基于多Agent及多方法集成的复杂工艺优化模型

刘跃华,蒋伟进,李超良

(湖南商学院 计算机与电子工程学院,湖南 长沙,410205)

摘 要:针对复杂工艺中涉及多因子、高噪声、非线性过程关系和模糊对象问题,提出一种集成多种智能计算方法的优化模型。该模型以多Agent技术来组织,划分为决策支持层、系统重构层和数据集成层,Agent间以Ontology 来实现信息传递。在建模过程中,利用Chebyshev多项式的正交性质和递推性质,将过程输入变量正交化、线性化后,再应用偏最小二乘回归法计算模型参数,优化Agent在交互方式下通过变异的遗传算法来获取模糊工艺的最优解。以MOLDFLOW软件获取的注塑数据来训练BP(Back propagation)神经网络。结果表明:该优化系统的平均预测精度较BP神经网络提高3.23%。

关键词:多代理系统;偏最小二乘法回归;遗传算法;工艺优化

中图分类号:TP18 文献标识码:A 文章编号:1672-7207(2009)03-0767-07

Complex process optimal model based on multi-agent and multi-method integration

LIU Yue-hua, JIANG Wei-jin, LI Chao-liang

(Department of Computer and Electronic Engineering, Hunan Business College, Changsha 410205, China)

Abstract: In order to optimize the complex process involving multi-factor, high noise, non-linear relationship between the process of process and fuzzy objects, an intelligent optimal model which integrates a variety of calculating methods was proposed. The model based on multi-Agent technology was divided into layers, the system reconfiguration layer and data integration layer. The communication between the Agents of this model was realized by Ontology. In modeling, the model parameters were calculated by using Chebyshev polynomials orthogonal and partial least-squares regression method. In the interactive mode, the fuzzy optimal solution was calculated by the optimization Agent using the improved genetic algorithm. BP (Back propagation) neural network was trained by injection data obtained from MOLDFLOW software. The results show that the average prediction accuracy of this system increases by 3.23%, compared with that of BP neural network.

Key words: multi- Agent system (MAS); partial least squares regression; genetic algorithm; process optimization

人工智能技术与计算机技术的发展,使Agent技术成为解决复杂系统结构问题的重要方法,Agent技术[1]以协同科学为指导、人工智能理论为基础,具有交互能力,相互间可以并行协作,协同使用资源,共同完成决策任务;可以对已有的Agent进行封装、定制、继承,将原有的代码集成到新系统中,实现系统重构,可以拥有本地知识,并赋予一定的学习能力,从而可以逐步完善整个系统的性能;具有自主性,对分布式应用提供强有力的支持,系统的稳定能得到增强,不会造成“单点故障”现象。MAS技术在智能诊断[2]、工作流管理[3]等方面得到广泛应用。蒋伟进 等[2, 4-5]对地震信号检测、冶金、化工、水泥等生产工艺过程进行了分析,发现其工艺过程机理复杂,主要表现在:生产过程存在许多不确定因素,同时,还存在许多客观误差;同一生产产品有多个性能指标要求;工艺涉及的工序较多,每道工序所涉及的参数(温度、时间、电流、电压波型、化学成分等)多。显然,针对这样复杂的工艺过程,很难用精确的数学表达式来描述生产过程,常需采用多种优化方法的集成才能取得好的预测和控制效果,为此,吴敏等[6]针对多工况焦炉加热过程的特点提出了火道温度模糊控制的机制;贺湘宇等[7]采用偏最小二乘回归算法对挖掘机液压系统进行故障诊断;柳桂国等[8]用基于Chebyshev最佳逼近的偏正交分解的方法提取工业轴承的震动信号特征,以便对轴承的故障现象进行判断。但工业生产过程优化的对象是多因子、高噪声、非线性、非高斯分布和非均匀分布的数据集,要对这样复杂的工业过程给出精确的优化数据是很困难的。在此,本文作者以多智能体Agent将多种优化算法集成,建立一个能对复杂工业进行优化的决策模型,模型的预测结果能给用户提供合理的决策数据。

