文章编号:1004-0609(2014)08-2020-06

Al和RE对Zn-Al合金镀层组织和耐蚀性的影响

贺志荣,何 应,刘继拓,解 凯

(陕西理工学院 材料科学与工程学院,汉中723003)

摘 要:采用烘干溶剂法在Q235钢表面获得Zn-(0.02~5)%Al和Zn-5%Al-0.05%RE(质量分数)合金镀层,用光学显微镜和扫描电镜观察合金镀层的宏观形貌和表面、断面组织形貌,用能谱仪分析合金镀层的合金元素分布,分别用中性盐雾实验和全浸腐蚀实验研究合金镀层的耐腐蚀性能。结果表明,锌浴中Al的质量分数为0.02%时,Zn-Al合金镀层的光亮度最好,随着Al含量增加光亮度下降;Zn-Al基合金镀层中,从外层的h相到接近钢基体的G相中,Zn含量逐渐减少,Fe和Al含量逐渐增加;随着镀浴中Al含量增加,热浸镀Zn-Al合金镀层的腐蚀速率减小;添加稀土元素能提高Zn-Al合金镀层的耐腐蚀性能。

关键词:Zn-Al合金;Zn-Al-RE合金;热镀锌;镀层组织;耐腐蚀性能

中图分类号:TG174.442 文献标志码:A

Effects of Al and RE on microstructure and corrosion resistance of Zn-Al alloy coatings

HE Zhi-rong, HE Ying, LIU Ji-tuo, XIE Kai

(School of Materials Science and Engineering, Shaanxi University of Technology, Hanzhong 723003, China)

Abstract: The hot-dip galvanizing alloys of Zn-(0.02-5)%Al and Zn-5%Al-0.05%RE (mass fraction) were obtained on the surface of Q235 steel by solvent drying method. The macroscopic morphology, the surface and section microstructures of the alloy coatings were observed by optical microscopy and SEM. The element distribution in the alloy coatings was analyzed by energy disperse spectroscopy, and the corrosion resistance of the alloy coatings was investigated by the neutral salt spray test and full immersion corrosion, respectively. The results show that the coating lightness is excellent when the Al content is 0.02% (mass fraction), and the coating lightness declines with increasing the Al content. The Zn content reduces and the Fe and Al contents increase gradually in the outer h phase and G phase close to the steel substrate. The corrosion rate of the hot-dip galvanizing Zn-Al alloy coating decreases with increasing the Al content in Zn-Al alloy bath. The corrosion resistance can be enhanced with the addition of rare earth elements in the Zn-Al alloy bath.

Key words: Zn-Al alloy; Zn-Al-RE alloy; hot-dip galvanizing; coating microstructure; corrosion resistance

金属的腐蚀现象遍及国民经济和国防建设的各个领域,危害十分严重,给社会造成巨大损失。热浸镀锌技术是目前世界上最基本、使用最广泛的钢材防腐蚀方法[1-2]。Zn-Al合金是一种防腐蚀材料,主要用作钢铁制品表面的防腐蚀镀层,与纯锌和纯铝镀层相比较,Zn-Al合金镀层具有粘附性强、耐磨性和抗腐蚀性好、成本低等特点,是理想的热镀层保护材料,具有广泛的用途。在热浸镀Zn-Al合金中Al含量在0.005%~0.020%范围内时,能明显改善锌液的流动性,增加镀层表面的光亮性,减少锌浴表面的氧化量,降低锌灰和锌渣的生成量,但是对镀层的组织结构和耐蚀性能影响不大,且使用这种合金热镀时,不需要改变传统的热镀锌工艺。当Al含量大于0.15%时,Al会在Zn/Fe界面形成一层连续Fe2A15,抑制Fe-Zn合金相的形成,进而减薄了合金镀层的厚度,但这种抑制作用非常短暂,作用效果有限。当锌浴中的Al含量超过0.06%后,锌浴中的Al会与传统助镀剂中的氯化锌和氯化铵发生反应,引起助镀剂失效而造成漏镀,这一问题使Al含量大于0.15%的Zn-Al合金在工业上的应用受到了限制[3]。除Al外,添加稀土RE[4-6]、 Ni[7-8]等合金元素亦能提高热浸镀锌合金镀层的耐蚀性能,Galfan(Zn-Al-RE)合金为其典型代表,该合金镀层具有较强的阴极保护作用,其耐蚀性能为传统镀锌涂层的2~3倍[9]。目前,对Zn-Al和Zn-Al-RE合金镀层的成分、组织和性能的研究尚不充分,为了开发外观漂亮、性能优异的Zn-Al基热浸镀合金镀层,深入研究合金成分和热浸镀工艺对镀层组织和性能的影响具有重要意义。本文作者拟采用溶剂烘干法制备不同Al含量的热浸镀Zn-(0.02~5)%Al合金镀层和Zn-5%Al-0.05%RE合金镀层,用光学显微镜、扫描电镜和能谱仪观察分析合金镀层的表面和截面组织及元素分布,用盐雾试验箱和全浸腐蚀实验方法研究Al含量和添加稀土对锌铝合金镀层形貌、组织和耐腐蚀性能的影响。

