烧结优化配矿模型的设计与软件开发

袁晓丽1,范晓慧2,万 新1,陈许玲2,胡 林1,张明远1,杜长坤1

(1. 重庆科技学院 冶金与材料工程学院,重庆,401331;

2. 中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘 要:针对铁矿石烧结配矿的特点,提出2种获得合适配矿方案的方法;应用BP神经网络技术和遗传优化技术分别建立烧结矿质量模拟模型和烧结寻优配矿模型;采用Visual C++ 6.0与Matlab混合编程的方式,开发烧结优化配矿模型的系统软件。研究结果表明:烧结矿质量模拟模型具有良好的泛化能力和自适应能力,并且预报准确率较高,转鼓强度预报命中率为90%,抗磨强度为86.67%,筛分指数为83.33%;采用烧结寻优配矿模型得到的优化配矿方案既可满足铁矿石供应情况,又可保证烧结矿的质量指标,优化效果明显,烧结优化配矿模型的系统软件实用性强,具有强大的存储、计算、预报和优化等功能。

关键词:烧结;优化配矿;质量模拟模型;寻优配矿模型

中图分类号:TP18 文献标志码:A 文章编号:1672-7207(2009)06-1476-06

Design and development of optimizing iron oresmatching model and software

YUAN Xiao-li1, FAN Xiao-hui2, WAN Xin1, CHEN Xu-lin2, HU Lin1, ZHANG Ming-yuan1, DU Chang-kun1

(1. School of Metallurgy and Materials Engineering, Chongqing University of Science and Technology, Chongqing 401331, China;

2. School of Resources Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: Two methods to obtain a proper iron ores matching scheme were put forward. Sinter quality simulating model and optimizing iron ores matching model were built by using BP neural network technology and genetic algorithms technology, respectively. In addition, the software of optimizing matching ores system model was developed using a mixing programming mode of Visual C++ 6.0 development tool and Matlab programming language. The results show that the sinter quality simulating model has good generalization and self-adaptation abilities. Moreover, this model has a high predictive hit-ratio. The predictive hit-ratio for tumbler strength, abrasion strength and screen index are 90%, 86.67% and 83.33%, respectively. The optimizing iron ores matching model can give the best iron ores matching scheme, which makes the cost lower and the quality of sinter good. The optimizing iron ores matching model has a good optimizing effect. The software of optimizing matching ores system model has some advantages such as good practicability, as well as powerful functions of storage, calculation, prediction and optimization.

Key words: sintering; optimization iron ores matching; model of sinter quality; optimizing iron ores matching model

随着钢铁工业的不断发展,铁矿资源日趋贫瘠,铁矿石价格不断攀升;优质铁矿资源减少,使得烧结生产所用铁矿种类日益繁多,如何在满足烧结矿产质量指标要求的前提下,合理搭配铁矿、降低原料成本成为业界关注的焦点问题之一[1-6]。目前,企业在确定配矿方案时,通常是根据以前的配矿方案,凭专家的配矿经验进行微量调整,然后,根据烧结矿的质量决定下一步的方案。对于新矿种,一般根据单烧和配矿烧结试验结果,决定其配加比例。采用这些方法最大的缺点是比较盲目,难以掌握规律,且有可能失控。如果能够在已知配矿方案基础上,对烧结矿质量进行预报,或者在已知约束范围的配矿方案中找出优化的配矿方案,使之满足某个烧结矿质量指标达到最优值,就能很好地解决以上问题。

国内外对烧结矿质量模拟和优化模型的研究比较多,最典型的有:Kawaguchi等[7]在大量烧结试验的基础上,建立了铁矿石烧结综合模拟模型,该模型能预报烧结矿质量、能耗、生产率和其他操作性能;巴西CVRD公司对各种矿石的微观结构及其对烧结过程的影响进行了大量的研究,应用人工神经网络模拟了铁矿石微观结构与烧结性能和烧结矿质量之间的关系,来评价铁矿石的烧结性能[8];吕学伟等[9]把遗传算法用于烧结配料优化计算,它独有的惩罚函数可以灵活地处理各种约束条件,通过控制惩罚度来划分约束条件的优先顺序,使配料过程的计算机运算更符合烧结操作者的意愿,实现人工智能;刘代飞[10]在神经网络模型的基础上结合遗传算法建立了烧结工艺参数优化模型,计算出最佳的工艺参数模型;李云涛[11]建立了由化学成分约束和产质量优化组成的优化配矿模型,可以在满足烧结矿生产化学成分要求及在一定的产质量指标要求下得到多种配矿方案;范晓慧等[12]对铁矿石的物理性质、化学性质、微观性质与其烧结性能之间的对应关系进行了研究,并建立了铁矿石烧结性能预报模型。但是,国内外在烧结矿质量模拟和优化模型的研究方面,有些没有考虑配矿方案,有些考虑获得配矿方案的方法比较单一,不能根据配矿的实际情况较全面灵活地获得合适的配矿方案。在此,本文作者针对烧结配矿的特点,提出2种获得合适配矿方案的方法。

