文章编号: 1004-0609(2005)06-0966-09

配合-共沉淀法制备锑掺杂二氧化锡(ATO)粉

杨建广, 唐谟堂, 杨声海, 唐朝波

(中南大学 冶金科学与工程学院, 长沙 410083)

摘 要: 在充分回收含锡阳极泥有价金属的基础上, 采用从锡锑二次资源中直接提取的高纯氯锡酸铵和氯氧锑为原料, 合成了性能优良的纳米级锑掺杂二氧化锡(ATO)粉。 针对液相共沉淀法制备ATO的过程中, 锡和锑的水解不同步从而未能实现真正共沉淀掺杂的问题, 以(NH4)2SnCl6和Sb4O5Cl2为原料, 采用配合-共沉淀法, 考察了反应过程中的pH、 反应温度、 掺锑浓度、 煅烧温度、 前驱体洗涤次数和分散剂种类等对ATO粒度和形貌的影响, 确定了最优化条件, 即: 滴定终点pH=3, 反应温度60℃, 锑掺杂浓度10%(质量分数), 热处理温度600℃, 前驱体洗涤次数为6次, 采用分散剂c, 并进行了实验验证。

关键词: 锑掺杂二氧化锡; 配合-共沉淀; 纳米粉体

中图分类号: 文献标识码: A

Transparent conductive oxide ATO powders prepared by complex-co-precipitation method

YANG Jian-guang, TANG Mo-tang, YANG Sheng-hai, TANG Chao-bo

(School of Metallurgical Science and Technology,

Central South University, Changsha 410083, China)

Abstract: Based on the fully reclaiming of the valuable metal, pure (NH4)2SnCl6 and Sb4O5Cl2 were directly extracted form tin anode slurry, by using Sb4O5Cl2 and (NH4)2SnCl6 as precusors, fine antimony doped tin oxide(ATO) powder with excerllent performance was prepared by complex-co-precipitation, which can resolve some traditional problems when preparing ATO powder, such as conglomeration; limited material, expen sive cost and, etc. Especially, this method can make Sn4+ and Sb3+ hydrolyze at the same speed and get more even doped tin oxide. The optimal experimental condition is as: terminal pH value, reactive temperature 60℃, Sb doped concentration is 10%, heat treating temperature is 600℃, wash time is 6, and using dispersant c.

Key words: complex-co-precipitation; antimony doped tin oxide; nano-powders

锑掺杂二氧化锡(Antimony doped tin oxide, ATO)是一种具有优良导电性能的金属氧化物复合粉, 广泛应用于抗静电塑料、 涂料、 纤维、 显示器抗静电防辐射涂层材料、 红外吸收隔热材料、 气敏元件和太阳能电极材料等方面[1-4]。

目前常用的液相共沉淀制备ATO的方法存在一些缺点: 1)由于Sb3+和Sn4+的离子水解不同步, 用常规的共沉淀方法制得的ATO前驱粉实际上是Sn(OH)4和Sb4O5Cl2两种沉淀不均匀的混合物, 最终制得的ATO粉未能实现真正意义上的完全均匀掺杂; 2)常态下SnCl4 和SbCl3都极易水解, 加料时为保证锡锑均以离子形式存在, 在配制混合液的过程中必须加入大量的酸, 然后加大量的碱使之产生沉淀, 这必然提高了生产成本, 同时也会造成大量NH4Cl废液的排放; 3)SnCl4·5H2O和SbCl3在常态下均易潮解和挥发, 难以准确计量; 4)以SnCl4和SbCl3为原料制备ATO成本相对较高[5-11]。

为解决以上存在的问题, 文献[12]对SnCl4-NH4Cl-HCl-H2O体系进行了热力学分析, 认为该体系中的SnCl4能在高酸度下以(NH4)2SnCl6形式沉淀出来, 为以含锡原料直接制取ATO用高纯(NH4)2SnCl6提供了理论依据。 在上述研究的基础上, 本研究使用特定配合剂加入到Sb4O5Cl2的水溶液中以防止锑的提前水解, 将该溶液和(NH4)2SnCl6溶液混合后, 加入适当的沉淀剂强制水解, 控制一定的pH值, 然后以一定搅拌速度搅拌, 使锡锑在分子级的水平上达到均匀共沉淀, 反应完全及陈化完全后, 收集干燥前驱体, 经表面处理后在一定的升温机制下煅烧该前驱体, 得到完全掺杂的超细ATO粉。 该方法为配合-共沉淀法。

