热机处理对CoCrFeNiMn高熵合金显微组织和力学性能的影响

来源期刊:中国有色金属学报(英文版)2018年第5期

论文作者:付建新 曹承明 童伟 彭良明

文章页码:931 - 938

关键词:高熵合金;冷轧;显微组织;拉伸性能;锯齿流变

Key words:high entropy alloy; cold rolling; microstructure; tensile properties; serrated flow

摘 要:通过均匀化热处理、冷轧和再结晶退火方法制备CoCrFeNiMn高熵合金。采用X射线衍射议、光学显微镜、扫描电子显微镜和多功能试验机研究热机处理对合金显微组织和不同温度下拉伸性能的影响。结果表明,再结晶退火后,铸态树枝晶结构转化为等轴晶结构,在此过程中仅观察到单一的面心立方相。在最大轧制比(40%)条件下得到的晶粒最细的合金由于晶界强化作用表现出最高的强度,而其伸长率随温度呈凹形变化特征。较粗晶粒合金的伸长率和加工硬化能力都随温度升高而单调下降。中间温度观察到的锯齿流变是由于位错的有效钉扎作用,它证明了动态应变强化的发生,并导致伸长率的降低。另外,拉伸断面上的韧窝呈典型的塑性断裂特征。

Abstract: The CoCrFeNiMn high entropy alloy was produced by homogenization, cold rolling and recrystallization. The effects of thermomechanical processing on microstructures and tensile properties at different temperatures were investigated using X-ray diffractometry (XRD), optical microscopy (OM), scanning electron microscopy (SEM) and multi-functional testing machine. The results show that dendritic structures in cast alloy evolve into equiaxed grains after being recrystallized, with single face-centered cubic (FCC) phase detected. The most refined alloys, stemming from the highest rolling ratio (40%), exhibit the highest strength due to the grain boundary strengthening, while the variation of elongation with temperature shows a concave feature. For the coarse-grained alloys, both the ductility and work hardening ability decrease monotonically with increasing temperature. Serrated flow observed at intermediate temperatures is attributed to the effective pinning of dislocations, which manifests the occurrence of dynamic strain hardening and results in the deterioration in ductility. Besides, dimples on the fracture surfaces indicate the typical ductile rupture mode.

Trans. Nonferrous Met. Soc. China 28(2018) 931-938

Jian-xin FU, Cheng-ming CAO, Wei TONG, Liang-ming PENG

CAS Key Laboratory of Mechanical Behavior and Design of Materials, Department of Modern Mechanics, School of Engineering Science, University of Science and Technology of China, Hefei 230027, China

Received 6 December 2016; accepted 22 May 2017

Abstract: The CoCrFeNiMn high entropy alloy was produced by homogenization, cold rolling and recrystallization. The effects of thermomechanical processing on microstructures and tensile properties at different temperatures were investigated using X-ray diffractometry (XRD), optical microscopy (OM), scanning electron microscopy (SEM) and multi-functional testing machine. The results show that dendritic structures in cast alloy evolve into equiaxed grains after being recrystallized, with single face-centered cubic (FCC) phase detected. The most refined alloys, stemming from the highest rolling ratio (40%), exhibit the highest strength due to the grain boundary strengthening, while the variation of elongation with temperature shows a concave feature. For the coarse-grained alloys, both the ductility and work hardening ability decrease monotonically with increasing temperature. Serrated flow observed at intermediate temperatures is attributed to the effective pinning of dislocations, which manifests the occurrence of dynamic strain hardening and results in the deterioration in ductility. Besides, dimples on the fracture surfaces indicate the typical ductile rupture mode.

Key words: high entropy alloy; cold rolling; microstructure; tensile properties; serrated flow

1 Introduction

In recent years, high entropy alloys have been studied and exploited owing to their simple solid solution structures and excellent performance [1-3]. Among these alloys, the equiatomic CoCrFeNiMn high entropy alloy, as single FCC solid solution displays high ultimate strength and good ductility [4-6]. Although some second phase precipitates began to form in this alloy after prolonged annealing at 500 and 700 °C [7,8], it still exhibits excellent thermodynamic stability due to its sluggish diffusion effect compared to other high entropy alloys [9]. Moreover, homogenous equiaxed grains can be obtained using conventional thermomechanical processing such as homogenization, rolling and subsequent recrystallization annealing [10,11]. These characteristics make this alloy a promising and ideal prototype for investigating the intrinsic mechanism in high entropy alloys to establish a solid foundation for further improving its mechanical properties via adding other adequate elements (i.e., Al or C) and controlling microstructures [12,13].