1 配矿模型的研究方法

一般来说,一个合适的配矿方案必须同时满足以下4个条件:

a. 具有合适混匀矿物理、化学性能和烧结矿的化学性能。

b. 满足现有铁矿石的供应量。

c. 混匀矿、烧结矿成本最低。

d. 满足烧结矿质量指标。

目前,条件a~c基本可以通过混匀配矿计算和烧结配料计算得到满足。如果要使配矿方案同时具备条件d,一般通过进行大量的烧结配矿试验,对配矿方案进行不断摸索,这样不仅耗费大量的人力、物力和财力,而且试验效果不一定明显。随着世界铁矿石资源的不断变化以及企业对铁矿石种类、配比的调整和对烧结生产降本增效提出更高的要求,传统的配矿方法已不能完全满足实际生产的需要。在此,提出2种获得合适配矿方案的方法。

首先,可以通过混匀配矿计算和烧结配料计算满足条件a的配矿方案组。但是,由于铁矿石在烧结过程中所表现出的行为和性能是极其复杂的,不同的矿种具有不同的烧结性能,即使在混匀矿化学成分、粒度组成相同的情况下,配矿方案不同,混匀矿的烧结性能也有差异。这就需要找出配矿方案与烧结矿质量指标之间的内在关系,建立烧结矿质量模拟模型,对烧结矿质量指标进行预报。若满足烧结矿质量指标,则能得到合适的配矿方案。这是一种获得传统配矿方案的方法。

此外,如果在混匀矿物化性能和烧结矿质量一定的条件下,如何找出最佳的配矿方案,这就需要采用全局寻优的遗传算法,建立寻优配矿模型,在满足烧结矿质量指标和铁矿石供应量的条件下,得到优化的配矿方案。这是一种用于求解相对复杂的配矿方案的方法。

2 烧结矿质量模拟模型的建立

铁矿石配矿方案与烧结矿质量之间存在着非常复杂的关系,具有非线性、时变性和不确定性等特征。鉴于BP神经网络在处理非线性系统方面的优越性,采用BP神经网络技术来建模。

但是,一般的BP算法存在学习效率低,收敛速度慢,易陷入局部极小状态以及网络的泛化能力弱等缺点,本文对BP算法进行改进,采用改进的BP算法即Vogl快速算法[13]。它含有“批处理”思想,包括加入动量项和学习速率优化2个部分。计算式为:

该算法的优越性在于:每一个输入样本对网络不立即产生作用,而是等到全部输入样本到齐,进行误差累积求和,集中修改权值,即根据总误差E(p)修正权值、学习速率η和动量参数mc,依据误差是否降低选择式(1)或式(2)进行计算。若η和mc越大,则每次权值的改变越剧烈,会导致学习过程发生振荡;较小的η和mc虽然有利于学习过程的收敛,但导致学习时间增长。故对η和mc的选择可根据式(3)和式(4)采用自适应的调节方法选取。

烧结矿质量模拟模型的输入层参数为铁矿石的配比,输出层为转鼓强度、抗磨强度和筛分指数。网络结构如下:输入层为22,隐含层为45,输出层为3,动量项为1.0,学习初始速率为3.33,初始权值为0.5,初始阈值都为1.0,最大训练步数为100 000,网络训练最小总误差为0.001,隐含层激励函数采用 函数;预报模型的评价方法采用基于“允许误差限”的绝对命中率法。

