文章编号:1004-0609(2007)10-1586-06

Cu基块状非晶晶化过程的微区变形及力学性能

李春燕1, 2,寇生中1, 2,胡 勇1, 2,丁雨田1, 2,许广济1

(1. 兰州理工大学 甘肃省有色金属新材料省部共建国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金省部共建教育部重点实验室,兰州 730050)

摘 要:在玻璃转变温度以下选择350、400、475及600 K进行1 h的等温退火,用纳米压痕仪、扫描电镜等研究Cu基块状非晶晶化过程的力学性能及变形。Cu基块状非晶在纳米压头作用下体现弹?塑性变形方式,载荷—位移曲线和压痕周边多重剪切带的特征证明了塑性变形的存在。350 K退火试样具有较大的压痕硬度HV和弹性模量E值及较小的塑性变形量dn值;400 K退火后,HV和E值显著减小,dn值明显增大;475 K退火后,有少量晶体相析出,但合金以非晶的特性为主,HV和E值继续减小,dn值继续增大;600 K退火后,晶体相进一步长大和析出,其固溶强化和弥散强化使合金的HV和E值有所增加,dn值略有减小。对塑性变形机理进行了初步分析。

关键词:Cu基块状非晶;晶化;纳米压痕;变形;力学性能

中图分类号:TG 139.8 文献标识码:A

Deformation and mechanical properties of

Cu-based bulk metallic glasses during crystallization

LI Chun-yan1, 2, KOU Sheng-zhong1, 2, HU Yong1, 2, DING Yu-tian1, 2, XU Guang-ji1

(1. State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials, Lanzhou University of Technology,

Lanzhou 730050, China;

2. Key Laboratory of Non-ferrous Metal Alloys, Ministry of Education, Lanzhou University of Technology,

Lanzhou 73005, China)

Abstract: 350, 400, 475 and 600 K below glass transition temperature were chosen for isothermal annealing for 1 h. Mechanical properties and deformation of Cu-based bulk metallic glasses(BMGs) during crystallization were studied with nanoindentation instrument and scanning electron microscope(SEM). The results indicate Cu-based BMGs deform in elastic-plastic modes under a nanoindenter. Load-displacement curve and multiple shear bands around a nanoindenter confirm the existence of plastic deformation. The sample annealed at 350 K exhibits higher microhardness(HV), elastic modulus(E), and lower plastic deformation(dn); HV and E values decrease and dn value increases significantly at 400 K; crystal phases exist at 475 K, but the major properties of the alloy is amorphous. HV and E values reduce and dn value increases continually; with growth and precipitation of crystal phases at 600 K, solid solution strengthening and dispersion strengthening of the phases slightly augment HV and E values, and reduce dn value. The plastic deformation mechanism during crystallization is preliminarily analyzed.

Key words: Cu-based bulk metallic glass; crystallization; nanoindentation; deformation; mechanical properties

20世纪90年代以来,出现了毫米级乃至厘米级块状非晶[1?4],人们对块状非晶的拉伸、压缩、疲劳、冲击等性能进行了广泛的研究[5?8]。但这些研究大都围绕块状非晶的宏观变形及性能进行,对非晶的微观变形及性能研究较少。纳米压痕法是近年来出现的一种测试材料微区力学性能的新方法,被广泛用于研究固体材料的力学性质。与传统的显微硬度测试法不同,纳米压痕法可测出载荷—位移曲线,根据该曲线可确定材料某一微区的硬度、弹性模量,并且可以确定其变形特点。此外,还可以根据压痕周边的变形情况为分析材料的变形机理提供有价值的信息。人们对淬态的块状非晶合金微区(压头作用区)表面所产生的塑性变形以及压痕周围的变形情况(剪切带)已有不少研究[9?16],但对块状非晶合金晶化过程中微区的力学性能及其变形情况的研究相对较少。Cu基块状非晶是准脆性材料,单轴压缩时承受正压力,仅发生较小的塑性变形。而用纳米压痕法研究时,试样承受多轴应力束缚,能够发生显著的塑性变形,并提供更多的塑性变形过程的信息,从而有助于深入研究非晶的塑性变形机理。本文作者以Cu50Zr42Al8块状非晶合金为研究对象,采用纳米压痕法研究其晶化过程的微区变形特点及力学性能,并对其塑性变形机理进行初步分析。

