Parametric optimization of electrochemical machining of Al/15% SiCp composites using NSGA-Ⅱ

C. SENTHILKUMAR1, G. GANESAN1, R. KARTHIKEYAN2

1. Department of Manufacturing Engineering, Annamalai University, Annamalai Nagar – 608002, Tamilnadu, India;

2. Department of Mechanical Engineering, BITS, Dubai

Received 8 November 2010; accepted 12 April 2011

Abstract: Electrochemical machining (ECM) is one of the important non-traditional machining processes, which is used for machining of difficult-to-machine materials and intricate profiles. Being a complex process, it is very difficult to determine optimal parameters for improving cutting performance. Metal removal rate and surface roughness are the most important output parameters, which decide the cutting performance. There is no single optimal combination of cutting parameters, as their influences on the metal removal rate and the surface roughness are quite opposite. A multiple regression model was used to represent relationship between input and output variables and a multi-objective optimization method based on a non-dominated sorting genetic algorithm-II (NSGA-II) was used to optimize ECM process. A non-dominated solution set was obtained.

Key words: electrochemical machining; metal removal rate; surface roughness; non-dominated sorting genetic algorithm (NSGA-II)

1 Introduction

Metal matrix composites (MMC) are gaining increasing attention for applications in aerospace, defense, and automobile industries. These materials have been used in automobile brake rotors and various components in internal combustion engines. The limitation of MMC is that the machining of these composites is very difficult due to the highly abrasive nature of ceramic reinforcements [1]. Non-conventional machining techniques, such as electro-discharge machining (EDM), laser beam machining (LBM), electron beam machining (EBM) and electrochemical machining (ECM) have been utilized for machining [2]. Electrochemical machining (ECM) is a non-traditional process used mainly to cut hard or difficult metals, where the application of a traditional process is not convenient [3]. Optimization techniques are required to identify the optimal combination of parameters for maximizing the ASOKAN et al [4] optimized metal removal rate (MRR) and minimizing the surface roughness in ECM process. Quite a few researchers have tried to optimize the machining performance by adopting different optimization techniques. ASOKAN et al [4] optimized metal removal rate and surface finish with grey relational analysis and ANN model. ANN model gave a better prediction based on the deviation between training and testing data sets. MUNDA and BHATTACHARYYA [5] determined the optimal combination of the machining parameters and their combination effects on the desired response criteria. The optimality search model under the various process variable conditions for maximizing the metal removal rate, minimizing the radial over cut (ROC) value of various machined workpieces was formulated based on the response surface methodology (RSM). In single objective optimization, one attempts to obtain the best design or decision, which is usually the global minimum or maximum depending on the optimization problem. In the case of multiple objectives, there may be one solution, which is the best with respect to all objectives. In ECM process, it is difficult to find a single optimal combination of parameters for both MRR and surface roughness as the parameters influence them differently. Hence, there is a need for a multi-objective optimization method to arrive at the solutions to this problem. Classical methods for solving multi-objective problem suffer from drawback. These methods transform the multi-objective problem into single objective by assigning some weights based on their relative importance [6]. Also these classical methods fail when the function becomes discontinuous. Since genetic algorithm (GA) is a good tool for solving multi-objective optimization and it works with a population of points, it seems natural to use multi-objective GA in ECM process to determine the optimal solution point from the best performance to capture a number of solutions simultaneously. Multi-objective genetic algorithm (MOGA), vector evaluated genetic algorithm (VEGA), non-dominated sorting genetic algorithm (NSGA) and (NSGA-II) are examples of GA based multi-objective solution methods. The non-dominated sorting GA-II (NSGA-II) is a fast, elitist multi-objective genetic algorithm that is widely used for generating the Pareto frontier. Its main advantage in solving multi-objective problems is that it leads the search toward the global Pareto front while maintaining diversity of the solution set along that front. In the present work, the experiments are designed using central composite rotatable design (CCD). From the experimental data, multiple regression models for the metal removal rate and surface roughness (Ra) are developed. The machining parameters, electrolyte concentration, electrolyte flow rate, applied voltage and tool feed rate, are optimized using NSGA-II algorithm to maximizing MRR and minimizing surface roughness.