Unfortunately, resembling most of austenitic TWIP steels, the mechanical behavior of CoCrFeNiMn alloy shows a disadvantage of relatively low yield strength [14]. In order to modify this disadvantage for cast alloy, several approaches have been attempted by various researchers. One of these approaches is the adjustment of chemical constituent ratio [15,16], or the addition of substitutional (interstitial) elements to the matrix alloy [17,18], which significantly improves the strength, but with a deterioration in ductility especially for the latter method. Another impactful approach is the refinement of microstructure and texture by means of severe plastic deformation and heat treatments as mentioned above, which has already been extensively applied to numerous traditional alloys [19-21], as well as a limited number of high entropy alloys [22,23]. According to the classical Hall-Petch relationship, the yield strength can be effectively increased by refining the recrystallized grains, with the high ductility maintained.

Accordingly, to improve the tensile properties of the alloy with a satisfactory balance between strength and ductility, it is quite essential to primarily study the evolution of microstructure in depth via thermomechanical processing. In particular, the present attention is mainly focused on the temperature dependence of the tensile properties of the alloys with different recrystallized grain sizes, since almost all the previous investigations were conducted on single grain-sized alloy, and furthermore, the contribution of microstructure to the deformation behavior at high temperatures was still ambiguous.

In the present study, the alloys with different grain sizes (25-100 μm) were prepared by drop casting, homogenization, cold rolling and recrystallization. The microstructural evolution was characterized and the quasi-static tensile tests of the alloys with different grain sizes were performed at elevated temperatures. Fracture morphologies were also observed to investigate the fracture mechanism.

2 Experimental

The equiatomic CoCrFeNiMn alloy was produced by vacuum induction melting the constituent elements with at least 99.9% purity in argon atmosphere. The ingots were re-melted at least five times and then dropped cast into a rectangular steel mold with dimensions of 120 mm × 65 mm ×10 mm. The drop cast ingots were homogenized at 1100 °C for 24 h in vacuum followed by furnace cooling. They were subsequently cold rolled (CR) with different reductions in thickness as 20%, 30% and 40%. The rolled sheets were recrystallized at 900 and 1000 °C for 1 h, respectively.

Flat dog bone specimens with a gauge length of 25 mm and a cross section of 5.6 mm × 1.5 mm were machined from the recrystallized sheets and then mechanically ground to 2000 grit sand paper to remove surface asperities. Quasi-static tensile tests were conducted on a CSS-3905 multi-functional testing machine between room temperature (RT) and 800 °C at a strain rate of 3×10-4 s-1. Microstructural observation was performed using OM after etching in an aqueous solution of HCl+H2O2+Cu(NO3)2. A grain was defined by the distinct optical contrast to the neighboring ones, and the average grain size was evaluated by the Nano Measurer software. To ensure the accuracy, at least 20-30 grains in each condition were picked up, and irregular grains were measured by several different orientations. Phase constitution was identified by XRD with Cu Kα radiation. Fracture surfaces were observed by using SEM (XL30 ESEM) operated at 20 kV.

3 Results and discussion

3.1 Phase and microstructures

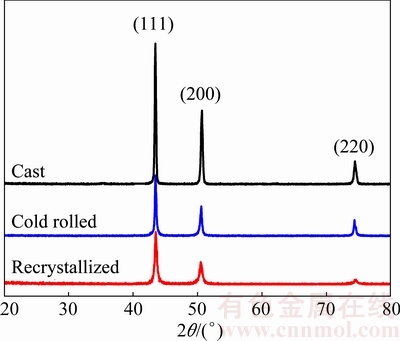

Figure 1 shows the XRD patters of the alloy in cast, cold rolled and subsequent recrystallized states. It is obviously noted that only simple FCC solid solution phase is detected, and there are no more second phase precipitates even after severe plastic deformation and annealing. The results indicate the excellent phase stability of the alloy.