1 实验

选用Cu50Zr42Al8(摩尔分数,%)块状非晶合金作为实验材料,所用原材料纯度大于99.8%。采用冷坩埚悬浮熔炼设备熔炼母合金,用铜模吸铸法熔铸直径为d 4 mm的圆棒非晶试样。熔炼和吸铸过程均在氩气保护气氛中进行。由NETZSCH STA 449C型差热扫描量热计(DSC)测定出Cu50Zr42Al8块状非晶合金的玻璃转变温度Tg为723 K,晶化温度Tx为773 K。退火实验在真空退火炉中氩气保护下进行,退火温度在低于Tg温度选择,分别为350、400、475和600K,退火时保温时间为1 h。由D/max-2400型大功率转靶衍射仪(XRD)进行试样晶化过程的结构分析。

纳米压痕试样的尺寸为d 4 mm×1 mm,采用金刚石无齿锯从圆棒上截取,然后将试样磨平并抛光。利用NANOTEST600型纳米压痕仪分别测定试样在淬态、350、400、475和600 K退火试样的载荷—位移曲线,由此得到试样晶化过程的硬度HV及弹性模量E值。纳米压痕仪压入深度为1 000 nm,测量值为5个点的平均值。压痕周边的变形情况采用JSM?5600LV型低真空扫描电子显微镜进行观察。

2 实验结果

2.1 XRD分析

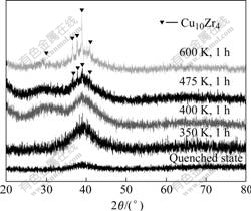

淬态、350、400、475和600 K退火态试样的XRD分析结果如图1所示。可以看出,淬态、350与400 K等温退火试样的衍射谱都由典型的非晶的漫散射峰组成,没有明显的与结晶相相对应的衍射峰,说明为完全非晶结构;475 K等温退火试样的衍射图出现明显的与结晶相相对应的衍射峰,该相标定为Cu10Zr7,表明Cu50Zr42Al8块状非晶合金在475 K退火后已经发生晶化;600 K等温退火试样的结晶相衍射峰明显增强增多,而且同样标定为的二元相Cu10Zr7。

图 1 不同温度等温退火试样的XRD谱

Fig.1 XRD patterns of samples after annealing at different temperatures

2.2 晶化过程的微区变形及力学性能

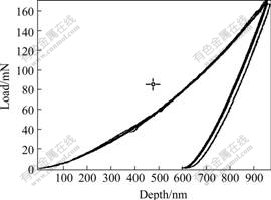

图2所示为Cu50Zr42Al8块状非晶合金淬态样的加载和卸载的载荷—位移曲线。可以看出,加载与卸载曲线均具有非线性特性,但两者并没有重合。卸载时弹性变形只恢复了一部分,表明其余部分发生了塑性变形。为了定量地表征塑性变形的大小,以卸载曲线和位移轴的交点与零点的距离即最大残留位移dn为塑性变形的表征参数。dn越大,变形回复值越小,说明永久变形量越大。350、400、475及600 K退火试样的载荷—位移曲线也有同样的特征,表1列出了各个状态试样的塑性变形量dn、硬度HV及弹性模量E的值。

图2 Cu50Zr42Al8块状非晶合金淬态样的载荷—位移曲线

Fig.2 Load-displacement curves of Cu50Zr42Al8 BMG

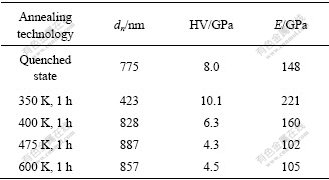

表1 Cu50Zr42Al8合金的纳米压痕实验参数

Table 1 Nanoindentation parameters of Cu50Zr42Al8 alloy after annealing at different temperatures