2 Experimental

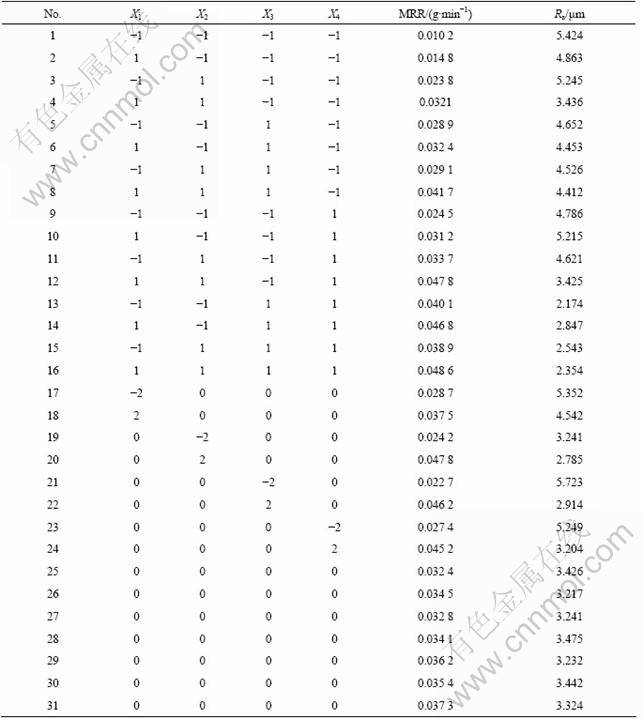

The work material used for the present investigation is LM 25Al/15%SiCp composites with dimensions of 30 mm in diameter and 6 mm in height. The composites were manufactured by a stir casting method. The experiments were planned using CCD for the design of experiments (DOE), which helps to reduce the number of experiments. Since the considered factors were multi-level variables whose outcome effects were not linearly related, it was decided to use five-level test for each factor. The machining parameters used and their levels are presented in Table 1. The ECM experiments were conducted in METATECH ECM equipment. The tool was made up of copper with a square cross section. The electrolyte used for experimentation was fresh sodium nitrate (NaNO3) solution with varying electrolyte concentration due to its less throwing power. Experiments were conducted according to central composite second order rotatable design (CCD) as depicted in Table 2. In the present study, the machining performance was evaluated by the following responses.

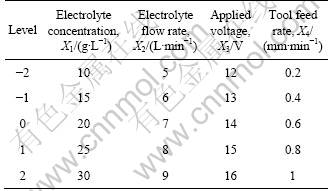

Table 1 Original values of machining parameters

2.1 Metal removal rate

Metal removal rate (MRR) is one of the most important criterion determining the machining operation, with a higher rate always preferred in such operations. The metal removal rate is calculated using the following expression:

(1)

(1)

2.2 Average surface roughness

Surface finish is another important aspect in the machining of composites. The average surface roughness (Ra), which is mostly used in industry, was taken up for the present study. The roughness was measured with a sampling length of 10 mm. The average surface roughness was measured using a Talysurf tester. The experimental results are presented in Table 3.

3 Statistical modeling

The statistical models based on the second-order polynomial equations were developed for MRR and Ra using the experimental results and are given below:

MRR =-0.5256+0.00028X1+ 0.0459X2 +0.0419X3+

0.1029X4-0.000028 X12 +0.000023 X22-

0.000036X32 +0.00244 X42+0.000354 X1X2-

0.000079X1X3+0.00019 X1X4-0.00323X2X3-

0.00596X2X4-0.1002X3X4 (2)

Ra=73.0472-1.0145X1-0.8046X2-8.0862X3+

20.103X4+0.0157X12-0.0918X22+0.2346X32+

5.2893X42-0.0456X1X2+0.0413X1X3+0.15X1X4+

0.2044X2X3-0.0956X2X4-2.2513X3X4 (3)