函数;预报模型的评价方法采用基于“允许误差限”的绝对命中率法。

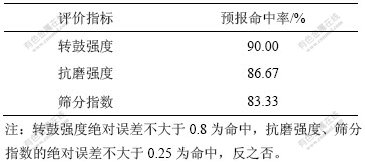

烧结矿质量预报模型的评价指标为转鼓强度、抗磨强度和筛分指数。烧结矿质量模拟模型的预报命中率见表1。

表1 预报模型各评价指标命中率

Table 1 Predictive hit-ratio of model

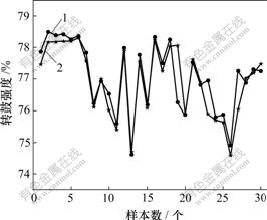

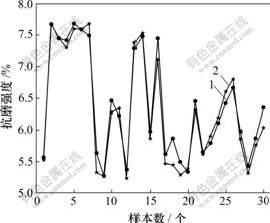

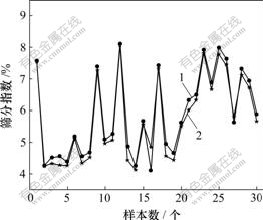

本研究取自国内某钢铁厂近5 a的数据,对数据进行处理后,设定样本数96组,前30组作为模型的预报样本数,后66组作为模型的训练样本数。预报曲线如图1~3所示。

1—实际值;2—预报值

图1 转鼓强度的预报曲线

Fig.1 Predictive curves of tumbler strength

1—实际值;2—预报值

图2 抗磨强度的预报曲线

Fig.2 Predictive curves of abrasion strength

1—实际值;2—预报值

图3 筛分指数的预报曲线

Fig.3 Predictive curves of screen index

由图1~3可知,预报值与实际值拟合较好,转鼓强度、抗磨强度和筛分指数预报命中率分别为90.00%,86.67%和83.30%,说明该预报模型具有较强的泛化能力和自适应能力,网络的预报误差比较 小,能够比较准确地预报铁矿石的烧结性能各评价指标。对于该系统的数据,在已知配矿方案的前提下,可以通过该模型对烧结矿的质量进行预报,据预报结果检验配矿方案是否为合适的配矿方案。

3 烧结寻优配矿模型的建立

为了解决各种优化计算问题,目前存在多种优化算法,如遗传算法、单纯形法、梯度法、分枝定界法[14]等。遗传算法是建立在自然选择和群体遗传学基础上的随机、迭代、进化并具有广泛适用性的搜索方法,是一种可用于复杂优化计算的鲁棒搜索算法。

烧结寻优配矿模型的目的就是在已知约束范围的配矿方案中找出优化的配矿方案,使之满足某个质量指标达到最优值。本研究采用的是BP网络模型提供的网络结构,模型的输入参数为22种铁矿石的配比,输出参数为铁矿石烧结性能3个评价指标(筛分指数、抗磨强度和转鼓强度)。

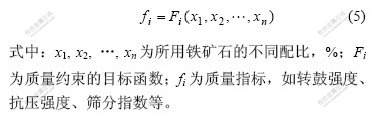

对质量约束提供的3个评价指标中,若选定1个质量指标进行约束,则质量约束可以用1个目标函数来表示:

在设计优化配矿模型时,x1, x2, …, xn分别表示优化配矿的决策变量,x表示一种配矿方案。以选定的铁矿石配比x1, x2, …, xn作为决策变量,那么,一组配矿方案 就可作为遗传过程中的个体。矿石变量以一定编码方式表示,配矿方案x则由选定的n种铁矿石顺序连接成x1, x2, …, xn,从而构成了染色体的编码 方法。

就可作为遗传过程中的个体。矿石变量以一定编码方式表示,配矿方案x则由选定的n种铁矿石顺序连接成x1, x2, …, xn,从而构成了染色体的编码 方法。

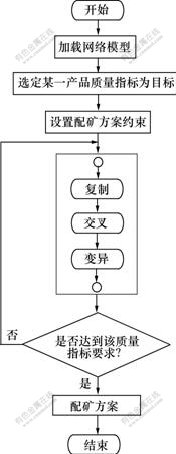

采用遗传优化算法实现质量优化模型时,优化参数包括铁矿石配比约束和铁矿石总配比约束,评价指标为质量约束。铁矿石配比约束和铁矿石总配比约束可以在群体初始化时实现。质量指标约束是多维的,包括转鼓强度、抗磨强度和筛分指数3项,如式(5)所示。把某一质量指标约束的具体值作为个体的评价函数,就可以利用配矿优化模型来计算个体的适应 度。通过遗传进化,可以产生满足质量要求的配矿方案。图4所示为利用遗传算法生成最优配矿方案算法示意图。

