DOI: 10.11817/j.ysxb.1004.0609.2020-39523

热加工工艺对挤压态FGH4096合金临界晶粒长大的影响

刘松浩,司家勇,陈 龙

(中南林业科技大学 机电工程学院,长沙 410004)

摘 要:基于挤压态FGH4096合金双圆锥台试样热压缩变形及过固溶热处理试验,结合DEFORM有限元软件数值模拟,确定试样中各等效应变范围内临界晶粒长大分布规律,研究热加工工艺对挤压态FGH4096合金临界晶粒长大的影响。结果表明:在温度980~1060 ℃、应变速率0.003~0.03 s-1条件下,双圆锥台试样热变形后再经过固溶热处理,合金临界晶粒长大的窗口条件从低温低应变速率向高温高应变速率转变,其中(980 ℃、0.03 s-1)、(1060 ℃、0.003 s-1)条件下可以避免出现临界晶粒长大,并获得均匀晶粒组织。当变形温度为980 ℃时,随着应变速率的增加,异常晶粒长大程度减小,且合金临界晶粒长大位置的临界等效应变数值降低;当应变速率为0.03 s-1时,随着变形温度的升高,异常晶粒长大程度增大,且试样发生临界晶粒长大的等效应变区域扩大。

关键词:FGH4096合金;挤压态;热压缩;过固溶热处理;临界晶粒长大

文章编号:1004-0609(2020)-06-1317-12 中图分类号:TG156 文献标志码:A

FGH4096粉末高温合金作为航空发动机涡轮盘件关键材料,其主要制备工艺路线是热等静压+等温锻造+热处理;但随着国内对挤压技术的完善,其制备工艺逐渐转变为热挤压+等温锻造+热处理[1-2],能够有效地消除热等静压态中原始颗粒边界,并充分细化晶粒,使合金组织更加细小均匀[3-4]。FGH4096合金涡轮盘件经等温锻造后的热处理制度通常采用高于强化相γ′溶解温度的过固溶热处理,得到30~50 μm的均匀晶粒组织;但若工艺控制不当,合金在热处理过程中在临界应变或临界应变速率区域出现200~500 μm的异常晶粒,称为临界晶粒长大现象[5-8]。这些异常晶粒的存在严重影响涡轮盘件的耐久性和可靠性。国内外学者对合金异常晶粒形成机制进行了大量研究:有些学者[9-11]研究了晶界的碳化物及γ′相对异常晶粒长大的阻碍作用;有些学者[12-14]探究了在不同应变速率和应变条件下产生的位错结构与异常晶粒长大的关系;有些学者[15-17]关注于晶界形态及晶界能对异常晶粒长大的影响。杨杰等[18]对热等静压态FGH96合金异常晶粒长大与变形工艺参数进行了研究,表明当变形速率与变形温度相匹配时,在小应变区域可以避免出现异常晶粒组织。目前,关于FGH4096合金异常晶粒长大的研究主要集中在热等静压态或室温压缩变形[18-20],并未明确表明粉末高温合金异常晶粒长大与临界应变量或临界应变速率之间的对应关系,而对挤压态FGH4096合金临界晶粒长大的研究更是鲜见报道。

本文开展了挤压态FGH4096合金临界晶粒长大的研究工作,利用DEFORM有限元软件对双圆锥台试样进行压缩数值模拟并优化,结合试样在变形温度980~1060 ℃、应变速率0.003~0.03 s-1热变形后经过固溶热处理的微观组织分析,探讨了变形温度、应变速率对试样不同等效应变范围内临界晶粒长大分布规律的影响,研究了挤压态FGH4096合金双圆锥台试样发生临界晶粒长大的窗口条件,为实际生产获得理想组织和优异性能的粉末高温合金涡轮盘件提供理论参考和依据。

1 实验

1.1 试验材料

试验材料为FGH4096粉末高温合金挤压棒材,化学成分见表1。其制备流程如下:在真空炉中采用感应加热的方法将母合金进行熔炼,采用氩气雾化法制粉工艺获得所需的粉末颗粒,将所得的粉末颗粒经过真空脱气后密封在不锈钢容器中并封焊,将容器放置在1110 ℃、150 MPa的环境下进行4 h包覆热等静压,最终将热等静压后的坯料按挤压比12:1热挤压成棒材。为了保证挤压态FGH4096合金热压缩变形前试样组织的均匀性,在挤压棒材横截面1/2半径位置机加工出双圆锥台试样。

表1 挤压态FGH4096合金化学成分

Table 1 Chemical composition of extruded FGH4096 alloy (mass fraction, %)