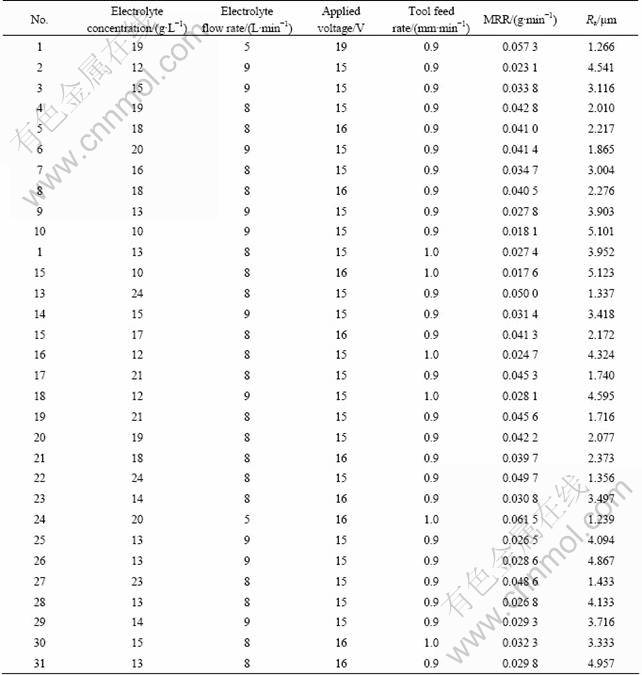

Table 2 Experimental data according to central composite second order rotatable design

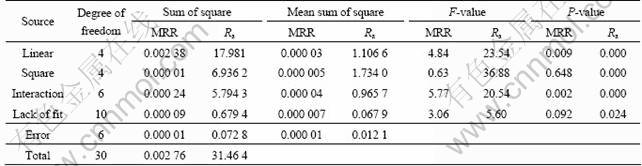

Table 3 Test results of ANOVA

4 Optimization

To optimize the cutting parameters in the machining of GFRP composites, a non-dominated sorting genetic algorithm was used. The objective sets for the present study were as follows: 1) Maximization of the metal removal rate; 2) Minimization of average surface roughness (Ra).

The two-objective genetic algorithm optimization method used is a fast, elitist non-dominated sorting genetic algorithm (NSGA-II) developed by DEB et al [7]. This algorithm uses the elite-preserving operator, which favors the elites of a population by giving them an opportunity to be directly carried over to the next generation [8].

5 NSGA-II algorithm

The non-dominated sorting genetic algorithm has been criticized for its high computational complexity, lack of elitism and its choice of the optimal parameter value for sharing parameter σ. The NSGA-II is a modified version, which has a better sorting algorithm, incorporates elitism and does not require the choosing of a sharing parameter a priori. There are two key concepts in NSGA-II: a fast non-dominated sorting of the population and a crowding distance.

5.1 Non-dominated sort

The initialized population is sorted based on non-domination. The non-domination is an individual and is said to dominate another if its objective function is no worse than the other and at least in one of its objective functions is better than the other. The fast-sort algorithm was described in Ref. [9]:

5.2 Crowding distance

In NSGA-II, in addition to the fitness value, a new parameter called “crowding distance” is calculated for each individual. The crowding distance is a measure of how close an individual to its neighbors. Crowding distance is assigned front wise: comparing the crowding distance between two individuals in a different front is meaningless. The basic idea behind the crowding distance is finding the Euclidean distance between each individual in a front based on their m objectives in m-dimensional hyperspace. Initially, a random parent population of P0, of size N is generated. The population is sorted based on non-domination level. Each solution is assigned a fitness level, and the best level is 1. Thus, minimization of fitness is assumed. Binary tournament selection, recombination and mutation operators are implemented to generate the child Q0, of size N. The procedure for the remaining generation (for t ≥ 1) can be found in Ref. [7].