本文作者以广西某厂电解锡阳极泥为原料, 在已充分回收其有价金属的基础上, 以该阳极泥直接生产出的高纯氯氧锑(Sb4O5Cl2)和高纯氯锡酸铵((NH4)2SnCl6)为原料, 采用配合-共沉淀方法合成出超细ATO粉。 并考察了反应温度、 pH值、 掺锑浓度、 分散剂种类和煅烧温度等因素对粉体粒度形貌的影响, 得出了最佳实验条件。

1 实验

1.1 实验方法

1) 称取22.04g(NH4)2SnCl6, 稀释至400mL, 称取0.383g Sb4O5Cl2放入盛有100mL去离子水的烧杯中, 称取1.2g配合剂A加入到溶有Sb4O5Cl2的烧杯中, 搅拌至澄清后将该配合溶液加入已稀释的(NH4)2SnCl6溶液中, 搅拌至澄清透明。

2) 配制3mol/L的氨水溶液300mL待用。

3) 在1000mL的烧杯中加入150mL去离子水, 将该烧杯置于60℃超级恒温水浴中保温一定时间之后, 加入1.5%(质量分数)表面活性剂B, 玻璃搅拌仪以60r/min的转速搅拌。 将沉淀剂和配合液以一定的滴加速度, 采用并加方式加入其中, 在30min内滴加完, 控制滴定终点(pH=1.5), 加料结束后继续反应20min, 再加入表面改性剂1, 继续反应10min后停止搅拌, 于室温陈化6h。

4) 采用倾泻及共沸腾方式收集ATO前驱体, 并于80℃干燥。

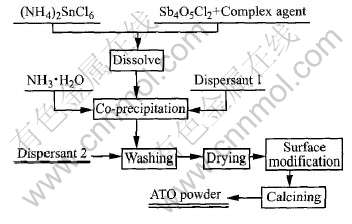

5) 于650℃煅烧已干燥的前驱体3.5h后, 使用表面改性剂2对ATO粉进行表面改性, 干燥得到最终ATO导电粉。 图1所示为配合一共沉淀法制备ATO的流程图。

图1 配合-共沉淀法制备ATO的流程图

Fig.1 Flow chart of fabrication of ATO by complex-co-precipitation

1.2 结果分析及表征

用日本JEOL电子公司的JSM-5600LV型扫描电镜观察所制得的ATO粉的粒度形貌, 并对颗粒尺寸进行实测。 用RAX-18型X射线衍射仪进行粉末晶相结构分析, 运用Scherrer公式估算不同样品的平均晶粒度。

2 结果与分析

2.1 pH值对粉体粒度和形貌的影响

在超细粉的制备过程中, 溶液的pH值是最大的影响因素之一, pH值大小将直接决定反应的可行性及反应进行的方向。

从热力学角度来看, 由于热力学属于宏观科学的范畴, 自然无法解释pH值对晶粒大小、 形貌和物相的影响。 对于水合氧化物, pH值直接影响溶液的平衡离子积值, 通常来讲, pH值越大, 水合氧化物或碱式盐的沉淀粒度就越小。

对本体系而言, 由于Sn(OH)4为两性氢氧化物, 在(NH4)2SnCl6强制水解和Sb4O5Cl2中和脱氯配位-共沉淀反应体系中, 主体相存在水合锡离子水解动态平衡:

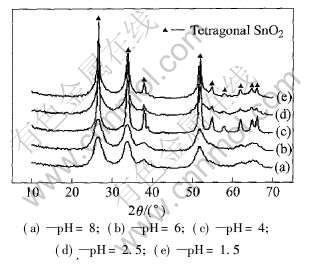

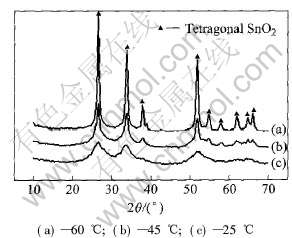

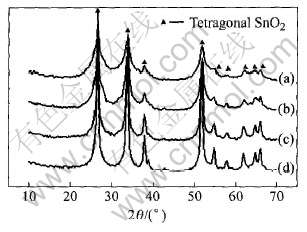

pH值对控制本反应的水解速度及水解过程起着相当重要的作用。 图2所示为控制不同pH值而恒定其它反应条件时制得的样品经650℃热处理3.5h后得到的掺杂ATO超细粉的X射线衍射谱。 从图2中可以看出, 所得样品具有金红石结构, 在本研究的锑掺杂浓度范围内, 锑的掺入并没有形成锑氧化物的分相, 也并未改变二氧化锡的晶体结构。 但锑的掺入影响了结晶取向和平均结晶粒度, 使样品的X射线衍射峰的位置发生了微小偏移。 根据X射线衍射谱, 利用Scherrer公式, 可粗略推算得到晶粒的平均尺寸, 进而得到晶粒平均尺寸随pH值的变化关系(见图3)。