Fig. 1 XRD patterns of cast, cold rolled (40% reduction in thickness) and recrystallized (900 °C for 1 h) alloys

From the thermodynamic point of view, two parameters, the atomic-size difference δ and a new parameter Ω derived from Hume-Rothery rules are proposed to predict the formation of solid solution phases in high entropy alloys [24,25]:

(1)

(1)

(2)

(2)

where ri is the atomic radius of the ith element,  is the average atomic radius, ci is the molar ratio, Tmix is the average melting temperature of the alloy system, ΔHmix and ΔSmix are the enthalpy of mixing and the entropy of mixing, respectively. These parameters are expressed by

is the average atomic radius, ci is the molar ratio, Tmix is the average melting temperature of the alloy system, ΔHmix and ΔSmix are the enthalpy of mixing and the entropy of mixing, respectively. These parameters are expressed by

(3)

(3)

(4)

(4)

(5)

(5)

where (Tm)i is the melting temperature of the ith element, R is the molar gas constant (8.314 J/(K·mol)),  is the enthalpy of mixing between the ith and jth elements. According to various reported data, it was concluded that Ω≥1.1 and δ<6.6% are the criteria for forming single solid solutions.

is the enthalpy of mixing between the ith and jth elements. According to various reported data, it was concluded that Ω≥1.1 and δ<6.6% are the criteria for forming single solid solutions.

In our present CoCrFeNiMn alloy system, the values of ΔHmix and ΔSmix are calculated to be -4.16 kJ/mol and 13.38 J/(K·mol), respectively. The average melting temperature Tmix is calculated to be 1792 K based on Eq. (3). As a result, the parameters Ω and δ are deduced to be 5.77 and 0.92%, respectively. It is obviously noticed that the values fall into the region where single solid solutions of FCC, body-centered cubic (BCC) or FCC + BCC are easily formed.

From an electronic structure point of view, another parameter, valence electron concentration (VEC), was proposed to predict the stable formation of FCC or BCC phase in high entropy alloys [26]:

(6)

(6)

where (VEC)i is the VEC for the ith element. According to previous study, FCC phases were found to be stable when VEC≥8, while BCC phases were prone to form when VEC<6.87. The VEC value of the current alloy is calculated to be 8, demonstrating the stable formation of FCC phase in CoCrFeNiMn alloy.

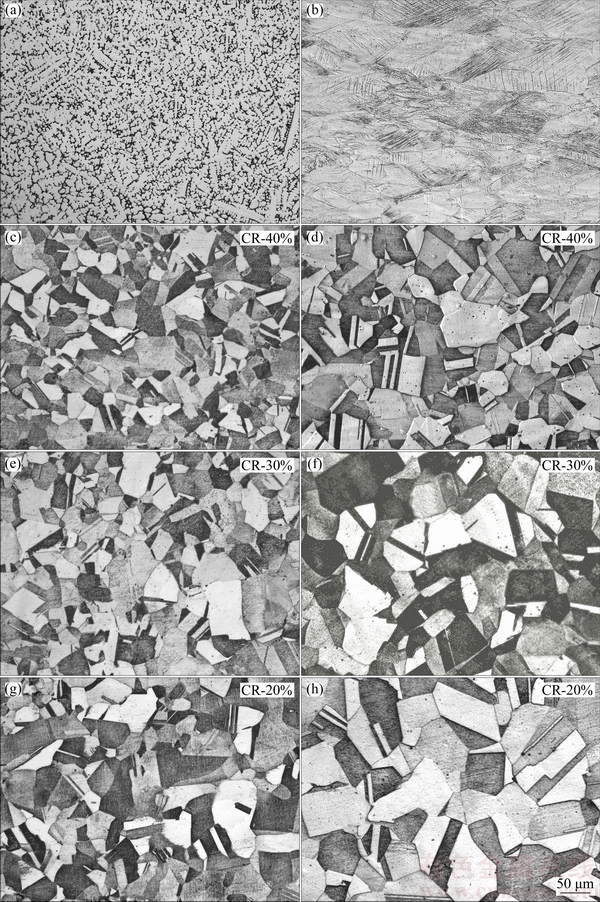

Fig. 2 Microstructures of alloys in cast (a), cold rolled (40% reduction in thickness) (b), recrystallized at 900 °C for 1 h (c, e, g) and at 1000 °C for 1 h (d, f, h) states