1 实验

1.1 试样制备

用Q235钢作为热浸镀基体材料,其化学成分为Mn 0.12~0.2,Si 0.30~0.7,S 0.2~0.3,P<0.045,余量Fe(质量分数,%),试样尺寸为30 mm×30 mm×3 mm。对钢基体试样进行侧面钻吊挂孔,打磨去除表面氧化皮,获得平整光滑的表面。在石墨坩埚中用先熔化纯锌锭再熔化纯铝排或含10%稀土的稀土铝中间合金的方法配制Zn-Al合金镀浴,成分为Zn-xAl(x=0.02%,0.5%,5%,质量分数)和Zn-5%Al-0.05%RE,以下分别简写为Zn-0.02Al、Zn-0.5Al、Zn-5Al和Zn-5Al-0.05RE。

热浸镀合金镀层制备过程如下:钢铁基体→碱洗除油→水洗→酸洗除锈→水洗→电解活化助镀→干燥→浸镀液→冷却。其中,碱洗试剂为10%NaOH(质量分数)溶液,时间为3 min,酸洗试剂为5%HCl(质量分数)溶液,时间为30 s。电解活化助镀的电流为0.5 A、时间为2 min,助镀后烘干温度为120 ℃,时间为8 min。将盛有锌铝熔池合金的石墨坩埚置于电阻炉中加热熔化,将数显温度表的插探针插入锌铝合金熔池监测熔池温度,浸镀温度为450 ℃,浸镀时间为1 min,热浸镀后将试样匀速提出,迅速水淬。

1.2 镀层的成分与组织分析

用酒精对样品表面进行超声波清洗10 min,再用蒸馏水冲洗干净后吹干。用照相机记录热浸镀样品的宏观形貌;用EPIPHOT TME200型倒置金相显微镜分析镀层表面的组织形态;将试样锯成10 mm×10 mm小块,经磨平、抛光后用2%(体积分数)硝酸酒精腐蚀数秒,用蒸馏水冲洗干净后滴上酒精吹干,用JSM-6390LV扫描电镜(SEM)分析镀层断面的显微组织;用JSM-6700F场发射SEM及其附带的高性能X射线能谱仪(EDS)分析合金镀层断面的组织和合金元素分布。

1.3 耐腐蚀性能测定

用FQY015型气流式中性盐雾试验箱测定镀层的耐腐蚀性能,腐蚀液为5%NaCl(质量分数),pH值为6.5~7.2,实验时盐雾箱内温度控制在35 ℃左右,周期性喷雾288 h。先后用自来水、蒸馏水、饱和醋酸铵溶液、酒精清洗样品,再晾干、称量,最后计算腐蚀速率[10]。全浸腐蚀实验法是将试样完全浸入5%Na2SO4(质量分数)溶液,试样在35 ℃保温120 h后取出,经上述清洗、晾干、称量等程序后计算腐蚀速率。每个成分的合金镀层进行3组腐蚀试验,计算出平均腐蚀速率。

2 结果与分析

2.1 镀层的宏观形貌

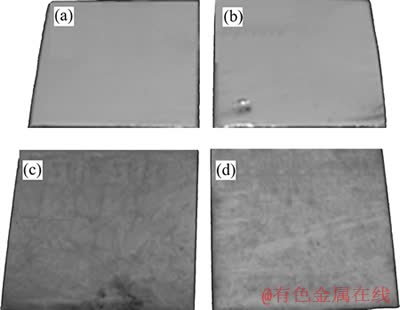

Zn-Al和Zn-Al-RE合金镀层的宏观形貌如图1所示。可以看出,当Al的加入量为0.02%时镀层的光亮性最好(见图1(a)),Al含量为0.5%时镀层的光亮性下降(见图1(b)),Zn-5Al合金镀层的光亮性最差(见图1(c)),在Zn-5Al合金中添加0.05%RE后,合金镀层的光亮性得到改善(见图1(d))。