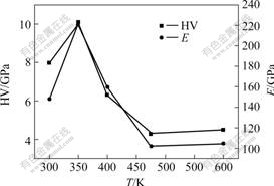

硬度HV和弹性模量E与退火温度T的关系如图3所示。可见,Cu50Zr42Al8块状非晶合金经过不同温度的退火处理后,HV和E具有相同的变化趋势。350 K退火试样的HV和E值最大;400 K退火试样的HV和E值开始变小;475 K退火试样的HV和E值降到最小;600 K退火试样的HV和E值稍有增加。

图3 Cu50Zr42Al8合金的HV、E与T的关系

Fig.3 HV and E as function of T of Cu50Zr42Al8 alloy

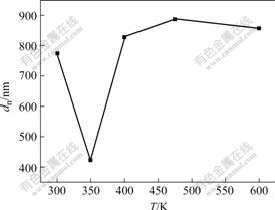

图4所示为塑性变形dn与退火温度T的关系。可以看出,dn的变化趋势与HV和E的变化趋势相反。350 K退火试样的dn值最小,表明只发生很小的塑性变形;400 K退火试样的dn值明显增大,说明此时发生较大的塑性变形;475 K退火试样的dn值继续增加,表明发生更大的塑性变形;600 K退火试样的dn值略有减小,表明塑性变形的程度稍有减少。

图4 Cu50Zr42Al8合金的dn与T的关系

Fig.4 dn as function of T of Cu50Zr42Al8 alloy

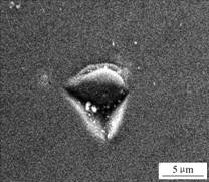

图5所示为Cu50Zr42Al8块状非晶合金试样400 K的纳米压痕及周围变形的SEM像,可以看出三角形压痕一边存在多个圆环,每个圆环高低不平表现为“堆起(pile-up)”。这种堆起应看作是在压头作用下压痕周围形成的剪切带,并且这些剪切带高度局域化(仅在压痕周围形成)。堆起还呈现波纹状,这是非晶在变形过程中的粘性流动行为,粘性流动行为越强表明发生的塑性变形越明显。这些在纳米压痕条件下的变形行为与拉伸、压缩等变形行为不同的是,后者表现为单一剪切带及弹性?断裂行为,而前者表现为多重剪切带及弹?塑性行为[15]。

图5 Cu50Zr42Al8块状非晶合金400 K退火后的压痕周边形貌

Fig.5 Deformation morphology around indent of Cu50Zr42Al8 BMG after annealing at 400 K

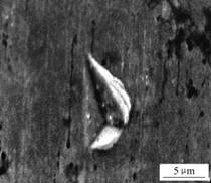

图6所示为Cu50Zr42Al8块状非晶合金在475 K退火后的压痕形貌,从图6可以观察到三角形压痕两侧存在明显的堆起或波纹,即三角形两侧都产生明显的剪切带,表明475 K退火试样与400 K退火试样相比较发生了更大的塑性变形,与图4结果吻合。

图6 Cu50Zr42Al8块状非晶合金475 K退火后的压痕周边形貌

Fig.6 Deformation morphology around indent of Cu50Zr42Al8 BMG after annealing at 475 K

3 分析与讨论

3.1 晶化过程的硬度变化

研究表明[17?18],在Tg以下退火(未发生晶化),非晶合金的热、磁、电及力学性能等几乎所有的性能都发生改变。就力学性能而言,硬度随退火温度的提高而提高,这在薄带及块状非晶中的研究中已得到证明。本研究表明:试样在Tg以下不同温度进行保温1 h的退火处理后,HV值在350 K退火后(未发生晶化)是增大的,而在400 K退火后(未发生晶化)又是减小的,与人们的研究结果不符。

