic system; heat transfer; simulation; loader

液压传动技术因其传递功率大、效率高、结构简单和使用方便等优点,广泛应用于工程机械等领域[1]。但液压系统工作时,由于存在摩擦、泄露等功率损失,会产生大量热量,使油温升高。油温过高不仅会导致油液的物理、化学性质改变,还会导致元器件和系统的可靠性、稳定性和寿命大大降低,功率损失增大,燃油消耗率增加[1]。装载机转向和工作装置均为液压传动,同样容易出现过热问题,特别是在夏季环境温度较高的情况下。在保证转向和工作性能前提下,减小液压系统的功率损失,降低液压系统油温是装载机液压系统的研究重点。目前,在国内装载机上,所应用的转向液压系统主要有2种形式,即同轴流量放大转向系统和流量放大转向系统[2]。转向系统作为装载机的重要组成部分,其性能决定着整机的作业效率和行驶安全性,因此对于转向系统的研究改进具有重要意义[3]。本文作者以装载机的2种转向液压系统为研究对象,分别介绍其工作原理并对各自的优缺点加以比较;利用集总参数法建立传热模型,与试验数据比较验证模型精度;针对某50型轮式装载机几种典型作业方式,利用传热模型,对2种转向液压系统配置的装载机分别进行热平衡仿真计算,根据仿真结果对系统和作业方式进行评价。

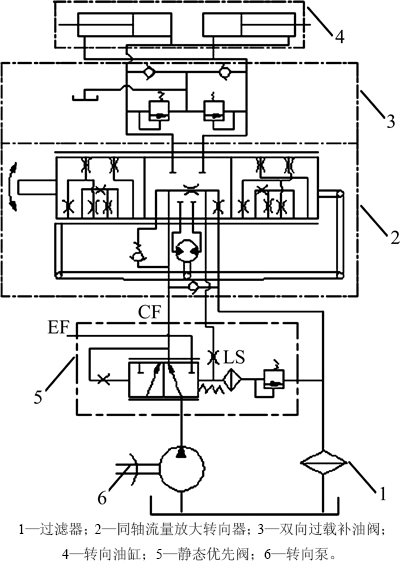

1 装载机转向液压系统

同轴流量放大液压转向系统主要由优先阀、同轴流量放大器、转向油缸等3部分组成, 其油路原理图如图1所示。本文研究的是TLF1型同轴流量放大转向器,该转向器是一种具有流量放大能力的静液压转向元件。同轴流量放大液压转向系统具有操纵省力、转向灵敏、平稳、总体布置方便和系统效率高等优点,在目前国内50型装载机上普遍采用。但该系统转向时压力损失较大,与普通的转向系统相比节能效果并不明显[4-5]。

图1 同轴流量放大转向液压系统原理图

Fig. 1 Schematics of coaxial flow amplification steering hydraulic system

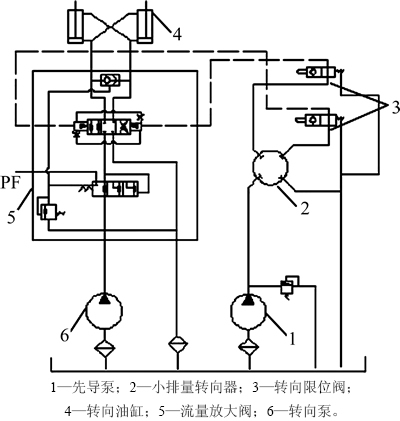

流量放大转向液压系统的油路原理图如图2所示,其组成主要包括转向器、转向油缸、流量放大阀等。该型系统的原理是采用小排量的转向器提供先导油源,控制流量放大阀阀芯的开度,实现用小流量控制大流量,用低压先导压力控制高压转向压力的系统。这种转向系统存在的主要缺点是装载机的转向阻力不能完全在转向盘上体现出来、转向特性不稳定,有转向滞后、转向发飘的现象[6]。

图2 流量放大转向液压系统原理图

Fig. 2 Schematics of flow amplification steering hydraulic system

2 装载机液压系统传热模型

2.1 传热理论

如果固体内部的导热热阻和其表面的换热热阻相比是很小的话,任何时刻固体中的温度在空间上是均匀的,可以认为整个固体在同一瞬间均处于同一温度下,这种忽略物体内部导热热阻的简化分析方法称为集中参数法[7]。利用集总参数法解决传热问题时,毕渥数Bi必须满足下列条件:

(1)

(1)

