文章编号:1004-0609(2008)05-0799-06

高能喷丸TA17近α钛合金晶粒细化机制

韩 靖,盛光敏,胡国雄

(重庆大学 材料科学与工程学院,重庆 400044)

摘 要:为研究TA17近α钛合金在高能喷丸(HESP)过程中的晶粒细化机制,采用高能喷丸对TA17近α钛合金棒材端面进行处理,利用光学显微镜(OM)、扫描电子显微镜(SEM)、透射电子显微镜(TEM)和X射线衍射仪对喷丸变形层组织进行表征,按照变形层中不同深度的组织特征对晶粒细化机制进行探讨。结果表明:在喷丸表面形成35 nm左右的等轴纳米晶,在孪晶形成层中粗晶内形成较厚的孪晶薄片,在过渡层中位错滑移使孪晶薄片内生成小角度取向的亚晶,在纳米层中亚晶被转变成随机取向的等轴纳米晶。

关键词:钛合金;高能喷丸;纳米晶;孪生;位错

中图分类号:TG 142.1 文献标识码:A

Mechanism of grain refinement for TA17 near α Ti alloy by high energy shot peening

HAN Jing, SHENG Guang-min, HU Guo-xiong

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: In order to research the mechanism of grain refinement in TA17 near α Ti alloy, the cross section surface of TA17 near α Ti alloy bars were treated by high energy shot peening(HESP). The microstructures feature in plastic deformation layer were characterized and researched by optical microscopy(OM), scanning electron microscopy(SEM), transmission electron microscopy(TEM) and X-ray diffraction(XRD). The grain refinement mechanism was researched according to different depth microstructures feature in the deformation layer. The results show that the equiaxed nanograins with about 35 nm are synthesized on the peening surface. In the twin forming layer, the twin lamellas are generated in coarse grains. In the transition layer, twin lamellars are transformed into with small angle by dislocation slip. And in the nanometer crystalline grain layer, subgrain are transformed into randomly oriented equiaxed nanograins.

Key words: titanium alloy; high energy shot peening; nanograin; twin; dislocation slip

纳米材料由于晶粒细小,界面密度高,能够为原子扩散提供大量通道,因而大大提高了原子的扩散系数[1]。另外,晶界处存在位错、空位和亚晶界等非平衡缺陷以及大量的存储能,有利于原子的化学反 应[2-3]。在纳米材料的制备方面,自从20世纪80年代初,BIRRINGER等[4]采用金属蒸发—原位冷压成形法制备出纳米晶体样品以来,相继发展了非晶晶化法[5]、各种沉积法[6]和剧烈塑性变形法[7]等,这些方法因各自存在一定的局限性难以实现工业化生产。20世纪末, LU等[8]提出了金属块体材料表面自纳米化(SNC)概念,其原理是利用外加载荷使金属块体材料表面的局部发生塑性变形,引入大量非平衡缺陷和界面使常规粗大晶粒细化成纳米晶粒。该方法制备出的纳米晶粒的化学成分与基体的相同,不存在界面污染和孔洞等缺陷。同时,纳米层和基体间结合紧密,不易脱 落。使用该方法已实现了多种金属材料[9-11]的表面纳米化,并运用到表面化学热处理中[12-17],大大提高了化学热处理过程中原子的扩散系数,降低了热处理时间,提高了金属材料的表面性能,为低温高效化学热处理开辟了新途径。

目前尚未见到将表面自纳米化运用到异种金属材料扩散连接的报道,本研究对TA17近α钛合金进行表面自纳米化处理,以制备出表面含有纳米晶层的钛合金扩散连接试样,提高了钛合金和其它异种金属扩散连接时的原子扩散系数,降低了连接温度,缩短了连接时间,提高了扩散连接接头的性能。本文作者就TA17近α钛合金经高能喷丸自纳米化过程中的晶粒细化机制进行了研究。

1 实验

1.1 实验材料

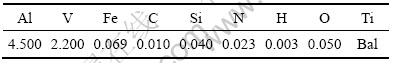

采用规格为d12 mm×3 mm的TA17近α钛合金棒材,其化学成分如表1所列。为了便于研究,须将棒材在760 ℃下真空退火3 h,获得20~50 μm的α相等轴粗大晶粒,晶界处有少量的β相(见图1(a))。在高能喷丸处理前,将棒材的喷丸端面用金相砂纸磨制到1200#砂纸,然后抛光,以获得光洁平整的表面。

