3Cr2Mo钢CCT曲线的测定与分析

李红英,王法云,曾翠婷,李阳华,曹俊

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:在Gleeble-1500热模拟机上测定3Cr2Mo钢以不同冷却速度连续冷却时的膨胀曲线,结合金相-硬度法、示差热分析法(DSC)获得该钢的连续冷却转变曲线(CCT曲线)。根据测得的CCT曲线,分析以不同冷却速度连续冷却时的组织转变;阐明冷却速度与组织的演变以及硬度变化的关系。比较分析所测CCT曲线与同类转变曲线的异同。研究结果表明:马氏体转变的临界冷却速度为1.0~1.5 ℃/S;为生产实践和新工艺的制定提供了参考依据。

关键词:3Cr2Mo钢;CCT曲线;热模拟;DSC

中图分类号:TG151.2;TG151.3 文献标志码:A 文章编号:1672-7207(2011)07-1928-06

Determination and analysis of CCT curves of 3Cr2Mo steel

LI Hong-ying, WANG Fa-yun, ZENG Cui-ting, LI Yang-hua, CAO Jun

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The different dilatometric curves of continuous cooling transformation were determined by Gleeble-1500 thermal mechanical simulation. By dilatometric change and DSC analysis referencing microscopic test and hardness measurement, the continuous cooling transformation (CCT) diagram was obtained. According to the CCT diagram obtained above, the transformation of austenite at different cooling rates were analyzed, and the relationship between the cooling rates and the variation of microstructure and hardness was disclosed. At last the similar transition curve was investigated. The results show that martensite transition critical cooling velocity is 1.0-1.5 ℃/s. All those provide the references for productive practice and establishing new technic.

Key words: 3Cr2Mo steel; CCT curve; thermal mechanical simulation; DSC

钢的连续冷却转变曲线(CCT曲线)能够系统反映冷却速度对相转变开始点、相变进行程度和相变所得组织的影响规律,是合理制定热处理工艺的重要依据,也是研究固态相变理论的重要基础[1]。3Cr2Mo钢是国内较早开发的塑料模具钢,综合力学性能好,淬透性好,且具有很好的抛光性能,目前已得到了广泛的应用[2-4]。使用3Cr2Mo钢,一般先进行预硬化处理,即进行淬火-高温回火处理[5-6],要控制淬火组织就要参考其相变动力学曲线。但由于CCT曲线的测定比较困难,目前资料中多是有关TTT图的测定与研究[7-8],而实测的CCT曲线数量少且精度不高,此外,由于测试钢种的成分、测量条件(试样的原始状态、奥氏体化温度、保温时间、冷却条件等)不同,测得的CCT曲线与厂方3Cr2Mo 钢轧材的实际生产偏离较大。为此,本文作者选择接近3Cr2Mo 钢实际生产的测量条件测定其连续冷却转变曲线(CCT曲线),并观测了不同冷却速度的3Cr2Mo钢的转变产物和硬度。

1 实验方法

试验用钢为热轧态的3Cr2Mo 钢板,板厚80 mm,从钢板上截取试样后加工成直径×高度为6 mm×10 mm和4 mm×8 mm 2种规格的试样,测水淬膨胀曲线采用4 mm×8 mm的试样,其他冷却速度的膨胀曲线采用6 mm×10 mm试样。

采用膨胀法并结合金相-硬度法[8]以及DSC热分析法来确定实验钢的相变温度。利用DSC热分析法确定其临界转变温度Ac1和Ac3以及低速冷却对应的相变温度(≤0.5 ℃/s)。以0.83 ℃/s的升温速率将试样升到880 ℃,保温10 min,然后分别以0.05,0.10,0.30,0.50 ℃/s的冷却速度降至室温,升温过程中测得Ac1和Ac3,在降温过程中确定不同冷速对应的相变点,通过较慢(0.05 ℃/s)的冷却曲线确定相变温度Ar1和Ar3。利用Gleeble-1500热模拟机测定膨胀曲线,在2 min内将试样加热至880 ℃,保温10 min,分别以10种不同的冷却速度(0.7~45.0 ℃/s) 冷却试样,获得膨胀曲线,再由膨胀曲线确定相变温度。