图2 不同pH值条件下ATO粉的X射线衍射谱

Fig.2 XRD patterns of ATO powder at different pH

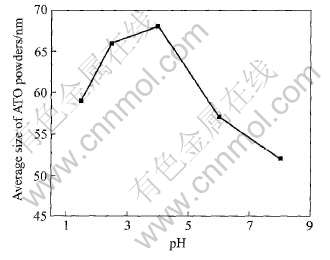

图3 ATO粉的平均尺寸与pH之间的关系

Fig.3 Relationship between average size of ATO powders and pH

从图3可以看到, 随着pH值升高, 晶粒尺寸随之增大, 并在pH值为4~5之间时出现最大峰值, 随后晶粒尺寸又逐渐减小。

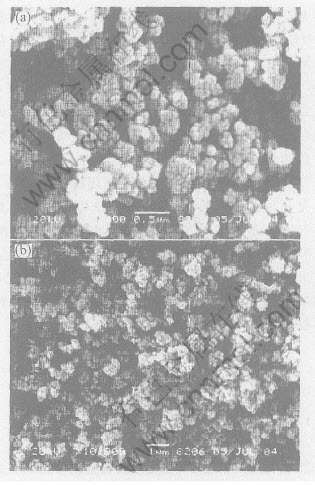

图4所示为pH=1.5值时ATO粉的SEM像。 从图3可以看出, 由X射线衍射半宽高计算得出粉末粒度小于SEM所量出的粉末粒度。 这是由于X射线衍射测定的是样品的平均晶粒尺寸, SEM观察得到的是样品的颗粒尺寸, 而每个颗粒可能由若干个晶粒构成, 颗粒之间可能有不同程度的聚集, 因而不同测量方法所得的结果有不同的数值, 物理意义也不尽相同。 通常根据样品比表面积计算的等效平均颗粒尺寸最大, SEM次之, X射线衍射结果最小, 但SEM较为直观, 结果也相对更可靠[12]。

图4 pH为1.5时ATO粉体的SEM像

Fig.4 SEM images of ATO powders at pH 1.5

从图2、 3和4可以看出: 所得的粉体粒度分布都较均匀, 分散性都较好, 超大团聚颗粒较少, 而pH=1.5时的样品晶粒尺寸小于其它pH值时的样晶粒颗粒尺寸。 从粉体粒度的因素考虑, 选择pH为1.5~3为最佳反应酸度区间。

2.2 反应温度对粉体粒度的影响

图5所示为控制不同反应温度恒定其它条件时制得的ATO超细粉的X射线衍射谱。 从图5可看出, 样品与四方相SnO2的JCPDS标准卡片数据大致相符, 表明样品具有四方相金红石结构。 在实验所用掺杂浓度样品中, 锑的掺入并没有带来新的物相结构, 但是它使样品衍射峰的位置发生了微小迁移, 表明了配合-共沉淀法能较好地实现了复合掺杂。

图5 不同配合-共沉淀温度时ATO粉的X射线衍射谱

Fig.5 XRD patterns of ATO powders at different complex-coprecipitation temperatures

从图5中还可看到, 随着温度的逐渐升高, 样品的X射线衍射峰逐渐变窄, 说明随着共沉淀温度的升高, 所制得ATO粉的晶粒逐渐增大, 晶型逐渐趋于完整, 这和上述结论一致。

根据超细颗粒生成的动力学和热力学原理, 当反应温度过低时, 水解过程中粒子的形成主要受扩散控制, 温度低使扩散速度缓慢, 成核时间较长, 不利于水解反应这类吸热反应的发生, 反应生成的沉淀呈胶体状, 洗涤相当困难。 当反应温度过高时, 虽然溶液中粒子的扩散速度加快, 但晶核长大的速度更快, 晶核的长大占主导作用, 较大的晶核使粒径分布变宽, 从而影响了最后制备出来的粉末性能。 因此在本研究中, 由于保持较高的过饱和度, 反应可在较低的温度(〈 80℃)下进行。 但当反应温度过低时, 对类似于水解的这一类吸热反应, 成核诱导时间太长, 反应生成的沉淀近似胶体状, 造成后续的洗涤和过滤相当困难。 当反应温度升高时, 氨水溶液挥的发加剧, 使得反应pH值难以稳定控制。 综上所述, 确定共沉淀的反应温度为60℃。