1 模型的过程划分与功能描述

1.1 系统的组织结构

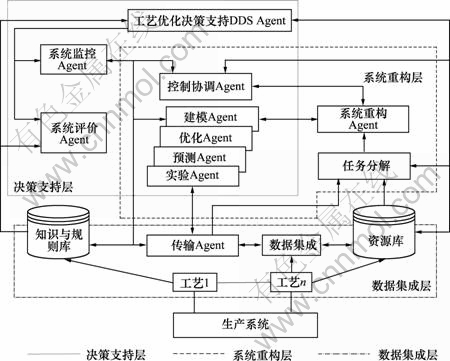

图1所示为基于MAS的复杂工业优化决策模型的组织构架,该系统从功能和角色上划分为3个层次:决策支持层、系统重构层和数据集成层。决策支持层是系统的指挥和监管中心,其主要任务是:系统全局参数的定义,决策规则的制定与修正,以往工艺数据的综合与分析,新工艺的学习与积累,各子系统的监管与协调,对决策系统优化效果进行总结和评估,与用户进行决策信息的交互等。系统重构层是本决策模型的核心部分,也是具体优化任务的执行层,其主要任务是:将决策支持层交给的任务进行分解后分配到相应的Agent子系统中执行,对生产工艺的算法建模,优化工艺配方,根据实验和预测结果重构工艺模型等。数据集成层是系统的数据组织、储存的部分。本系统采用可扩展标记语言(XML)对生产工艺中数据进行集成和封装,其内容主要是:XML良好的可扩展性;数据内容与形式的分离;遵循严格的语法要求,具有可校验性;可以包括语法描述,便于不同系统之间、不同数据库之间信息的交互。优化决策系统通过图2中的消息传输系统和接口Agent实现与用户的信息交互。

1.2 系统中各主要Agent的功能

a. 接口Agent,或称用户界面Agent。代替用户发出过程启动请求,代替用户自动处理消息或等待用户处理,并将处理过程存入知识库中,为用户提供工艺处理的建议。

图1 系统的层次结构

Fig.1 Layer structure of system

图2 系统与用户的接口

Fig.2 Interface of system with user

b. 任务分解Agent。多Agent接收到任务后,首先将该任务分解成为多个子任务,并将这些子任务分别分配给系统中的执行单元Agent去执行,接收到任务的这些执行单元Agent在协调控制Agent的管理下相互协作,共享资源系统,完成各自任务。当所有任务完成后,协调Agent将这些子任务的结果进行集成,形成整个任务的结果。任务的分解有赖于“启发式算法”和知识库中以往的经验。

c. 传输Agent(消息传递系统)。将接收系统监控、系统协调、实验Agent或用户接口等Agent传来的数据,经转换后传送给动态建模等Agent中;同时,也负责将动态建模Agent等预测信息传递给实验Agent和接口Agent。消息的定义包括消息的类型、消息发送者、消息的接受者、消息的内容等。本系统中的消息原语有请求、应答、通告等类型。

d. 系统评价Agent。保存决策Agent作出的决策方案,利用一定的评价准则对各个方案进行评估,以检测该决策方案是否能够取得预期的结果。最后,将决策方案和评估结果发送给用户。

e. 系统监控Agent。对系统整体运行状况进行监控和必要日志,将监控结果及时传递给协调控制Agent,便于协调资源访问冲突,及时处理异常情况。

f. 协调控制Agent。监视系统的行为和状态;为公共信息访问提供交互服务;将任务分解后的各子任务分配到相应的执行单元中,并协调其执行过程;整理、分析和存储系统中的信息,为决策提供丰富的信息资源;为整个决策建立完整的全局参数。

