文章编号:1004-0609(2007)02-0265-05

化学沉淀法制备CeO2-La2O3-ZrO2陶瓷粉末

周宏明,易丹青,肖来荣

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用化学沉淀法制备了La2Zr2O7(LZ)和CeO2-La2O3-ZrO2(LCZ)陶瓷粉末。通过电感耦合等离子体原子发射光谱(ICP-AES)、X射线衍射、DSC及霍尔流速计等分析方法,对粉末的化学组成、不同CeO2掺杂量LCZ的相组成、不同煅烧温度下的相组成、高温相稳定性和流动性能进行了研究。结果表明:所制备粉末的组成与锆酸镧烧绿石相的组成相近;热处理温度600 ℃时粉末为无定形的混合氧化物,900 ℃时转化为复合氧化物,1 150 ℃时转变为单一的锆酸镧烧绿石相;高温下LCZ无明显相变;温度高于1 400 ℃煅烧后,LCZ的流动性显著改善,可用于等离子喷涂。

关键词:锆酸镧;复合陶瓷;热障涂层;化学沉淀法

中图分类号:TB 323 文献标识码:A

Preparation of CeO2-La2O3-ZrO2 ceramic powder by

chemical precipitation method

ZHOU Hong-ming, YI Dan-qing, XIAO Lai-rong

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Lanthanum zirconate (La2Zr2O7, LZ) and CeO2-La2O3-ZrO2 (LCZ) composite ceramic powders were prepared by the chemical precipitation. The chemical composition of the powders was analyzed by inductively coupled plasma-atomic emission spectrometry (ICP-AES). The crystallogrphic phases of LZ and LCZ with different CeO2 doped concentrations were determined by X-ray diffractometry. Differential scanning calorimetry (DSC) and TG were used to analyze the phase stability of LCZ sintered at different temperatures. The Hall flow meter was performed to determine the flowability of LCZ powder. The results show that the compositions of all prepared ceramic powders are similar to that of La2Zr2O7 with pyrochlore structure, the ceramic powders are amorphous mixed oxide at 600 ℃, the amorphous mixed oxide is converted to composite oxide when temperature rises to 900 ℃, and the composite oxide is converted to single La2Zr2O7 with pyrochlore structure at 1 150 ℃. The LCZ powders keep pyrochlore structure and no phase transformations occur for LCZ at high temperatures (1 350 ℃). The flowability of LCZ powder sintered at 1 400 ℃ is improved clearly, and which could be used in plasma spray coatings.

Key words: lanthanum zirconate; composite ceramics; thermal barrier coatings; chemical precipitation

近年来,随着航空燃气涡轮机向高流量比、高推重比及高进口温度方向发展,燃烧室中的燃气温度和压力也不断提高。目前,燃气温度已接近2 000 K,因此航空发动机涡轮叶片的合金材料上需喷涂热障涂层以承受1 600 ℃以上的涡轮进口温度[1-2]。热障涂层大多采用由陶瓷隔热表层和金属粘结底层组成,6%~8%(质量分数)氧化钇稳定的氧化锆(YSZ)是目前使用最广泛的陶瓷隔热表层材料[3-5]。由于YSZ热障涂层的长期使用温度为1 200 ℃以下,温度过高会导致YSZ相变加剧,容易被烧结,氧传导速率增加,金属粘结层容易被氧化,从而导致涂层脱落失效,已难以满足涡轮进口温度进一步提高的需要。

为提高热障涂层的使用温度和延长其使用寿命,开发满足下一代超音速发动机用的热障涂层,世界各国已投入大量的人力和物力研究开发新的热障涂层材料[6-9]。目前,针对新的热障涂层陶瓷材料的开发主要集中于稀土锆酸盐。Vassen等[10]合成了SrZrO3、BaZrO3和La2Zr2O7 3种陶瓷粉体,发现在1 200 ℃时,La2Zr2O7(简称LZ)表现出优异的热稳定性和抗热震性能,但La2Zr2O7的热膨胀系数较小,30~1 000 ℃时为9.1×10-6 K-1,因而其应用受到限制。研究表明[11],CeO2具有较大的热膨胀系数,LZ中加入CeO2可改善其热膨胀系数,使其有望成为一种优良的抗高温热障涂层陶瓷材料(LCZ)。刘喜华等[12]采用化学共沉淀制备了LCZ陶瓷粉末,并对其化学成分和相结构进行研究。本文作者采用共沉淀-煅烧法制备了锆酸镧(LZ)和CeO2-La2O3-ZrO2三元复合氧化物陶瓷粉末(LCZ),并首次对其化学组成、不同CeO2掺杂量的LCZ的相组成、LZ和LCZ在不同煅烧温度的相组成及其高温相稳定性以及不同条件下处理粉末的流动速度和松装密度进行了系统研究,为LZ和LCZ用作热障涂层陶瓷材料及其等离子喷涂的制备提供理论依据。