式中:V为固体体积;A为固体表面积;h为对流换热系数;k为导热系数。

当Bi≤0.1时,物体中最大与最小的过余温度之差小于5%,对于一般工程计算,精度已经足够精确。

基于集中参数模型,液压元件可以看作含有一定容积的液压容腔,将液压容腔内的油液作为流动节点,将容性元件的外壁作为传热表面节点。流动节点反映油液的热运动,传热表面节点描述传导、对流和辐射3种传热方式的热运动。应用集中参数模型建立液压系统RC网络传热模型。

2.2 液压元件和管路传热计算

装载机液压系统传热部件主要包括:液压泵、液压阀、液压油缸、液压管路、液压油箱和液压油散热器。由于液压元件的外壁一般为导热系数比较高的金属材料,而且厚度相对较小,可以忽略外壁的导热热阻。为计算方便,将装载机的液压油缸,简化为1个无杆腔节点和1个有杆腔节点。

将装载机液压系统分为18个流动节点和5个传热表面节点,每个节点内温度被假设为一致的。对于每个节点,根据能量守恒定律可以得到如下公式[8-13]:

(2)

(2)

式中:T为节点温度; 为环境温度;R为热阻;W为节点对外界做功量;m为质量;cv为比定容热容;下标i和j代表节点;下标t+1和t为当前和先前的时间步长;

为环境温度;R为热阻;W为节点对外界做功量;m为质量;cv为比定容热容;下标i和j代表节点;下标t+1和t为当前和先前的时间步长; 为时间步长。

为时间步长。

由于液压系统中液压油采用强制循环方式,所以液压油与管路的换热主要是强制对流换热。根据流动的性质, 可分别采用管内层流或湍流换热实验关联式进行计算。

管槽内层流采用Sieder-Tate关联式:

(3)

(3)

管槽内湍流应用Dittus-Boelter关联式:

(4)

(4)

式中:Nu为努塞尔数;Re为雷诺数;Pr为普朗特数,是动量扩散能力与热量扩散能力的一种量度;l为管路长度;d为管路直径; 为动力黏度;下标f和w分别表示流体的定性温度为流体平均温度和壁面温度。

为动力黏度;下标f和w分别表示流体的定性温度为流体平均温度和壁面温度。

液压元件和管路外侧强制对流关联式:

(5)

(5)

式中:C和n为常数,由实验数据确定;定性温度为 。

。

液压油散热器的传热采用传热单元数法,其传热量为

(6)

(6)

式中: 为散热器的效能;

为散热器的效能; 为散热器两侧冷、热流体中热容小的流体热容;t3和t4分别为热、冷流体的入口温度。

为散热器两侧冷、热流体中热容小的流体热容;t3和t4分别为热、冷流体的入口温度。

2.3 高速跑车试验工况

针对装载机生产厂家在产品工业性试验中普遍采用的高速跑车试验工况,对建立的装载机液压系统模型利用Matlab进行瞬态温度仿真,并将仿真结果与试验数据进行比较, 验证模型精度。模型中所需的压力和流量等参数均通过试验测量而得。

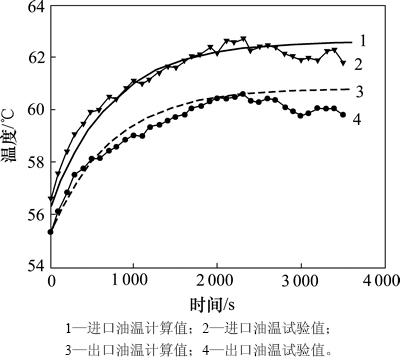

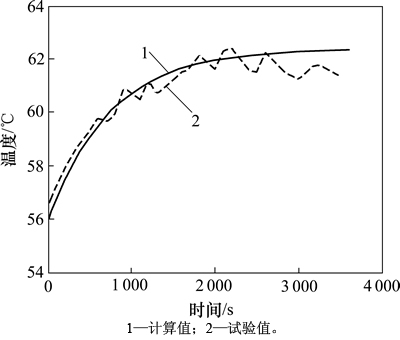

图3所示为液压油散热器进出口油温。由图3可见:液压油散热器油温计算值和试验值比较一致。在高速跑车试验工况中,环境温度为31.8 ℃,液压油散热器进口初始油温为56.4 ℃,出口初始油温为55.3 ℃,进出口油温差为1.1 ℃;散热器前端空气初始温度为40.0 ℃,散热器后端空气初始温度为48.5 ℃,前后端空气温差为8.5 ℃。跑车1 h后,计算和试验值都显示系统达到热平衡。此时液压油散热器进口油温为 62.5 ℃,出口油温为60.4 ℃,进出口油温差为2.1 ℃;散热器前端空气温度为40.6 ℃,散热器后端空气温度为52.8 ℃,前后端空气温差为12.2 ℃。