g. 建模及重构Agent。因为在实际生产过程中,过程变量之间往往存在大量相关关系,甚至非线性相关关系。当过程变量间存在线性相关时,可采用偏最小二乘法(PLS)[9]计算模型参数。但由于PLS方法采用线性关系来联系输入和输出因子,因而,并不能有效地应用于非线性较强的过程。在这种情况下,要有效地对变量维数降阶,需要采用非线性PLS方法。本文作者采用基于Chebyshev多项式改进的多元多项式非线性回归PLS方法来建模,其思想是:利用Chebyshev多项式的正交性质和递推性质,将过程输入变量正交化、线性化,应用PLS方法计算模型参数并还原,从而得到比较精确的模型。在进行动态建模过程中,Agent会将模型的适用范围、性能参数、模型表达式等信息通过接口Agent通告用户,Agent能识别用户的指示,建立全局和局部模型,也可以根据已有的实验数据自定义建模。当实验数据变化时,在与用户交互下和重构Agent的协作下自动修改已有 模型。

h. 优化Agent。蒋伟进等[5]对基于序列二次规划和遗传算法求解最优配方进行了探讨。然而,许多复杂工业系统中存在各种模糊非线性生产计划和调度问题。在生产工艺过程中特别是新工业流程中,只能给出其模糊目标和资源约束条件,达到符合一定满意度的目标。本文采用沿加权梯度方向进行变异的遗传算法[10],寻求最优解所在的邻域,该邻域就是模糊环境下的最优解。当然,若能给出明确的目标、约束函数和满意度为100%,则该方法的求解就是精确解。显然,本文提出的优化模型适用范围更大,能给用户提供更合理的决策依据。

1.3 Agent之间的通信

Agent之间的通信可以通过Ontology[11](本体)智能来实现。Ontology借助一定的规范方式来显性地表示领域中的概念、概念的属性、概念之间的关系以及相应的约束和推理原则。创建Ontology的目标就是提供一种机器可以处理的语义描述机制,使得知识语义能够在不同的智能代理(软件和人)之间传递和交流。

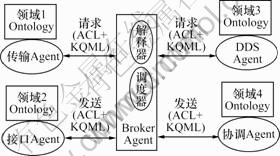

Agent遵循ACL(Agent communications language)通信协议,使用基于知识的查询与操作语言KQML来实现信息交互。KQML 提供了一个Agent交换信息和知识的架构,其核心是一套可扩展的表述行为集,其中包含了希望接收方执行的一些动作,它为Agent定义了一些允许其访问彼此知识库和目标库的操作,以请求、应答、通告等原语传递信息,这些行为构成了Agent之间相互通信的基础。其通信机制如图3所示。

图3 Agent之间的通信流程

Fig.3 Communication flow of agent between agent

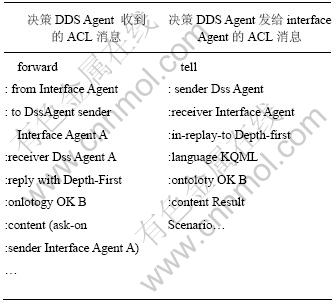

Agent常代表系统中的不同角色,拥有单独的Ontology[3],这样,Agent 间就很难有效地相互通信。对于一个多Agent系统,使用公共的Ontology,每个Agent就能共享公共Ontology。Broker Agent(中介Agent)可以促使多Agent共享知识和信息,它的作用与Agent间的匹配器作用类似,提供一个公共的Ontology来解释Agent 的上下文,并且传送这些内容给其他Agent。中介Agent由2个组件构成:解释器和调度器。当中介Agent接收到一个请求时,它的调度器就会发送这个请求给解释器,根据转换规则,如本体间的匹配,解释器将该请求转换成目标Agent可以理解的形式发送过去,这样,就实现了多Agent 间的信息交换。表1所示为用Java JATLite编程实现本系统中决策Agent与接口Agent之间的通信信息。

表1 Agent之间的通信信息

Table 1 Communication messages of Agents

2 建模与优化Agent中的技术

2.1 基于Chebyshev的非线性PLS建模

根据Chebyshev与最佳逼近理论[8, 12-13],原始信号 在插值点的逼近函数Ln(x)表示为:

在插值点的逼近函数Ln(x)表示为:

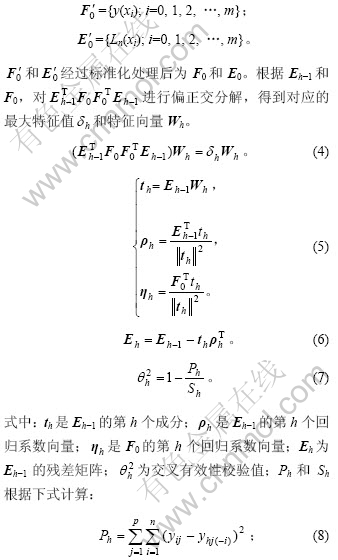

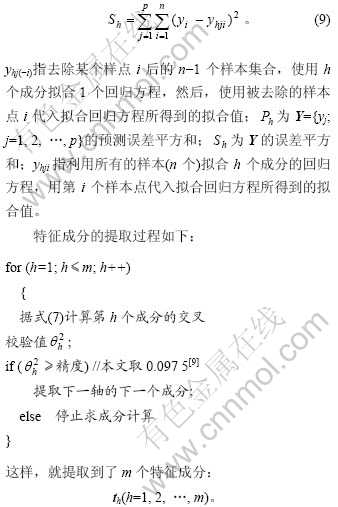

步骤1 对Chebyshev多项式进行偏正交分解提取原始信号y(x)的特征成分[8]。设:

步骤2 对线性化后的式子进行PLS建模。

设取得m个成分th(h=1, 2, …, m),则关于δh(h=1, 2, …, m)的模型为:

步骤3 获取模型参数,并还原成多元多项 式[6, 10, 13]。

2.2 最优求解

遗传算法是当今影响最广泛的进化算法之一,因其具有较强的随机搜索和智能计算能力而被广泛应用于工程优化过程中。针对本文研究的对象是复杂工业过程的问题求解,采用文献[14]中基于遗传算法的模糊非线性规划,以交互式方法来求解优化工业配方。其思想是:首先,要求决策者给出模糊最优解可接受的隶属度(满意度);其次,通过人机接口将描述目标和资源约束的隶属度显示在计算机上,以帮助决策者选择隶属度类型;引导决策者给出其偏好的(模糊的)优化目标和约束条件,通过沿加权梯度方向变异的遗传算法找到模糊最优解。其优化步骤如下[10]。

步骤1 初始化。输入可以接受的满意度 ,最大遗传代数max_gen和种群规模pop_size;输入决策者考虑的判据集CI={0, 1, 2, …, n, n+1, …, n+m, n+m+1}。其中:0代表目标函数;j=1, 2, …, n,代表决策变量;j=n+1, n+2, …, n+m,代表约束;j=n+m+1,代表加权满意度之和。给出判据

,最大遗传代数max_gen和种群规模pop_size;输入决策者考虑的判据集CI={0, 1, 2, …, n, n+1, …, n+m, n+m+1}。其中:0代表目标函数;j=1, 2, …, n,代表决策变量;j=n+1, n+2, …, n+m,代表约束;j=n+m+1,代表加权满意度之和。给出判据 的初值和初始上下界;输入描述模糊目标模糊约束的隶属度函数类型。

的初值和初始上下界;输入描述模糊目标模糊约束的隶属度函数类型。

步骤2 通过 随机产生初始种群,并计算其隶属度

随机产生初始种群,并计算其隶属度 。其中:

。其中: U(0, 1);i=1, 2, …, n; j=1, 2, …, pop_size;

U(0, 1);i=1, 2, …, n; j=1, 2, …, pop_size; 是变量x第i个元素的上界。

是变量x第i个元素的上界。

Set k=1

do while k≤max_gen

{

步骤3 对于个体j (j=1, 2, …, pop_size),计算其适应值和被选择概率。

步骤4 用父代xi,通过下式产生新的个体xj:

。 (12)

。 (12)