1 实验

1.1 实验设备与原料

实验采用抽滤泵、真空干燥箱、马弗炉和电动搅拌机。原料为CeO2(分析纯),La2O3(99.99%),ZrOCl2?8H2O(分析纯),盐酸(1.19),氨水(0.91),无水乙醇(分析纯)。

1.2 实验步骤

将La2O3溶于浓盐酸中,CeO2溶于有还原剂的盐酸中,ZrOCl2·8H2O溶于温水中,按组成配比将3份溶液倒入同一容器,充分搅拌使其混合均匀。将混合料液缓慢注入盛有氨水(1?1)的容器中,同时不断搅拌,立即生成沉淀。为使镧、铈、锆的氢氧化物沉淀完全,整个过程中控制体系的pH值在10.0以上[13]。用水和无水乙醇洗去沉淀中的Cl-,过滤,将滤饼装入培养皿中,在120 ℃下真空干燥12 h脱去结合水,经过研磨后,装入刚玉坩埚中升温至设定的温度焙烧5 h,自然冷却后取出,研磨后过350目标准筛,得到的粒径小于40 μm的LZ和LCZ陶瓷粉末,再将粉末进行相结构、热稳定性以及流动性能分析。

1.3 分析方法

实验中用Jarrell-Ash Atom Comp 960786电感耦合等离子体原子发射光谱仪(ICP-AES)测定产物的化学成份。采用SIEMENSD-500型X射线全自动衍射仪对产物作相结构分析,分析条件为Cu Kα辐射,工作电压40 kV,工作电流250 mA,扫描范围10?~85?,扫描速度为8(?)/min。用德国NETZSCH DSC204差式扫描量热仪测定LCZ陶瓷粉末的TG和DTA曲线,结合XRD分析研究其高温相稳定性,采用氧化铝坩埚,升温速率10 K/min,温度范围为室温~1 350 ℃。采用霍尔流速计测定LZ和LCZ陶瓷粉末的流动速度和表观密度。

2 结果与讨论

2.1 陶瓷粉末的化学组成

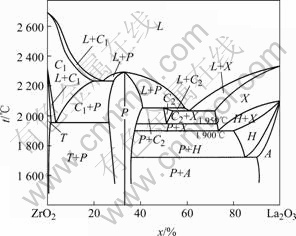

由La2O3-ZrO2的相图[14]可知,锆酸镧的烧绿石相存在于一个较宽的范围内(图1中P区域),即0.87 (La2O3) ? 2(ZrO2)~1.15(La2O3) ?2(ZrO2),La和Zr的摩尔比为0.87~1.15。

图1 La2O3-ZrO2的相图

Fig.1 Phase diagram of La2O3-ZrO2: L is liquid phase; A is hexagonal ss; C1 is cubic ss of CaF2 type; C2 is cubic ss of Ti2O3 type; H is hexagonal ss; P is pyrochlore-type compound; T is tetragonal ss; X is cubic ss

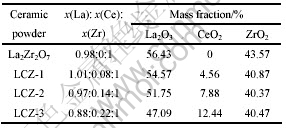

采用电感耦合等离子体原子发射光谱仪(ICP- AES)对所制备的陶瓷粉末的化学成分进行分析,结果见表1。

表1 陶瓷粉末的化学组成

Table 1 Chemical composition of ceramic powders

由表1可知,锆酸镧和不同CeO2掺杂量的锆酸镧陶瓷粉末中的La和Zr的摩尔比均在0.87~1.15之间,因此,从组成来看,表1中所制备陶瓷粉末的组成与烧绿石相组成相同或相近,图2所示的物相分析结果也证明了这一点。

2.2 CeO2掺杂量的锆酸镧粉末物相组成的影响

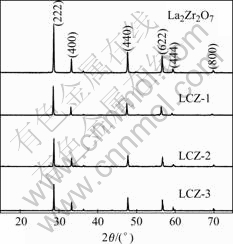

通过X射线衍射对不同CeO2掺杂量的锆酸镧粉末的物相组成进行了分析,结果见图2。

图2 不同CeO2掺杂量的锆酸镧粉末的物相组成

Fig.2 XRD patterns of lanthanum zirconate ceramic powders doped with different CeO2 concentration calcined at 1 400 ℃ for 5 h

