钢铁厂铁鳞硫酸的浸出过程

彭长宏,胡振光,戴 劲,傅 锋

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘 要:为制备高纯氧化铁,以钢铁厂铁鳞为原料,考察液固比、温度、时间和硫酸用量对铁浸出率的影响。研究确定硫酸浸出过程的工艺条件,分析浸出过程的动力学机理。确定硫酸浸出铁鳞的最佳工艺条件为:液固比3?1,温度100 ℃,时间6.0 h,硫酸用量为理论量的1.25倍。在此优化工艺条件下,铁鳞中Fe的平均浸出率为91.69%。动力学研究结果表明,铁鳞的硫酸浸出过程在动力学上属收缩核模型,即满足1/2(1-at)-2/3-1/2=Kt,受化学反应的控制,反应活化能为70.40 kJ/mol。

关键词:铁鳞;硫酸浸出;动力学

中图分类号:O642.4;TQ136.1 文献标识码:A 文章编号:1672-7207(2009)04-0874-05

Leaching process of millscale from steel plant

PENG Chang-hong, HU Zhen-guang, DAI Jin, FU Feng

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: For preparation of high-purity iron oxide, a study on the leaching of millscale from steel plant and the effects of the liquid-solid ratio, the reaction temperature, the leaching time and the sulfuric acid excessive times was investigated. The best technical conditions of the leaching process were ascertained, and the kinetics of leaching was studied. The results show that when liquid-solid ratio is 3?1, the sulfuric acid excess is 1.25 times, reaction temperature is 100 ℃ and the leaching time is 6.0 h, the average leaching rate of Fe in the three comprehensive experiments is 91.69%. The leaching process is controlled by chemical reaction and can be described by the shrinking core model with activation energy of 70.40 kJ/mol.

Key words:millscale; sulfuric acid leaching; kinetics

钢铁企业在生产钢铁制品的过程中,会产生约为钢产量1.0%的氧化铁,俗称“铁鳞”。我国现有钢铁产量约5亿t/a,产铁鳞约500万t/a[1],其化学和物理性能存在一定差异[2-4],但主成分是氧化铁。目前,国内外对铁鳞的处理方法是用于制备Fe2O3[5]。该生产工艺简单,产品的附加值低,如何提高Fe2O3的质量,实现钢铁厂铁鳞的高价值利用意义重大。采用陶瓷法技术制备锰锌软磁铁氧体,高纯Fe2O3用量占70%左右[6]。当前国内Mn-Zn铁氧体的总产量约为23万t,去除外资企业的产量5.87万t,实际内资企业铁氧体的产量约17.13万t,约需Fe2O3 12万t。国产可用于制备Mn-Zn铁氧体的Fe2O3的产量约8万t,缺口约4万t,必须从境外进口补充。境外供应商主要有:日本的JFE、韩国的EG和DONGBU,德国的Thyssen-krupp与我国台湾省的中钢等。若能将铁鳞制成锰锌铁氧体用的高纯Fe2O3,将极大提高铁鳞的利用价值。为此,本文作者提出采用钢铁厂铁鳞为原料制备高性能锰锌铁氧体用氧化铁。但是,钢铁厂铁鳞的杂质成分复杂,含量较高[7],根据对锰锌软磁铁氧体材料制备的大量研究[8-10]可知,实现钢铁厂铁鳞制备高性能锰锌铁氧体用Fe2O3的前提和关键是实现铁鳞中Fe的浸出和浸出液净化,使影响锰锌铁氧体性能的杂质成分降 低[11]。本文作者研究了钢铁厂铁鳞硫酸浸出过程的工艺条件,探索浸出过程的动力学机理。

1 实 验

1.1 实验原料

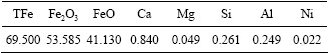

铁鳞取自湖南衡阳钢管厂,经球磨后粒径小于0.18 mm,其化学成分见表1。

表1 铁鳞的化学成分

Table 1 Chemical composition of millscale

质量分数/%

1.2 硫酸用量计算

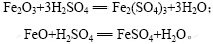

在用硫酸浸出钢铁厂铁鳞粉料过程中,主要反应式如下:

根据铁鳞粉料的化学成分和硫酸用量,计算在硫酸铁鳞浸出过程中的硫酸用量。

1.3 实验方法

采用单因素实验研究方法,分别考察液固比、反应温度、反应时间和硫酸用量等因素对铁鳞中Fe浸出率的影响规律。搅拌速度除标明外均为400 r/min,反应在500 mL的三口烧瓶中进行。

1.4 铁的分析

称取一定量的样品用浓HCl溶解后,再用SnCl2还原并加入HgCl2、硫磷混酸和二苯胺磺酸钠指示剂,用重铬酸钾标准溶液滴定至终点。

2 结果与讨论

2.1 液固比对铁鳞中Fe浸出率的影响

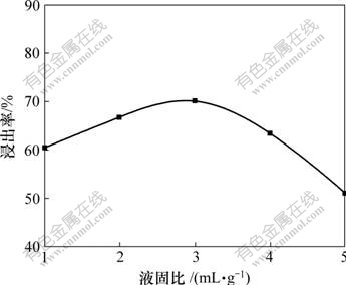

在固定浸出时间为3.0 h,反应温度为90 ℃和硫酸用量等于理论用量的条件下,考察液固比(液体体积与固体质量之比)对铁鳞中Fe浸出率的影响规律,结果见图1。

图1 液固比对Fe浸出率的影响

Fig.1 Effect of liquid-solid ratio on leaching rate of Fe

从图1可知,随着液固比的增大,Fe的浸出率先增大后减小,在液固比为3?1时,Fe的浸出率达到70.04%。产生上述现象的原因是:当液固比太小时,溶液的酸度高,FeSO4和Fe2(SO4)3浓度较大,降低了溶液中H+的活度,不利于铁鳞中Fe的浸出;随着液固比增大,溶液中H+的活度增大,有利于铁鳞中Fe的浸出。但当液固比超过一定值之后,溶液酸度降低,Fe的浸出率开始显著下降。因此,取铁鳞硫酸浸出过程的最佳液固比为3?1。

2.2 温度对Fe浸出率的影响

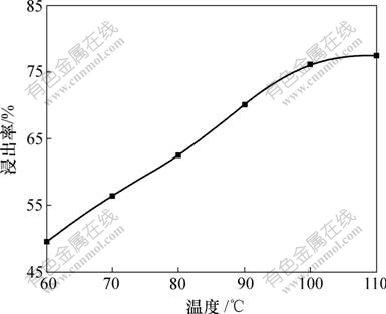

在固定液固比为3?1,硫酸用量等于理论用量,浸出时间为3.0 h的条件下,考察反应温度对铁鳞中Fe浸出率的影响规律,结果见图2。

图2 反应温度对Fe浸出率的影响

Fig.2 Effect of reaction temperature on leaching rate of Fe

由图2可看出,铁鳞中Fe的浸出率随温度的升高显著增大,当温度由60 ℃升高到100 ℃时,铁鳞中Fe的浸出率由49.62%提高到76.18%,温度每升高 10 ℃,Fe的浸出率平均提高6.64%。但是,当温度由100 ℃升高到110 ℃时,铁鳞中Fe的浸出率仅提高0.25%。考虑到温度过高时溶液中水的蒸发量太大,以及设备材质要求高,取铁鳞硫酸浸出过程的温度为100 ℃。

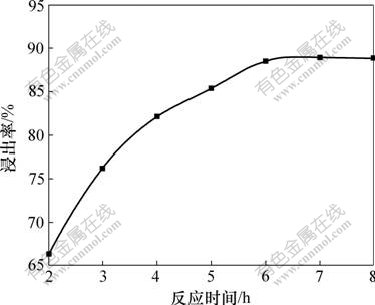

2.3 反应时间对浸出率的影响

在固定液固比为3?1,浸出温度为100 ℃,硫酸用量等于理论用量的条件下,考察浸出时间对铁鳞中Fe浸出率的影响规律,结果见图3。

图3 反应时间对Fe浸出率的影响

Fig.3 Effect of reaction time on leaching rate of Fe

从图3可知,铁鳞中Fe的浸出率随浸出时间的延长而增大,当反应时间由1 h增加到6 h时,Fe的浸出率由66.42%增大到88.49%,Fe的浸出率提高了22.07%,浸出率增长较快;当反应时间延长到7.0 h时,Fe的浸出率仅提高0.42%,延长至8 h,Fe的浸出率几乎没有变化,浸出过程已经平衡,理论最大浸出率为88. 91%。考虑到以上因素,取铁鳞硫酸浸出的最优时间为6.0 h。