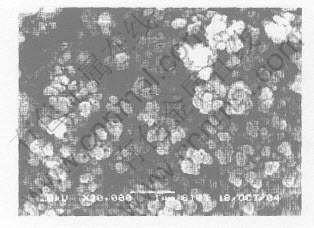

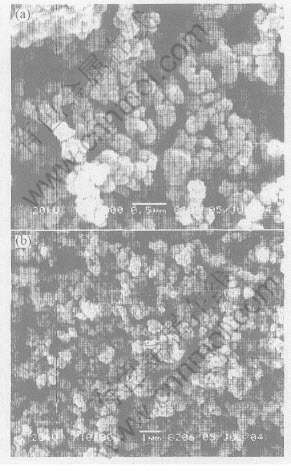

图6所示为共沉淀温度60℃时ATO粉的SEM像。 从图6中可以看出, 粉体的粒度较均匀, 粒径约80~90nm左右, 形貌较为均一, 晶粒呈现典型的球状或仿球状。

2.3 前驱体洗涤次数对粉体粒度形貌的影响

采用湿化学沉淀法制备超细粉体具有工艺简单, 成本低的优点, 但在粉体粒度控制和粉体的过滤、 洗涤时存在一些问题。 想获得超细颗粒, 则过滤性能较差, 反之, 则粒度不易得到保证。 要得到超细氧化物粉体, 需获得颗粒细小、 分布均匀的前

图6 配合-共沉淀温度60℃时ATO粉体的SEM像

Fig.6 SEM image of ATO at complex- coprecipitation temperature of 60℃

驱体, 而此时的过滤性能就变差。 研究中发现, 过滤速度不仅与粒子的粗细有关, 还取决于滤饼的厚度、 温度、 液固比等。 通过减压抽滤, 使用定量快速滤纸比普通定性滤纸的抽滤速度要快得多。 尽管如此, 随着洗涤次数的增加, 抽滤速度还是越来越慢, 以至无法分离。

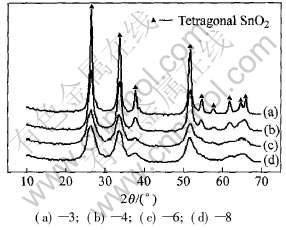

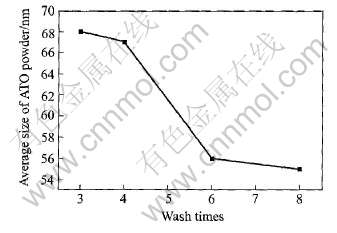

采用配合-共沉淀法制备ATO粉体时, 前驱体氧化物水合物也存在着难以分离的弊端, 用去离子水洗涤3次后, 前驱体沉淀表面吸附的分散剂几乎全部被洗掉, 溶液pH值也明显降低, 沉淀由刚开始的易于沉降变成难以分离的胶状沉淀, 而此时易于引起硬团聚的Cl-和NH+4还没有除去。 另外, 前驱体沉淀洗涤次数越多, 固液分离所需的时间就越长, 甚至无法分离。 为获得超细分散的ATO粉, 必须使用适当的前驱体洗涤方式, 并搞清洗涤次数及洗涤方式对ATO粉体性能的影响。 本研究采用配合-共沉淀法制备了ATO的前驱体沉淀, 并初步探索了解决采用配合-共沉淀法制备超细ATO前驱体沉淀过程中沉淀难以洗涤及分离问题的方法。 采用先倾泻陈化后的溶胶上清液, 再用60℃的适量蒸馏水冲稀溶胶后, 静置6h, 然后过滤分离。 实验考察了冲稀洗涤次数和粉体晶粒尺寸的关系, 结果如图7和8所示。

从图7和8可以看出, 随着去离子水洗涤次数的增加, 粉体粒径逐渐变小。 这是由于在干燥阶段, 干凝胶中非架桥羟基产生硬团聚所致。 前驱体中残余的NH+4和Cl-使干凝胶中非架桥羟基数量大大增加, 干燥过程的粒子长大, 而煅烧过程中又容易产生硬团聚, 而ATO粉体中的Cl-还会在应用过程中对使用部件产生腐蚀作用, 因此应尽量减