Cu50Zr42Al8块状非晶在350 K退火时发生了结构弛豫,研究表明:结构弛豫过程中原子发生的聚集重排大大提高了非晶中的有序度,从而产生更多更大的有序原子团簇(cluster)。Chen等[19]提出,非晶是由具有大自由体积且高局域自由能的类液区及具有小自由体积且低局域自由能的类固区所组成。Cohen等[20?21]根据逾渗理论并结合自由体积的概念提出了非晶的平衡相变理论,认为非晶合金中的每个原子均具有一定的自由体积,自由体积小于某一临界值的原子团称为类固体胞,而大于临界值的原子团称为类液体胞。所以非晶合金实际上是由两个部分组成:一部分是具有大自由体积且高局域自由能的类液体胞,另一部分是嵌入类液体胞结构内的具有小自由体积且低局域自由能的类固体胞,即有序原子团簇。当Cu50Zr42Al8块状非晶合金在350 K进行退火时,合金中原子发生长程集聚重排,同时产生更多更复杂的有序原子团簇,即具有大自由体积且高局域自由能的类液体胞逐步被具有小自由体积且低局域自由能的类固体胞所代替,从而使得类固原子团数目不断增加,而类液体胞数目不断减少,因此整个体系的自由体积不断减小。伴随着自由体积的减小,造成变形过程中粘度的增加。Doolittle方程[10]揭示出粘度与自由体积间存在以下关系:

由式(1)可以看出,粘度η随Vf的减小增长很快,而粘度η的增加提高了非晶抵抗变形的能力,从而使HV值增大。

400 K退火试样的XRD谱显示为完全非晶,但在同样的退火工艺条件,与350 K退火试样相比,其HV值却是减小的(图3)。这可能是因为试样在压头作用下产生了新的自由体积[14],此时整个体系的自由体积是增加的。伴随着自由体积的增加,变形过程中的粘度减小。由式(1)可以看出:粘度η随Vf的增加减小很快,而粘度η的减小降低材料抵抗变形的能力,从而使HV值减小。

475 K退火试样的HV值达到最小,是因为在晶化初期,析出相Cu10Zr7的体积分数较少,整个体系的特性还是以非晶的特性为主。在压头作用下,产生新的自由体积,在新的自由体积与析出相Cu10Zr7的共同影响下,合金具有很差的抵抗变形的能力,因此体现出很低的HV值。

600 K退火试样的HV值又开始增大,这是因为经过该温度退火后,原有的Cu10Zr7相不断长大,而且新的Cu10Zr7相不断形成,而且弥散分布于非晶基体上,因此试样为非晶和晶体的复合相。此时整个体系以晶体的特性为主,析出相Cu10Zr7的固溶强化和弥散强化作用使得合金具有较强的抵抗变形的能力,从而使合金的HV值增大[22]。

3.2 晶化过程的塑性变形及其机理

从实验结果可以看出:在纳米压头作用下,Cu基块状非晶在压痕周围可产生较大的塑性变形,这完全不同于其在单向拉伸或压缩条件下塑性变形极小的结果。

塑性变形量dn在很大程度上取决于原始自由体积量和其移动及再分配的速度[23]。另外,应力状态或几何约束条件也是影响塑性变形的重要因素[11]。当纳米压头作用于非晶合金表面时,紧靠其区域内的一部分原子被压入自由体积区。一方面,这些区的结构将发生偏振,同时伴随着一些不可恢复的变形,即在剪切带形成之前所产生的塑性变形;另一方面,在压头作用下将产生新的自由体积,这些自由体积被聚集到和压头具有一定方向的狭窄区域内。新的自由体积被聚集到狭窄的区域内后,由于压头周围的几何约束,使该区域未达到断裂所需足够软化程度就发生滑移。在压力的连续作用下,压痕周围会同时产生多个自由体积局域化的区域并产生滑移形成变形。这种渐进的变形过程形成了压痕周围的表面形貌,即多重圆环或多重剪切带,塑性变形过程即为:剪切带形成之前的塑性变形、自由体积的局域化和多重剪切带的形成和发展。这几个阶段塑性变形的积累构成了由载荷—位移曲线所反映的塑性变形量dn。由以上塑性变形过程可看出自由体积与塑性变形的关系,即平均自由体积越多,粘性流动单元就越多,塑性变形量dn就越大。

