文章编号:1004-0609(2015)08-2091-08

酒石酸钠体系阳极氧化对TB8钛合金薄板疲劳性能的影响

余永水1,谢兰生1,陈明和1,黄 珺2,洪海华2

(1. 南京航空航天大学 机电学院,南京 210016;

2. 中国直升机设计研究所,景德镇 333001)

摘 要:采用以酒石酸钠为成膜剂的电解体系对0.5 mm厚的TB8钛合金薄板进行阳极氧化处理,采用扫描电镜(SEM)观察疲劳断口及氧化膜的显微形貌,采用X射线衍射仪(XRD)、能谱分析仪(EDS)对覆在钛合金基体上的阳极氧化膜进行物相分析,研究以酒石酸钠为成膜剂的TB8钛合金薄板阳极氧化疲劳断裂机理。结果表明:阳极氧化处理后,表面形成了一层厚2 μm左右的均匀致密的氧化膜,氧化膜主要由金红石型与锐钛型TiO2混合晶体组成;阳极氧化处理可有效去除表面缺陷,降低了裂纹源的萌生及疲劳裂纹的扩展速率,使疲劳条纹更加均匀细致;以酒石酸钠为成膜剂制备的TB8钛合金薄板经阳极氧化处理,在疲劳寿命为1×104下,其疲劳强度相对于母材的提高了44%左右。

关键词:TB8钛合金;阳极氧化;疲劳性能;断口形貌

中图分类号:TG115.5;TG146.2 文献标志码:A

Effects of anodic oxidation on fatigue property of TB8 titanium alloy sheet in sodium tartrate electrolyte

YU Yong-shui1, XIE Lan-sheng1, CHEN Ming-he1, HUANG Jun2, HONG Hai-hua2

(1. College of Mechanic and Electronic Engineering, Nanjing University of Aeronautics and Astronautics,

Nanjing 210016, China;

2. China Helicopter Research and Development Institute, Jingdezhen 333001, China)

Abstract: Anodic oxidation of 0.5 mm-thickness TB8 titanium alloy sheet in the electrolyte system with sodium tartrate as film-forming agent was investigated. The microstructures of the fatigue fracture and the anodic oxide films were observed by scanning electron microscopy (SEM). Meanwhile, the phase composition of the oxide films on the titanium alloy substrate was determined by X-ray diffractometry (XRD) and energy dispersive spectrometry (EDS).The fatigue fracture mechanism of both unanodized and anodized TB8 titanium alloy sheet was investigated in the film-forming agent of sodium tartrate. The results show that, a uniform dense oxide film about 2 μm-thickness forms on the surface after anodic oxidation, the coating is composed of rutile TiO2 and anatase TiO2. The surface defects are eliminated effectively, the initiation and propagation rate of the crack source reduce, resulting in the fatigue striations more uniform and detailed. The fatigue strength of TB8 titanium alloy sheet after anodic oxidation in the film-forming agent of sodium tartrate, increases by about 44%, compared with the base metal at the fatigue life of 1×104 cycles.

Key words: TB8 titanium alloy; anodic oxidation; fatigue property; fracture morphology

钛合金是一种密度小、耐腐蚀性好、比强度高的结构和功能材料,具有非常优越的耐高温性能和易钝化性能,被广泛应用于工业生产中,尤其是在航空航天、石油化工、医药等诸多领域[1]。TB8钛合金是国家“九五”期间重点科技攻关研制的一种超高强度钛合金,与美国在20世纪90年代研制的钛合金β21S相似,具有良好的抗氧化性能、耐蚀性能和综合力学性能的新型亚稳态β钛合金,是理想的结构材料,具有广阔的应用前景[2-4]。

随着钛合金的广泛应用,对钛合金的各项性能提出了更高的要求。利用阳极氧化技术在其表面制备出一层纳米TiO2阳极氧化膜,可以进一步提高钛合金的耐蚀性、耐磨性及生物相容性,已成为近年来研究的热点[5-8]。通过调节阳极氧化的电压、时间、电解液成分等参数,可以改变氧化膜的组成、结构以及厚度,从而提高阳极氧化膜的性能[9-11]。在传统的阳极氧化研究中,大多采用硫酸-磷酸为成膜剂的电解体系,该类成膜剂呈酸性,易在钛合金材料的应用中产生氢脆,影响其力学性能。而采用碱性阳极氧化工艺则不会产生氢脆现象,同时碱性阳极氧化方法更加经济、环保[12]。