在锌液中加入0.005%~0.02%的Al后,锌浴中的Al被选择性氧化而使表面形成一层连续的Al2O3膜,使锌浴表面很难被氧化从而获得较为光亮的镀层[3]。同时,镀层表面也由于Al的存在形成了一层Al2O3保护膜,对锌层提供了一个物理保护层,阻止了锌被空气氧化,有利于保持锌的金属光泽[11]。当Al的加入量为5%时,锌浴成分接近共晶成分,凝固过程中镀层表面会形成较厚的连续氧化铝覆盖层或富铝浮渣Fe2Al5Znx等[12],从而使镀层变得灰暗,光亮性显著下降。

图1 Zn-0.02Al, Zn-0.5Al, Zn-5Al和Zn-5Al-0.05RE合金镀层的宏观形貌

Fig. 1 Macroscopic morphologies of Zn-0.02Al (a), Zn-0.5Al (b), Zn-5Al (c) and Zn-5Al-0.05RE (d) alloy coatings

此外,本文作者在研究浸镀Zn-5Al和Zn-5Al- 0.05RE时发现,Zn-5Al锌浴表面较粘稠、锌浴流动阻力较大,而Zn-5Al-0.05RE合金镀层试样提出镀浴时,镀浴流动性较好,试样底部镀层的平整度和锌灰附着程度明显得到改善,这表明RE能提高锌浴的流动性,降低锌浴的润湿角和表面张力,使合金镀层表面的光亮性明显提高。

2.2 镀层表面的显微组织

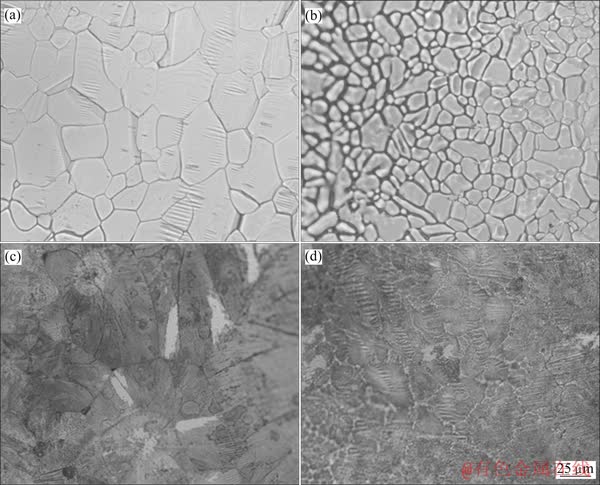

实验用Zn-Al和Zn-Al-RE合金镀层表面的显微组织如图2所示。由图2可知,随Al含量增加,镀层晶粒先细化后粗化,Zn-0.5Al合金镀层的晶粒最细(见图2(b))。晶粒越细,单位体积内晶粒越多,形变时同样的形变量可分散到更多的晶粒中,产生较均匀的形变而不会造成局部应力集中,裂纹不会过早产生与发展,故Zn-0.5Al合金镀层的强度和塑韧性会提高。此外,由图2还可看出,随Al含量增加,镀层的亮度降低,Zn-5Al合金镀层的亮度最低。比较图2(c)和2(d)可知,加入稀土元素可使合金镀层的组织细化、均匀化,并使合金镀层的亮度有所提高。

2.3 镀层断面的显微组织

图2 Zn-0.02Al, Zn-0.5Al, Zn-5Al和Zn-5Al-0.05RE合金镀层表面的显微组织

Fig. 2 Surface microstructures of Zn-0.02Al (a), Zn-0.5Al (b), Zn-5Al (c) and Zn-5Al-0.05RE (d) alloy coatings