基于上述理论,本研究中试样经350 K等温退火后整个体系的自由体积减少很快,因此具有很小的dn值;试样经400 K等温退火后,整个体系的自由体积是增加的,此时的粘性流动单元也是增多的,因此dn值是增加的(图4),从压痕形貌也可以看出较大的塑性变形(图5);试样经475 K等温退火后,虽然有晶体相Cu10Zr7析出,但因为晶体相体积分数较小,整个体系的特性还是以非晶的特性为主。在压头作用下,产生新的自由体积,在新的自由体积与析出相Cu10Zr7的共同影响下,合金具有很差的抵抗变形的能力,因此体现出很大的dn值(图4),从压痕形貌也可以看出试样在压头作用下发生了很大的塑性变形(图6);试样经600 K等温退火后,析出相Cu10Zr7的固溶强化和弥散强化等作用使得合金具有较强的抵抗变形的能力,因此在压头作用下体现出较小的dn值。非晶在晶化过程中在多轴应力状态下的塑性变形是一个复杂的过程,因此建立塑性变形和自由体积间更完善的关系是今后亟待解决的问题。

4 结论

1) Cu基块状非晶晶化过程在纳米压头作用下体现弹—塑性变形方式,载荷位移曲线和压痕周边多重剪切带的特征证明了塑性变形的存在。

2) 350 K退火试样具有较大的压痕硬度HV和弹性模量E值及较小的塑性变形量dn值;400 K退火后,HV和E值显著减小,dn值明显增大;

3) 475 K退火后,有少量晶体相析出,但合金以非晶的特性为主,HV和E值继续减小,dn值继续增大;600 K退火后,晶体相进一步长大和析出,其固溶强化和弥散强化使合金的HV和E值有所增加,dn值略有减小。

REFERNECES

[1] Inoue A, Nishiyama N, Amiya K, et al. Ti-based amorphous alloys with a wide supercooled liquid region[J]. Mater Lett, 1994, 19(3/4): 131?135.

[2] 门 华, 徐 坚. Mg-Cu-Zn-Y块状金属玻璃的形成[J]. 金属学报, 2001, 37(12): 1243?1246.

MEN Hua, XU Jian. Formation of Mg-Cu-Zn-Y bulk metallic glass[J]. Acta Metallurgica Sinica, 2001, 37(12): 1243?1246.

[3] Calin M, Eckert J, Schultz L. Improved mechanical behavior of Cu-Ti-based bulk metallic glass by in situ forming of nanoscale precipitates[J]. Scripta Mater, 2003, 48(6): 653?658.

[4] Kim Y C, Lee J C, Cha P R, et al. Enhanced glass forming ability and mechanical properties of new Cu-based bulk metallic glasses[J]. Materials Science and Engineering, 2006, A437(2): 248?253.

[5] Johnson W L. Bulk glass-forming metallic alloys: Science and technology[J]. MRS Bull, 1999, 10(3): 42?56.

[6] Yokoyama Y, Fukaura K, Sunada H. Fatigue properties and microstructures of Zr55Cu30Al10Ni5 bulk glassy alloys[J]. Mater Trans JIM, 2000, 41(6): 675?680.

[7] Inoue A, Zhang T. Impact fracture energy of bulk amorphous Zr55Al10Cu30Ni5 alloy[J]. Mater Trans JIM, 1996, 37 (11): 1726?1729.