疲劳性能是衡量结构材料的重要性能指标,任何影响疲劳性能的因素都会受到重视,阳极氧化对钛合金疲劳性能的影响同样受到人们的关注。近几年来国内外学者对钛合金阳极氧化疲劳性能开展了广泛的研究[13-14]。刘建华等[15]采用以酒石酸钠为成膜剂的电解液对TC18钛合金进行阳极氧化,相对于传统硫酸-磷酸阳极氧化其疲劳性能得到了一定的改善,与母材基本相接近。CHEN等[16]采用水热处理的方法对钛合金阳极氧化进行处理,其疲劳性能相对于母材提高了12%左右。EBRAHIMI等[17]对Ti-4Al-2V钛合金在600℃环境中热氧化处理2 h,其疲劳性能相对于母材也得到了一定的提高。然而目前对钛合金阳极氧化疲劳性能的研究大多集中于棒材或厚度大于1.5mm的板材[15-18] ,对钛合金薄板阳极氧化疲劳性能的研究却尚未报道。

本文作者选用厚度小于1 mm的钛合金薄板为研究对象,采用以酒石酸钠为主盐的碱性电解液,对0.5 mm厚的TB8钛合金薄板进行阳极氧化处理,在薄板表面形成一层均匀致密的氧化膜,研究该阳极氧化膜的形貌、成分及相组成,对比测试TB8钛合金薄板母材及阳极氧化处理后试样的拉伸性能和疲劳性能,并分析其疲劳断裂机制。

1 实验

1.1 试样的制备

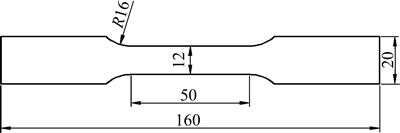

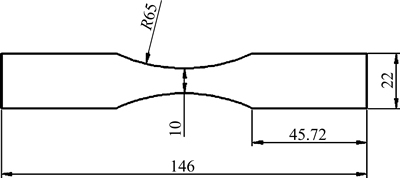

本试验所用TB8钛合金薄板由北京航空材料研究院提供,其名义成分(质量分数)为Ti-15Mo-3Al- 2.7Nb-0.2Si. 试验的板材厚度为0.5 mm,拉伸试验的试样尺寸按照GB/T 228.1—2002《金属材料拉伸试验第1部分:室温试验方法》设计,尺寸示意图如图1所示。疲劳试验的试样尺寸按照GB/T 26076—2010《金属薄板(带)轴向力控制疲劳试验方法》[19]设计,尺寸如图2所示。

图1 TB8钛合金薄板拉伸试样几何形状及尺寸示意图

Fig. 1 Shape and dimension of tensile sample of TB8 titanium alloy sheet (Unit: mm)

图2 TB8钛合金薄板疲劳试样几何形状及尺寸

Fig. 2 Shape and dimension of fatigue sample of TB8 titanium alloy sheet (Unit: mm)

在进行阳极氧化试验之前,对试样表面进行清洁处理,处理工艺为碱洗-水洗-酸洗-水洗-吹干,以达到表面除油、除污的目的,待阳极氧化试验。

阳极氧化试验采用HB1700型阳极氧化直流稳压电源,将TB8钛合金作为阳极,1Cr18Ni8Ti不锈钢板作为阴极,阳极与阴极面积比不低于1:2。电解液采用以酒石酸钠为主盐的水溶液,其成分如下:65 g/L酒石酸钠(C4H4O6·Na2·2H2O)、300 g/L NaOH、30 g/L乙二胺四乙酸(C10H16N2O8)、6 g/L硅酸钠(NaSiO3·9H2O)。试验过程中采用恒压阳极氧化法,电压为10 V,时间为15 min,电流密度为5~8 A/dm2,采用磁力搅拌均匀电解液。

1.2 试验方法

在SDS-50电液伺服动静试验机上,分别对母材及经过阳极氧化处理的试样进行拉伸及疲劳性能测试。拉伸试验测试过程按照GB/T 228.1—2002拉伸试验国家标准进行,拉伸速率为0.001 mm/s,试验温度为室温。疲劳试验测试过程按照GB/T 26076—2010薄板疲劳试验国家标准进行,采用轴向力控制疲劳试验,应力比R=0.1,加载频率f=15 Hz,载荷为正弦波控制。试验选取的最大应力以母材及经阳极氧化处理的静拉伸强度为依据,取抗拉强度的45%~85%为最大应力,测定不同应力水平下的疲劳寿命。