图3 液压油散热器进出口油温

Fig. 3 Oil temperature of import and export of hydraulic oil cooler

图4所示为油箱内液压油油温。由图4可见:液压油初始温度为56.0 ℃,液压油箱内油温在62.32 ℃时系统达到平衡,此后液压油箱内油温略有下降是由于环境温度下降。经仿真结果和试验结果比较,模型的准确度满足工程设计需要。

图4 油箱内液压油油温

Fig. 4 Oil temperature in hydraulic oil tank

3 多种作业方式转向液压系统热平衡仿真

3.1 转向液压系统热平衡仿真分析

装载机的作业方式主要有I形作业法、L形作业法、V形作业法和T形作业法。针对这4种作业方式,考虑转向液压系统功率损失情况,进行温度仿真计算,预测液压系统油温。

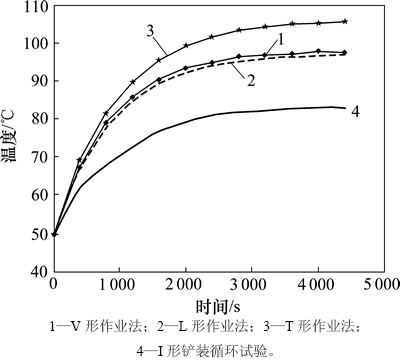

图5所示为同轴流量放大转向液压系统油箱内油温。由图5可见:I形铲装循环试验工况是主机厂家普遍采用的工业性试验工况,虽然在4种作业工况中,作业周期时间最短,但由于缺少转向动作,热平衡温度最低。V,L和T形3种作业工况的铲装作业时间与I形铲装循环试验工况相同;V和L形作业工况热平衡温度很接近;T形作业工况转向液压系统单独转向时间为最长,功率损失大,热平衡温度最高。

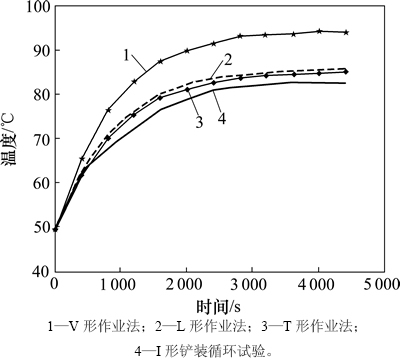

图6所示为流量放大转向液压系统油箱内油温。由图6可见:装载机转向液压系统在仿真时间约60 min后,系统生热功率等于散热功率,液压系统达到热平衡。配置流量放大转向液压系统装载机在3种工况下液压油箱内油温都没有超过100 ℃。由于V形作业方式1个工作循环时间最短,相同时间内完成的工作循环次数最多,相应功率损失大,热平衡温度最高。

图5 同轴流量放大转向液压系统油箱内油温

Fig. 5 Oil temperature within tank of coaxial flow amplifying steering hydraulic system

图6 流量放大转向液压系统油箱内油温

Fig. 6 Oil temperature within tank of flow amplifying steering hydraulic system

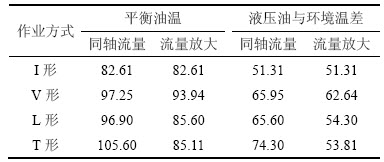

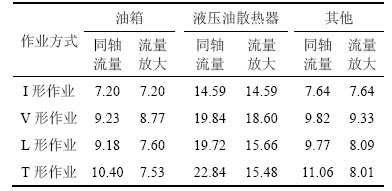

表1所示为各个作业方式液压系统热平衡时的油温。由表1可以看出:虽然配置同轴流量放大转向液压系统装载机在I形作业方式中液压系统热平衡温度没有超过85 ℃,满足液压油允许工作温度范围,但其他3种作业方式下系统平衡温度都超过90 ℃,T形作业方式甚至超过100 ℃,无法满足装载机正常工作要求。配置流量放大转向液压系统的装载机也存在相同的问题。

由于I形铲装循环试验工况不是2种装载机液压系统配置的最大热负荷工况,所以只依靠I形铲装循

表1 液压系统热平衡油温

Table 1 Oil temperature of heat balance of hydraulic system ℃

环热平衡试验结果设计液压油散热器散热功率,会造成液压系统散热能力过低,工作中油温过高,无法满足实际工作需要。针对不同配置液压系统,要采用不同作业方式的热平衡试验验证。