图4 产生配矿方案算法示意图

Fig.4 Diagram of algorithm producing iron ores matching scheme

图5 系统的功能结构

Fig.5 Functions and structure of system

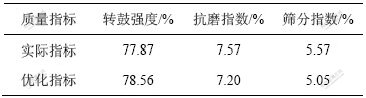

以国内某钢铁公司优化配矿方案G3-001对应的质量指标为例,研究得到优化前、后的结果对比如表2和表3所示。其中铁矿石配比(质量分数)约束范围为:澳大利亚粉0~54%,阿索门粉0~40%,高纽粉0~52%,综合粉0~5%。

表2 优化前、后配矿方案G3-001对比

Table 2 Comparison of iron ores matching scheme G3-001 before and after optimizing w/%

表3 优化前、后质量指标对比

Table 3 Comparison of quality index before and after optimizing

该模型是在约束铁矿石配比的前提下,使转鼓强度达到最大值得到的优化结果。从优化配矿结果可以看出,通过模型优化后,矿粉的配比发生了变化,澳大利亚粉和综合粉的配比略有降低,阿索门粉配比稍增加,高纽粉配比有较大幅度增加;转鼓强度增加约0.69%,抗磨指数和筛分指数分别降低0.37%和0.52%。由此可知,优化效果明显。此外,高纽粉在与澳大利亚、阿索门粉和综合粉的搭配中,高纽粉的烧结性能使得烧结矿质量指标提高。

4 优化配矿模型系统软件的开发

系统采用Visual C++ 6.0与Matlab混合编程的方式开发系统软件,Visual C++ 6.0具有C++语言支持面向对象程序设计的所有特性,同时为软件开发人员提供了完整的编辑、编译、运行和调试工具及建立在Win32 API(应用程序接口)基础上的MFC(Microsoft Foundation Class Library)类库,从而有效地缩短了应用程序开发周期[15-16]。Matlab具有高性能的数值计算和可视化功能,它在数值分析、信号处理、系统辨识、特殊函数和图形等方面具有广泛的应用。系统的功能结构如图5所示。优化配矿模型系统软件主要包括4个模块:数据库模块、计算配矿模型模块、BP神经网络建模模块、优化模型参数的设置和运算模块,该软件具有强大的存储、计算、预报和优化等功能。

5 结 论

a. 应用神经网络技术建立了烧结矿质量模拟模型,模型预报准确率较高,转鼓强度、抗磨强度和筛分指数的预报命中率分别达到90%,86.67%和83.33%,另外,该模型具有较强的泛化能力和自适应能力。

b. 应用遗传优化技术建立了烧结寻优配矿模型。在保证烧结矿质量指标的和铁矿石供应量的条件下获得优化的配矿方案,具有较好的优化效果。

c. 采用Visual C++6.0与Matlab混合编程的方式,开发了烧结优化配矿模型的软件,软件实用性强,界面友好,操作方便,具有强大的存储、计算、预报和优化等功能。

参考文献:

[1] 熊冬保, 周少瑜. 优化锰铁高炉配矿结构[J]. 铁合金, 2003, 24(6): 4-5.

XIONG Dong-bao, ZHOU Shao-yu. Optimizing ore mix constitution for ferromanganese of iron ores matching blast furnace[J]. Ferro-Alloys, 2003, 24 (6): 4-5.

[2] 毛晓明, 朱 彤, 李加福. 宝钢烧结投产以来的技术进步[J]. 炼铁, 2005, 24(S): 99-100.

MAO Xiao-ming, ZHU Tong, LI Jia-fu. The sintering- technology innovations in Baosteel[J]. Ironmaking, 2005, 24(S): 99-100.

[3] 王光东. 湘钢原料性能及配矿试验研究[J]. 烧结球团, 2002, 27(5): 4-7.

WANG Guang-dong. Experimental study on sintering properties of materials and mix proportioning in Xiangtan I&S Co.,Ltd[J]. Sintering and Pelletizing, 2002, 27(5): 4-7.