其中:βk为用随机数发生器产生的具有下降均值的Erlang分布随机步长;D(x)为 的加权梯度方 向[11]。

的加权梯度方 向[11]。

步骤5 对于个体j,计算其隶属度函数 ,更新最优隶属度

,更新最优隶属度 和判据r 的上下界。

和判据r 的上下界。

k=k+1

}

步骤6 输出最优隶属度 和决策者满意的判据上下界,终止算法。

和决策者满意的判据上下界,终止算法。

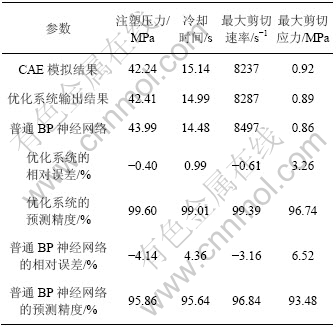

3 仿真检验

注塑工艺涉及温度、压力、剪切应力、剪切速率、注塑时间等众多因素,因此,在注塑成型开发与设计阶段,人们广泛使用CAE(Computer aided engineering)软件MOLDFLOW来试模[15],以取得理想的工艺参数。本文采用Moldflow MPI6.1 进行注塑模拟,获得120组合格的样本数据,将其中110组用于训练神经网络,剩余的10组用来对训练好的网络进行验证。优化系统的初始输入参数选择遗传算子种群规模pop_size为100,最大进化遗传代数max_gen为200,满意度为0.95。表2所示为本优化系统预测结果、普通BP神经网络与CAE试模结果的对比,其中,模具温度为40.92 ℃,熔体温度为269 ℃,注塑时间为 1.44 s。

表2 优化系统输出结果与其他模型的对比

Table 2 Comparison of optimizing system output results with other models

从本系统优化结果、普通BP神经网络的预测结果与CAE试模结果的对比可以看到,本系统对4个输出项的预测精度分别为99.60%,99.01%,99.39%和96.74%,其平均精度为98.68%;而普通BP神经网络对4个输出项的预测精度分别为95.86%,95.64%,96.84%和93.48%,其平均精度为95.45%。本优化系统的平均预测精度比普通神经网络BP提高3.23% 。通过使用不同的输入参数值进行多次优化和CAE模拟验证,误差都比较小,说明本系统优化结果比神经网络预测结果具有更高预测精度。

4 结 论

a. 在控制因素多、工艺复杂的工业生产中,用单一的工艺配方优化方法无法得到很好的效果,用多Agent集成多种智能计算技术来对复杂工艺的优化进行决策,能提高计算速度、预测精度和可靠性,给用户提供合理的决策依据。

b. 在许多复杂工业系统中,存在各种模糊非线性生产计划和调度问题,在生产工艺过程中特别是在新工业流程中,只能给出一个模糊目标和资源约束条件,达到符合一定满意度的目标。优化Agent采用沿加权梯度方向进行变异的遗传算法,用交互方式寻求模糊环境下的最优解,因此,模型的适应性好。

c. 采用。域enton MOU Hai-wen.l04; 28(5), 本工艺优化模型与采用普通BP神经网络相比,所得预测精度提高3.23%。

参考文献:

[1] 丁士拥. 网络坦克作战系统基于MAS的决策过程分析与研究[J]. 计算机工程与设计, 2008, 29(21): 5526-5530.

DING Shi-yong. Analysis and research for decision support proceeding of networking-tank operation system[J]. Computer Engineering and Design, 2008, 29(21): 5526-5530.

[2] 蒋伟进. 基于MAS的分布式智能诊断方法与应用研究[J]. 控制理论与应用, 2004, 28(5): 82-88.

JIANG Wei-jin. Research on diagnosis model distributed intelligence and key technique based on MAS[J]. Control Theory and Applications, 2004, 28(5): 82-88.

[3] 刘 菲, 侯海文. 基于Multi-agent的轻量级工作流系统[J]. 计算机工程, 2007, 33(20): 72-74.

LIU Fei, HOU Hai-wen. Lightweight workflow system based on multi-agent technology[J]. Computer Engineering, 2007, 33(20): 72-74.

[4] 刘跃华, 曾迎生. 信号处理中去噪算法的改进仿真[J]. 计算机工程与应用, 2009, 45(4): 149-151.