6 Discussion

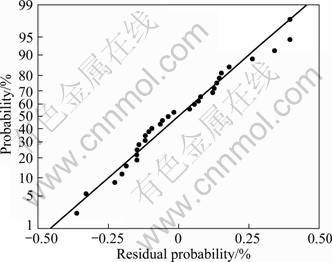

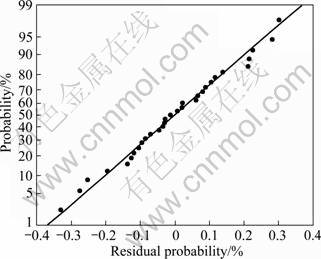

The electrochemical machining characteristics of LM25Al/SiCp composites were studied. The second- order polynomial models were developed for MRR and Ra. The MRR was calculated using Eq. (1). The fit summary indicates that the quadratic model is statistically significant for analysis of MRR. The value of R2 is over 95%, which indicates that the developed regression model is adequately significant at a 95% confidence level. It provides an excellent relationship between the machining parameters and the MRR. An analysis of variance (ANOVA) was performed for MRR and the results are presented in Table 3. The normal probability plot for MRR is presented in Fig.1. It can be noticed that the residuals fall on a straight line, which means that the errors are normally distributed and the regression model is well fitted with the observed values. Similarly, the value of R2 for Ra is 97%, which means that the regression model provides an excellent explanation of the relationship between the independent variables (factors) and the response Ra. The associated P-value for the model is lower than 0.05 (i.e. level of significance α=0.05, or 95% confidence), which indicates that the model can be considered statistically significant. The ANOVA table for the quadratic model for Ra is presented in Table 3. Figure 2 displays the normal probability plot for Ra. It is observed that the residuals are distributed normally and in a straight line, and hence the model is adequate.

Fig. 1 Normal probability plot for MRR

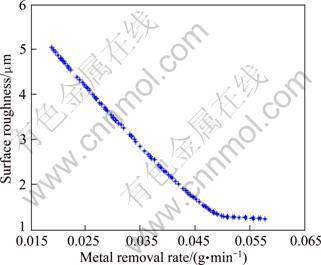

In the present work, a non-dominated sorting genetic algorithm, NSGA-II, was used to optimize multiple performances using the second-order models created. The NSGA-II algorithm ranked the individuals based on dominance. The details are given in section 5 and also in Ref. [7]. The control parameters in NSGA-II were adjusted to obtain the best performance. The parameters used are: probability of crossover of 0.9 with distribution index of 20, mutation probability of 0.25 and population size of 100. It was found that the above control parameters produce better convergence and distribution of optimal solutions. The 1 000 generations were generated to obtain the true optimal solution. The non-dominated solution set obtained over the entire optimization is shown in Fig. 3. This figure shows the formation of the Pareto front leading to the final set of solutions. 31 out of 100 sets were presented in Table 4. Since none of the solutions in the non-dominated set is absolutely better than any other, any one of them is the “better solution”. As the best solution can be selected based on individual product requirements, therefore the process engineer must select the optimal solution from the set of available solutions. If the engineer desires to have a better surface finish, higher metal removal rate, a suitable combination of variables can be selected from Table 4. From the experimental results presented in Table 2, the parameters listed in the experiment number 13 lead to minimum Ra of 2.174 ?m and the corresponding MRR of 0.040 1 g/min, where the electrolyte concentration, electrolyte flow rate, applied voltage and tool feed rate are 15 g/L, 6 L/min, 15 V and 0.8 mm/min, respectively. By using NSGA-II, the optimized Ra value very close to the experimental value has been selected from Table 4. For trail No. 15, the Ra value is 2.172 ?m and the corresponding MRR is 0.413 g/min, and the pertinent parameters are electrolyte concentration, electrolyte flow rate, applied voltage and tool feed rate, which are 17 g/L, 8 L/min, 16 V and 0.9 mm/min, respectively. This indicates that the values obtained from the optimization technique are in close agreement with the experimental values and more or less for the same parameter settings.

Fig. 2 Normal probability plot for Ra

Fig. 3 Optimal chart obtained through NSGA-II

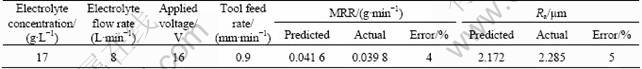

The verification of the test results under the selected optimum conditions for the cases of MRR and Ra are shown in Table 5. The predicted machining performance is compared with the actual machining performance and a good agreement is obtained between their performance. From the analysis of Table 5, it can be observed that the calculated error is small. The error between the experimental and the predicted values for MRR and Ra lie within 4% and 5%, respectively. Obviously, this confirms excellent reproducibility of the experimental conclusions.