1.2 试验方法

利用MTS力学试验机对双圆锥台试样在变形温度980、1020和1060 ℃,应变速率0.003、0.01和0.03 s-1条件下进行高温压缩实验,压下量为15%。将压缩后的双圆锥台试样沿压缩方向电火花线切割分成8等份,对每份不同变形条件下的试样进行温度为1150℃的过固溶热处理,保温1 h后,快速水冷以保留高温组织。将压缩变形及过固溶热处理后的试样进行磨制、抛光后,采用Kallings腐蚀液(5 g CuCl2+100 mL C2H5OH+100 mL HCl)进行腐蚀,使用Leica光学显微镜和Oxford XMAX20扫描电镜对不同热加工工艺条件下的试样微观组织进行观察,并利用Image Pro Plus图像分析软件对试样各区域平均晶粒尺寸进行分析,所用方法为截线法。

为了确定双圆锥台试样热压缩变形后的等效应变分布,引入挤压态FGH4096合金的双曲正弦函数本构模型和相应材料参数[21-23],将其输入DEFORM有限元软件,对不同尺寸双圆锥台试样进行压缩数值模拟,确定最佳双圆锥台试样尺寸。对所选双圆锥台试样压缩数值模拟得到试样截面等效应变分布,结合不同热加工工艺下的微观组织进行分析,获得不同等效应变下合金临界晶粒长大的分布规律。

2 结果与分析

2.1 DEFORM数值模拟分析

2.1.1 双圆锥台试样几何设计

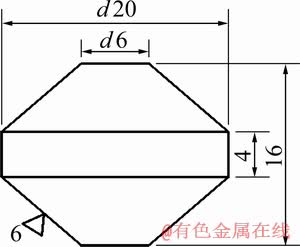

双圆锥台形试样能快速地获取同一变形温度、应变速率,不同等效应变下微观组织演化特征及临界晶粒长大区域等信息[24-26]。为设计适合本研究所用的挤压态FGH4096合金双圆锥台试样几何尺寸,本文采用L25(45)正交试验法选择具有代表性的组次进行热压缩数值模拟试验,能够有效减少试验次数。双圆锥台试样关键几何尺寸有:总高度H,直壁高度h,外圆直径D,水平端面直径d,如图1所示。每个关键尺寸因子对应5种水平,共设有25组正交热压缩数值模拟方案,分别见表2和表3。

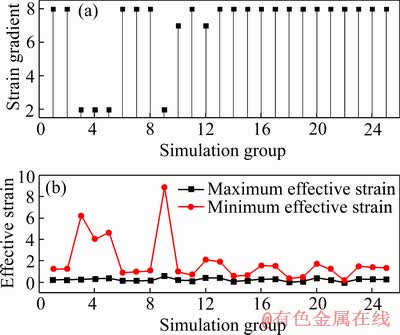

在有限元数值模拟中,为了兼顾模拟的计算效率和精度,本文考虑双圆锥台为轴对称回转体,选取双圆锥台试样模型为实际模型的1/4,锻造上模具和下模具为全尺寸。将建立的三维几何模型导入DEFORM中进行前处理设置,上下模具均视为刚体,双圆锥台试样为弹塑性物体。双圆锥台试样模型网格采用绝对划分法,其最小元素尺寸为0.2 mm,尺寸比率为2。各模拟组的双圆锥台试样在变形温度1060 ℃、应变速率0.01 s-1条件下的压缩数值模拟后,试样纵截面中心至外缘的等效应变如图2所示,获得各模拟组的等效应变梯度数和等效应变范围如图3所示。由图2和3可见,当双圆锥台试样几何尺寸为3、4、5、9、10和12模拟组进行压缩数值模拟时,试样纵截面中心至外缘的等效应变梯度数小于8,试样纵截面中心至外缘的等效应变之间分布范围广,无法确定双圆锥台试样压缩数值模拟后其纵截面中心至外缘等效应变分布具体数值。为了与实际热压缩变形后的试样相对照,以便区分异常晶粒所在等效应变范围,因此,对数值模拟组中的双圆锥台试样几何尺寸进行筛选,排除等效应变量呈阶梯递减不均匀试样。综合考虑模拟组中试样纵截面中心至外缘的等效应变梯度数为8时,第13组效果最佳,获得最大的等效应变范围0.406~1.91,确定双圆锥台试样几何尺寸如图4所示。总高度为16 mm,直壁高度为4 mm,外圆直径为20 mm,水平端面直径为6 mm。

图1 双圆锥台试样尺寸示意图

Fig. 1 Schematic diagram of size of double-cone sample

表2 双圆锥台试样关键几何尺寸

Table 2 Key geometric sizes of double-cone samples

表3 双圆锥台试样有限元数值模拟实验方案

Table 3 Finite element numerical simulation experiment scheme of double-cone samples

图2 双圆锥台试样等效应变分布

Fig. 2 Effective strain distribution of double-cone samples

图3 双圆锥台试样等效应变梯度数及等效应变值变化

Fig. 3 Variation of effective strain gradient and effective strain value of double-cone samples