采用扫描电子显微镜(Scanning electron microscope, SEM, JSM-6360LV)对母材及经过阳极氧化处理的试样表面、氧化膜及疲劳断口形貌进行观察,采用JSM-6360LV自带的能谱仪(Energy dispersive spectrometer, EDS)对阳极氧化膜的化学成分进行分析,并利用X射线衍射(X-ray diffraction, XRD, D/MAX-2400)分析氧化膜及母材的相组成,扫描速度为0.02 (°)/s。

2 结果与分析

2.1 阳极氧化膜的形貌

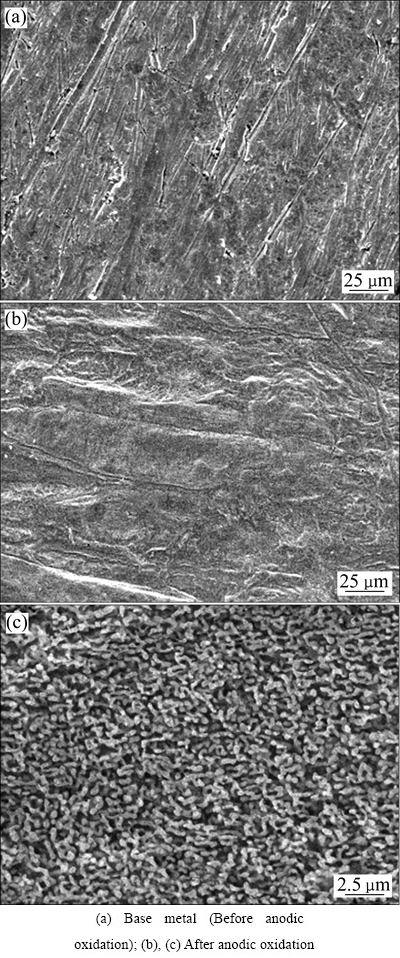

图3所示为TB8钛合金在以酒石酸钠为主盐的电解体系中,氧化时间15 min、电压10 V的阳极氧化前后的表面形貌。由图3(a)可以看出,在未经过阳极氧化处理之前,TB8钛合金表面有明显的沟槽样的划痕。由图3(b)和(c)可以看出,经过阳极氧化处理后,TB8钛合金表面划痕明显减少,形成一层较为均匀致密且孔径细小的氧化膜。

钛合金对其表面缺陷具有很强的敏感性,但经过阳极氧化处理后,钛合金表面被一层微纳米级的氧化膜覆盖,将容易产生应力集中或出现疲劳源的尖锐区域钝化,表面特征得到了很大的改善,因此,阳极氧化处理能有效去除钛合金材料表面缺陷,是提高钛合金材料表面完整性的有效方法。

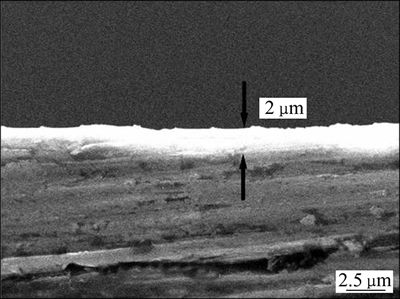

阳极氧化处理中,随着氧化时间的延长和氧化电压的升高,氧化膜逐渐生长并变厚,氧化膜厚度一般可达10 nm~30 μm,但过厚的氧化膜将不保持在同一水平面上,呈高低起伏状,且易于分层脱落,影响钛合金的性能[20]。图4所示为TB8钛合金在以酒石酸钠为主盐的电解体系中,氧化时间15 min、电压10 V条件下的阳极氧化膜的截面SEM像,由图4可以看出,氧化膜的厚度为2 μm左右,且氧化膜表面较为平整。

2.2 阳极氧化膜的相组成及成分分析

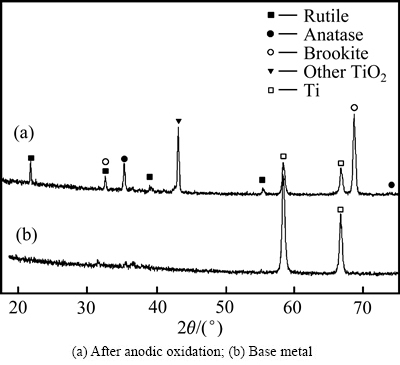

图5所示为TB8钛合金薄板母材和经阳极氧化处理的氧化膜XRD谱。由图5可以看出,氧化膜中锐钛型TiO2和金红石型TiO2的衍射峰都比较明显,不同晶面的衍射峰也十分明显,说明在钛合金基体表面上生成的是以金红石型TiO2和锐钛型的TiO2晶体为主的氧化膜,且其晶体的硬度高于无定型TiO2氧化膜的[7]。此外,还含有板钛型及其他形式的TiO2氧化膜,相比无固定形状排列的表面,氧化膜层具有更好的性能。