表1 TA17钛合金的化学成分

Table 1 Chemical composition of TA17 alloy (mass fraction, %)

1.2 实验方案

高能喷丸所使用的设备为6050B型喷丸机,其工作原理是:工作仓内的钢丸在负压作用下被吸附到高压喷枪喷嘴处,钢丸在高压气流的带动下高速冲击到试样表面,冲击到试样表面的每一颗钢丸都使表面发生局部塑性变形。其中,高压气流在进入喷枪前经除湿干燥处理,以防污染样品表面。为了防止高能喷丸时试样表面金属向边沿外流动,须制作一内径与棒材外径相同的紧固夹具套住处理端面,约束金属流动。喷丸钢丸直径为1.0 mm,喷嘴到试样表面的距离为50 mm,喷丸工作压力为0.6 MPa,喷丸时间分别为1、5和13 min。

喷丸处理后将试样喷丸端沿纵向剖开磨制成金相试样,用Kroll(6%HNO3、2%FH、92%H2O)试剂浸蚀,在OLYMPUS-GX41型金相显微镜和Nova NanoSEM型扫描电子显微镜(SEM)下进行观察分析。将喷丸表面用布抛光清洁后在D/Max-1200 型X射线衍射仪上进行衍射分析,采用靶材为Cu靶( =0.154 056 nm,

=0.154 056 nm, 采用石墨单色仪分离),得到不同喷丸时间的X射线衍射谱。为了进一步分析喷丸过程中的晶粒细化机制,在经喷丸13 min样品的表面层取样制成透射电子显微镜(TEM)薄膜样品,在PHILIP-TECNAI20型透射电子显微镜下观察分析。

采用石墨单色仪分离),得到不同喷丸时间的X射线衍射谱。为了进一步分析喷丸过程中的晶粒细化机制,在经喷丸13 min样品的表面层取样制成透射电子显微镜(TEM)薄膜样品,在PHILIP-TECNAI20型透射电子显微镜下观察分析。

2 结果与分析

2.1 光学显微镜观察

图1所示为经不同喷丸时间试样纵剖面的显微组织。图1(a)所示为试样未经喷丸的原始退火显微组织。由图1(a)可看出,组织为钛合金α相等轴粗晶,有少量的β相,晶界清晰,晶粒内不存在孪晶。图1(b)所示为喷丸1 min试样的金相照片。由图1(b)可看出,在距表面约230 μm左右深度处开始出现孪晶,形成一变形层,随着深度的减小,孪晶密度逐渐增大,且出现孪晶交叉,在距表面约20 μm左右深度内,晶粒形状、大小和晶界已不能辨别,说明该区域内发生了剧烈的塑性变形,晶粒已经细化到一定程度,在金相显微镜下已不能分辨其形貌。图1(c)和(d)所示分别为试样喷丸5和13 min后的显微组织。由图1(c)和(d)可看出,它们开始出现在孪晶深度约为250 μm处,但剧烈塑性变形层的厚度不一样,喷丸5 min的剧烈塑性变层厚度约为80 μm,而喷丸13 min的约为120 μm。由3个喷丸试样的显微组织可以看出,在一定的应力和应变速率作用下,剖面形成的变形层厚度大致相同,只是随喷丸时间的增加,剧烈塑性变形层的厚度在逐渐增加,同时变形层中的孪晶密度增大。在变形层内存在一些黑色区域,可以看出一个黑色区域就是一原始粗晶的范围,这是由于经高能喷丸后,原始粗晶内形成了高密度的孪晶及其交叉,由于孪晶界不耐腐蚀,且原始粗晶的位向不同,经Kroll试剂浸蚀后在金相显微镜下呈现出黑色区域。

图1 喷丸不同时间试样纵剖面的显微组织

Fig.1 Microstructures of longitudinal section of samples after HESP for different times: (a) Untreated; (b) 1 min; (c) 5 min; (d) 13 min