图4 双圆锥台试样尺寸

Fig. 4 Size of double-cone samples (Unit: mm)

2.1.2 双圆锥台试样载荷分析

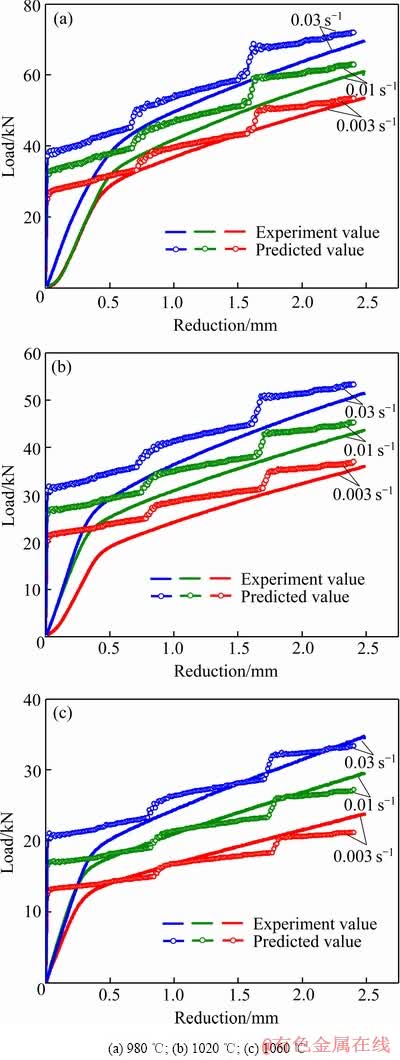

为了全面考虑挤压态FGH4096合金临界晶粒长大可能出现的等效应变量范围,本文对双圆锥台试样进行总变形量为15%的热压缩变形,获取合金临界晶粒长大窗口条件。利用DEFORM软件对双圆锥台试样在变形温度980~1060 ℃、应变速率0.003~0.03 s-1的热压缩过程进行数值模拟,其热压缩数值模拟的载荷与实验中实际载荷进行比较,如图5所示。从图5中可见,挤压态FGH4096合金在热压缩变形初始阶段,实际载荷随着应变的增加而快速攀升;但随着变形的继续,载荷逐渐趋于平稳地增加,且该合金在热压缩变形时,在恒定变形温度条件下,载荷随着应变速率的升高而增大;在恒定应变速率条件下,载荷随着变形温度的升高而减小。双圆锥试样热压缩数值模拟仿真与实验得出的载荷相近,其相对平均误差为7.32%。排除实验所带来的测试误差,本文中双圆锥台试样数值模拟的载荷与试验所测的载荷曲线吻合较好,能够较好地描述挤压态FGH4096合金热变形过程中的载荷变化情况,为后续工作中双圆锥台试样在不同变形条件下压缩数值模拟,以获得的试样截面等效应变分布与实验中实际等效应变对比提供了理论基础。

图5 不同温度下双圆锥台试样热压缩数值模拟与实际载荷比较

Fig. 5 Comparison of numerical simulation of actual compression and actual load of double-cone specimens at different temperatures

2.2 过固溶热处理后临界晶粒长大现象

图6 双圆锥台试样等效应变等高线分布及宏观组织(980 ℃,0.003 s-1)

Fig. 6 Effective strain contour distribution and macroscopic structure of double-cone samples (980 ℃, 0.003 s-1)

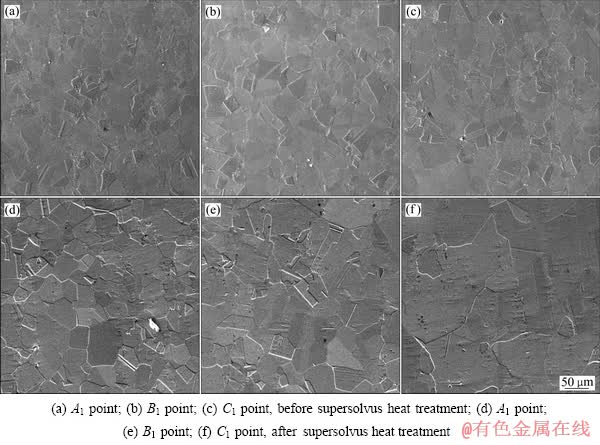

图7 双圆锥台试样过固溶热处理前后不同等效应变处的SEM像(980 ℃,0.003 s-1)

Fig. 7 SEM images of different effective strains regions of double-cone samples before and after solution heat treatment (980 ℃, 0.003 s-1)