The microstructural evolution of different alloys is shown in Fig. 2, with three rolling ratios and two recrystallization temperatures. Typical dendritic and interdendritic structure is observed in the cast alloy (Fig. 2(a)), which results from elemental segregation during quick freezing process in the mold. After being homogenized and cold rolled 40% in thickness, the microstructure evolves into coarse and long strip-shaped grains with numerous slip bands generated along different directions (Fig. 2(b)). It can be observed that different sets of bands cross with each other at an angle of 120°. After the alloy is further recrystallization annealed, equiaxed grains are formed and several annealing twins occur in the interior of grains. The distinct contrast in color represents different crystallographic orientations of the equiaxed grains. Comparing the microstructures from Fig. 2(c) to Fig. 2(h), it can be found that both the rolling ratio and recrystallization temperature exert prominent effects on the average grain size, that is, higher rolling ratio or lower recrystallization temperature (above the lowest temperature at which recrystallization begins to occur) creates more refined grains. After severe plastic deformation, the density of vacancies and dislocations in the alloy was considered to drastically increase, which provided sufficient distortional energy for recovery and recrystallization. Nucleation of new grains and nuclei growth occurred during the subsequent annealing process, and effectively, refined the grains [27,28].

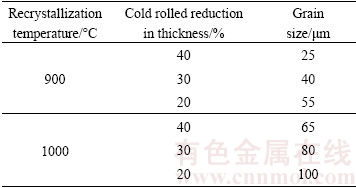

The evaluated average grain sizes of the recrystallized alloy are depicted in Table 1. The values vary in a range from 25 μm (CR-40%, 900 °C, 1 h) to 100 μm (CR-20%, 1000 °C, 1 h). These results are consistent with the previous report [10] which possesses the rolling ratio up to 96% and the recrystallization temperature as low as 800 °C.

Table 1 Average grain sizes of recrystallized alloy

3.2 Mechanical properties

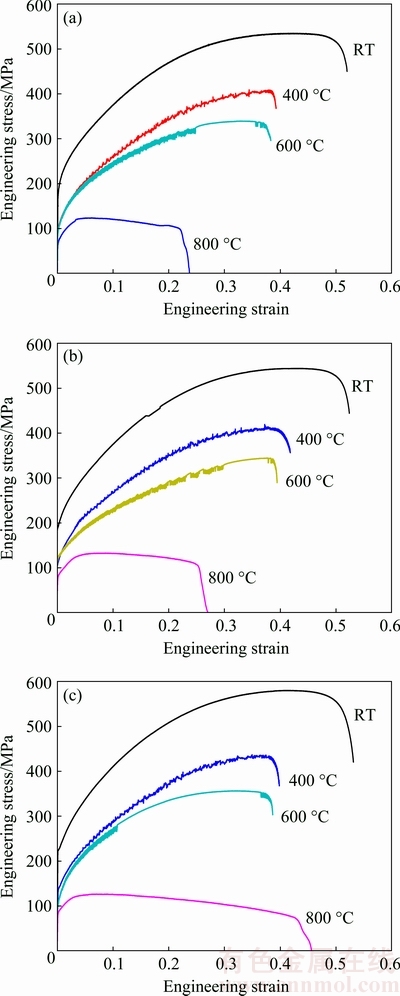

Tensile stress-strain curves for the alloys recrystallized at 900 °C and three rolling ratios are shown in Fig. 3. All the alloys exhibit the significant temperature dependence of strength and ductility, with their largest values appearing at RT. The stress-strain curves in the temperature range from RT to 600 °C develop from significant yield points up to the maximum tensile stress followed by the quick occurrence of failure. However, the curves at 800 °C reach the maximum stress shortly after the yield points and experience relatively long softening processes, especially for CR-40% alloy whose elongation reaches as high as 45.5% (Fig. 3(c)). As a manifestation of dynamic strain aging (DSA), pronounced serrations are observed in the intermediate temperature of 400-600 °C for all the three alloys. It should be noticed that the serrations at 600 °C display discontinuous features.

Fig. 3 Temperature dependence of engineering stress-strain curves of alloy with rolling ratios of 20% (a), 30% (b) and 40% (c) and recrystallization temperature of 900 °C for 1 h

It is ordinarily proposed that serrated flow was dominated by thermally activated diffusion of solutes pining and unpinning dislocations [29,30]. When the accumulating concentration of solutes around the dislocations reaches a critical value, the pinning process occurs, leading to the appearance of serrations. According to the constitutive model of DSA, the concentration of solute Cs at the dislocation line can be expressed by [31]

(7)

(7)

where c is the solute concentration in the matrix, T is the thermodynamic temperature, D(=D0exp[-Q/(RT)]) is the diffusion coefficient, and ta is the effective aging time. In the present CoCrFeNiMn high entropy alloy, there exists no rigorous “solute” or “solvent” and all the constituent elements might get involved in the aging process by means of short-range order or clustering [32]. On the basis of Eq. (7), it can be inferred that at RT, there are so limited species and number of solutes to be activated and almost no dislocations can be captured. While at 800 °C, the thermal vibration of atoms is too large to settle down the effective locking process. As a consequence, serrations are observed in the intermediate temperature range due to the effective pinning of dislocations.