金相样品用常规的机械研磨及抛光方法制备,采用4%的硝酸酒精溶液浸蚀,在POLYVAR-MET金相显微镜进行组织观察。每个试样测出4~6个点的洛氏硬度(HRC),取其平均值。

2 实验结果

2.1 3Cr2Mo钢的临界点

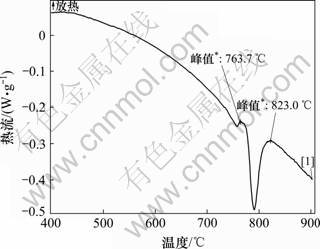

3Cr2Mo钢的DSC曲线如图1所示。可见:由DSC法测得实验钢升温时的临界点Ac1为 763.7 ℃,Ac3为823 ℃。由膨胀法测得降温时的马氏体转变开始点Ms为330 ℃,马氏体转变结束点Mf为180 ℃。

2.2 金相组织和硬度

通过膨胀曲线和DSC降温曲线可以分析奥氏体转变产物的类型和数量,但是,当转变量较少时,曲线上不能显现明显的相变点,测量的准确度受到影响。金相法作为其补充和必要的校准手段,可以提高测量的准确度,如果转变产物不易鉴别出来,就需要辅以硬度法来确定转变产物。

图1 3Cr2Mo钢DSC曲线

Fig.1 DSC curve of 3Cr2Mo steel

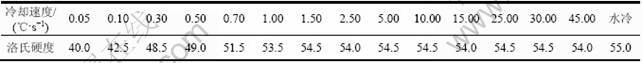

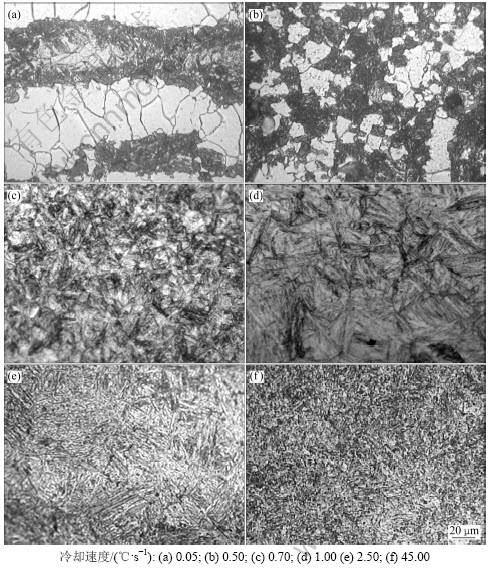

图2所示为部分冷却速度对应的金相组织照片。表1所示为以不同冷却速度冷却到室温的洛氏硬度(HRC)。

2.3 CCT曲线绘制

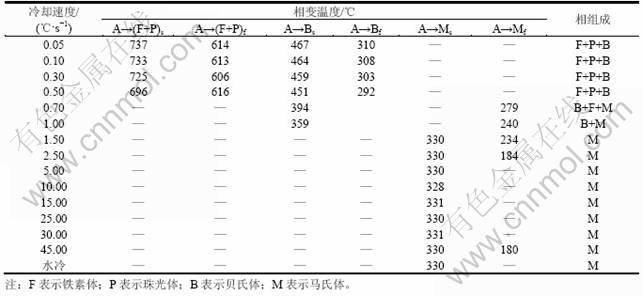

结合金相组织和洛氏硬度,根据降温膨胀曲线以及DSC曲线(低冷速)上的切点或极点可确定出不同冷速下对应的过冷奥氏体相变温度[9-10],如表2所示。

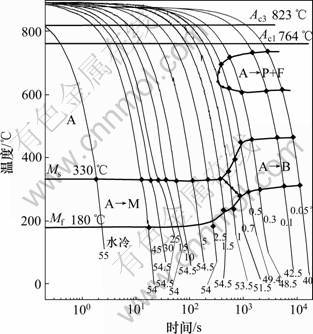

将表2所示的相变点绘制到温度-时间半对数坐标上,用连线法将物理意义相同的点连接起来,同时标出Ac1,Ac3和Ms,即可得到相应的CCT曲线,如图3所示,图中冷却曲线旁的数字为冷却速度,冷却曲线下端的数字为以此速度冷却至室温的洛氏硬度(HRC)。

