Mg-Gd-Y-Zr合金在773和823 K热处理时的氧化行为

邓运来1, 2,杨柳1, 2,郭天才1, 3,李文瑛1, 3,张新明1, 2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410012;

3. 航天科工防御技术研究试验中心,北京,100854)

摘 要:采用金相显微镜(OM)观察、X线衍射(XRD)、扫描电镜(SEM)和能谱分析(EDS)等分析测试技术,研究Mg-Gd-Y-Zr合金在773和823 K热处理时的氧化行为。研究结果表明:合金热处理后表面氧化物的主要成分为Y2O3和Zr2Gd2O7的混合物;合金在773 K保温48 h热处理后,表面被轻微氧化,显微组织与热处理前无明显差别;合金在823 K保温48 h热处理后表面氧化严重,形成较厚氧化层,氧化层中沿晶界分布有很多尺寸为5~10 μm的方形及形状不规则粒子;合金在773 K热处理时不需用保护气氛,而在823 K热处理需用保护气氛。

关键词:Mg-Gd-Y合金;热处理;表面氧化

中图分类号:TG174.3 文献标志码:A 文章编号:1672-7207(2010)02-0483-06

Oxidization of Mg-Gd-Y-Zr alloy during

heat treatment process at 773 and 823 K

DENG Yun-lai1, 2, YANG Liu1, 2, GUO Tian-cai1, 3, LI Wen-ying1, 3, ZHANG Xin-ming1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education, Changsha 410012, China;

3. Defence Technology Research and Test Center, China Aerospace Science and Industry Corporation,

Beijing 100854, China)

Abstract: The oxidation behavior of as-cast Mg-Gd-Y-Zr alloy during heat treatment process at 773 and 823 K was studied by using optical microscopy, X-ray diffraction, and scanning electron microscopy. The results show that the thin layer formed on the surface of Mg-Gd-Y-Zr alloy during heat treatment process is mainly composed of Y2O3 and Zr2Gd2O7. Being heat treated at 773 K for 48 h, the surface of Mg-Gd-Y-Zr alloy is oxidized so slightly that there are no many differences between surface layer and secondary surface layer while there is an oxidizing layer formed which contains a lot of RE-rich particles when being heat treated at 823 K for 48 h. Mg-Gd-Y-Zr alloy should be protected by other gases during heat treatment process at 823 K and need not be protected at 773 K.

Key words: Mg-Gd-Y alloy; heat treatment; surface oxidation

国内外已报道了具有优异耐热性能的Mg-Y-Nd系(如WE54和WE43)[1-2]和Mg-Gd-Y系(GY94)[3-4]等镁-稀土(Mg-RE)合金。特别是Mg-Gd-Y系合金,比此前报道的综合性能优异的耐热镁合金WE54具有更高的耐热性能[3-5],近几年来,人们对该合金的微观结构与性能以及制备工艺均进行了研究[6-12]。由于稀土元素与氧的亲和力大于镁与氧的亲和力[13],单质稀土元素比镁更容易被氧化,且Mg-RE合金的均匀化、固溶等热处理温度一般都需在673 K以上[14]。根据镁合金铸件热处理操作的有关标准,一般认为,当镁合金热处理温度超过673 K时,必须使用SF6,SO2和CO2等保护性气氛,以防止镁合金表面氧化和燃烧[15]。但是,上述3种镁合金热处理常用保护性气体不仅会造成严重的大气污染,还会增加合金的生产成本。而针对Mg-RE合金的氧化行为与机理研究却鲜有报道。因此,研究Mg-RE合金在空气环境中加热的氧化问题,对于确定其环保而经济的热处理工艺,获得Mg-RE合金良好的耐蚀性能均具有十分重要的意义。本文作者以1种Mg-Gd-Y-Zr合金为例,研究该合金在空气环境中加热时的氧化行为,以便为揭示Mg-RE合金的氧化机理与探求更加合理的加工热处理工艺提供实验依据。

1 实验

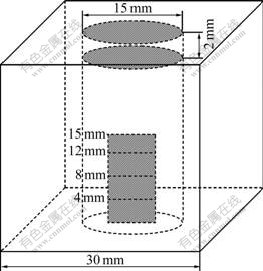

本文所用Mg-Gd-Y-Zr合金的名义成分为Mg-7Gd-3Y-0.6Zr(以下简称GY73K),从该合金直径为60 mm的圆锭上用线切割机割取所需试样。均匀化 (固溶)热处理的试样尺寸(长×宽×高) 为30 mm×30 mm×30 mm,热处理温度选为773 K和823 K,时间为48 h。热处理后用线切割机切出直径为15 mm、长为30 mm的试棒,分别分析试棒表面层(端面)及次表面层(距端面2 mm处),以及试棒剖面距端面0~15 mm处的组织。取样示意图如图1中阴影部分所示。

图1 试样加工示意图

Fig.1 Machining sketch map of test sample

采用XJP-6A金相显微镜和配有Gensis60能谱仪(EDS)的Sirion200场发射等扫描电镜观察合金显微组织,采用Rigaku D/Max 2500型18 kW转靶X线衍射仪进行XRD物相分析。