双圆锥台试样在变形温度980 ℃、应变速率0.003 s-1条件下进行热压缩,其模拟的等效应变等高线分布及过固溶热处理前后试样宏观组织如图6所示。最大等效应变变形区域出现于上下两端面外缘与外圆锥面的交界处,并呈弧形向试样中心部位扩展;由于双圆锥台试样在压缩过程中两端面与压头之间存在摩擦,导致试样两端面中心出现难变形区,该区域的等效应变与试样最外缘的等效应变近似。对双圆锥台试样过固溶热处理前大等效应变0.81~0.86区域内的A1处、中等效应变0.15~0.21区域内的B1处和小等效应变0.004~0.045区域内的C1处微观组织进行观察,结果如图7(a)~(c)所示。由于双圆锥台试样热压缩变形后A1处到C1处的等效应变是梯度降低,大等效应变区域内的A1处微观组织动态再结晶较多,晶粒组织较均匀,平均晶粒尺寸为24 μm。随着等效应变量的减小,晶粒尺寸缓慢地增大,中等效应变B1处平均晶粒尺寸为29 μm,在小等效应变C1处平均晶粒尺寸为33 μm。结果表明:挤压态FGH4096合金在变形温度980 ℃、应变速率0.003 s-1条件下热压缩变形后,其锻态组织均未出现异常晶粒长大。

将热压缩变形后的双圆锥台试样进行温度为1150 ℃、保温时间为1 h的过固溶热处理,双圆锥台试样在不同等效应变区域内的A1、B1、C1三个位置处微观组织如图7(d)~(f)所示。在最大等效应变A处晶粒组织较均匀,平均晶粒尺寸为44 μm,且从最大应变量到出现异常晶粒的临界等效应变量之前,随着等效应变量的减小,晶粒尺寸缓慢的增大;中等效应变B处平均晶粒尺寸为48 μm,而在小等效应变0.004~0.045范围内的C1处出现临界晶粒长大,平均晶粒尺寸为170 μm。图8所示为在1150 ℃保温1 h后的试样C1位置异常晶粒处的微观组织。图8(a)和(b)所示分别为其不同放大倍数的SEM像。可见在异常晶粒内部存在未完全融合的台阶状晶界和细小晶粒,这表明异常晶粒是由大晶粒吞并小晶粒形成;图8(c)所示为其金相组织,可见异常晶粒的晶界较为清晰,而被吞并的小晶粒未完全融合的晶界不明显。可以发现,未热处理试样的微观组织晶粒细小均匀,呈圆形或方形,晶界清晰;而在1150 ℃热处理试样出现晶粒长大的区域,晶粒的大小不均匀,形状不规则,晶界不易分辨,存在未完全融合的小晶粒和晶界。

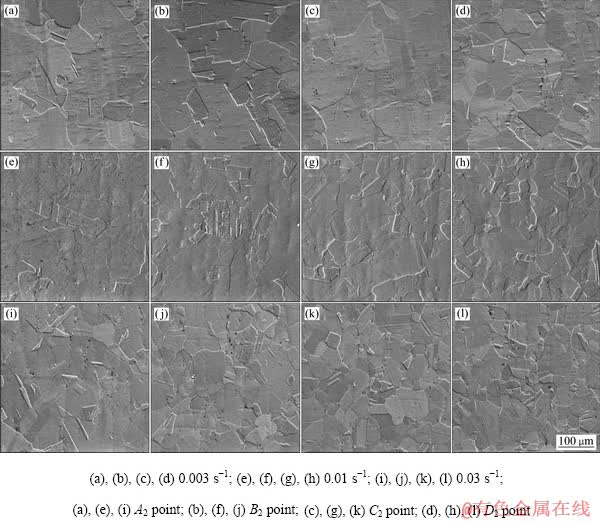

在变形温度980~1060 ℃、应变速率0.003~0.03 s-1热压缩变形后,双圆锥台试样经过固溶热处理,其局部等效应变线分布如图9所示。对试样局部等效应变0.004~0.045区域内的A2、B2、C2和D2四个位置处晶粒组织进行观察与统计,不同热变形条件下试样经过固溶热处理合金临界晶粒长大区域的分布规律见表4(表中Y表示有临界晶粒长大,N表示无临界晶粒长大)。从表4可以明显观察到挤压态FGH4096合金临界晶粒及正常晶粒分布的等效应变范围。图10所示为双圆锥台试样在四个不同等效应变区域的平均晶粒尺寸。结合表4分析,合金临界晶粒长大现象从低温低应变速率条件向高温高应变速率条件转变,其中试样在(980 ℃、0.03 s-1)、(1060 ℃、0.003 s-1)条件下热压缩变形后经过固溶热处理,局部等效应变区域合金晶粒尺寸随等效应变量的减小而缓慢地增大,但晶粒组织分布均匀,均未出现异常晶粒长大。