由图3可知,当3Cr2Mo钢以不同速度连续冷却时,过冷奥氏体会析出铁素体和发生珠光体转变(A→F+P)、贝氏体转变(A→B)以及马氏体转变(A→M)。随着冷却速度的增大,铁素体的析出量、珠光体的转变量和贝氏体的转变量减少,而马氏体的转变量则越来越多,当冷却速度达到一定值时,转变产物全部为马氏体组织。

表1 不同冷却速度对应的洛氏硬度(HRC)

Table 1 Hardness of specimens at different cooling velocities

图2 3Cr2Mo钢连续冷却转变后的金相组织

Fig.2 Microstructure of 3Cr2Mo steel after continuous cooling transformation

表2 不同冷却速度对应的相变温度

Table 2 Transformation points of steel at different cooling velocities

图3 3Cr2Mo钢过冷奥氏体连续冷却转变曲线(CCT曲线)

Fig.3 Continuous cooling transformation curve of 3Cr2Mo steel (CCT diagram)

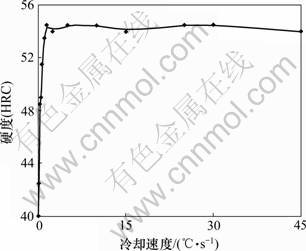

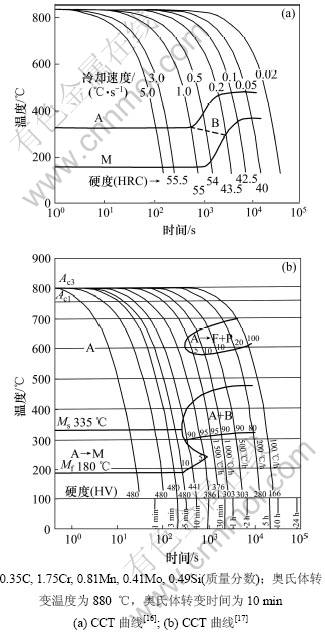

表3 3Cr2Mo钢成分

Table 3 Chemical composition of 3Cr2Mo steel

3 分析与讨论

3.1 不同冷却速度对应的组织和硬度分析

由图2所示的不同冷速对应的室温金相组织可以看出,3Cr2Mo钢过冷奥氏体连续冷却时可获得各种不同的组织,如铁素体、珠光体、贝氏体、马氏体[11-12];当冷却速度小于0.7 ℃/s时,转变产物为细片状珠光体、羽毛状贝氏体以及块状铁素体的混合物,随着冷却速度增大,贝氏体的含量增加,铁素体的含量降低,块状尺寸相应减小;当冷却速度为0.7 ℃/s时,转变产物以贝氏体为主,只含有少量颗粒状的铁素体和少量的针状马氏体;当冷却速度为1 ℃/s时,转变产物为贝氏体和少量针状马氏体;当冷却速度达到和超过1.5 ℃/s时,转变产物为马氏体。

先共析铁素体的析出与碳在奥氏体中的扩散密切相关,3Cr2Mo钢的Cr和Mo等主要合金元素能提高碳在奥氏体中的扩散激活能,降低碳的扩散速度,推迟奥氏体的扩散分解过程,所以,只有冷却速度比较慢(0.05~0.70 ℃/s)时才有先共析铁素体生成,因而提高3Cr2Mo钢的淬透性[13]。随着冷却速度增加,一方面,新旧相自由能差增大,临界晶核形核功降低,促进了铁素体形核率的增大;另一方面,温度迅速降低,原子活动能力减小,先共析铁素体的长大受扩散控制,使其在转变产物中所占比例逐渐减少;当冷速达到某一临界值时(3Cr2Mo钢大约为1 ℃/s),形成的铁素体晶核不能长大,先共析铁素体的析出完全受到抑制。