Previous investigation concerning the serrated behavior has indicated that serrations may play a significant role in the deterioration in ductility [33]. As the dynamic interaction between dislocations and solutes leads to the localized plastic instability, that is, plastic deformation transforms into an inhomogeneous mode, the probability of failure primarily occurs in the localized zones and thereby promoting premature necking instability [34].

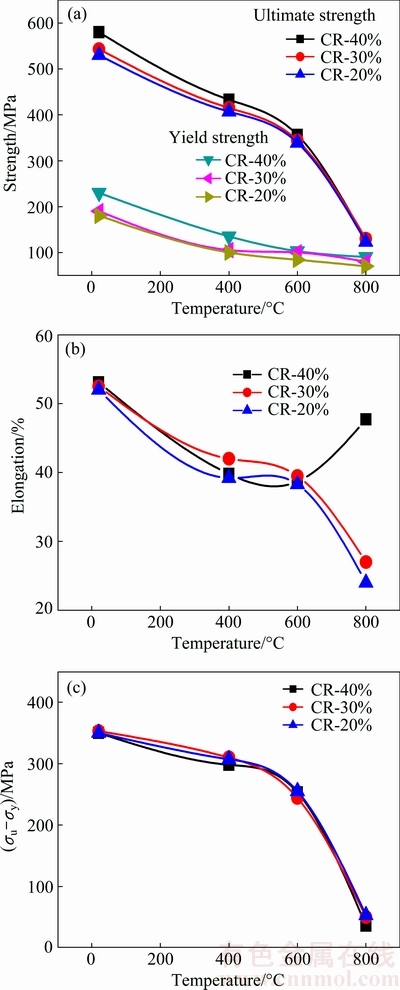

Fig. 4 Temperature dependence of ultimate strength and yield strength (a), elongation (b) and degree of work hardening (σu-σy) (c) of alloy at three rolling ratios and recrystallization temperature of 900 °C for 1 h

For a better interpretation, the temperature dependence of strength, elongation and degree of work hardening is exhibited in Fig. 4. By comparing the tensile strengths of the alloys at three rolling ratios (Fig. 4(a)), higher values are generally obtained for the higher rolling ratio alloys which create more refined grains. The Hall-Petch relationship between mechanical properties (strength or hardness) and grain size of CoCrFeNiMn alloy has already been illustrated by LIU et al [35]. They attributed the grain size effects to the block against gliding dislocations by grain boundaries. The plateau values in both ultimate and yield strength are observed in the intermediate temperature range, where the strength values decrease more slowly, identical to previous report investigating the tensile properties of high- and medium-entropy alloys [36]. In contrast to the gradual decrease for yield strength, the ultimate strength experiences a steep drop at 800 °C. The elongation to fracture shows complicated temperature dependence, as shown in Fig. 4(b). Similarly, following by the plateau values (38%-41%) in the intermediate temperature range, the elongations drop sharply down to approximately 25% at 800 °C for the two alloys with lower rolling ratios. However, a significant increase is observed for the CR-40% alloy due to the large softening plastic strain, corresponding to the stress-strain curve in Fig. 3(c). Therefore, it could be presumed that refining grains help to prolong the softening ductility at higher temperatures [32]. The degree of work hardening monotonously decreases with increasing temperature, with almost the same trend for the three alloys, as shown in Fig. 4(c). The plateau in the intermediate temperature range can also be associated with DSA caused by serrations, which enhanced the work hardening ability to a certain degree. In addition, the sharp decrease at 800 °C indicates the high temperature softening process.