与同轴流量放大转向液压系统相比,流量放大转向液压系统油温升高幅度较小,最高平衡油温低 11.66 ℃,且发生在不同的作业方式下。

3.2 液压系统散热分析

装载机液压系统的散热主要依靠液压油散热器和油箱,以及其余液压元件和管路的散热[14-16]。环境温度31.3℃时,装载机在I形作业,V形作业、L形作业和T形作业工况中,液压系统处于热平衡状态时的散热功率,见表2。

表2 液压系统热平衡时散热功率

Table 2 Cooling power of heat balance of hydraulic system kW

3.3 转向液压系统功率损失分析

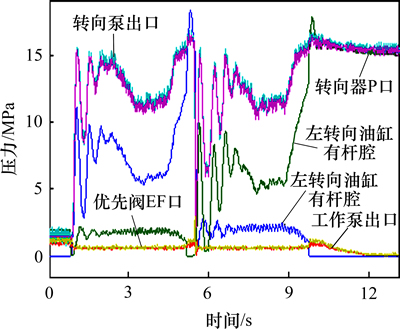

图7所示为同轴流量放大转向液压系统压力。由图7可见:装载机最大油门快速打方向盘从左极限位置到右极限位置再到左极限位置,转向泵出口与转向器P口(优先阀CF)的压力损失很小,而转向器P口到转向油缸内的压力损失很大保持在5 MPa左右。工作装置液压系统此时没有工作,工作系统压力很小,所以,经EF口合流到工作系统压力损失约为10 MPa,功率损失较大。

图7 同轴流量放大转向液压系统压力

Fig. 7 Coaxial flow amplifying steering hydraulic system pressure

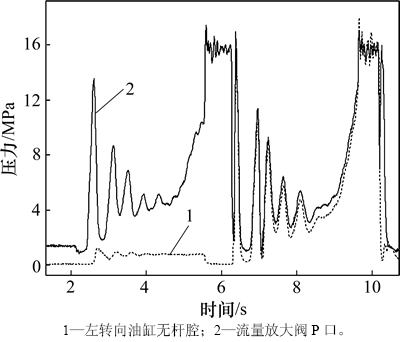

图8所示为流量放大转向液压系统压力。 由图8可见:装载机最大油门快速转向时冲右极限位置到左极限位置再到右极限位置转向时流量放大阀的压力损失不到1 MPa。

图8 流量放大转向液压系统压力

Fig. 8 Amplifying steering hydraulic system pressure

国内装载机液压泵基本都使用定量齿轮泵,液压泵通过皮带与发动机曲轴相连,当发动机的转速一定时,泵的流量基本不变。虽然采用双泵合流系统,减小一部分功率损失,但因系统不能根据负载的需要而调节流量输出,仍然导致系统的能量利用率较低。当发动机的转速提高时,泵的供油流量会随着转速的提高而增加,双泵合流液压系统中转向系统合流到工作系统中流量通过多路阀回流,从而造成较大的能量损失。特别是在发动机高速运转模式下慢速转向时,此时转向泵出口压力由转向负载决定,通过优先阀合流的压力油越多,溢流损失越大,温升越高。

对装载机转向液压系统进行功率损失计算,见表3,相比同轴流量放大转向液压系统,流量放大转向液压系统装载机单独转向动作中节能58.8%,复合动作节能15.3%。

表3 转向液压系统功率损失

Table 3 Power loss of steering hydraulic system kW

4 结论

1) 装载机工业性试验中普遍采用的I形铲装循环工况,由于工作中缺少转向动作,并不是装载机液压系统最大热负荷工况。

2) 同轴流量放大转向液压系统装载机在T形作业工况中,液压系统热平衡温度最高对这种配置的装载机要按照T形作业方式进行热平衡试验验证。流量放大转向液压系统装载机在V形作业工况中,液压系统热平衡温度最高,配置流量放大转向液压系统的装载机要按照V形作业方式进行热平衡试验验证。

参考文献:

[1] 秦四成. 国内装载机技术进步的思考[J]. 工程机械, 2010, 41(5): 48-50.

QIN Sicheng. Consideration on domestic loader technical progress[J]. Construction Machinery and Equipment, 2010, 41(5): 48-50.

[2] 郭庆新, 靳乔, 李清华. 装载机两种转向系统的比较[J]. 工程机械与维修, 2010(7): 168-169.