2 实验结果

2.1 微观组织

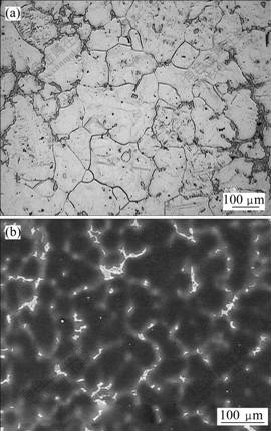

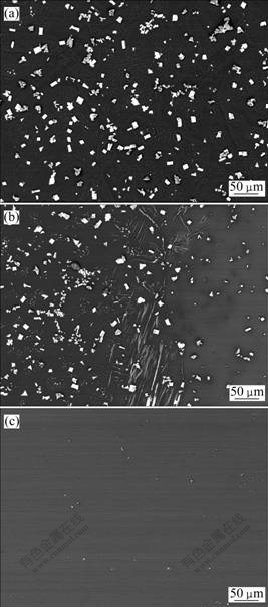

将经过热处理的试样抛光腐蚀后,分别对其进行金相和扫描电镜观察。图2(a)所示是GY73K合金铸态的金相显微组织,图2(b)所示是其SEM背散射电子像。从图2可以看出:GY73K合金铸态的显微组织由α-Mg基体和网状非平衡共晶组织及弥散分布的圆形粒子组成。网状非平衡共晶组织沿晶界不连续分布,晶粒内部零星分布的圆形粒子经EDS分析为Zr-rich粒子。

(a) 金相显微组织;(b) SEM像

图2 GY73K合金铸态的显微组织

Fig.2 Microstructures of as-cast GY73K alloy

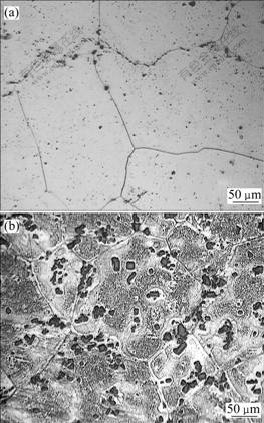

图3所示是合金在773和823 K保温48 h热处理条件下的显微组织。2个样品抛光后在同一腐蚀液中进行腐蚀,腐蚀时间相同。从图3(a)可见:合金在773 K保温48 h热处理后,晶界边缘处的网状共晶组织已经融入基体,残留有圆形初生相Zr-rich粒子及热处理过程中产生的块状粒子,合金晶界清晰,晶粒略有长大。从图3(b)可见:合金在823 K保温48 h热处理后,显微组织已发生很大变化,晶粒长大,晶界较明晰。晶界处存在很多大尺寸的方块粒子及形状不规则粒子,尺寸为5~10 μm。合金组织在腐蚀剂作用下,晶内呈黑色,脱溶粒子的周围区域变色不明显。

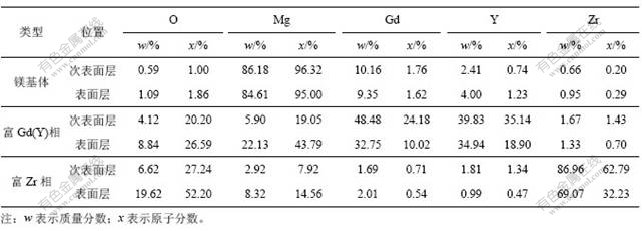

图4所示是合金在773 K保温48 h热处理后的表面层(端面)试样和次表面层(距端面2 mm处)试样的SEM像,并对图中箭头标记的地方进行EDS分析。从图4可以看出:合金在773 K保温48 h热处理后表面层(端面)和次表面层(距端面2 mm处)的微观组织无明显差别,均在晶界处残留有方形粒子,GY73K合金在773 K保温48 h热处理后,SEM显微结构主要由基体(α),Gd(Y)-rich和Zr-rich粒子组成。表1列出了基体(α-Mg),Gd(Y)-rich粒子和Zr-rich粒子的EDS分析结果。从表1可知:合金表面层(端面)的基体(α-Mg)和Gd(Y)-rich和Zr-rich粒子的含氧量都比次表面层(距表面层2 mm处)的略高。

热处理工艺:(a) 773 K,48 h;(b) 823 K,48 h

图3 GY73K合金热处理后的显微组织

Fig.3 Microstructures of GY73K alloy after heat treatment

(a) 表面层(端面);(b) 次表面层(距端面2 mm处)

图4 773 K热处理后表面氧化层的SEM像及

EDS分析结果

Fig.4 SEM micrograph and EDS analysis results of oxidizing layer alloy solution treated at 773 K