[8] Bruck H A, Rosakis A J, Johnson W L. The dynamic compressive behavior of beryllium bearing bulk metallic glasses[J]. J Mater Res, 1996, 11(2): 503?511.

[9] Vaidyanathan R, Dao M, Ravichandran G, et al. Study of mechanical deformation in bulk metallic glass through instrumented indentation[J]. Acta Mater, 2001, 49(18): 3781?3789.

[10] Schuh C A, Nieh T G. A nanoindentation study of serrated flow in bulk metallic glasses[J]. Acta Mater, 2003, 51(1): 87?99.

[11] 武晓峰, 张海峰, 李 宏, 等. Zr基大块非晶合金的微区变形及力学性能[J]. 中国有色金属学报, 2003, 13(6): 1369?1373.

Wu X F, Zhang H F, Li H, et al. Deformation and mechanical properties of Zr-based bulk metallic glasses under nanoindenter[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1368?1373.

[12] Greer A L, Castellero A, Madge S V, et al. Nanoindentation studies of shear banding in fully amorphous and partially devitrified metallic alloys[J]. Materials Science and Engineering, 2004, A375/377: 1182?1185.

[13] Drozdz D, Kulik T, Fecht H J. Nanoindentation studies of Zr-based bulk metallic glasses[J]. Journal of Alloys and Compounds, 2007, 441(1/2): 62?65.

[14] Jiang Q K, Nie X P, Jiang J Z, et al. Room-temperature nanoindentation measurements of La-based bulk metallic glass[J]. Scripta Materialia, 2007, 57(2): 149?152.

[15] Bhowmick R, Raghavan R, Chattopadhyay K, et al . Plastic flow softening in a bulk metallic glass[J]. Acta Materialia, 2006, 54(16): 4221?4228.

[16] Liu L, Chan K C. Plastic deformation of Zr-based bulk metallic glasses under nanoindentation[J]. Materials Letters, 2005, 59(24/25): 3090?3094.

[17] Lubhorsky F E. 非晶态合金[M]. 柯 成, 唐与湛, 罗阳, 等译. 北京: 冶金工业出版社, 1989: 250?340.

Luborsky F E. Amorphous metallic alloys[M]. KE Chen, TANG Yu-zhan, LUO Yan, et al, transl. Beijing: Metallurgy Industry Press, 1989: 250?340.

[18] Xing L Q, Bertrand C, Dallas J D. Nanocrystal evolution in bulk amorphous Zr57Cu20Al10Ni8Ti5 alloy and its mechanical properties[J]. Mater Sci Eng A, 1998, 241: 216?225.

[19] Chen H S, Inoue A, Masumoto T. Two-stage enthalpy relaxation behaviour of (Fe0.5Ni0.5)83P17 and (Fe0.5Ni0.5)83B17 amorphous alloys upon annealing[J]. J Mater Sci, 1985, 20(7): 2417?2438.

[20] Cohen M H, Grest G S. Liquid-glass transition, a free-volume approach[J]. Phys Rev B, 1979, 20(3): 1077?1098.

[21] Grest G S, Cohen M H. Liquid-glass transition: Dependence of the glass transition on heating and cooling rates[J]. Phys Rev B, 1980, 21(9): 4113?4117.

[22] 苏 勇, 无 炜, 陈翌庆, 等. 非晶Al-Y-Nd-Ni合金的晶化行为[J]. 特种铸造及有色合金, 2004, 1: 24?25.

Su Y, Wu W, Chen Y Q, et al. Crystallization behavior of amorphous Al-Y-Nd-Ni alloy[J]. Special Casting & Nonferrous Alloys, 2004, 1: 24?25.

[23] Spaepen F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses[J]. Acta Metall, 1982, 30(7): 447?452.

基金项目:国家自然科学基金资助项目(50371016)

收稿日期:2007-01-22;修订日期:2007-07-13

通讯作者:寇生中,教授,博士;电话:0931-2973942;E-mail: kousz@lut.cn

(编辑 陈爱华)