GUO Qingxin, JIN Qiao, LI Qinghua. The comparison of two kinds of steering system of loader[J]. Construction Machinery & Maintenance, 2010(7): 168-169.

[3] 王同建, 陈晋市, 赵锋, 等. 全液压转向系统机液联合仿真及试验[J]. 吉林大学学报(工学版), 2013, 43(3): 652-656.

WANG Tongjian, CHEN Jinshi, ZHAO Feng, et al. Mechanical- hydraulic co-simulation and experiment of full hydraulic steering systems[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43(3): 652-656.

[4] 金青. 同轴流量放大液压转向系统动态特性参数化建模与仿真研究[J]. 常州工学院学报, 2008, 21(2): 12-16.

JIN Qing. Parametric modeling and dynamic simulating for coaxial flow amplifier and hydraulic steering system[J]. Journal of Changzhou Institute of Technology, 2008, 21(2): 12-16.

[5] 李锦, 宋德朝, 刘金龙. TLF型同轴流量放大转向器的工作原理及故障排除[J]. 拖拉机与农用运输车, 2007, 34(1): 94-95.

LI Jin, SONG Dechao, LIU Jinlong. Operation principle for model TLF coaxial flow amplifying steering and its trouble removal[J]. Tractor & Farm Transporter, 2007, 34(1): 94-95.

[6] 王桂民. 50型装载机转向液压系统节能探讨[J]. 工程机械与维修, 2010(10): 168-170.

WANG Guimin. Energy saving in 50 type loader steering hydraulic system[J]. Construction Machinery & Maintenance, 2010(10): 168-170.

[7] 杨世铭, 陶文铨. 传热学[M]. 4版. 北京: 高等教育出版社, 2006: 162-171, 371-376.

YANG Shiming, TAO Wenquan. Heat transfer[M]. 4th ed. Beijing: Higher Education Press, 2006: 162-171, 371-376.

[8] Scott T C, Uphold J. Thermal modeling of power steering system performance[C]// SAE, 2009: 1039-1044.

[9] ANKUR KUMAR, JYESHTHARAJ B JOSHI, ARUN K NAYAK. A review on the thermal hydraulic characteristics of the air-cooled heat exchangers in forced convection[J]. Sadhana, 2015, 40(3): 673-755.

[10] Scott T C, Joshi D S. Engine cooling module sizing using combined 1-dimensional and CFD modeling tools[C]// SAE, 2009: 1079-1098.

[11] SHEN K, LI F, NI J. 1D/3D coupling calculation analysis on bus cooling system[J]. Energy & Power Engineering, 2014, 14(6): 550-556.

[12] PARK S H, ALAM K, JEONG Y M, et al. Modeling and simulation of hydraulic system for a wheel loader using AMESim[C]// ICROS-SICE International Joint Conference 2009. Fukuoka, Japan: Fukuoka International Congress Center, 2009: 2991-2996.

[13] Yang S Y, Kwon S K, Jin S M.Hydraulic simulation and remote control system of field robot[C]// Control, Automation, Robotics and Vision. Hanoi, Vietnam, 2008: 2303-2308.

[14] 王剑鹏, 秦四成. 装载机液压系统性能与能耗分析[J]. 建筑机械, 2014(5): 114-118.

WANG Jianpeng, QIN Sicheng. Research on performance and power loss of hydraulic system for wheel loader[J]. Construction Machinery, 2014(5): 114-118.

[15] 王剑鹏, 秦四成, 田中笑. 50型轮式装载机液压系统热平衡分析与验证[J]. 工程机械, 2008, 39(9): 54-57.

WANG Jianpeng, QIN Sicheng. TIAN Zhongxiao. Analysis and verification for heat balance of hydraulic system of a model 50 wheel loader[J]. Construction Machinery and Equipment, 2008, 39(9): 54-57.

[16] 王剑鹏, 秦四成, 杨立光, 等. 装载机液压系统的传热仿真分析[J]. 吉林大学学报(工学版), 2016, 46(1): 153-158.

WANG Jianpeng, QIN Sicheng, YANG Liguang, et al. The simulation analysis of heat transfer in hydraulic system of the loader[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(1): 153-158.

(编辑 杨幼平)

收稿日期:2015-05-20;修回日期:2015-07-26

基金项目(Foundation item):国家科技支撑计划项目(2013BAF07B04) (Project(2013BAF07B04) supported by the National Key Technology Support Program of China)

通信作者:秦四成,教授,博士生导师,从事工程车辆节能控制研究;E-mail: qsc925@hotmail.com