过冷奥氏体的冷却远离平衡态,易出现贫碳区和富碳区的涨落,加上随机出现的结构涨落和能量涨落,在贫碳区建构铁素体,而在富碳区建构渗碳体或碳化物,二者共析共生,互为因果,任何一相都可能领先,而结果都是形成珠光体的晶核。3Cr2Mo钢在较低速度冷却时,在高温区生成细片状珠光体。珠光体是共析铁素体和共析碳化物有机结合的整合组织。在过冷奥氏体的连续冷却过程中,随着温度的降低,碳的扩散速度减慢,碳原子难以进行较大距离的迁移,珠光体片间距越来越小,共析愈来愈困难;当温度降低到Bs点时,共析将不能进行,贝氏体优先在晶界单独析出;当温度继续降低时,铁原子和碳原子都不能发生扩散,只能通过切变发生晶格改组,发生马氏体转变。随着冷却速度的增大,过冷奥氏体极大远离平衡态,当达到Ms点时,在奥氏体晶粒内的位错或层错处,发生结构涨落和能量涨落,并通过位错或层错的运动,迅速放大这种涨落,发生马氏体转变[14-15]。

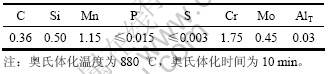

图4所示为根据表1所绘制的硬度与冷却速度变化的关系曲线。由图4可以看出:当冷却速度小于1.5 ℃/s时,曲线斜率较大,说明硬度随着冷却速度增大显著提高;当冷速为0.05 ℃/s时,对应洛氏硬度为40.0;当冷速为1 ℃/s时,对应的洛氏硬度为53.5;当冷却速度大于1.5 ℃/s时,曲线趋于水平,硬度趋于稳定,洛氏硬度为54.5左右。由组织分析可知,3Cr2Mo钢过冷奥氏体冷却过程可能出现铁素体、珠光体、贝氏体、马氏体等转变产物,当冷却速度由0.05 ℃/s增加到0.7 ℃/s时,对应转变产物的铁素体含量逐渐降低,贝氏体含量逐渐增加,硬度呈直线上升;在0.7~1.5 ℃/s的冷却速度范围内,主要生成贝氏体组织;随着冷速的增大,马氏体含量增加,硬度相应增大;当冷却速度达到和超过1.5 ℃/s时,其转变产物为马氏体组织,硬度不会出现大幅度的变化,曲线趋于水平。

3.2 临界冷却速度的确定

由显微组织和硬度测试结果及图3所示的CCT曲线可以看出:对应0.7 ℃/s的冷却速度,3Cr2Mo钢不存在先共析铁素体转变,只有贝氏体转变。但从图2(c) 可以看出存在极少量的颗粒状铁素体,因生成量极少,膨胀曲线没有体现过冷奥氏体发生铁素体转变的情况;当冷速达到1.0 ℃/s时,根据膨胀曲线和显微组织,可以判定已不存在铁素体转变,只发生贝氏体转变。因此,判断3Cr2Mo钢贝氏体转变的临界冷却速度为0.7~1.0 ℃/s。当冷速为1.0 ℃/s时,转变产物为贝氏体和马氏体的混合组织;当冷速为1.5 ℃/s时,没有发现贝氏体,只有马氏体,因此,判断3Cr2Mo钢马氏体转变的临界冷却速度为1.0~1.5 ℃/s。

图4 3Cr2Mo钢硬度随冷速变化的关系曲线

Fig.4 Relationship between HRC and cooling velocity of 3Cr2Mo Steel after continuous cooling transformation