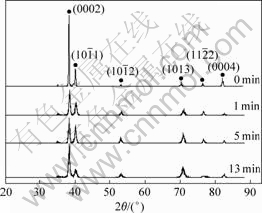

2.2 XRD分析

图2所示为经不同喷丸时间处理后试样的XRD谱。由图2可以看出,试样经不同喷丸时间后,衍射峰都出现了一定程度的宽化,并随喷丸时间的增加,宽化程度逐渐加大,衍射峰的宽化主要是由于晶粒细化和晶格畸变引起的,说明经喷丸1 min后,试样表面层晶粒已经发生了一定程度的细化,并产生了晶格畸变。将衍射峰的强度值与钛的JCPDS卡片上的标准值对比表明,经高能喷丸处理后在组织中并未产生织构。

图2 经不同喷丸时间处理后试样表面的XRD谱

Fig.2 XRD patterns of surface layers of samples after HESP for different times

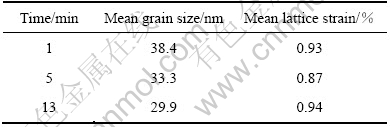

利用MDI Jade5.0软件对XRD数据进行处理计算,得到试样经不同喷丸时间后的平均晶粒直径和晶格畸变(见表2)。由表2可知,试样经不同时间喷丸处理后,表面晶粒都已细化到约(35±5) nm。

2.3 SEM观察

图3所示为喷丸时间为13 min的纵剖面变形层中不同深度的SEM像。其中图3(a)所示为整个变形层的形貌。经测量变形层的厚度达253.52 μm,剧烈塑性变形层的厚度达121.81 μm,这和图1(d)的观察结果相符合。图3(b)所示为距表面230 μm左右变形层接近基体附近的照片。由图3(b)可看出,在某一晶粒内形成了2 μm左右的单向孪晶片,而与之相邻的部分晶粒中则不存在孪晶。图3(c)所示为距表面150 μm左右处的观察结果。由图3(c)可以看出,相邻的所有晶粒内都出现了孪晶,晶粒取向不同,其孪晶的取向也不同,同时孪晶片的密度和厚度也各不相同,部分晶粒内还出现了孪晶交叉,将原始粗晶分割成细小的四边形小块。图3(d)所示为距表面约80 μm深度处某一晶粒的组织形貌,原始粗晶经多方向孪晶交叉分割后形成了亚微米级的长条形颗粒,具有一定的取向性,原始粗晶的形状和晶界还能隐约区辨。由图3可见,TA17近α钛合金经高能喷丸13 min后,在约80 μm深度处已经形成了亚微米级的细小颗粒,这将有助于晶粒的进一步细化及纳米晶的形成。

表2 不同喷丸时间的晶粒直径和晶格畸变

Table 2 Mean grain size and mean lattice strain of samples after HESP for different times

图3 喷丸13 min样品不同深度的SEM像

Fig.3 SEM images at different depths of sample after HESP for 13 min: (a) Total deformation layer; (b) About 230 μm depth; (c) About 150 μm depth; (d) About 80 μm depth

2.4 TEM观察内粒0nmANG

图4所示为高能喷丸13 min试样距表面约50 μm处的TEM像。由图4(a)可看出,一孪晶片内不同取向的位错将孪晶分割成A、B、C、D、E和F等亚晶,亚晶的尺寸约为150 nm,具有一定位向。且随着位错的不断增殖和滑移,在孪晶界处聚集形成位错墙和位错缠结,将亚晶转变成多边形的等轴晶粒(见图4(b))。对应的选区电子衍射(SAED)斑点已经变成衍射环,这是由于晶粒细化和取向随机的结果,由前述XRD衍射数据计算可知,喷丸表面的晶粒尺寸已经达到40 nm以下。由图4观察及分析可知,在距表面50 μm深度左右,形成了小角度取向的亚晶,且随深度的减小进一步转变为等轴纳米晶粒。

图4 高能喷丸13 min试样距表面约50 μm 处的TEM像

Fig.4 TEM images of layer about 50 μm away from topmost treated surface of sample after HESP for 13 min:

(a) Subgrains in twin by dislocation slip; (b) Nanograins in twin lamellar by dislocation walls