图8 异常晶粒的微观组织

Fig. 8 Microstructures of abnormal grains

图9 双圆锥台试样局部等效应变等高线分布

Fig. 9 Local effective strain contour distribution of double-cone specimens

表4 双圆锥试样临界晶粒长大区域的分布规律

Table 4 Distribution of CGG zone in double-cone sample

图10 双圆锥台试样不同等效应变区域的平均晶粒尺寸

Fig. 10 Average grain size of different effective strain regions of double-cone specimen

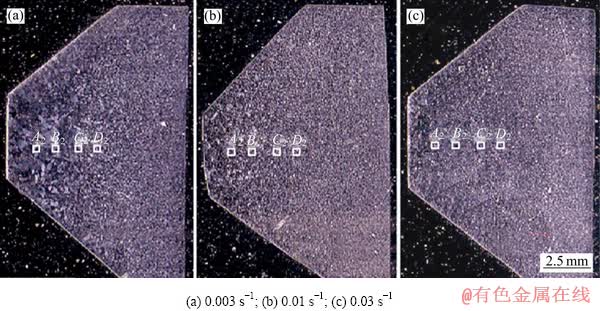

2.3 应变速率对临界晶粒长大的影响

为了考察应变速率对合金临界晶粒长大范围及异常晶粒长大程度的影响,双圆锥台试样在变形温度980 ℃,应变速率0.003 s-1、0.01 s-1和0.03 s-1热压缩变形后经过固溶热处理,其宏观组织如图11所示。图12所示为双圆锥台试样在等效应变0.004~0.045区域内的A2、B2、C2和D2四个不同等效应变范围内的微观组织。其中,B2位置与C1为同一位置,图8所示的压缩温度980 ℃、应变速率0.003 s-1条件下C1处的异常长大晶粒与图12(b)相对应。试样出现的临界晶粒长大等效应变分布范围及该范围内的平均晶粒尺寸进行定量分析,当应变速率为0.003 s-1时,微观组织中临界晶粒长大等效应变范围0.004~0.037,平均晶粒尺寸达202 μm;当应变速率为0.01 s-1时,临界晶粒长大等效应变范围0.004~0.029,平均晶粒尺寸达175 μm;当应变速率为0.03 s-1时,等效应变0.004~0.045区域内的晶粒尺寸差异不明显,平均晶粒尺寸为69 μm。从各应变速率的微观组织可以发现,合金临界晶粒长大的等效应变量和应变速率相关,随着应变速率的增加,双圆锥台试样发生临界晶粒长大位置的临界等效应变数值逐渐降低,临界晶粒长大区域的等效应变范围逐渐缩小。结合图10发现,当应变速率为0.003 s-1,双圆锥台试样在A2、B2和C2处发现明显的异常晶粒长大,A2处比D2处的平均晶粒尺寸大148 μm。当应变速率为0.03 s-1,双圆锥台试样在A2、B2、C2和D2处晶粒组织分布均匀。当变形温度为980 ℃时,随着应变速率的增加,异常晶粒长大程度减小。

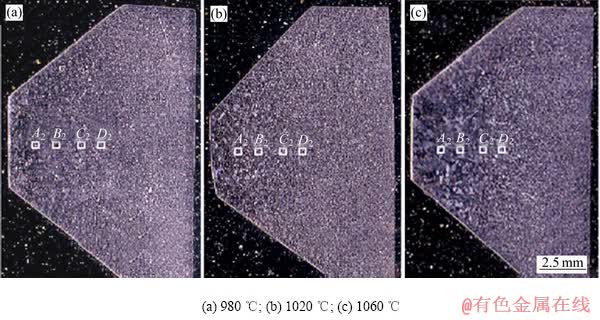

2.4 热变形温度对临界晶粒长大的影响

图13所示为双圆锥台试样在应变速率0.03 s-1、变形温度980、1020和1060 ℃条件下热压缩变形后经过固溶热处理的宏观组织,对不同等效应变区域内的A2、B2、C2和D2三个位置处微观组织进行分析,如图14所示。由图14可知,当变形温度为980 ℃时,等效应变0.004~0.045区域内的晶粒组织分布均匀,平均晶粒尺寸为69 μm,未出现异常晶粒长大;当变形温度为1020 ℃时,微观组织中临界晶粒长大等效应变范围0.004~0.02,平均晶粒尺寸达170 μm;当变形温度为1060 ℃时,临界晶粒长大的临界等效应变数值增大,临界晶粒长大等效应变范围扩大为0.004~0.037,平均晶粒尺寸达197 μm。当应变速率为0.03 s-1时,随着变形温度的增加,双圆锥台试样发生临界晶粒长大位置的临界等效应变数值逐渐增大,临界晶粒长大的等效应变范围逐渐扩大,异常晶粒长大程度增大。