3.3 测得的CCT曲线与文献报道的CCT曲线比较

图5所示为文献[16-17]中P20钢的CCT曲线。与本文测得3Cr2Mo钢的CCT曲线比较,可见:图5(a)没有铁素体和珠光体转变区,较粗略;图5(b)中的转变区域基本相同,均有铁素体和珠光体析出区、贝氏体转变区和马氏体转变区,但本文所测曲线偏右,这是因为所用试样的化学成分和奥氏体化工艺存在一定的差别。奥氏体成分越均匀,奥氏体就越稳定,新相形核和长大过程所需要的时间就越长,过冷奥氏体连续冷却转变曲线就越往右移。图5(b)所示的CCT曲线奥氏体温度和保温时间分别为850 ℃和5 min,而本实验的奥氏体温度为880 ℃、保温时间为10 min,得到更为稳定的过冷奥氏体以及较粗大的奥氏体晶粒,从而延缓奥氏体的分解,因此,测得的曲线较图5(b)所示的曲线偏右,但更接近厂方现场生产的实际情况。含碳量对过冷奥氏体连续冷却转变曲线的影响很大,亚共析钢铁素体-珠光体转变部分随奥氏体中含碳量的增加逐渐右移,随奥氏体中含碳量的增加,Ms点及Mf点降低。图5(b)中的C含量为0.35%,本实验3Cr2Mo钢的C含量为0.36%,因此,含碳量较高也是所测曲线偏右的原因之一。

图5 P20钢的CCT曲线

Fig.5 CCT diagrams of P20 steel

4 结论

(1) 采用膨胀法并结合金相-硬度法以及DSC热分析法测得了3Cr2Mo钢的CCT曲线,为制定热处理工艺提供了重要依据。

(2) 当冷却速度小于0.7 ℃/s时,转变产物为珠光体、贝氏体以及块状的铁素体组织;当冷却速度为0.7℃/s时,转变产物为贝氏体、颗粒状铁素体以及少量的针状马氏体;当冷却速度为0.7~1.5 ℃/s时,主要为羽毛状的贝氏体组织以及少量的针状马氏体组织;当冷速达到和超过1.5 ℃/s时,转变产物为马氏体。

(3) 实验钢贝氏体转变的临界冷却速度为0.7~1.0 ℃/s,马氏体转变的临界速度为1.0~1.5 ℃/s。

参考文献:

[1] 张世中. 钢的过冷奥氏体转变曲线图集[M]. 北京: 冶金工业出版社, 1993: 18-20.

ZHANG Shi-zhong. The steel atlas of super-cooling austenitic transition curve[M]. Beijing: Metallurgical Industry Press, 1993: 18-20.

[2] 肖文军, 徐春晖, 周天瑞. 我国塑料模具钢的发展前景及应用现况[J]. 南方金属, 2006(4): 2-4.

XIAO Wen-jun, XU Chun-hui, ZHOU Tian-rui. Development and application of plastic die steels in China[J]. Southern Metals, 2006(4): 2-4.

[3] 倪亚辉, 丁义超. 常用塑料模具钢的发展现状及应用[J]. 塑料工业, 2008(9): 5-8.

NI Ya-hui, DING Yi-chao. Development and application of common used Steels for plastic mould[J]. China Plastics Industry, 2008(9): 5-8.

[4] Song D L, Gu J F, Zhang W M, et al. Numerical simulation on temperature and microstructure during quenching process for large-sized AISI P20 steel blocks used as plastic die[J]. Transactions of Materials and Heat Treatment, 2004, 25(5): 740-745.

[5] Gehricke B, Schryff I. Trends in plastic mould steel applications[C]//Proceedings of the 5th International Conference on Tooling. Austria: Montanuniversitat Leoben, 1999: 83-90.

[6] Sera T, Unino M. Development of new free-cutting plastic mould steel[C]//Proceedings of the 5th International Conference on Tooling, Austria: Montanuniversitat Leoben, 1999: 653-660.