由图2可见,CeO2掺杂量为0时,粉末的强峰数据与La2Zr2O7的JCPDS卡片73-0444相符,与文献[10]报道的结果一致,说明所制备的陶瓷粉末为烧绿石结构。文献[15]报道,在La2Zr2O7烧绿石结构中,由ZrO6八面体构成大的网状结构,La3+填充在由六个ZrO6构成的八面体孔隙中。在满足电中性的条件下,La3+和Zr2+可以被具有相近离子半径的其它离子替代。由图2可看出,在不同CeO2掺杂量下,粉末的衍射峰与不掺杂时一致,只是峰的强度略有差别,表明LCZ仍保持单一的烧绿石结构;图中未见La、Ce和Zr的氧化物峰,表明掺杂的Ce已经完全被固溶到La2Zr2O7的晶格中。

2.3 热处理温度对锆酸镧粉末物相组成的影响

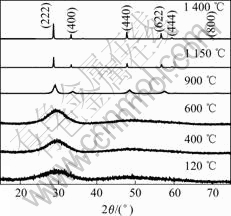

通过X射线衍射考察了不同热处理温度对锆酸镧粉末(CeO2掺杂量为8%)的物相组成的影响,结果如图3所示。

图3 不同热处理温度下锆酸镧粉末的物相组成

Fig.3 XRD patterns of Lanthanum zirconate ceramic powders treated at different temperatures (CeO2 concentration: 8%; Time: 5 h)

图3表明,在120℃下真空干燥后得到的微粉为La、Zr和Ce的氢氧化物。热处理后,氢氧化物分解,生成无定形的氧化物混合物,从XRD曲线中可以发现,直到热处理温度升高到600 ℃时,微粉仍然保持这种无定型态;热处理温度升高至900 ℃后,得到La、Zr和Ce的复合氧化物;随着热处理温度的增加,La2Zr2O7晶相逐渐形成,经1 150 ℃以上温度热处理后的陶瓷微粉的XRD曲线具有尖锐的特征峰,形成单一的烧绿石结构的La2Zr2O7晶相。由图3还可看出,由于温度升高使粉末结晶长大,结晶更完整,密实度提高,导致衍射峰宽度随温度升高而减小,衍射峰的强度减小。

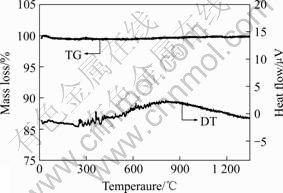

2.4 锆酸镧粉末相结构的稳定性

通过DTA和TG考察了1 400 ℃热处理5 h得到的锆酸镧粉末在室温~1 350 ℃下相结构的稳定性,结果见图4。从图4可以看出,LCZ的DSC曲线相对平滑,无明显的峰出现。文献[12]的研究表明,YSZ(Y2O3部分稳定的ZrO2)在1 214 ℃处出现一个较尖锐的吸热峰,对应于亚稳相t′ 向四方相t和立方相c的转变。结合图3的分析结果,可知LZ和LCZ陶瓷粉末在室温~1 350 ℃的范围内,均能保持单一的烧绿石结构,表明其高温相稳定性能要优于YSZ。

图4 LCZ的TG和DTA曲线

Fig.4 TG and DTA analysis of LCZ (Calcination temperature: 1 400 ℃, Time: 5 h, CeO2 mass concentration: 8%)

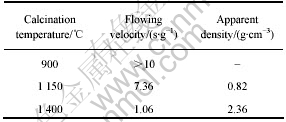

2.5 LCZ粉末的流动性

粉末的几何构形、松装密度、粒度分布和流动速度是粉末可喷涂性的关键因素,而粉末能以特定的速度连续不断地流入等离子体喷枪,是粉末可喷涂的前提条件。文献[13]的研究结果表明,热处理温度的高低对粉末的流动性有重要影响,所制备的粉末过350目标准筛后,采用霍尔流速计测定了不同热处理温度对LCZ粉末流动速度和表观密度的影响,结果见表2。

表2 LCZ粉末的流动性

Table 2 Flowability of LCZ powder at different temperatures

从表2可以看出,LCZ陶瓷粉末的流动速度和表观密度均随热处理温度的升高而增大,而且显然只有当热处理温度在1 400 ℃以上时,LCZ陶瓷粉末才具有较好的流动速度,这是由于粉末在1 400 ℃烧结后,变得比较致密,松装密度增大,从而提高了粉末的流动速度。

3 结论

1) 利用化学沉淀法制备了La2Zr2O7和LCZ陶瓷粉末,考察了不同Ce掺杂量对粉末物相结构的影响,结果表明La2Zr2O7和LCZ陶瓷粉末均为单一的烧绿石结构。