图3 TB8钛合金阳极氧化处理前后表面SEM像

Fig. 3 SEM images of TB8 titanium alloy surface before and after anodic oxidation

图4 TB8钛合金表面阳极氧化膜截面SEM像

Fig. 4 SEM image of cross section of anodic oxidation films on TB8 titanium alloy surface

图5 TB8钛合金阳极氧化前后的XRD谱

Fig. 5 XRD patterns of TB8 titanium alloy before and after anodic oxidation

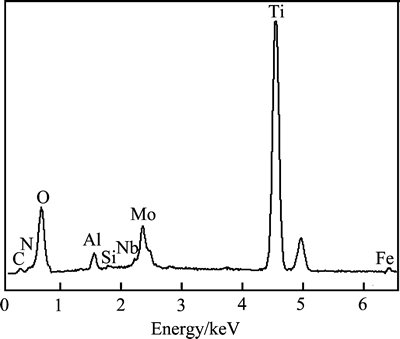

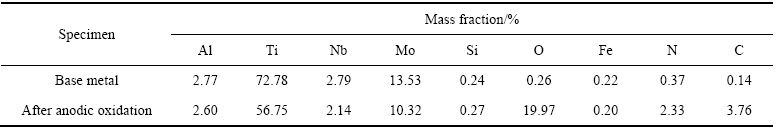

图6 所示为TB8钛合金阳极氧化后的氧化膜EDS谱,可以检测出氧、铝、钛、钼等元素,表1所列为阳极氧化前后的表面化学成分比较,由表1可知,经过阳极氧化处理后,TB8钛合金表面氧的相对含量增加了19.71%(质量分数),Ti的相对含量减少了16.03%。结合TB8钛合金阳极氧化前后的XRD分析(见图5),可以进一步说明氧化膜的主要成分为TiO2,也可能含有少量的低价钛及铝的氧化物。

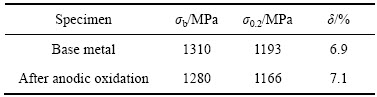

2.3 拉伸性能

经过阳极氧化处理后,钛合金表面形成一层均匀致密的阳极氧化膜,可以进一步提高钛合金的耐腐蚀性、耐磨性等性能,但该氧化膜是一陶瓷材料,与其基体材料尤其是超薄板的力学性能差异大,可能会影响钛合金板材的力学性能。因此,需要对母材和阳极氧化处理后的试样进行拉伸试验,测定其室温拉伸性能,试验结果如表2所列。

由表2可知,阳极氧化处理后TB8钛合金试样的抗拉强度为母材的97.71%,下降2.19%;屈服强度为母材的97.73%,下降2.27%。这表明在静载下,经过阳极氧化处理后TB8钛合金薄板的力学性能与母材的相接近,阳极氧化处理并未对TB8钛合金薄板的力学性能产生较大的影响。

图6 TB8钛合金表面阳极氧化膜的EDS谱

Fig. 6 EDS spectrum of anodic oxidation films on TB8 titanium alloy surface

2.4 疲劳性能分析

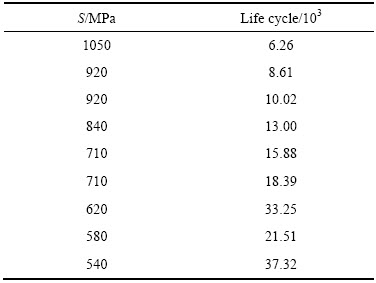

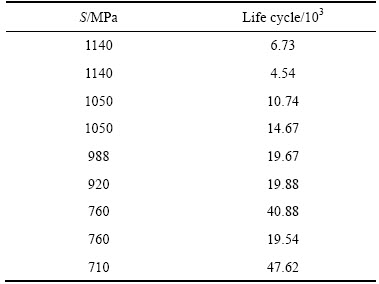

TB8钛合金薄板母材及经阳极氧化处理试样的疲劳试验结果如表3和4所列。可认为疲劳寿命和应力水平之间满足双对数线性关系[21],即S-N曲线可采用最常用的幂指数式表示: 。其中:m为待定系数;C为常数。两边取对数即可得到在双对数坐标下母材的S-N曲线线性回归模型:

。其中:m为待定系数;C为常数。两边取对数即可得到在双对数坐标下母材的S-N曲线线性回归模型:

(1)

(1)

式中:S为应力控制试验的最大应力 ;N为失效循环数;a和b为待定系数。

;N为失效循环数;a和b为待定系数。

表1 TB8钛合金阳极氧化前后的表面化学成分比较

Table 1 Comparison of surfaces chemical composition of TB8 titanium alloy before and after anodic oxidation

表2 TB8钛合金阳极氧化前后的拉伸试验结果

Table 2 Tensile test results of TB8 titanium alloy before and after anodic oxidation

表3 TB8钛合金母材疲劳试验结果

Table 3 Fatigue test results of TB8 titanium alloy

表4 TB8钛合金阳极氧化处理后试样的疲劳试验结果

Table 4 Fatigue test results of TB8 titanium alloy after anodic oxidation

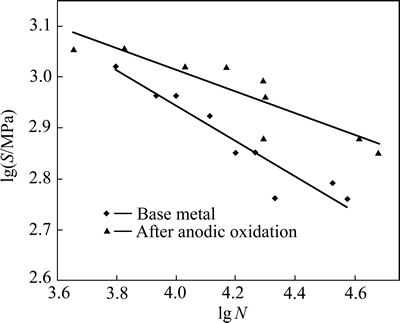

根据表3和4的数据,可得到母材和阳极氧化处理的S-N曲线如图7所示。根据式(1)可得母材和阳极氧化处理后T8钛合金的S-N线性方程为

对于母材:

(2)

(2)

对于经阳极氧化处理后TB8钛合金试样:

(3)

(3)

从图7中两条S-N曲线的变化趋势看,经阳极氧化处理试样的疲劳寿命在相同应力水平下要高于母材的疲劳寿命,在相同疲劳寿命下,经阳极氧化处理试样的疲劳强度要高于母材的。TB8钛合金薄板母材及经阳极氧化处理试样的疲劳强度均随着循环次数的增大而降低。而阳极氧化处理试样的疲劳曲线的斜率小于母材的,说明随着循环次数的增加,阳极氧化处理试样的疲劳强度降低的程度要小于母材疲劳强度降低的程度。两条曲线有相交的趋势,表明在低应力条件下,阳极氧化处理试样对疲劳性能有显著的影响,随着应力的升高,阳极氧化处理对疲劳性能的影响逐渐减小。

图7 TB8钛合金母材与经阳极氧化处理试样的疲劳寿命S-N曲线

Fig. 7 Fatigue life S-N curves of unanodized and anodized TB8 titanium alloy

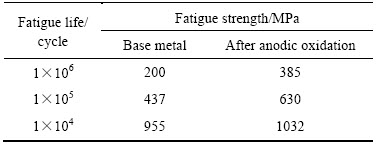

由S-N线性方程(见式(2)和(3)),在疲劳寿命周期为1×106、1×105和1×104下,可得TB8钛合金母材及经阳极氧化处理试样的疲劳强度(见表5)。由表5可以看出,经过阳极氧化处理试样的,疲劳性能得到了明显改善,在疲劳寿命周期分别为1×106、1×105和1×104下,经过阳极氧化处理试样的疲劳强度分别为母材的1.93、1.44、1.08倍;当疲劳寿命周期增大时,经过阳极氧化处理试样的疲劳强度比母材的疲劳强度高。

表5 指定疲劳寿命下TB8钛合金母材与经阳极氧化疲劳强度对比

Table 5 Comparison of fatigue strength of unanodized and anodized TB8 titanium alloy in definite fatigue life