[7] 宋冬利, 顾剑锋, 胡明娟. 预硬型塑料模具钢P20和718等温转变曲线的测定与分析[J]. 金属热处理, 2003, 28(12): 27-29.

SONG Dong-li, GU Jian-feng, HU Ming-juan. Measurement and analysis of TTT Diagrams of pre-hardened plastic die steels P20 and 718[J]. Metal Heat Treatment, 2003, 28(12): 27-29.

[8] 杨胜蓉. YB/T 5128-93钢的连续冷却转变曲线图的测定方法(膨胀法)[M]. 北京: 中国标准出版社, 1993: 1-9.

YANG Sheng-rong. Continuous cooling transformation curve method of YB/T 5128-93 steel (Expansion text)[M]. Beijing: China Standard Press, 1993: 1-9.

[9] 李红英, 耿进峰, 龚美涛, 等. 65Mn钢奥氏体连续冷却转变曲线(CCT图)[J]. 材料科学与工艺, 2005, 13(3): 302-304.

LI Hong-ying, GENG Jing-feng, GONG Mei-tao, et al. Continuous cooling transformation curve of undercooling austenite about 65 Mn (CCT)[J]. Material Science and Technology, 2005, 13(3): 302-304.

[10] 李红英, 丁常伟, 张希旺, 等. 16MnR钢奥氏体连续冷却转变曲线(CCT图)[J]. 材料科学与工程学报, 2007, 25(5): 727-730.

LI Hong-ying, DING Chang-wei, ZHANG Xi-wang, et al. Continuous cooling transformation curve of under cooling austenite about 16MnR steel (CCT)[J]. Journal of Materials Science and Engineering, 2007, 25(5): 727-730.

[11] 任颂赞, 张静江, 陈质如, 等. 钢铁金相图谱[M]. 上海: 上海科学技术文献出版社, 2003: 1-38.

REN Song-zan, ZHANG Jing-jiang, CHEN Zhi-ru, et al. Iron metallographic graph[M]. Shanghai: Shanghai Science and Technology Publishing House, 2003: 1-38.

[12] Krielaart G P, Zwaag S V. Simulations of proeutectoid ferrite formation using a mixed control growth model[J]. Materials Science and Engineering A, 1998, 246(1/2): 104-116.

[13] 李毅, 王宁, 高秀华, 等. 27CrMo27S钢奥氏体连续冷却转变曲线[J]. 热加工工艺, 2006, 35(16): 51-52.

LI Yi, WANG Ning, GAO Xiu-hua, et al. Austenite continuous cooling transformation curve of 27CrMo27S steel[J]. Hot-working Process, 2006, 35(16): 51-52.

[14] 刘宗昌. 钢中相变的自组织[J]. 金属热处理, 2003, 28(2): 13-18.

LIU Zong-chang. Self-organization in the phase transformation of steel[J]. Metal Heat Treatment, 2003, 28(2): 13-18.

[15] 徐祖跃. 马氏体相变与马氏体[M]. 北京: 科学出版社, 1980: 1-45.

XU Zu-yue. Martensite transformation and Martensite[M]. Beijing: Science Press, 1980: 1-45.

[16] 陈千. 预硬化P20塑料模具试制[J]. 特钢技术, 2001(1): 72-74.

CHEN Qian. Trial product of pre-hardening P20 plastic steel[J]. Special Steel Technology, 2001(1): 72-74.

[17] 于健. P20塑料模具钢组织和性能的研究[D]. 包头: 包头钢铁学院材料加工工程系, 2003: 10.

YU Jian. Research on the organization and performance of P20 plastic steel[D]. Baotou: Baotou Steel Institute. Department of Materials Processing Engineering, 2003: 10.

(编辑 赵俊)

收稿日期:2010-08-10;修回日期:2010-10-16

基金项目:湖南省科技重大专项(2008FJ1003)

通信作者:李红英(1963-),女,湖南湘乡人,教授,博士生导师,从事材料强韧化研究;电话:0731-88836328;E-mail: lhying@csu.edu.cn