图11 变形温度980 ℃、不同应变速率下热变形后经过固溶热处理的试样宏观组织

Fig. 11 Macroscopic structures of specimen after solution heat treatment after deformation at 980 ℃ and different strain rates

图12 双圆锥台试样经过固溶热处理后不同等效应变处的SEM像(980 ℃,0.003~0.03 s-1)

Fig. 12 SEM microstructures of different effective strains regions of double-cone specimen after solution heat treatment (980 ℃, 0.003-0.03 s-1)

图13 应变速率0.03 s-1、不同变形温度下热变形后经过固溶热处理的试样宏观组织

Fig. 13 Macroscopic structures of specimen subjected to solution heat treatment after thermal deformation at deformation rate of 0.03 s-1 and different deformation temperatures

图14 双圆锥台试样经过固溶热处理后不同等效应变处SEM像(980~1060 ℃,0.03 s-1)

Fig. 14 SEM images of different effective strains regions of double-cone specimen after solution heat treatment (980-1060 ℃, 0.03 s-1)

3 结论

1) 挤压态FGH4096合金双圆锥台试样热压缩变形时的载荷随着变形温度的升高而减小,随着应变速率的降低而减小。DEFORM有限元压缩数值模拟和实验获得载荷曲线吻合较好,其相对平均误差为7.32%。

2) 挤压态FGH4096合金双圆锥台试样在热压缩变形后的锻态组织均未出现临界晶粒长大,而试样经过固溶热处理后出现临界晶粒长大现象;合金临界晶粒长大的窗口条件从低温低应变速率向高温高应变速率转变,但在(980 ℃、0.03 s-1)、(1060 ℃、0.003 s-1)条件下获得均匀晶粒组织,并未出现合金临界晶粒长大。

3) 挤压态FGH4096合金双圆锥台试样热变形后经过固溶热处理,当固定变形温度为980 ℃时,随着应变速率从0.003 s-1增加到0.01 s-1,试样发生临界晶粒长大的等效应变范围从0.004~0.037变化至0.004~0.029,临界晶粒长大区域平均晶粒尺寸从202 μm减小到175 μm,应变速率增大到0.03 s-1时未发现临界晶粒长大现象;当固定应变速率为0.03 s-1时,变形温度980 ℃时试样未出现临界晶粒长大现象,随着变形温度从1020 ℃升高至1060 ℃,试样发生临界晶粒长大的等效应变范围从0.004~0.02增大到0.004~0.037,临界晶粒长大区域平均晶粒尺寸也从170 μm增至197 μm。

REFERENCES

[1] 邹金文, 汪武祥. 粉末高温合金研究进展与应用[J]. 航空材料学报, 2006, 26(3): 244-250.

ZOU Jin-wen, WANG Wu-xiang. Development and application of P/M superalloy[J]. Journal of Aeronautical Materials, 2006, 26(3): 244-250.

[2] 张义文, 胡本芙. 拓扑密堆μ相对含Hf的镍基粉末高温合金组织和性能的影响[J]. 金属学报, 2016, 52(4): 445-454.

ZHANG Yi-wen, HU Ben-fu. Effects of topologically close packed phase on microstructure and properties in powder metallurgy ni-based superalloy with Hf[J]. Acta Metallurgica Sinica, 2016, 52(4): 445-454.

[3] 国为民, 董建新, 吴剑涛, 张凤戈, 陈淦生, 陈生大. FGH96镍基粉末高温合金的组织和性能[J]. 钢铁研究学报, 2005, 17(1): 59-63.

GUO Wei-min. DONG Jian-xin, WU Jian-tao, ZHANG Feng-ga, CHEN Gan-sheng, CHEN Sheng-da. Microstructure and properties of PM superalloys FGH96[J]. Journal of Iron and Steel, 2005, 17(1): 59-63.

[4] 刘小涛, 丁晗晖, 杨 川, 刘 锋, 黄 岚, 江 亮. 热挤压态FGH96粉末冶金高温合金的显微组织与力学性能[J]. 中国有色金属学报, 2016, 26(2): 354-364.

LIU Xiao-tao, DING Han-hui, YANG Chuan, LIU Feng, HUANG Lan, JIANG Liang. Microstructure and mechanical properties of hot extruded FGH96 powder metallurgy superalloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 354-364.

[5] CHO Y K, YOON D Y, HENRY M F. The effects of deformation and pre-heat-treatment on abnormal grain growth in René 88 superalloy[J]. Metallurgical and Materials Transactions A, 2001, 32: 3077-3090.

[6] WHITIS D D. Recovery and recrystallization after critical strain in the nickel-based superalloy René 88 DT[C]// Superalloys 2004. Warrendale: The Minerals, Metals and Materials Society, 2004: 391-400.