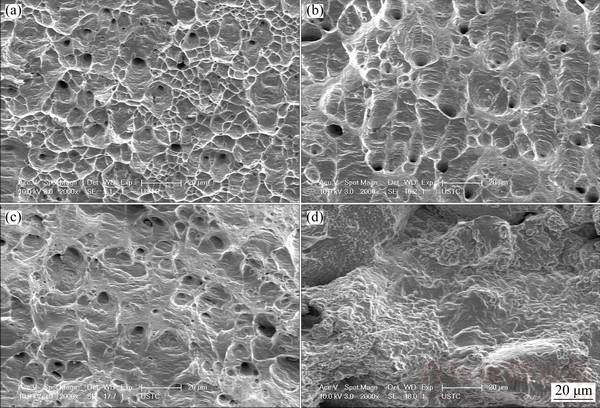

Fig. 5 Fractographs of alloy (CR-40%, 900 °C, 1 h) tested at RT (a), 400 °C (b), 600 °C (c) and 800 °C (d)

3.3 Fractograph

The fracture morphologies of the alloy tested at different temperatures are shown in Fig. 5. At RT, cohesive tearing facets with deep equiaxed dimples are observed, which indicates the typical ductile rupture characteristic (Fig. 5(a)). When the temperature increases to 400 °C and 600 °C, respectively, massive annular striation patterns around the dimples become notable, with cohesive tearing facets disappearing (Figs. 5(b) and (c)). The decrease in tensile ductility in the intermediate temperature range may be related to the striation patterns. At 800 °C, a large number of small dimples distribute on the uneven fracture surface, and no deep equiaxed dimples or striations can be observed besides several secondary cracks. The disappearance of serrations at this temperature (Fig. 3(c)) as well as the increasing elongation and the sharp decreasing work hardening (Figs. 4(b) and (c)) has manifested the softening process at high temperature, which can be reflected by the dense small dimples on the morphology. However, the appearance of secondary cracks terminates the ductility for a better development.

4 Conclusions

1) Adequate thermomechanical treatment including rolling and recrystallization annealing can produce homogenous and equiaxed microstructures for the cast CoCrFeNiMn alloy. Increasing the rolling ratio or decreasing the recrystallization temperature (above the lowest recrystallization temperature) contributes to refining the equiaxed grains.

2) The alloys exhibit the highest strength for the most refined-grain alloy. An abnormal ductility- temperature variation is observed as the ductility decreases with increasing temperature, except for the CR-40% alloy whose lowest elongation appears in the intermediate temperature range. The deteriorated ductility is attributed to the serrated flow as observed in stress-strain curves, which manifests the DSA process during plastic deformation.

3) The dimples on the fracture morphologies indicate the typical ductile rupture characteristic. However, the appearance of striation patterns in the intermediate temperature range corresponds to the serrations and the deteriorated ductility.

References

[1] ZHANG Yong, ZUO Ting-ting, TANG Zhi, GAO M C, DAHMEN K A, LIAW P K, LU Zhao-ping. Microstructures and properties of high-entropy alloys [J]. Process in Materials Science, 2014, 61: 1-93.

[2] LI Bao-yu, PENG Kun, HU Ai-ping, ZHOU Ling-ping, ZHU Jia-jun, LI De-yi. Structure and properties of FeCoNiCrCu0.5Alx high-entropy alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 2958-2964.

[3] REN Ming-xing, LI Bang-sheng, FU Heng-zhi. Formation condition of solid solution type high-entropy alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 991-995.

[4] JI Wei, WANG Wei-min, WANG Hao, ZHANG Jin-yong, WANG Yu-cheng, ZHANG Fan, FU Zheng-yi. Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering [J]. Intermetallics, 2015, 56: 24-27.

[5] OTTO F, YANG Y, BEI H, GEORGE E P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high- entropy alloys [J]. Acta Materialia, 2013, 61(7): 2628-2638.

[6] LAURENT-BROCQ M, AKHATOVA A,  L, CHEBINI S, SAUVAGE X, LEROY E, CHAMPION Y. Insights into the phase diagram of the CrMnFeCoNi high entropy alloy [J]. Acta Materialia, 2015, 88: 355-365.

L, CHEBINI S, SAUVAGE X, LEROY E, CHAMPION Y. Insights into the phase diagram of the CrMnFeCoNi high entropy alloy [J]. Acta Materialia, 2015, 88: 355-365.

[7] OTTO F,  M, RAABE D, EGGELER G, GEORGE E P. Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures [J]. Acta Materialia, 2016, 112: 40-52.

M, RAABE D, EGGELER G, GEORGE E P. Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures [J]. Acta Materialia, 2016, 112: 40-52.

[8] PICKERING E J,  R, STONE H J, JONES N G. Precipitation in the equiatomic high-entropy alloy CrMnFeCoNi [J]. Scripta Materialia, 2016, 113: 106-109.