2.5 疲劳断口形貌分析

2.5.1 典型疲劳源附近断口形貌

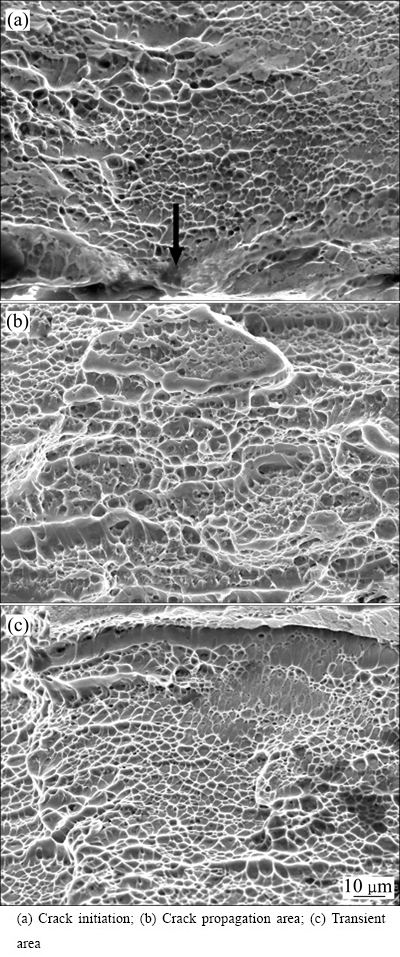

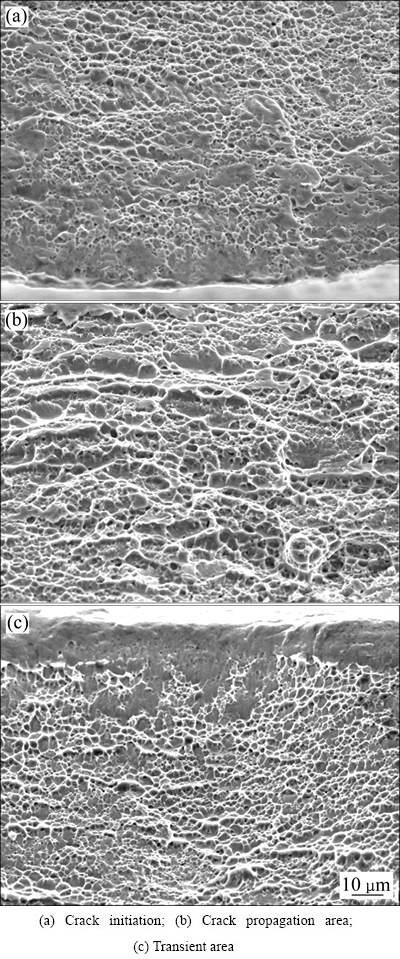

为了进一步分析经阳极氧化处理试样和母材疲劳断裂的特征,对加载平均应力为710MPa的试样断口的形貌进行了观察与分析(见图8和9)。疲劳裂纹起始位置可能出现在夹杂物、材料表面缺陷及次表面缺陷处[22]。图8(a)和图9(a)所示分别为母材和经阳极氧化处理试样疲劳源附近断口形貌。通过断口表面辐射状标记可以判定疲劳源位置,发现裂纹均起源于试样表面。这是由于在循环应力作用下,试样自由表面形成驻留滑移带,随后形成挤出脊和侵入沟,最终形成微裂纹[23]。

图8 未阳极氧化试样疲劳断口形貌

Fig. 8 Fractographs of fatigue fracture for unanodized sample

图9 经阳极氧化处理试样的疲劳断口形貌

Fig. 9 Fractographs of fatigue fracture for anodic oxidation sample

由图8(a)及9(a)可以看出,经过阳极氧化处理试样的疲劳源附近表面相对较均匀,而母材的疲劳源附近表面有明显的表面缺陷,致使某些局部区域应力集中严重,产生塑性变形进而发展成为疲劳微裂纹,裂纹萌生,致使母材疲劳寿命与经阳极氧化处理试样的相比要低。

2.5.2 典型疲劳扩展区及瞬断区形貌

由图8(b)及图9(b)所示的母材和经阳极氧化处理试样的疲劳扩展区可以看出,母材及经阳极氧化处理试样的疲劳扩展区均由许多大小不同、高低不等的小断块组成,这是因为疲劳裂纹在扩展过程中呈现一定的晶体学取向,在穿越晶界时方向发生改变。但经过阳极氧化处理试样的疲劳裂纹扩展形成的辉纹比母材的更细致,脆性断裂的程度也稍弱一些,有效抑制了裂纹扩展的速率。由图8(c)和图9(c)所示的母材及经阳极氧化处理试样的瞬断区可以看出,经过阳极氧化处理试样的瞬断区的韧窝及疲劳条带比母材的更加均匀,排列更加规则,进一步说明了以酒石酸钠为成膜剂的电解液对TB8钛合金薄板进行阳极氧化处理,有效抑制了裂纹源的产生及疲劳裂纹的扩展。