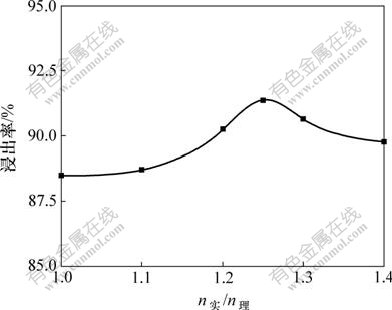

2.4 硫酸用量对Fe浸出率的影响

在固定液固比3?1,时间6.0 h和反应温度100 ℃的条件下,考察硫酸用量对铁鳞中Fe浸出率的影响规律,结果见图4。其中, 为硫酸实际用量与理论用量之比(mol/mol)。

为硫酸实际用量与理论用量之比(mol/mol)。

由图4可知,硫酸用量对铁鳞中Fe的浸出率影响较大,随着硫酸用量的增加,铁鳞中Fe的浸出率先增大后减小。当硫酸用量为理论量的1.25倍时,铁鳞中Fe的浸出率达到91.36%,但随着硫酸用量的进一步增加,铁鳞中Fe的浸出率反而呈现减小的趋势。产生上述现象的原因在于:当硫酸用量较小时,溶液的酸度低,铁鳞中Fe浸出率也低;随着硫酸用量的增加,溶液的酸度增加,铁鳞中Fe的浸出率增大;但当硫酸用量为理论量1.3倍时,反应体系的液固比实际已达到2?1,结果导致溶液酸度过高和黏度增大,降低了溶液中H+的活度,造成铁鳞中Fe的浸出率降低。

图4 硫酸用量对Fe浸出率的影响

Fig.4 Effect of different sulfuric acid excessive times on leaching rate of Fe

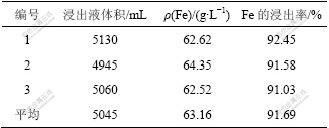

2.5 铁鳞浸出过程的综合条件实验

依据上述条件所得实验结果,综合考虑设备材质和生产效率等因素,确定铁鳞硫酸浸出过程的最优工艺条件如下:液固比为3?1,反应温度为100 ℃,反应时间为6.0 h,硫酸用量为理论量1.25倍。在上述优化工艺条件下,进行了3次综合条件实验,结果见表2。

表2 综合条件实验结果

Table 2 Result of experiments under comprehensive condition

从表2可知,在上述优化工艺条件下,铁鳞硫酸浸出过程中Fe均具有较高的浸出率,其平均浸出率达91.69%。

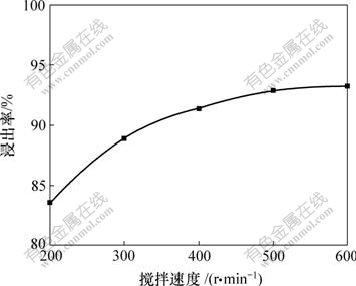

3 浸出过程动力学机理

浸出过程属多相反应,铁鳞的浸出过程就是铁鳞粉料与硫酸溶液所组成的固-液多相反应,浸出过程控制步骤由化学反应控制或反应物扩散决定[12],铁鳞粉料的硫酸浸出速率可能是由液膜扩散控制或化学反应控制。

搅拌速度对液膜扩散控制的反应浸出率影响非常大,提高搅拌强度,扩散控制的反应浸出率可提高40%~70%[13]。为此,在上述优化工艺条件下,考察搅拌速度对Fe浸出率的影响,结果见图5。

图5 搅拌速度对Fe浸出率的影响

Fig.5 Effect of stirring speed on leaching rate of Fe

分析图5发现,当搅拌速度由200 r/min提高到600 r/min时,浸出率提高9.68%,只体现出一般固相物系在液相中充分分散所产生的浸出率提高的效果。据此,判断铁鳞粉料硫酸浸出反应的控制步骤不是扩散控制[12-13]。