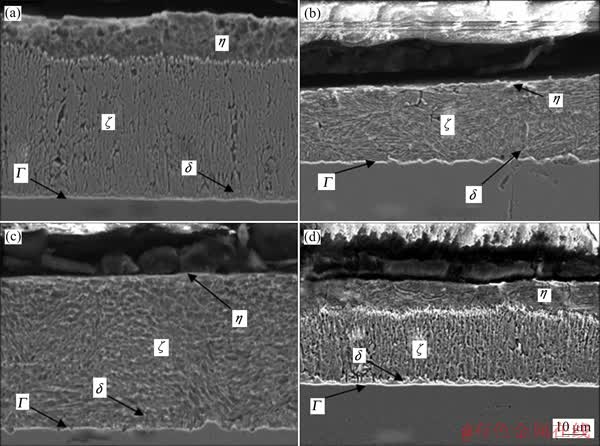

图3 Zn-0.02Al, Zn-0.5Al, Zn-5Al和Zn-5Al-0.05RE合金镀层断面的显微组织

Fig. 3 Section microstructures of Zn-0.02Al (a), Zn-0.5Al (b), Zn-5Al (c) and Zn-5Al-0.05RE (d) alloy coatings

图3所示为Zn-Al和Zn-Al-RE合金镀层断面的显微组织。由图3可以看出,随Al含量增加,Zn-Al合金镀层的密度增加,镀层的厚度先减小后增加,Zn-0.5Al合金镀层的厚度最薄;厚而疏松的ζ相明显减薄,与之相邻的δ相有所增厚并使镀层与钢基体的结合力增强,而镀层密度的提高有助于其耐腐蚀性能的增强。由图3(d)可以看出,添加稀土元素后,合金镀层的厚度虽然变薄,但密度大幅度提高,对外界水、大气和杂质的阻挡作用增强,有效地降低了晶间腐蚀倾向,这正是稀土提高镀层耐腐蚀性能的原因。

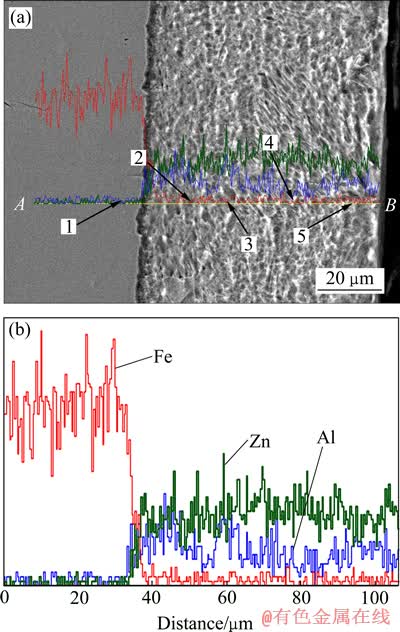

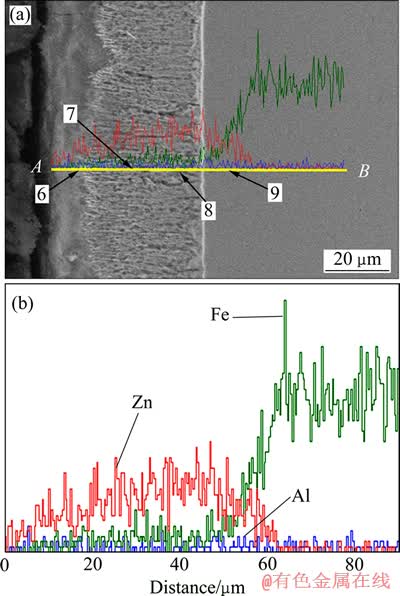

2.4 镀层断面的合金元素分布

图4和5所示分别为Zn-5Al和Zn-5Al-0.05RE合金镀层断面组织中合金元素的分布状况。其中,图4(a)和5(a)所示为其镀层截面的微观形貌,图4(b)和5(b)所示分别为其镀层主要元素的能谱,扫描方向从A到B。由图4可知,镀层组织比较致密,镀层由富Al相和富Zn相交错的层状共晶组织构成中间层和最外层,镀层的内层和基体层由Fe、Zn、Al互扩散形成Fe-Al-Zn金属间化合物构成。由图5可见,镀层明显分为3层,镀层的内层由Fe-Al相金属间化合物 (Fe2Al5)的齿状合金层构成;镀层的外层由富Al和富Zn的共晶组织构成;微量RE元素因在仪器测量最低限度之外而未检测到,故镀层成分主要由Al、Fe和Zn组成。

图4 Zn-5Al合金镀层的SEM形貌及主要元素线扫描结果

Fig. 4 SEM morphology(a) and line scanning results(b) of Zn, Fe, Al elements in Zn-5Al alloy coating

图5 Zn-5Al-0.05RE合金镀层的SEM形貌及主要元素线扫描结果

Fig. 5 SEM morphology and line scanning results of Zn, Fe, Al elements in Zn-5Al-0.05RE alloy coating