7 Conclusions

1) The ECM process parameters were optimized by using non-dominated sorting genetic algorithm (NSGA-II), and a non-dominated solution set was obtained. The second order polynomial models developed for MRR and Ra were used for optimization.

2) The choice of one solution over the other depends on the process engineer’s requirements. If the requirement is a better Ra or higher MRR, a suitable combination of variables can be selected.

3) The optimized value of Ra obtained through NSGA-II is 2.172 ?m and the corresponding MRR is 0.413 g/min, and the pertinent parameters are electrolyte concentration, electrolyte flow rate, applied voltage and tool feed rate, which are 17 g/L, 8 L/min, 16 V and 0.9 mm/min, respectively.

4) Optimization will help to increase production rate considerably by reducing machining time. The objectives such as MRR and Ra were optimized using a multi-objective optimization method, non-dominating sorting genetic algorithm-II. A Pareto-optimal set of 100 solutions was obtained.

Table 4 Optimal combinations of parameters for ECM process

Table 5 Validation test results for electrochemical machining of Al/15%SiCp composite using NaNO3

References

[1] MOHAN B, RAJADURAI A, SATYANARAYANA KG. Electric discharge machining of Al/SiCp metal matrix composites using rotary tube electrode [J]. Journal of Materials Processing Technology, 2004, 153-154: 978-985.

[2] ZHANG Z, ZHU D, QU N, WANG M. Theoretical and experimental investigation on electrochemical micromachining [J]. Microsystem Technology, 2007, 13: 607-612.

[3] EBEID S J, HEWIDY M S, TAWEEL T A E I, YOUSSEF A H. Towards higher accuracy for ECM hybridized with low frequency vibrations using the response surface methodology [J]. Journal of Materials Processing Technology, 2004, 149: 432-438.

[4] ASOKAN P, RAVI KUMAR R, JEYAPAUL R, SANTHI M. Development of multi-objective optimization models for electrochemical machining process [J]. International Journal of Advanced Manufacturing Technology, 2008, 39: 55-63.

[5] MUNDA J, BHATTACHARYYA B. Investigation into electrochemical micromachining (EMM) through response surface methodology based approach [J]. International Journal of Advanced Manufacturing Technology, 2008, 35: 821-832.

[6] KURIAKOSE S, SHUNMUGAM M S. Multi-objective optimization of wireelectro discharge machining process by non-dominated sorting genetic algorithm [J]. Journal of Materials Processing Technology, 2005, 170: 133-141.

[7] DEB K, PRATAP A, AGARWAL S, MEYARIVAN T. A fast and elitist multiobjective genetic algorithm: NSGA-II [J]. IEEE Transactions on Evolutionary Computation, 2002, 6(2): 182-197.

[8] FU B. Piezo electric actuator design via multiobjective optimization methods [D]. Germany: University of Paderborn, 2005.

[9] SESHADRI A. A fast elitist multi-objective genetic algorithm NSGA-II [EB/OL]//http://www.mathworks.com. Internet specification. [2007].

基于需求分类遗传算法的Al/15% SiCp复合材料

电化学加工工艺参数的优化

C. SENTHILKUMAR1, G. GANESAN1, R. KARTHIKEYAN 2

1. Department of Manufacturing Engineering, Annamalai University, Annamalai Nagar – 608002, Tamilnadu, India;

2. Department of Mechanical Engineering, BITS, Dubai

摘 要:电化学加工(ECM)是一种重要的非传统加工工艺,主要用于加工难加工材料和错综复杂的型材。作为一个复杂的过程,很难确定最优参数去改善切削性能。金属去除率和表面粗糙度是最重要的输出参数,决定切削性能。由于切削参数对金属去除率和表面粗糙度的影响不一致,从而没有简单的切削参数的最佳组合。 用多元回归模型来表示输出与输入变量之间的关系,并用基于需求分类遗传算法 (NSGA-II)的多目标优化方法来优化ECM过程,得到一个需求解集。

关键词:电化学加工;金属去除率;表面粗糙度;需求分类遗传算法(NSGA-II)

(Edited by YANG Hua)

Corresponding author: C. SENTHILKUMAR; E-mail: csmfg_au@yahoo.com

DOI: 10.1016/S1003-6326(11)61010-8