2) 考察了不同热处理温度对LCZ陶瓷粉末相结构的影响,结果表明温度升高到600 ℃时,微粉仍然保持混合氧化物的无定形态;温度升高至900 ℃时,得到La、Zr和Ce的复合氧化物;随着热处理温度的,La2Zr2O7晶相逐渐形成,经1 150 ℃热处理后陶瓷微粉的XRD曲线具有尖锐的特征峰,形成了单一烧绿石结构的La2Zr2O7晶相。

3) DSC分析结果表明, LCZ粉末在室温~1 35℃范围内均能保持单一的烧绿石结构,其高温相稳定性良好。

4) 随热处理温度的升高,LCZ陶瓷粉末的流动速度和表观密度均增大,当热处理温度在1 400 ℃以上时,LCZ陶瓷粉末具有良好的流动速度,可用于等离子喷涂。

REFERENCES

[1] Uwe S, Christoph L, Klaus F. Some recent trends in research and technology of advanced thermal barrier coatings [J]. Aerospace Science and Technology, 2003, 7: 73-80.

[2] 林 锋, 于月光, 蒋显亮, 等. 等离子体喷涂纳米结构热障涂层微观组织及性能[J]. 中国有色金属学报, 2006, 16(3): 482-487.

LIN Feng, YU Yue-guang, JIANG Xian-liang, et al. Microstructures and properties of nanostructured TBCs fabricated by plasma spraying [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 482-487.

[3] Sohn Y H, Lee E Y, Nagaraj B A. Microstructure characterization of thermal barrier coatings on high presser turbine blades [J]. Surf Coat Technol, 2001, 146/147: 132-137.

[4] Chwa S O, Ohmori A. Microstructures of ZrO2-8 wt. % Y2O3 coatings prepared by a plasma laser hybrid spraying technique [J]. Surf Coat Technol, 2002, 153: 304-308.

[5] Brandon J R, Taylor R. Phase stability of zirconia-based thermal barrier coatings(Part Ⅱ). Zirconia-ceria alloys [J]. Surf Coat Technol, 1991, 46(1): 91-96.

[6] David R C, Simon R P. Thermal barrier coating materials [J]. Materials Today, 2005, 6: 22-29.

[7] Wu J, Wei X Z, Padture N P, Klemens P G, Gell M, Garcia E. Low-thermal-conductivity rare-earth zirconates for potential thermal-barrier-coating applications [J]. J Am Ceram Soc, 2002, 85(12): 3031-3036.

[8] Dietrich M, Vassen R, Stover D. LaYbO3, a candidate for thermal barrier coating materials [J]. Ceram Eng Sci Proc, 2003, 24(3): 637-643.

[9] David R C. Materials selection guidelines for low thermal conductivity thermal barrier coatings [J]. Surf Coat Technol, 2003, 163/164: 67-74.

[10] Vassen R, Cao X Q, Tietz F, Basu D, Stoever D. Zirconates as new materials for thermal barrier coating [J]. Journal of the American Ceramic Society, 2000, 83(8): 2023-2028.

[11] Cao X Q, Vassen R, Stoever D. Ceramic materials for thermal barrier coatings [J]. Journal of European Ceramic Society, 2004, 24: 1-10.

[12] 刘喜华, 毛 红, 宋 波, 等. La2O3-CeO2-ZrO2粉的制备及性能 [J]. 北京科技大学学报, 2004, 26(4): 404-406.

LIU Xi-hua, MAO Hong, SONG Bo, et al. Preparation and behavior of La2O3-CeO2-ZrO2 powders [J]. Journal of University of Science and Technology Beijing, 2004, 26(4): 404-406.

[13] 李报厚, 张登君, 张冠东. 共沉淀-煅烧法制备CeO2-Y2O3-ZrO2陶瓷粉末[J]. 化工冶金, 1997, 18(2): 97-101.

LI Bao-hou, ZHANG Deng-jun, ZHANG Guan-dong. Preparation of CeO2-Y2O3-ZrO2 ceramic powder by the coprecipition-calcination method [J]. Engineering Chemistry & Metallurgy, 1997, 18(2): 97-101.

[14] Roth R S, Negas T, Cook L P. Phase diagrams for ceramists [A]. Smith G. Proceedings of Science and Technology of Zirconia (Vol. 4) [C]. Columbus: American Ceramic Society, 1981.

[15] Subramanian A, Aravamudan G, Subba Rao G V. Oxide pyrochlores—a review[J]. Prog Solid State Chem, 1983, 15: 55-58.

基金项目:中南大学博士后基金资助项目(76132017)

收稿日期:2006-04-26;修订日期:2006-11-01

通讯作者:周宏明,博士后,副教授;电话:0731-8830092; E-mail: ipezhm@yahoo.com.cn

(编辑 龙怀中)