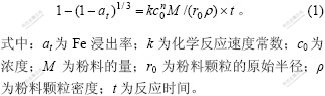

当化学反应控制为控制步骤,且反应没有生成新的固相时,该反应的动力学模型可用收缩核模型描述,符合下述速度方程[14]:

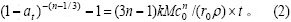

考虑浓度c的变化,对上述模型进行修正[12],得到:

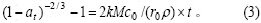

令n=1,式(2)变为:

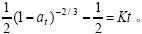

再令 ,则式(3)变为:

,则式(3)变为:

即:受化学反应控制的硫酸浸出反应的浸出率与反应时间成比例关系。

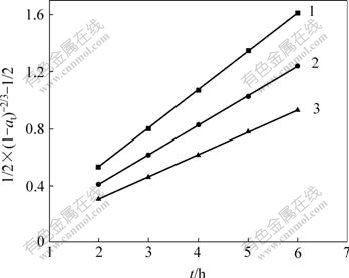

根据实验结果,按 对时间t作图,结果见图6。

对时间t作图,结果见图6。

浸出温度/℃: 1—100; 2—90; 3—80

图6 温度不同时化学反应控制收缩核模型

Fig.6 Shrinking core model controlled by chemical reaction procedures at different temperatures

由图6可知,铁鳞硫酸浸出过程符合化学反应控制的反应模型,故可判断浸出反应的控制步骤为化学控制。

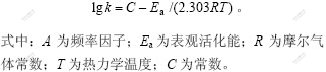

根据阿累尼乌斯公式 可得:

可得:

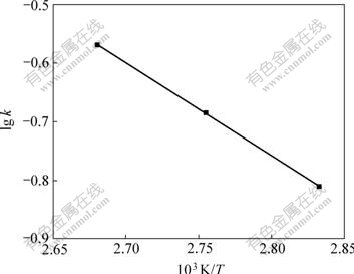

根据图6求得不同温度时的速度常数,得出lg k与1/T的关系,见图7。

图7 lg k与103 K/T的关系

Fig.7 Relationship between lg k and 103 K/T

由图7可以求出Ea/(2.303×103R)= 3.68,即表观活化能Ea=70.40 kJ/mo1。

4 结 论

a. 当液固比达到3?1时,铁浸出率达到最大,液固比再增大时,浸出率减小;当硫酸用量为理论用量的1.25倍时,铁浸出率达到最大值;当浸出时间达到6.0 h后,铁浸出率趋于稳定。

b. 温度对铁浸出率影响较大,在液固比为3?1,反应温度为100 ℃,反应时间为6.0 h,硫酸用量为理论量的1.25倍的优化工艺条件下,铁鳞中Fe的平均浸出率为91.69%。

c. 钢铁厂铁鳞的硫酸浸出过程符合液-固反应的收缩核模型,Fe浸出率与受化学反应控制的收缩核模型 较符合,反应的活化能为70.40 kJ/mol。

较符合,反应的活化能为70.40 kJ/mol。

参考文献:

[1] 李霸宇. 氧化铁——钢铁企业发展为磁性材料产业壮大提供支持[J]. 磁性材料及器件, 2005, 36(6): 45-49.

LI Ba-yu. Iron oxide: The rapid development of iron and steel companies in China: Providing supports to Chinese magnetic material industry[J]. Journal of Magnetic Materials and Devices, 2005, 36(6): 45-49.

[2] Koros P J. Dusts, scale, slags, sludges… not wastes, but sources of profits[J]. Metallurgical and Materials Transactions B, 2003, 34B(6): 769-779.

[3] Heino J, Laitila L, Hiltunen A, et al. Optimisation of steel plant recycling in Finland: Dusts, scales and sludge[J]. Resources, Conservation and Recycling, 2002, 35(1/2): 77-84.

[4] Nolasco-Sobrinho P J, Espinosa D C R, Tenorio J A S. Characterisation of dusts and sludges generated during stainless steel production in brazilian industries source[J]. Ironmaking and Steelmaking, 2003, 30(1): 11-17.