[4] 程国彪, 高丙寅, 张 春, 等. 大比例配用进口粉矿的烧结试验及生产[J]. 烧结球团, 2004, 29(1): 8-9.

CHENG Guo-biao, GAO Bing-yin, ZHANG Chun, et al. Sintering experiment and practice with higher proportion of imported fine ores[J]. Sintering and Pelletizing, 2004, 29(1): 8-9.

[5] 刘丽红, 许秋惠, 方丽平. 烧结配矿的试验研究[J]. 河北冶金, 2005, 20(6): 9-10.

LIU Li-hong, XU Qiu-hui, FANG Li-ping. Trial in ore proportioning in sintering[J]. Hebei Metallurgy, 2005, 20(6): 9-10.

[6] 刘振林, 蔡漳平. 高铁低硅烧结矿配矿技术的试验研究[J]. 钢铁, 2001, 36(12): 1-5.

LIU Zhen-lin, CAI Zhang-ping. Experimental investigation of proportioning ore technique for high iron and low silicon sinter[J]. Iron and Steel, 2001, 36(12): 1-5.

[7] Kawaguchi T, Sato S, Ichidate M, et al. Development and application of an integrated simulation model for iron ore sintering[J]. Transactions ISIJ, 1985, 25(2): 97-111.

[8] Pinheiro P, 杨天勇. CVRD的烧结工艺铁矿石评估方法[J]. 现代冶金, 2002, 30(2): 4-7.

Pinheiro P, YANG Tian-yong. Evaluating ways of sintering process iron ore of CVRD[J]. Modern Metallurgy, 2002, 30(2); 4-7.

[9] 吕学伟, 白晨光, 邱贵宝, 等. 三种优化烧结配料方法的比较[J]. 烧结球团, 2006, 31(2): 11-15.

L? Xue-wei, BAI Chen-guang, QIU Gui-bao, et al. Comparison of three calculation methods used in sinter mix proportioning optimation[J]. Sintering and Pelletizing, 2006, 31(2): 11-15.

[10] 刘代飞. 烧结过程工艺参数优化模型的研究[D]. 长沙: 中南大学资源加工与生物工程学院, 2004.

LIU Dai-fei. The research of optimal model for sintering processing parameters[D]. Changsha: School of Resources Processing and Bioengineering, Central South University, 2004.

[11] 李云涛. 烧结优化配矿模型的研究[D]. 长沙: 中南大学资源加工与生物工程学院, 2004.

LI Yun-tao. The research of sintering optimal matching system[D]. Changsha: School of Resources Processing and Bioengineering, Central South University, 2004.

[12] 范晓慧, 曾垂喜, 姜 涛, 等. 铁矿石烧结性能预报模型[J]. 中南大学学报: 自然科学版, 2005, 36(6): 949-954.

FAN Xiao-hui, ZENG Chui-xi, JIANG Tao, et al. Predictive model of iron ore sintering capabilities[J]. Journal of Central South University: Science and Technology, 2005, 36(6): 949-954.

[13] 焦李成. 神经网络计算[M] . 西安: 西安电子科技大学出版社, 1995.

JIAO Li-cheng. Neural network computation[M]. Xi’an: Xidian University Press, 1995.

[14] 唐文艳, 顾元宪. 遗传算法在结构优化中的研究进展[J]. 力学进展, 2002, 32(1): 26-27.

TANG Wen-yan, GU Yuan-xian. Advances of genetic algorithms in structural optimization[J]. Advance in Mechanics, 2002, 32(1): 26-27.

[15] Davis L. Handbook of genetic algorithms[M]. New York: van Nostrand Reinhold, 1991.

[16] 齐 舒. Visual C++ 6.0开发技巧及实例剖析[M]. 北京: 清华大学出版社, 1999.

QI Shu. Development skills and case analysis of Visual C++ 6.0[M]. Beijing: Tsinghua University Press, 1999.

收稿日期:2008-11-19;修回日期:2009-03-09

基金项目:新世纪优秀人才支持计划项目(NCET-05-0690)

通信作者:范晓慧(1969-),女,河北昌黎人,博士,教授,从事钢铁冶金数学模型与人工智能的研究;电话:0731-88830542;E-mail: csufanxiaohui@126.com