LIU Yue-hua, ZENG Ying-sheng. Simulation of improved denoising algorithm in signal processing[J]. Computer Engineering and Application, 2009, 45(4): 149-151.

[5] 蒋伟进, 许宇胜. 基于多方法集成的复杂工艺优化设计研究[J]. 计算机集成制造系统, 2006, 12(4): 533-539.

JIANG Wei-jin, XU Yu-sheng. Research on optimal design of complex process based on multi-method integration[J]. Computer Integrated Manufacturing Systems, 2006, 12(4): 533-539.

[6] 吴 敏, 雷 琪, 曹卫华. 基于多工况分析的焦炉加热过程火道温度模糊控制[J]. 中南大学学报: 自然科学版, 2008, 39(1): 155-161.

WU Min, LEI Qi, CAO Wei-hua. Flue temperature fuzzy control for coke oven heating process based on multi-operative modes analysis[J]. Journal of Central South University: Science and Technology, 2008, 39(1): 155-161.

[7] 贺湘宇, 何清华, 谢习华, 等. 基于偏最小二乘回归的挖掘机液压系统故障诊断[J]. 中南大学学报: 自然科学版, 2007, 38(6): 1152-1156.

HE Xiang-yu, HE Qing-hua, XIE Xi-hua, et al. Fault diagnosis of excavator hydraulic system based on partial least squares regression[J]. Journal of Central South University: Science and Technology, 2008, 39(1): 155-161.

[8] 柳桂国, 楼望建, 黄 道. 基于Chebyshev最佳逼近的偏正交分解特征提取方法[J]. 仪器仪表学报, 2008, 29(6): 1275-1279.

LIU Gui-guo, LOU Wang-jian, HUANG Dao. Feature extraction based on best uniform approximation of Chebyshev polynomial with nonlinear partial orthogonal decomposition[J]. Chinese Journal of Scientific Instrument, 2008, 29(6): 1275-1279.

[9] 王惠文. 偏最小二乘回归方法及其应用[M]. 北京: 国防工业出版社, 1999.

WANG Hui-wen. Partial least squares regression linear and nonlinear method[M]. Beijing: Defense Industry Press, 1999.

[10] Gen M, CHENG Run-wei. Genetic algorithms and engineering optimization[M]. USA: John Wiley & Sons Inc, 2000.

[11] Gruber T R. A translation approach to portable ontologies[J]. Knowledge Acquisition, 1993, 5(2): 199-220.

[12] 韩汉鹏. 偏最小二乘法在回归设计多因变量建模中的应用及其优化[J]. 数理统计与管理, 2007, 27(2): 303-207.

HAN Han-peng. Application of partial least-squares regression on multi-dependent variable model analysis of quadratic regression design and its optimal solution[J]. Application of Statistics and Management, 2007, 27(2): 303-307.

[13] 吴 琼, 原忠虎, 王晓宁. 基于偏最小二乘回归分析综述[J]. 沈阳大学学报, 2007, 19(2): 34-36.

WU Qiong, YUAN Zhong-hu, WANG Xiao-ning. Summary of partial least squares regression[J]. Journal of Shenyang University, 2007, 19(2): 34-36.

[14] Tang J, Wang D. An interactive approach based on a GA for a type of quadratic programming problem with fuzzy objective and resources[J]. Computer and Operations Research, 1997, 24(1): 413-422.

[15] 赖 鹏, 彭响方, 陈已明. Moldflow冷却分析在注塑模中的应用[J]. 塑料工业, 2007, 35(6): 891-897.

LAI Peng, PENG Xiang-fang, CHEN Yi-ming. Application of Moldflow in injection moulding[J]. China Plastics Industry, 2007, 35(6): 891-897.

收稿日期:2008-08-10;修回日期:2008-11-15

基金项目:湖南省自然科学基金重点资助项目(06JJ2033)

通信作者:刘跃华(1965-),男,湖南涟源人,副教授,从事智能信息系统与工作流的研究;电话:15802552882;E-mail: liuyyying@sina.com