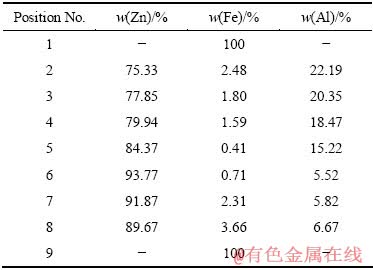

在图4(a)、5(a)所示镀层截面中选取点1~9进行元素扫描分析,其微区主要成分如表1所示,可以看出,按照从镀层的表层到内层的顺序,Zn含量逐渐减少,Fe和Al含量逐渐增加。Al与Fe的亲和力强,在热镀时Fe-Al金属间化合物将优先于Fe-Zn金属间化合物在基体表面生成。Fe-Al金属间化合物的优先生成对脆的Fe-Zn层有抑制作用,从而使镀层减薄,并且Fe-Al金属间化合物不容易参与阳极的溶解过程,较大程度地降低了Fe的危害[13]。

表1 图4和5合金镀层中主要元素分布的能谱分析结果

Table 1 EDS analysis results of main element distribution in alloy coating shown in Figs. 4 and 5

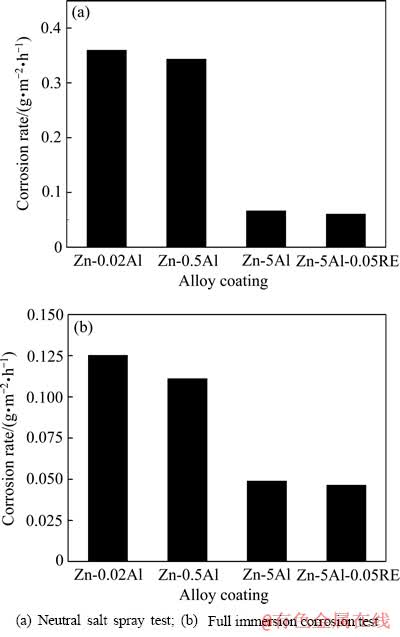

2.5 镀层的耐腐蚀性能

图6所示为4种合金镀层在中性盐雾实验(见图6(a))和全浸腐蚀实验(见图6(b))条件下的腐蚀速率。由图6可以看出,随着Al含量的增加,镀层的腐蚀速率减小;在5%Al(质量分数)锌浴中加入稀土元素镀层的耐腐蚀性能得到显著提高。其原因可能如下:1) 锌铝合金镀层的腐蚀主要是晶界腐蚀。如果将稀土元素加入锌铝合金浴中,由于稀土在铝中的溶解度大于在纯锌中的溶解度,故镀层急速冷却时,稀土有限富集在铝相中,提高了富铝相的电极电位,减小了各相的微电池作用,从而提高了晶界腐蚀的抗力[14]。2) 稀土元素具有净化晶界的作用,可抑制合金的晶间腐蚀[13]。

图6 不同合金镀层在不同腐蚀条件下的腐蚀速率

Fig. 6 Corrosion rates of different alloy coatings under different corrosion conditions

3 结论

1) 锌浴中Al的质量分数为0.02%时,Zn-Al合金镀层的光亮度最好,随着Al含量的增加光亮度下降。

2) Zn-Al基合金镀层中,从外层的η相到接近钢基体处的Γ相,Zn含量逐渐减少,Fe和Al含量逐渐增加。

3) 随着镀浴中Al含量增加,热浸镀Zn-Al合金镀层的腐蚀速率减小。添加稀土元素能提高Zn-Al合金镀层的耐腐蚀性能。

REFERENCES

[1] MARDER A R. The metallurgy of zinc-coated steel[J]. Progress in Mater Science, 2000, 45(3): 265-271.

[2] 何 应, 贺志荣, 张永宏, 刘继拓, 解 凯. 热浸镀锌助镀剂及助镀工艺研究进展[J]. 材料保护, 2013, 46(6): 13-16.

HE Ying, HE Zhi-rong, ZHANG Yong-hong, LIU Ji-tuo, XIE Kai. Research progress of fluxing agent and fluxing processes for hot-dip galvanizing[J]. Materials Protection, 2013, 46(6): 13-16.

[3] 孔 纲, 卢锦堂, 陈锦虹, 许乔瑜. 热浸镀锌浴中少量铝对镀层性能的影响[J]. 材料保护, 2002, 35(7): 17-19.