图7 不同洗涤次数ATO粉的X射线衍射谱

Fig.7 XRD patterns of ATO powders after different wash times

图8 洗涤次数对ATO粉平均晶粒大小的影响

Fig.8 Effect of wash times on average size of ATO powders

少粉体的NH+4和Cl-。 结合生产成本考虑, 前驱体洗涤6次为最佳。

2.4 掺锑浓度对粉体粒度形貌的影响

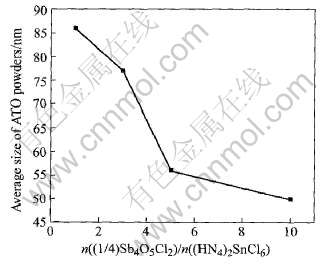

由配位-共沉淀法制得了不同掺锑浓度的ATO粉, 掺锑浓度(x)为1/4Sb4O5Cl2和(NH4)2SnCl6的摩尔比。 图9所示为不同锑掺杂浓度下ATO粉的X射线衍射谱。 从图9中可看出, 在掺杂浓度范围内, Sb的掺入并没有形成Sb2O3的分相及改变SnO2的晶体结构, SnO2粉的晶体结构仍为四方晶系的金红石结构。 但是掺杂影响了结晶取向和结晶粒度, 使样品X射线衍射峰的位置发生了微小迁移。 另外, 随着掺杂浓度的增加, ATO粉的结晶性变差, 样品的衍射峰变得越来越宽, 其强度也越来越弱。

运用Scherrer公式可估算出晶粒的平均尺寸。

图9 不同锑掺杂浓度下ATO粉的X射线衍射谱

Fig.9 XRD patterns of ATO powder with different Sb concentration

图10所示为样品晶粒平均尺寸与锑掺杂浓度的关系。 从图10中可以看出, 随着掺杂浓度的提高, 晶粒的平均尺寸越来越小。

图10 锑掺杂浓度与ATO粉晶粒平均尺寸的关系

Fig.10 Relationship between Sb concentration and average size of ATO powders

在掺杂剂Sb以Sb3+和Sb5+的形式扩散到SnO2晶格形成固溶体的过程中产生大量的晶格缺陷, 造成结晶度降低, 晶格结构不完整, 阻碍了晶粒的生长。 当掺杂浓度(x)等于10%时, 粉体晶粒尺寸的减小变缓, 可能是由于掺杂造成的大量缺陷有部分开始复合、 补偿, 从而使颗粒结晶度不至于继续降低所致。 此时锑的进一步掺杂对样品晶粒平均尺寸的影响变小。

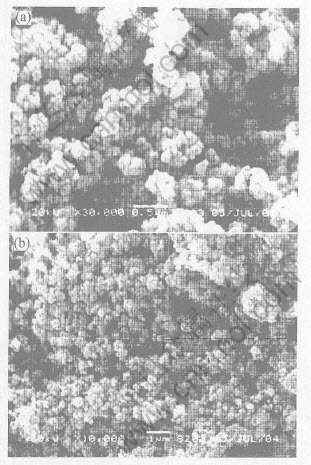

图11所示为掺锑浓度为10%时ATO粉的SEM像。 由图11可见, 粉末颗粒呈规则仿球形, 且在所得的样品中均没有分相存在, 说明掺入的锑原子固溶于氧化锡晶格中, 这与X射线衍射结果一致。 当掺杂浓度较大时, 粉末粒径较小, 比表面积较大, 表面能较高, 颗粒间的吸附作用增强, 形成微细颗粒的聚集体, 当掺杂浓度较低时, 粉末粒径较大, 粒度分布均匀, 其单分散性较好。 但Scherrer公式计算的粒径小于SEM的测定值。 这是由于Scherrer公式计算粒径为平均晶粒度, 而SEM测定值为颗粒度, 同时又有多种因素影响Scherrer公式计算粒径的准确性所致。 晶体中没有不均匀应变等晶格缺陷存在, 衍射峰宽化由晶粒尺寸大小引起, 当样品结晶度不好及晶体内部不是理想晶体时, 同样会导致衍射峰宽化, 而此时并不意味着晶粒尺寸就一定小[13-15]。

图11 掺锑浓度为10%时ATO粉的SEM像

Fig.11 SEM images of ATO powders with 10% Sb concentration

2.5 煅烧温度对粉体粒度形貌的影响

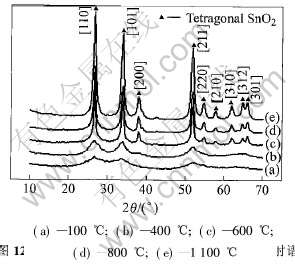

将实验制得的干粉样品分别于80~1100℃下进行热处理, 热处理时间均为3.5h, 对不同热处理温度样品进行X射线衍射和SEM测试。 图12所示为不同热处理温度时ATO粉的X射线衍射谱。