[7] 郭 婧, 姚志浩, 董建新, 张麦仓. 高温合金中晶粒异常长大及临界变形量研究进展[J]. 世界钢铁, 2011, 11(4): 38-45.

GUO Jing, YAO Zhi-hao, DONG Jian-xin, ZHANG Nai-cang. Progress in research of abnormal grain growth and critical deformation in superalloys[J]. World Iron and Steel, 2011, 11(4): 38-45.

[8] 王超渊, 东赟鹏, 宋晓俊, 方 爽, 于秋颖, 李 凯, 王淑云. 变形温度及变形量对挤压态FGH96合金晶粒异常长大的影响[J]. 航空材料学报, 2016, 36(5): 14-20.

WANG Chao-yuan, DONG Yun-peng, SONG Xiao-jun, FANG Shuang, YU Qiu-ying, LI Kai, WANG Shu-yun. Effect of deforming temperature and strain on abnormal grain growth of extruded FGH96 superalloy[J]. Journal of Aeronautical Materials, 2016, 36(5): 14-20.

[9] BENSON W E, WERT J A. The effect of initial grain size distribution on AGG in single-phase materials[J]. Acta Materialia, 1998, 46(15): 5323-5331.

[10] HUMPHREYS F J. A unified theory of recovery, recrystallization and grain growth, based on the stability and growth of cellular microstructures: Ⅱ. The effect of second-phase particles[J]. Acta Materialia, 1997, 45(12): 5031-5039.

[11] VANHERPE L, MOELANS N, BLANPAIN B, VANDEWALLE S. Pinning effect of spheroid second-phase particles on grain growth studied by three-dimensional phase-field simulations[J]. Computational Materials Science, 2010, 49: 340-350.

[12] KOO J B, YOON D Y, HENRY M F. The effect of smalldeformation on abnormal grain growth in bulk Cu[J]. Metallurgical and Materials Transactions A, 2002, 33(12): 3803-3811.

[13] BLANKENSHIP C P Jr, HENRY M F, HYZAK J M, ROHLING R B, HALL E L. Hot-die forging of P/M Ni-base superalloys[C]// Superalloys 1996. Warrendale: The Minerals, Metals and Materials Society, 1996: 653-662.

[14] 吕 炎, 曲万贵, 陈宗霖. 临界变形粗晶形成机理的探 讨[J]. 金属学报, 1986, 22(6): 489-493.

Lü Yan, QU Wan-gui, CHEN Zong-lin. An approach to mechanism of coarse grain formation after critical deformation[J]. Acta Metallurgica Sinica, 1986, 22(6): 489-493.

[15] LEE S B, YOON D Y, HENRY M F. Abnormal gain growth grain boundary faceting in a model Ni-base superalloy[J]. Acta Materialia, 2000, 48: 3071-3080.

[16] MAAZI N, PENELL R. Introduction of preferential Zenerdrag effect in Monte Carlo simulation of abnormal Gossgrain growth in the Fe-3% Si magnetic alloys[J]. Materials Science and Engineering A, 2009, 504: 135-140.

[17] 关小军, 刘运腾, 申孝民, 麻晓飞, 王丽君. 织构诱发晶粒异常长大的Monte Carlo模拟[J]. 材料热处理学报, 2008, 29(6): 179-183.

GUAN Xiao-jun, LIU Yun-teng, SHEN Xiao-min, MA Xiao-fei, WANG Li-jun. Modeling abnormal grain growth induced by texture using Monte Carlo method[J]. Transactions of Materials and Heat Treatment, 2008, 29(6): 179-183.

[18] 杨 杰, 王晓峰, 吉传波, 邹金文. 变形工艺对FGH96合金晶粒异常长大的影响[J]. 航空材料学报, 2014, 34(5): 7-11.

YANG Jie, WANG Xiao-feng, JI Chuan-bo, ZOU Jin-wen. Effect of forging process on abnormal grain growth of FGH96 superalloy[J]. Journal of Aeronautical Materials, 2014, 34(5): 7-11.

[19] 刘建涛, 刘国权, 胡本芙, 陈焕铭, 宋月鹏, 张义文. FGH96合金晶粒长大规律的研究[J]. 材料热处理学报, 2004, 25(6): 25-29.

LIU Jian-tao, LIU Guo-quan, HU Ben-fu, CHEN Huan-ming, SONG Yue-peng, ZHANG Yi-wen. Study on grain growth of PPM FGH96 superalloy[J]. Transactions of Materials and Heat Treatment, 2004, 25(6): 25-29.

[20] 杨 杰, 邹金文, 王晓峰, 吉传波, 周晓明. 热处理对FGH96合金异常晶粒长大的影响[J]. 材料工程, 2014(8): 1-7.