3 讨论

关于金属材料表面自纳米化过程中的晶粒细化机理,有研究[18]表明,在表面机械研磨处理(SMAT,一种表面自纳米化方法)过程中,晶粒细化机理主要取决于材料的层错能和晶体结构,具有高层错能的体心立方(bcc)晶格Fe(层错能约为200 mJ/m2),主要通过位错滑移形成位错墙和位错缠结将粗大晶粒细化成纳米晶粒;具有中等层错能的面心立方晶格(fcc)Cu(层错能约为78 mJ/m2),通过位错滑移形成位错胞以及孪生变形使粗晶细化。对于低层错能的面心立方晶格AISI304奥氏体不锈钢(层错能约为17 mJ/m2),主要靠孪生变形将粗大晶粒细化成纳米晶。最近,有关研究人员[19-21]研究了密排六方(hcp)晶格纯Co(层错能为(27±4) mJ/m2)、α纯钛(层错能大于300 mJ/m2)和AZ91D镁合金(层错能为60~78 mJ/m2) 表面自纳米化过程中的晶粒细化机理,尽管这3种金属的层错能相差较大,但它们在低应变作用下的晶粒细化机理都是通过孪生变形来实现。

在本研究中,根据前述显微组织的观察,可看出TA17近α钛合金试样经高能喷丸处理后,在距表面不同深度处,显微组织具有不同特征,在试样的表面形成了等轴纳米晶。按照纳米晶的形成过程和不同深度内显微组织的特征,可以将整个变形层分为孪晶形成层、过渡层和纳米晶层,以便对晶粒细化机理进行探讨。

3.1 孪晶形成层

TA17近α钛合金经高能喷丸处理后,在变形层与基体相邻区域,由于距表面深度大,应力和应变速率小,那些取向有利于孪生变形的晶粒首先产生了孪生变形,在晶内形成了单方向的孪晶片,而那些取向不利于孪生变形的晶粒则尚未开始产生孪生变形,晶粒内不存在孪晶,但随着深度的减少和应力的增加,晶粒内会相继发生孪生变形(见图1和3(b))。经观察分析,在这一区域内没有产生位错滑移。这是由于多晶体材料在外力作用下要产生均匀塑性变形,就必须至少有5个独立的滑移系,然而,具有密排六方晶格的TA17近α钛合金只有4个独立的滑移系,为了维持塑性变形,在低应变作用下只有靠孪生变形来实现。CHICHILI等[22]研究认为,在室温下,当应变低于15%时,钛首先通过孪生维持塑性变形。钛晶体中的孪晶面有 ,孪生方向为

,孪生方向为 ,变形温度和变形条件不同,将在不同的孪晶产生孪生变形,文献[20]中观察到纯钛在室温下沿

,变形温度和变形条件不同,将在不同的孪晶产生孪生变形,文献[20]中观察到纯钛在室温下沿 面形成了孪晶。对不同喷丸时间的试样测量,总变形层厚度大致相同,而孪晶形成层的厚度随时间减少而增厚,在孪晶形成层中,显微组织主要以含有单系孪晶的粗晶为主,且随深度的减小,应力逐渐增大,孪生变形也逐渐增大,孪晶片的厚度却逐渐越薄。孪晶形成层的组织特征表明了粗晶在低应力作用下开始细化的初时阶段。

面形成了孪晶。对不同喷丸时间的试样测量,总变形层厚度大致相同,而孪晶形成层的厚度随时间减少而增厚,在孪晶形成层中,显微组织主要以含有单系孪晶的粗晶为主,且随深度的减小,应力逐渐增大,孪生变形也逐渐增大,孪晶片的厚度却逐渐越薄。孪晶形成层的组织特征表明了粗晶在低应力作用下开始细化的初时阶段。