图12 不同热处理温度时ATO粉的X射线衍射谱

Fig.12 XRD patterns of ATO at different heat treated temperatures

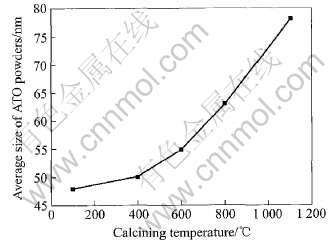

从图12可以看出, 较高温度处理(≥400℃)样品的X射线衍射数据与四方相SnO2的JCPDS标推卡片大致相符, 表明此样品具有四方相的金红石结构。 即使是经100℃干燥处理的样品, 其3个宽化峰也与四方相SnO2相应晶面对应, 在实验样品中, 也未见Sb的衍射峰, 表明Sb的掺杂并没有带来新的物相结构, 但是它使样品衍射峰的位置发生了较小的迁移。 这也表明共沉淀法使掺杂的Sb固溶于SnO2晶格中, 较好地实现了复合掺杂。 而低温样品(〈600℃)的X射线衍射谱只显示出[110]、 [101]和[211]面等强衍射峰, 其它弱衍射峰不明显。 随热处理温度的升高, 衍射峰逐渐尖锐, 衍射峰强度逐渐增加, [200]、 [220]、 [310]、 [312]和[301]面等弱衍射峰也逐渐明显, 说明SnO2的晶化特征逐渐明显, 晶体结构愈趋完整。 由于晶粒尺寸引起X射线衍射线宽化, 可运用Scherrer公式计算对应晶粒的平均尺寸。 图13所示为根据图12计算样品的平均晶粒度与煅烧温度的关系曲线。 从图13中可看出, 随着热处理温度的提高, 晶粒尺寸逐渐增大, 晶型逐渐完整, 在低温区(〈600℃)时, 晶粒长大缓慢, 随着热处理温度继续提高, 晶粒迅速长大, 达到1100℃时计算粒度达到78nm, 此时样品的晶化已相当完全。 图14所示为煅烧温度为600℃时粉体的SEM像。 从图14可看出, 当煅烧温度为600℃时, 图中晶粒已呈良好的球形及仿球形。

2.6 表面活性剂对粉体粒度形貌的影响

采用液相配合-共沉淀法制备氧化物超细粉末, 当形成一定的生产率时, 所用的混合盐溶液及沉淀剂的浓度往往不能太低, 因而前驱溶液的过饱和大, 反应离子的绝对浓度也高, 快速成核得到锡锑

图13 煅烧温度与ATO平均晶粒尺寸的关系

Fig.13 Relationship between calcining temperature and average size of ATO powders

图14 煅烧温度为600℃时ATO粉的SEM像

Fig.14 SEM images of ATO powders at heating temperature of 600℃

氧化物水合物前驱体溶胶。 当这些胶粒之间的范德华引力大于其双电层斥力并接近到一定程度时(静电机制失效)便开始产生聚集, 这种湿凝胶如果直接干燥, 必形成非常坚硬、 密实的硬团聚体, 即使经有机溶剂脱水处理, 三维网络状聚集体内包藏的水等杂质也不能全部脱尽, 仍会形成一定数量的硬团聚体。 因此, 控制沉淀反应器中胶粒的聚集, 避免形成会包藏水的大块网络状聚集体, 从而得到充分分散的胶粒, 制备出优良的ATO粉末。 在干燥过程中加入高分子表面活性剂, 只有很小的收缩现象, 表明湿粉体中毛细管力已很微弱, 使得高分子表面活性剂的引入实现了干燥过程的团聚控制。

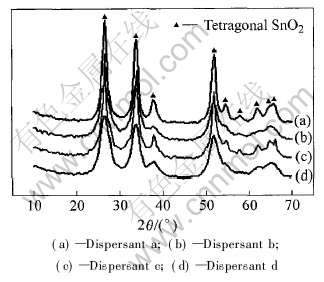

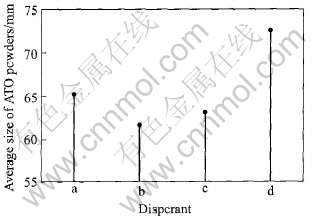

本研究探索某些合适的表面活性剂a、 b、 c、 d, 利用“静电因素”或“位阻稳定"的作用, 在制备ATO粉初期即沉淀形成过程, 加入适量的表面活性剂进行“胶体保护”, 以减轻粉末的团聚。 在固定其它反应条件不变时, 添加4种表面活性剂后所得ATO粉体衍射图谱如图15所示。