[5] 徐修生. 铁鳞深加工及其在永磁铁氧体中的应用[J]. 磁性材料及器件, 2002, 33(4): 44-45.

XU Xiu-sheng. Further processing of millscale and its application in permanent ferrite materials[J]. Journal of Magnetic Materials and Devices, 2002, 33(4): 44-45.

[6] 阳征会, 龚竹青, 马玉天, 等. 高纯纳米α-2Fe2O3粉体的制备及表征[J]. 中南大学学报: 自然科学版, 2006, 37(3): 487-492.

YANG Zheng-hui, GONG Zhu-qing, MA Yu-tian, et al. Preparation and characterization of high-purity α-2Fe2O3 nanoparticles[J]. Journal of Central South University: Science and Technology, 2006, 37(3): 487-492.

[7] 尹有祥, 孙 岩. 铁的氧化物和铁氧体磁性材料[J]. 磁性材料及器件, 2001, 32(5): 56-61.

YIN You-xiang, SUN Yan. Iron oxides and ferrite magnetic materials[J]. Journal of Magnetic Materials and Devices. 2001, 32(5): 56-61.

[8] 彭长宏, 慕思国, 唐谟堂, 等. 利用钢铁厂烟尘制备锰锌铁氧体共沉淀粉[J]. 中南大学学报: 自然科学版, 2006, 37(1): 31-35.

PENG Chang-hong, MU Si-guo, TANG Mo-tang, et al. Mn-Zn ferrite co-precipitation powders made from steel plant dust[J]. Journal of Central South University: Science and Technology, 2006, 37(1): 31-35.

[9] 彭长宏, 唐谟堂, 杨声海, 等. 直接法制备低功耗软磁铁氧体扩大实验研究[J]. 湿法冶金, 2003, 22(3): 142-146.

PENG Chang-hong, TANG Mo-tang, YANG Sheng-hai, et al. Research of enlarge experiments to fabricating low cost soft magnetic ferrite by using direct method[J]. Hydrimetallurgy, 2003, 22(3): 142-146.

[10] 黄小忠, 唐谟堂. 由软锰矿、闪锌矿、铁屑直接制取锰锌铁氧体软磁材料新工艺研究[J]. 中国锰业, 1996, 14(1): 42-44.

HUANG Xiao-zhong, TANG Mo-tang. The novel process of manufacturing Mn-Zn ferrites from pyxrolusite, sphalerite and steel scraps[J]. China’s Manganese Industry, 1996, 14(1): 42-44.

[11] 邵 峰, 李晓清, 钱琼辉. 锰锌铁氧体用氧化铁的性能要求[J]. 磁性材料及器件, 2004, 35(4): 42-43.

SHAO Feng, LI Xiao-qing, QIAN Qiong-hui. Requirements for properity of ferric oxide for MnZn ferrites[J]. Journal of Magnetic Materials and Devices, 2004, 35(4): 42-43.

[12] 李洪桂. 湿法冶金学[M]. 长沙: 中南大学出版社, 2002: 83-85.

LI Hong-gui. Science of hydro-metallurgy[M]. Changsha: Central South University Press, 2002: 83-85.

[13] 胡天觉, 曾光明, 袁兴中. 湿法炼锌废渣中硫脲浸出银的动力学[J]. 中国有色金属学报, 2001, 11(5): 933-937.

HU Tian-jue, ZENG Guang-ming, YUAN Xin-zhong. Leaching kinetics of silver extracted by thiourea from residue in hydrometallurgy of zinc[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 933-937.

收稿日期:2008-09-02;修回日期:2008-11-22

基金项目:国家高技术发展研究计划(863)项目(2006AA06Z373);广东省-教育部产学研专项基金资助项目(2006D904032);中国博士后科学基金资助项目(20060400884);广东省科技计划项目(2008A080403007-03)

通信作者:彭长宏(1966-),男,湖南长沙人,博士,副教授,从事直接法制备锰锌铁氧体功能材料及新型离子液体合成与应用研究;电话:0731-88836724;E-mail: Peng9103@163.com