3.2 过渡层

随着距表面深度的减小,应变速率逐渐增加,越来越多的晶粒取向有利于孪生,晶粒中产生了多系孪生变形,不同的孪晶系相互交叉,将粗晶分割成许多四边形小块(见图3(c))。且随着深度的进一步减小,应力应变进一步增大,四边形小块内再生出新孪晶,将它们分割成微米级的细小颗粒(见图3(d))。ZHU等[20]认为在纯钛的塑性变形中,当应变增加到一定程度时,位错运动起主要作用,大量孪晶以及孪晶交叉阻碍了位错的运动,在孪晶界处形成了高密度的位错。而在本研究中,在距表面约50 μm深度处,孪生变形已经减少,孪晶薄片内某些晶面的位错沿滑移面滑移,位错聚集在孪晶界处形成位错墙和位错缠结,将孪晶薄片分割成小角度的亚晶(见图4(a))。另外,纯钛的塑性变形模式(孪生或滑移)很大程度上取决于原始组织的结晶织构[20],本研究使用的TA17近α钛合金棒材是经热轧后在760 ℃保温3 h充分退火的等轴粗大晶粒,并不存在优先取向和方向性,因此,孪生和滑移并不是结晶织构造成的。由前述观察可知,随喷丸时间的增加,过渡层范围逐渐减小,且随着深度的减少,应变速率达到一定程度后,位错滑移逐渐取代孪生变形,将细小的孪晶片转变成亚晶,粗晶在持续多方向的应力应变作用下进一步细化。

3.3 纳米层

在距高能喷丸试样表面50 μm深度以内,受到持续多方向的高应力和高应变速率作用,同一孪晶片内出现了多个不同的滑移系,导致位错密度增加和位错间距减小,为了使系统的能量最小化,位错将发生重排再组形成位错墙,位错墙在孪晶片形成小角度的亚晶。当应变和应变速率增加时,小角度的亚晶通过位错滑移转变为大角度随机取向的等轴晶粒(见图4(b)),对应的选区电子衍射(SAED)斑表明亚晶界逐渐从低角度取向转变为大角度随机取向,随应变和应变速率增加,位错大量积聚促进亚晶旋转,最终在喷丸表面层形成随机取向的等轴纳米晶粒。

综上所述,可看出应力和应变速率在晶粒细化过程中起着极其重要的作用,在孪晶形成层中对应着低应力和低应变速率,组织特征以单系孪晶为主,过渡层对应着中等程度的应力和应变速率,组织特征以亚微米孪晶颗粒和亚晶为主,纳米层对应着高应力和高应变速率,组织特征以随机取向的等轴纳米晶为主。当然,这3个不同特征的组织层间并不是截然分开的,而是逐渐过渡,没有明显的界限。另外,纳米晶粒的尺寸并不能无限制的减小,这可能是由于在获得尺寸稳定的纳米晶粒后,在一定的应力应变速率下,位错增殖和位错湮没达到动态平衡状态,不能形成新的位错墙和位错缠结[18]。

4 结论

1) TA17近α钛合金在高能喷丸表面自纳米化过程中,孪晶开始出现的深度取决于应力和应变速率大小,而与喷丸时间关系不大,剧烈塑性变形层随喷丸时间的延长而增厚。

2) 高能喷丸使TA17近α钛合金的表面晶粒细化至35 nm左右,经喷丸13 min的钛合金形成了具有约50 μm厚的纳米晶粒表面层。即采用高能喷丸能够在TA17近α钛合金端面制备出含有纳米晶粒的表面层,以满足钛合金纳米化扩散连接的要求。

3) TA17近α钛合金在高能喷丸表面自纳米化过程中,其晶粒细化机制为:在低应变速率作用下产生孪生变形,将粗晶分割成较厚的孪晶片,随着应力及应变速率的增加,孪晶密度增大,将粗晶细化成亚微米级的孪晶薄片;当应变速率增大到一定程度后,细小的孪晶内产生位错滑移,位错在孪晶界处塞积形成位错墙将孪晶薄片转变成亚晶,且随着应变速率的进一步增大,位错滑移使亚晶晶界转动,从而形成大角度的等轴纳米晶。

REFERENCES

[1] GLEITER H. Nanocrystalline materials[J]. Progress in Materials Science,1989, 33(4): 223-315.

[2] SCHUMACHER S, BIRRINGER R, STRAUSS R, GLEITER H. Diffusion of silver in nanocrystalline copper between 303 and 373 K[J]. Acta Metal,1989, 37(9): 2485-2488.

[3] LU L, SUI M L, LU K. Superplastic extensibility of nanocrystalline copper at room temperature[J]. Science, 2000, 287(2): 1463-1466.

[4] BIRRINGER R, GLEITER H, KLEIN H P, MARQUARDT P. Nanocrystalline materials an approach to a novel solid structure with gas-like disorder[J]. Phys Letter A, 1984, 102(8): 365-369.