图15 添加不同分散剂所得ATO的X射线衍射谱

Fig.15 XRD patterns of ATO powders with different dispersants

从图15可以看出, 在几种不同分散剂条件下所得样品的X射线衍射数据与四方相SnO2的JCPDS标推卡片大致相符, 表明样品具有四方相的金红石结构。 在实验所用的掺杂浓度及分散剂加入浓度范围内所得的样品中, 未见Sb的衍射峰及其它杂相存在, 表明Sb的掺杂及分散剂的添加并没有带来新的物相结构, 但它使样品衍射峰的位置发生了较小的迁移。 这也表明共沉淀法使掺杂的Sb固溶于SnO2晶格中, 较好地实现了复合掺杂。 当使用的分散剂为a, b, c时, ATO粉体X射线衍射峰先宽后窄, 表明实验中所选用的几种分散剂对比效果明显, 但图15中曲线(d)的衍射峰过于宽化, 估计使用这种分散剂时, 所得ATO样品结晶度不好或者可能所得ATO晶体内部不是完整的理想晶体, 导致衍射峰宽化, 但并不意味着晶粒度就一定小。 因此确定使用表面分散剂c。

2.7 综合实验

对以上所确定的最佳条件进行综合实验验证。 在1000mL的烧杯中加入一定量的氯氧锑配成锑浓度为0.1mol/L的悬浊液750mL, 加入配合剂12g, 搅拌片刻, 生成澄清透明的配合溶液, 在10L的不锈钢桶中加入一定量的氯锡酸铵配成锡浓度为0.3mol/L的的溶液6L, 随后将两溶液混合均匀。 在2000mL的烧杯中配制成3mol/L的氨水溶液1500mL待用。 在10L的不锈钢桶中加入蒸馏水800mL, 水浴加热至60℃, 在恒定的搅拌速度下采用并加方式, 将锡锑配合溶液和氨水溶液均匀滴入不锈钢桶中, 保持滴定终点的pH为3左右, 60min加完料后继续反应30min, 然后加入包覆剂20g, 继续反应20min后常温陈化12h。 采用倾泻方式使固液分离, 采用煮沸脱水的方式制备干燥前驱体, 所得前驱体于600℃煅烧3.5h后即得纳米级ATO粉。

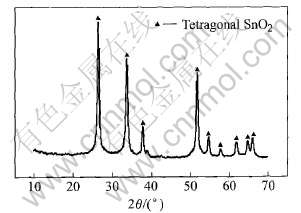

图17所示为综合试验制备ATO的X射线衍 射谱。 由图17可见, 综合实验所得样品的X射线衍射数据与四方相SnO2的JCPDS标推卡片很好相符, 表明样品具有四方相的金红石结构。 在实验条件范围内, 未见Sb及其它杂质的衍射峰, 表明Sb的掺杂并没有带来新的物相结构, 但是它使样品衍射峰的位置发生了较小的迁移。 这也表明共沉淀法使掺杂Sb固溶于SnO2晶格中, 较好地实现了复合掺杂。

图16 由scherrer公式计算所得ATO粒径

Fig.16 Relationship between dispersant and average crystallite size of ATO

图17 综合实验制备ATO的X射线衍射谱

Fig.17 XRD patterns of ATO powders prepared at synthetical condition

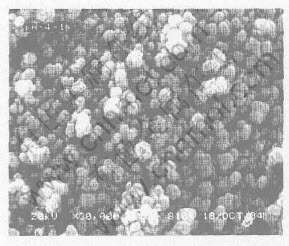

图18所示为采用配合-共沉淀法在优化条件下制得ATO粉的SEM像。 从图18中可看出, 粉末颗粒呈现规则的球形, 粒径范围较窄, 粒度较细(约75nm), 形貌较为均一, 在掺杂浓度样品中均没有分相存在, 说明掺入的锑原子固溶于氧化锡晶格中, 这与X射线衍射结果一致, 且粉末粒径比较小, 单分散性较好, 仅见一些轻微的软团聚。

图18 采用配合-共沉淀法在优化条件下制得ATO粉的SEM像

Fig.18 SEM image of ATO powders prepared under optimal reaction condition by complex-co-precipitation