R, STONE H J, JONES N G. Precipitation in the equiatomic high-entropy alloy CrMnFeCoNi [J]. Scripta Materialia, 2016, 113: 106-109.

[9] TSAI K Y, TSAI M H, YEH J W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys [J]. Acta Materialia, 2013, 61(13): 4887-4897.

[10] OTTO F, HANOLD N L, GEORGE E P. Microstructural evolution after thermomechanical processing in an equiatomic, single-phase CoCrFeMnNi high-entropy alloy with special focus on twin boundaries [J]. Intermetallics, 2014, 54: 39-48.

[11] SATHIARAJ G D, BHATTACHARJEE P P. Effect of cold-rolling strain on the evolution of annealing texture of equiatomic CoCrFeMnNi high entropy alloy [J]. Materials Characterization, 2015, 109: 189-197.

[12] HE J Y, LIU W H, WANG H, WU Y, LIU X J, NIEH T G, LU Z P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system [J]. Acta Materialia, 2014, 62: 105-113.

[13] STEPANOV N D, YURCHENKO N Y, TIKHONOVSKY M A, SALISHCHEV G A. Effect of carbon content and annealing on structure and hardness of the CoCrFeNiMn-based high entropy alloys [J]. Journal of Alloys and Compounds, 2016, 687: 59-71.

[14] STEPANOV N D, SHAYSULTANOV D G, CHERNICHENKO R S, YURCHENKO N Y, ZHEREBTSOV S V, TIKHONOVSKY M A, SALISHCHEV G A. Effect of thermomechanical processing on microstructure and mechanical properties of the carbon-containing CoCrFeNiMn high entropy alloy [J]. Journal of Alloys and Compounds, 2017, 693: 394-405.

[15] ZHU Z G, MA K H, YANG X, SHEK C H. Annealing effect on the phase stability and mechanical properties of (FeNiCrMn)(100-x)Cox high entropy alloys [J]. Journal of Alloys and Compounds, 2017, 695: 2945-2950.

[16] TASAN C C, DENG Y, PRADEEP K G, YAO M J, SPRINGER H, RAABE D. Composition dependence of phase stability, deformation mechanisms, and mechanical properties of the CoCrFeMnNi high-entropy alloy system [J]. JOM, 2014, 68(10): 1993-2001.

[17] WANI I S, SATHIARAJ G D, AHMED M Z, REDDY S R, BHATTACHARJEE P P. Evolution of microstructure and texture during thermo-mechanical processing of a two phase Al0.5CoCr- FeMnNi high entropy alloy [J]. Materials Characterization, 2016, 118: 417-424.

[18] WU Z, PARICH C M, BEI H. Nano-twin mediated plasticity in carbon-containing FeNiCoCrMn high entropy alloys [J]. Journal of Alloys and Compounds, 2015, 647: 815-822.

[19] WANG Xiao-feng, GUO Ming-xing, CAO Ling-yong, LUO Jin-ru, ZHANG Ji-shan, ZHUANG Lin-zhong. Influence of thermo- mechanical processing on microstructure, texture evolution and mechanical properties of Al-Mg-Si-Cu alloy sheets [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1752-1762.

[20] HUO W T, SHI J T, HOU L G, ZHANG J S. An improved thermo-mechanical treatment of high-strength Al-Zn-Mg-Cu alloy for effective grain refinement and ductility modification [J]. Journal of Materials Processing Technology, 2017, 239: 303-314.

[21] ZHANG Wei-dong, LIU Yong, WU Hong, LIU Bin, CHEN Zi-jin, TANG Hui-ping. Microstructural evolution during hot and cold deformation of Ti-36Nb-2Ta-3Zr-0.35O alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(5): 1310-1316.

[22] WANI I S, BHATTACHARJEE T, SHEIKH S, LU Y P, CHATTERJEE S, BHATTACHARJEE P P, GUO S, TSUJI N. Ultrafine-grained AlCoCrFeNi2.1 eutectic high-entropy alloy [J]. Materials Research Letters, 2016, 4(3): 174-179.

[23] WU Z, BEI H, PHARR G M, GEORGE E P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures [J]. Acta Materialia, 2014, 81: 428-441.

[24] ZHANG Y, ZHOU Y J, LIN J P, CHEN G L, LIAW P K. Solid-solution phase formation rules for multi-component alloys [J]. Advanced Engineering Materials, 2008, 10(6): 534-538.