[5] LU K, WANG J T. Relationship between crystallization temperature and pre-existing nuclei in amorphous Ni-P alloys[J]. Mater Sci & Eng, 1988, 97(1): 399-402.

[6] ERB U, ELSHERIK A M, PALUMBO G, AUST K T. Synthesis, structure and properties of electroplated nanocrystalline materials[J]. Nanostructured Materials, 1993, 2(4): 383-390.

[7] VALIEV R Z, KORZNIKOV A V, MULYUKOV R R. Structure and properties of ultrafine-grained materials produced by severe plastic deformation[J]. Mater Sci & Eng A, 1993, 168(2): 141-148.

[8] 卢 柯, 吕 坚. 形成纳米结构的机械方法和专用机械设备[P]. 中国 01122980.2, 200-02-20.

LU Ke, LU Jian. Mechanical way and special equipment for formation of nanostructures[P]. CN 01122980.2, 200-02-20.

[9] TAO N R, WANG Z B, TONG W P, SUI M L, LU J, LU K. An investigation of surface nanocrystallization mechanism in Fe by surface mechanical attrition treatment[J]. Acta Mater, 2002, 50(18): 4603-4616.

[10] WANG Z B, TAO N R. Effect of surface nanocrystallization on friction and wear properties in low carbon steel[J]. Mater Sci & Eng A, 2003, 352(1/2): 144-149.

[11] LIU G, LU J, LU K. Surface nanocrystallization of 316 stainless steel induced by ultrasonic shot peening[J]. Mater Sci & Eng A, 2000, 286(1): 91-95.

[12] TONG W P, TAO N R, WANG Z B, LU J, LU K. Nitriding iron at lower temperatures[J]. Science, 2003, 299(1): 686-688.

[13] WANG Z B, TAO N R, TONG W P, LU J, LU K. Diffusion of chromium in nanocrystalline iron produced by means of surface mechanical attrition treatment[J]. Acta Materialia, 2003, 51(14): 4319-4329.

[14] WANG Z B, LU J, LU K. Chromizing behaviors of a low carbon steel processed by means of surface mechanical attrition treatment[J]. Acta Materialia, 2005, 53(7): 2081-2089.

[15] TONG W P, TAO N R, WANG Z B, LU J, LU K. Nitriding iron and 38CrMoAl steel with a nanostructrued surface layer[J]. Journal of the Graduate School of the Chinese Academy of Science, 2005, 22(2): 230-238.

[16] ZHANG H W, WANG L, HEI Z K, LIU G, LU J, LU K. Low-temperature plasma nitriding of AISI 304 stainless steel with nano-structured surface layer[J]. Z Metall, 2003, 94(5): 1143-1147.

[17] BEI D H, GU J F, PAN J H, LU J, LU K. Gaseous nitriding process of surface nanocrystallized (SNCed) steel[J]. Journal of Materials Science & Technology, 2002, 18(6): 566-568.

[18] LU K, LU J. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment[J]. Mater Sci & Eng A, 2004, 375/377(7): 38-45.

[19] WU X, TAO N, HONG Y, LIU G, XU B, LU J, LU K. Strain-induced grain refinement of cobalt during surface mechanical attrition treatment[J]. Acta Mater, 2005, 52(7): 547-551.

[20] ZHU KY, VASSEL A, BRISSET F, LU K, LU J. Nanostructure formation mechanism of a-titanium using SMAT[J]. Acta Mater, 2004, 52(14): 4101-4110.

[21] SUN H Q, SHI Y N, ZHANG M X, LU K. Plastic strain-induced grain refinement in the nanometer scale in a Mg alloy[J]. Acta Materialia, 2007, 55(3): 975-982.

[22] CHICHILI D R, RAMESH K T, HEMKER K J. The high- strain-rate response of alpha-titanium: experiments, deformation mechanisms and modeling[J]. Acta Mater, 1998, 46(3): 1025-1043.

基金项目:国家自然科学基金资助项目(50675234);重庆大学研究生科技创新基金资助项目(200801A1B0100269)

收稿日期:2007-08-24;修订日期:2007-11-16

通讯作者:盛光敏,教授,博士;电话:015923026226;E-mail: gmsheng@cqu.edu.cn

(编辑 李艳红)