KONG Gang, LU Jin-tang, CHEN Jin-hong, XU Qiao-yu. Research and practice of low aluminum addition for hot galvanizing bath[J]. Mater Protection, 2002, 35(7): 17-19.

[4] PENG T, MAN R. Rare earth and Silone as chromate replaces for corrosion protection on galvanized steel[J]. Journal of Rare Earth, 2009, 27(1): 159-163.

[5] MANNA M, NAIDU G, RANI N, BANDYOPADHYAY N. Characterization of coating on rebar surface using hot-dip Zn and Zn-4.9Al-0.1 mischmetal bath[J]. Surface and Coating Technology, 2007(7): 1-7.

[6] 杨 云, 余宗森. 稀土对液态Zn-5wt.%Al合金与工业纯铁板反应的抑制作用[J]. 金属学报, 1993, 29(12): 14-20.

YANG Yun, YU Zong-sen. Effect of mischmetal on reaction between solid iron and liquid Zn+5wt%Al alloy[J]. Acta Metall Sin, 1993, 29(12): 14-20.

[7] 贺志荣, 何 应, 张永宏, 刘继拓, 解 凯. 热浸纯Zn和Zn-0.05Ni合金锌层组织性能的对比[J]. 材料热处理学报, 2013, 34(2): 152-156.

HE Zhi-rong, HE Ying, ZHANG Yong-hong, LIU Ji-tuo, XIE Kai. Comparative on microstructure and properties of hot-dip Zn and Zn-0.05Ni alloy coatings[J]. Trans Mater Heat Treat, 2013, 34(2): 152-156.

[8] 邵大伟, 贺志荣, 张永宏. Ni含量对Zn-Al-Ni合金镀层组织和耐腐蚀性能的影响[J]. 表面技术, 2013, 42(2): 18-19, 43.

SHAO Da-wei, HE Zhi-rong, ZHANG Yong-hong. Effect of Ni content on microstructure and corrosion resistance of hot-dip Zn-Al-Ni alloy coating[J]. Surface Technology, 2013, 42(2): 18-19, 43.

[9] 杨 霏. 钢丝单镀Galfan合金助镀剂及镀层组织和性能的研究[D]. 河北工业大学, 2003: 2-35.

YANG Fei. Research for flux used in one-step hot-dipping Galfan steel wire and study on properties & structure of the coating[D]. Hebei University of Technology, 2003: 2-35.

[10] 章江洪, 张英杰. 电镀锌稀土转化膜在5%NaCl溶液中耐蚀性能及耐蚀机理的研究[J]. 材料工程, 2011, 28(4): 84-85.

ZHANG Jiang-hong, ZHANG Ying-jie. Study of corrosion resistance and anti-corrosion mechanism of rare earth conversion coatings on zinc plating in 5% NaCl solution[J]. J Mater Eng, 2011, 28(4): 84-85.

[11] DVORAK P, JANDOV J. Hydrometallurgical recovery of zinc from hot dip galvanizing ash[J]. Hydrometallurgy, 2005, 77(1/2): 29-33.

[12] PISTOFIDIS N, VOURLIAS G, KONIDARIS S. Microstructure of zinc hot-dip galvanized coatings used for corrosion protection[J]. Mater Letters, 2006, 60: 786-789.

[13] 朱 立. 钢材热镀锌[M]. 北京: 化学工业出版社, 2006: 3-30.

ZHU Li. Hot-dip galvanizing of steels[M]. Beijing: Chemical Industry Press, 2006: 3-30.

[14] 唐 琦, 严 彪, 徐 政. 热浸镀Zn-5%Al-Re合金钢丝镀层的表面形貌[J]. 上海有色金属, 1999, 20(4): 157-161.

TANG Qi, YAN Biao, XU Zheng. Surface morphology of Zn-5%Al-RE coating hot dip plated on alloy steel wire[J]. Shanghai Nonferrous Metals, 1999, 20(4): 157-161.

(编辑 龙怀中)

基金项目:陕西省科技统筹创新工程计划资助项目(2011KTDZ01-03-06);陕西省大学生创新创业训练计划资助项目(1626);陕西理工学院研究生创新基金资助项目(SLGYCX1319)

收稿日期:2013-10-20;修订日期:2014-02-20

通信作者:贺志荣,教授,博士;电话:0916-2641895;E-mail: hezhirong01@163.com