3 结论

1) 从含锡锑二次资源中直接提取的高纯氯锡酸铵和氯氧锑能够合成出具有优良性能表征的纳米级ATO粉。

2) 配合-共沉淀法能解决传统液相共沉淀法制备ATO时锡、 锑水解不同步, 未能实现真正共沉淀掺杂的缺陷。 采用配合-共沉淀法以(NH4)2SnCl6和Sb4O5Cl2为原料, 最佳的实验条件: 滴定终点pH值为3, 反应温度为60℃, 锑掺杂量为10%, 煅烧温度为600℃, 前驱体洗涤6次, 采用分散剂c。 综合实验验证表明在此条件下能制备出掺杂均匀、 粒径分布窄、 形貌均一、 分散性较好的纳米级ATO粉。

3) 所得样品的X射线衍射数据与四方相SnO2的JCPDS标推卡片相符, 样品具有四方相的金红石结构。 在研究所用掺杂浓度及分散剂加入浓度的范围内所得样品中, 未见Sb的衍射峰及其它杂相存在, Sb的掺杂及分散剂的添加并没有带来新的物相结构, 但是它使样品衍射峰的位置发生了较小的迁移。 配合-共沉淀法使掺杂Sb固溶于SnO2晶格中, 较好地实现了复合掺杂。

REFERENCES

[1]CHI Yan-bo, CHEN Xue-hua. A method to prepare the inorganic anlistatig suspend solution[P]. CN C09K3/16. 2002-01-12.

[2]Rajpure K Y, Kusumade M N. Effect of Sb doping on properties of conductive spray deposited SnO2 thin films[J]. Materials Chemistry and Physics, 2000, 64(18): 184-188.

[3]Shanthi S, Subramanian C. Growth and characterization of antimony doped tin oxide thin films[J]. Journal of Crystal Growth, 1999, 197: 858-864.

[4]Nutz T, Uzum F, Haase M. Wet-chemical synthesis of doped nano-particles: blue-colored colloids of n-doped SnO2-Sb[J]. J Chem Phys, 1999, 110(24): 12142-12150.

[5]Sun K, Liu J, Browning N D. Correlated atomic resolution microscopy and spectroscopy studies of Sn (Sb) O2 nanophase catalysts[J]. Journal of Catalysis, 2002, 205(27): 266-277.

[6]Marcel C, Hegde M S. Electrochromic properties of antimony tin oxide (ATO) thin films synthesized by pulsed laser deposition[J]. Electrochimica Acta, 2001, 46(23): 2097-2104.

[7]ZHANG Jian-rong, GU Da. Prepared ATO conductive powder by wet chemistry way[J]. Function Material, 2002, 33(3): 122-126.

[8]Burgard D, Goebbert C, Nass R. Synthesis of nanocrystaline, redispersable antimony-doped SnO2 particles for the preparation of conductive, Transparent Coatings[J]. J Sol-Gel Sci Tech, 1998, 13(17): 789-792.

[9]YANG Jiang-guang, TANG Mo-tang, YANG Sheng-hai, et al. Conducting mechanism and theory conductivity of antimony doped tin oxide[J]. Micronanoelectronic Technology, 2004, 41(4): 18-20.

[10]YANG Jian-guang, TANG Mo-tang, YANG Sheng, et al. Coalescence forming of Nano-ATO powder in wet preparation and eliminating methods[J]. China Paint, 2004, 21(7): 33-36.

[11]YANG Jian-guang, TANG Mo-tang, YANG Sheng-hai, et al. Conducting mechanism and fabrication of antimony doped tin oxide(ATO): current status of R & D[J]. Materials Review, 2004, 18(3): 17-21.

[12]TANG Mo-tang, YANG Jian-guang, YANG Sheng-hai, et al. Thermodynamic calculation of Sn(Ⅳ)-NH+4-Cl-H2O system[J]. Trans Nonferrous Met Soc China, 2004, 14(4): 726-729.

[13]LU Fan, CHEN Song-ying. Some methods to evaluate fine powder[J]. ChinJ Appl Chem, 1994, 11(5): 68-70.

[14]LI Qing-shan, ZHANG Jing-zhao, SONG Li. Fabrication and character of antimony doped tin oxide[J]. Journal of East China University of Science and Technology, 2202, 28(2): 184-187.

[15]LI Qing-shan, ZHANG Jing-zhao, SONG Li. Effect of Sb concentration to characteristics of antimony doped tin oxide[J]. Journal of Inorganic Materials, 2002, 17(6): 1823-1828.

(编辑李艳红)

收稿日期: 2004-11-18; 修订日期: 2005-03-09

作者简介: 杨建广(1976- ), 男, 博士研究生.

通讯作者: 杨建广, 博士; 电话: 0731-8832572; E-mail: jianguang_yang@hotmail.com