3 结论

1) 采用以酒石酸钠为主盐的碱性电解液在TB8钛合金表面制得一层厚度约为2 μm的均匀致密的阳极氧化膜,改变了TB8钛合金表面带有沟槽样划痕的表面形貌。该氧化膜的主要成分以金红石型、锐钛型和板钛型的TiO2晶体为主,且有少量的低价钛及铝的氧化物存在。

2) 经阳极氧化处理后TB8钛合金薄板的拉伸性能与母材的基本接近,疲劳性能得到了明显改善。在疲劳寿命周期分别为1×106、1×105和1×104时,阳极氧化试样的疲劳强度相对于母材的分别提高了93%、44%和8%。

3) 阳极氧化处理能有效抑制TB8钛合金薄板表面裂纹源的产生及疲劳裂纹的扩展,是提高钛合金材料表面完整性的有效途径。

REFERENCES

[1] 董天祥, 杨春晟, 李 帆, 王 荣, 杨党纲. 国内航空金属材料成分分析技术现状及发展[J]. 材料工程, 2002, 12(3): 3-5.

DONG Tian-xiang, YANG Chun-sheng, LI Fan, WANG Rong, YANG Dang-gang. Development and actuality of composition analysis for aeronautical metal materials in China[J]. Journal of Materials Engineering, 2002, 12(3): 3-5.

[2] 黄 旭, 朱知寿, 王红红. 先进航空钛合金材料与应用[M]. 北京: 国防工业出版社, 2012: 6-23.

HUANG Xu, ZHU Zhi-shou, WANG Hong-hong. Advanced aeronautical titanium alloys and applications[M]. Beijing: National Defence Industry Press, 2012: 6-23.

[3] DUAN Yuan-pei, LI Ping, XUE Ke-min, ZHANG Qing, WANG Xiao-xi. Flow behavior and microstructure evolution of TB8 alloy during hot deformation process[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1199-1204.

[4] 薛克敏, 段园培, 李 萍, 张 青. TB8钛合金的热变形行为及加工图[J]. 材料工程, 2007, Z(1): 57-60.

XUE Ke-min, DUAN Yuan-pei, LI Ping, ZHANG Qing. Deformation behavior and processing map of high temperature deformation of TB8 alloy[J]. Journal of Materials Engineering, 2007, Z(1): 57-60.

[5] CHEN Z X, ZHOU K, LU X H, LAM Y C. Influence of hydrothermal exposure on surface characteristics and corrosion behaviors of anodized titanium[J]. Surfaces and Interfaces Analysis, 2014, 46(5): 307-313.

[6] TANAKA S I, FUKUSHIMA Y, NAKAMURA I, TANAKI T, JERKIEWICZ G. Preparation and characterization of microporous layers on titanium by anodization in sulfuric acid with and without hydrogen charging[J]. Applied Materials and Interfaces, 2013, 5(8): 3340-3347.

[7] 刘明辉, 翁 端, 蔡健平, 张晓云. 钛合金耐磨阳极氧化膜层结构和性能研究[J]. 材料工程, 2009, 19(12): 72-79.

LIU Ming-hui, WEN Duan, CAI Jian-ping, ZHANG Xiao-yun. Study of structure and performance of anti-wear anodizing coating of titanium alloys[J]. Journal of Materials Engineering, 2009, 19 (12): 72-79.

[8] KIM K, LEE B A, PIAO X H, CHUNG H J, KIM Y J. Surface characteristics and bioactivity of an anodized titanium surface[J]. Journal of Periodontal and Implant Science, 2013, 43(4): 198-205.

[9] POUILLEAU J, DEVILLIERS D, GARRIDO F, DURAND- VIDAL S, MAHE E. Structure and composition of passive titanium oxide films[J]. Materials Science and Engineering B, 1997, 47(3): 235-243.

[10] INDIRA K, NINGSHEN S, MUDALI K U, RAJENDRAN N. Effect of anodization parameters on the structural morphology of titanium in fluoride containing electrolytes[J]. Materials Characterization, 2012, 71: 58-65.

[11] 徐 飞, 潘 蕾, 白云瑞, 曹佳梦, 陶 杰, 陶海军, 蔡 蕾. 钛表面阳极氧化处理对TA2/聚醚醚酮(PEEK)粘结性能的影响[J]. 航空学报, 2014, 35(6): 1724-1732.