[25] SHENG H F, GONG M, PENG L M. Microstructural characterization and mechanical properties of an Al0.5CoCrFeCuNi high-entropy alloy in as-cast and heat-treated/quenched conditions [J]. Materials Science and Engineering A, 2013, 567: 14-20.

[26] GUO S, LIU C T. Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase [J]. Process in Natural Science: Materials International, 2011, 21(6): 433-446.

[27] WANG Bo, CHEN Xian-hua, PAN Fu-sheng, MAO Jian-jun, FANG Yong. Effects of cold rolling and heat treatment on microstructure and mechanical properties of AA 5052 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(8): 2481-2489.

[28] CHEN Zu-bin, LIU Chu-ming, XIAO Hong-chao, WANG Jun-kai, CHEN Zhi-yong, JIANG Shu-nong, SU Zai-jun. Effect of rolling passes on the microstructures and mechanical properties of Mg–Gd–Y–Zr alloy sheets [J]. Materials Science and Engeering A, 2014, 618: 232-237.

[29] WANG W H, WU D, SHAH S S A, CHEN R S, LOU C S. The mechanism of critical strain and serration type of the serrated flow in Mg–Nd–Zn alloy [J]. Materials Science and Engeering A, 2016, 649: 214-221.

[30] WANG Wen-hui, WU Di, CHEN Rong-shi, LOU Chang-sheng. Influence of temperature and strain rate on serration type transition in NZ31 Mg alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(11): 3611-3617.

[31] SPRINGER F, NORTMANN A, SCHWINK C. A study of basic processes characterizing dynamic strain ageing [J]. Physica Status Solidi A, 1998, 170: 63-81.

[32] OTTO F,  A, SOMSEN C, BEI H, EGGELER G, GEORGE E P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy [J]. Acta Materialia, 2013, 61(15): 5743-5755.

A, SOMSEN C, BEI H, EGGELER G, GEORGE E P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy [J]. Acta Materialia, 2013, 61(15): 5743-5755.

[33] VERMA P, SUDHAKAR RAO G, CHELLAPANDI P, MAHOBIA G S, CHATTOPADHYAY K, SANTHI SRINIVAS N C, SINGH V. Dynamic strain ageing, deformation, and fracture behavior of modified 9Cr–1Mo steel [J]. Materials Science and Engeering A, 2015, 621: 39-51.

[34] KING J E, YOU C P, KNOTT J F. Serrated yielding and the localized shear failure mode in aluminium alloys [J]. Acta Metallurgica, 1981, 29(9): 1553-1566.

[35] LIU W H, WU Y, HE J Y, NIEH T G, LU Z P. Grain growth and the Hall–Petch relationship in a high-entropy FeCrNiCoMn alloy [J]. Scripta Materialia, 2013, 68(7): 526-529.

[36] GALI A, GEORGE E P. Tensile properties of high- and medium-entropy alloys [J]. Intermetallics, 2013, 39: 74-78.

付建新,曹承明,童 伟,彭良明

中国科学技术大学 工程科学学院 近代力学系 中科院材料力学行为与设计重点实验室,合肥 230027

摘 要:通过均匀化热处理、冷轧和再结晶退火方法制备CoCrFeNiMn高熵合金。采用X射线衍射议、光学显微镜、扫描电子显微镜和多功能试验机研究热机处理对合金显微组织和不同温度下拉伸性能的影响。结果表明,再结晶退火后,铸态树枝晶结构转化为等轴晶结构,在此过程中仅观察到单一的面心立方相。在最大轧制比(40%)条件下得到的晶粒最细的合金由于晶界强化作用表现出最高的强度,而其伸长率随温度呈凹形变化特征。较粗晶粒合金的伸长率和加工硬化能力都随温度升高而单调下降。中间温度观察到的锯齿流变是由于位错的有效钉扎作用,它证明了动态应变强化的发生,并导致伸长率的降低。另外,拉伸断面上的韧窝呈典型的塑性断裂特征。

关键词:高熵合金;冷轧;显微组织;拉伸性能;锯齿流变

(Edited by Wei-ping CHEN)

Foundation item: Project (11572306) supported by the National Natural Science Foundation of China

Corresponding author: Liang-ming PENG; Tel: +86-551-63606964; Fax: +86-551-63606459; E-mail: penglm@ustc.edu.cn

DOI: 10.1016/S1003-6326(18)64727-2