YANG Jie, ZOU Jin-wen, WANG Xiao-feng, JI Chuan-bo, ZHOU Xiao-ming. Effect of heat treatment on abnormal grain growth of FGH96 superalloy[J]. Journal of Materials Engineering, 2014(8): 1-7.

[21] 陈 龙, 司家勇, 刘松浩, 廖 凯. 挤压态FGH4096合金的热变形行为及热加工图[J]. 材料导报, 2019, 33(12): 2047-2054.

CHEN Long, SI Jia-yong, LIU Song-hao, LIAO Kai. Hot deformation behavior and hot processing map of extruded FGH4096 superalloy[J]. Materials Reviews, 2019, 33(12): 2047-2054.

[22] 《中国航空材料手册》编委会. 中国航空材料手册(第2卷)[M]. 北京: 中国标准出版社, 2002: 323-368.

Editorials Board of China Aeronautical Materials Handbook. China Aeronautical Materials Handbook (Volume 2)[M]. Beijing: Standards Press of China, 2002: 323-368.

[23] 朱兴林, 刘 东, 杨艳慧, 牛关梅. FGH96合金包覆挤压过程数值模拟[J]. 航空材料学报, 2013, 33(1): 21-27.

ZHU Xing-lin, LIU Dong, YANG Yan-hui, NIU Guan-mei. Numerical simulation for canning extrusion process of FGH96[J]. Journal of Aeronautical Materials, 2013, 33(1): 21-27.

[24] SEMIATIN S L, WEAVER D S, KRAMB R C, FAGIN P N, GLAVICIC M G, GOETZ R L, FREY N D, ANTONY M M. Deformation and recrystallization behavior during hot workingof a coarse-grain, nickel-base superalloy ingot material[J]. Metallurgical and Materials Transactions A, 2004, 35(2): 679-693.

[25] 司家勇, 宋思远, 廖晓航, 黄再旺. DP工艺GH4169合金热加工高通量测试方法[J]. 中国有色金属学报, 2016, 26(6): 1204-1213.

SI Jia-yong, SONG Si-yuan, LIAO Xiao-hang, HUANG Zai-wang. High-throughput testing on hot working of delta-processed GH4169 alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(6): 1204-1213.

[26] WEAVER D S, SEMIATIN S L. Recrystallization and grain-growth behavior of a nickel-base superalloy during multi-hit deformation[J]. Scripta Materialia, 2007, 57(11): 1044-1047.

Effect of thermal processing on critical grain growth of extruded FGH4096 alloy

LIU Song-hao, SI Jia-yong, CHEN Long

(College of Mechanical and Electrical Engineering, Central South University of Forestry and Technology, Changsha 410004, China)

Abstract: Based on the hot compression deformation and supersolvus heat treatment of extruded FGH4096 alloy double-cone specimens, with the DEFORM numerical simulation, the distribution of critical grain growth (CGG) in different effective strain ranges was determined. The effect of hot working process on CGG of extruded FGH4096 alloy was studied. The results show that the window conditions for the CGG of the alloy range change from low strain rate at low temperature to high strain rate at high temperature, after the double-cone specimens deformed at temperature of 980-1060 ℃ and strain rate of 0.003-0.03 s-1 and treated by supersolvus heat treatment. Then the CGG can be avoided and uniform grain structure can be obtained at (980 ℃, 0.03 s-1) and (1060 ℃, 0.003 s-1).With the increase of strain rate, the degree of abnormal grain growth and the critical effective strain of CGG decreases at 980 ℃. On the other hand, with the increase of deformation temperature, the degree of abnormal grain growth increases and the effective strain region of CGG enlarges at strain rate of 0.03 s-1.

Key words: FGH4096 superalloy; hot extrusion; thermal compression; supersolvus heat treatment; critical grain growth

Foundation item: Project(16A220) supported by the Research Foundation of Education Bureau of Hunan Province, China; Project(2017JJ2403) supported by the Natural Science Foundation of Hunan Province, China; Project(2014207) supported by the Support Program for Scientific and Technological Innovation Team of the Higher Education Institutions of Hunan Province, China; Project(CX20192078) supported by the Graduate Innovation Foundation of Central South University of Forestry and Technology, China

Received date: 2019-09-03; Accepted date: 2019-12-25

Corresponding author: SI Jia-yong; Tel: +86-15973184730; E-mail: sjy98106@163.com

(编辑 龙怀中)

基金项目:湖南省教育厅重点研究项目(16A220);湖南省自然科学基金面上项目(2017JJ2403);湖南省高校科技创新团队支持计划项目(2014207);中南林业科技大学研究生科技创新基金资助项目(CX20192078)

收稿日期:2019-09-03;修订日期:2019-12-25

通信作者:司家勇,教授,博士;电话:15973184730;E-mail:sjy98106@163.com