XU Fei, PAN Lei, BAI Yun-rui, CAO Jia-meng, TAO Jie, TAO Hai-jun, CAI Lei. The effects of titanium surface anodization on the adhesive bonding strength between TA2/PEEK[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(6): 1724-1732.

[12] CAMARGO A, VOORWALD H. Influence of anodization on the fatigue strength of 7050-T7451 aluminium alloy[J]. Fatigue and Fracture of Engineering Materials and Structures, 2007, 30(11): 993-1007.

[13] KETABCHI A, WECK A, VARIOLA F, VARIOLA F. Influence of oxidative nanopatterning and anodization on the fatigue resistance of commercially pure titanium and Ti-6Al-4V[J]. Journal of Biomedical Materials Research B, 2015, 103(3): 563-571.

[14] 刘建华, 杨 康, 于 美, 李松梅, 吴 量, 郁秀梅. 酒石酸钠体系中TC18钛合金阳极氧化膜的制备、表征与疲劳性能[J]. 航空学报, 2014, 35(2): 902-910.

LIU Jian-hua, YANG Kang, YU Mei, WU Liang, YU Xiu-mei. Preparation, characterization and fatigue performance of anodic oxide film on titanium alloy TC18 in sodium tartrate electrolyte[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(2): 902-910.

[15] CHEN Z X, WANG W X, TAKAO Y, MATSUBARA T, REN L M. Characterization and fatigue damage of TiO2 layer on spark-anodized titanium before and after hot water treatment[J]. Applied Surface Science, 2012, 262(2): 2-7.

[16] EBRAHIMI A R, ZAREI F, KHOSROSHAHI R A. Effect of thermal oxidation process on fatigue behavior of Ti-4Al-2V alloy[J]. Surface and Coatings Technology, 2008, 203(3): 199-203.

[17] COSTA M Y P, VOORWALD H J C, PIGATIN W L, GUIMARAES V A, CIOFFI M O H. Evaluation of shot peening on the fatigue strength of anodized Ti-6Al-4V alloy[J]. Materials Research, 2006, 9(1): 107-109.

[18] GB/T 26076—2010. 金属薄板(带)轴向力控制疲劳试验方法[S].

GB/T 26076—2010. Metal sheets and strips-Axial-force- controlled fatigue testing method[S].

[19] 衣晓红, 樊占国, 张景垒, 李凤华, 田 昂. TC4钛合金表面阳极氧化制备TiO2多孔膜的实验研究[J]. 材料工程, 2010, 20(3): 38-41.

YI Xiao-hong, FAN Zhan-guo, ZHANG Jing-lei, LI Feng-hua, TIAN Ang. Experimental study of preparation of TiO2 porous films on the surface of TC4 titanium alloy by anodic oxidation[J]. Journal of Materials Engineering, 2010, 20(3): 38-41.

[20] LEE Y L, PAN J, HATHAWAY R B. 疲劳试验测试分析理论与实践[M]. 张然治, 译. 北京: 国防工业出版社, 2011: 79-89.

LEE Y L, PAN J, HATHAWAY R B. Fatigue testing and analysis theory and practice[M]. ZHANG Ran-zhi, transl. Beijing: National Defence Industry Press, 2011: 79-89.

[21] 刘翠云, 李焕喜, 马朝利. TC18钛合金耳片的断口形貌及疲劳性能[J]. 中国有色金属学报, 2010, 20(S1): s1050-s1054.

LIU Cui-yun, LI Huan-xi, MA Chao-li. Fractograph and fatigue behavior of TC18 titanium alloy lugs[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s1050-s1054.

[22] 齐立春, 黄利军, 黄 旭, 李志燕. 表面加工状态对Ti-1023钛合金疲劳性能的影响[J]. 中国有色金属学报, 2010, 20(S1): s1039-s1044.

QI Li-chun, HUANG Li-jun, HUANG Xu, LI Zhi-yan. Effect of surface machining state on fatigue property of Ti-1023 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s1039-s1044.

[23] 钟群鹏, 赵子华. 断口学[M]. 北京: 高等教育出版社, 2005: 131-164.

ZHONG Qun-peng, ZHAO Zi-hua. Fracture study[M]. Beijing: Higher Education Press, 2005: 131-164.

(编辑 龙怀中)

基金项目:江西省重大科技专项—先进直升机关键技术项目(20114ABE02100103103)

收稿日期:2014-12-01;修订日期:2015-03-06

通信作者:谢兰生,教授,博士;电话:13655176996;E-mail: meelsxie@nuaa.edu.cn