表1 GY73K合金773 K热处理后合金EDS分析结果

Table 1 EDS analysis results of GY73K alloy after heat treated at 773 K

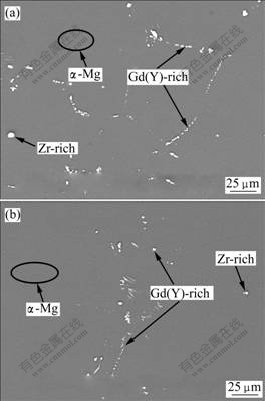

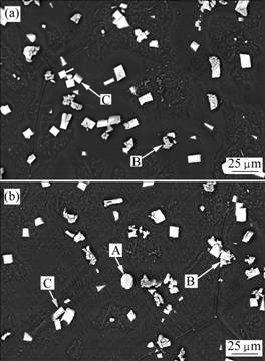

图5所示是合金在823 K热处理后合金表面氧化层和次表面层的SEM像。从图5可以看出:合金热处理时在氧化层中除圆形的Zr粒子外(如图5(b)中粒子A所示 ),另外产生2种形貌的粒子(如图中粒子B和C所示)。表2所示是图5中B和C 2种形貌的粒子和EDS分析结果。从表2可知:形状不规则粒子B是严重氧化的稀土粒子,而规则长方体粒子C则是轻微氧化的富稀土粒子。

(a) 表面层(端面);(b) 次表面层(距端面2 mm处)

图5 823 K热处理后表面氧化层的SEM像

Fig.5 SEM micrograph of oxidizing layer alloy

heat treated at 823 K

表2 GY73K合金823 K热处理后EDS分析结果

Table 2 EDS analysis results of GY73K alloy after

heat treated at 823 K

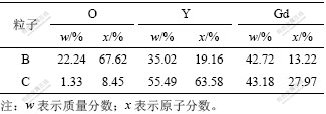

图6所示是合金在823 K保温48 h热处理后沿厚度方向距表面不同深度的SEM像。从图6可以看出:方形及不规则形状的第二相粒子数量沿表面向试样内部减少,尺寸也相应变小;在距表面4~8 mm的样品中发现明显的分界区,在此分界区内发现有很多针状相,这些针状物与基体呈一定角度的析出关系,所以,具有一定的排列方向。而形成这种针状物要求特定的溶质浓度,因此,这些针状相距离表面有一定的距离。在热处理试样分界区内离表面约10 mm处的中心部位,合金只在晶界处分布着少量伪共晶组织溶入基体后残留的方块粒子,其尺寸比表面被氧化的方形粒子尺寸要小得多。

距表面距离:(a) 0~4 mm;(b) 4~8 mm;(c) 8~15 mm

图6 GY73K合金在823 K保温48 h固溶处理后的SEM像

Fig.6 SEM micrographs of GY73K alloy heat treated at

823 K for 48 h

2.2 XRD物相分析

图7所示是对合金在空气中经过773 K保温48 h 和经过823 K保温48 h热处理后的表面层(端面)及次表面层(距表面2 mm处)的XRD谱。从图7 (a)可见:合金在空气环境下773 K热处理过程中,表面层(端面)样品的XRD衍射谱分别在29.45?,49.05?和58.13?处形成了3个较明显的衍射峰,据XRD分析结果可知这3个衍射峰为氧化物Y2O3和Zr2Gd2O7的叠加峰。而次表面层(距表面2 mm处)的XRD衍射谱中则只有α-Mg的衍射峰。同样,由图7(b)可见:在823 K空气中热处理时,也在表面层(端面)衍射谱中相应的角度处出现很明显的氧化物衍射峰,次表面层(距表面2 mm处)氧化物的衍射峰较表面的弱。因此,合金在无保护气氛条件下于823 K保温48 h热处理过程中,次表面层也被氧化。在相同的放大倍数下,图7(b)中空气中热处理时表面氧化物的叠加峰比图7(a)中的要高很多。根据XRD衍射理论,衍射峰面积越大,则所含物质越多,由此可见:合金在无保护气氛条件下,在773 K保温48 h热处理过程中,氧化不明显;合金在空气环境下823 K热处理过程中,氧化较773 K热处理时的氧化明显,所产生氧化产物较773 K时的多。

1—合金表面层;2—合金次表面层

热处理工艺:(a) 773 K,空气中;(b) 823 K,空气中

图7 GY73K合金热处理后表面层(端面)及次表面层(距表面2 mm处)的XRD谱

Fig.7 XRD patterns of surface layer (end plane), secondary surface layer (2 mm far from surface layer) of heat treated samples

3 讨论

GY73K合金在773 K保温48 h热处理后,表面层(端面)和次表面层(距表面层2 mm处)微观组织差别不大,合金氧化不明显。次表面层的衍射分析中没有氧化物的衍射峰,即距离表面2 mm处没有被氧化,这说明合金在773 K保温48 h热处理后表面氧化的深度不超过2 mm。XRD谱中并没有发现MgO的衍射峰,这是由于在热处理过程中MgO主要在表面形成,呈白色粉末状,且极容易从金属基体脱落;此外,在XRD衍射分析进行前将样品进行了轻微打磨,因此,残留的MgO量很少,不足以形成衍射峰。

GY73K合金在823 K保温48 h热处理后,不仅表面层(端面)氧化,次表面层(距表面2 mm处)也一定程度地被氧化。方形稀土粒子经过氧化后,成分会从纯稀土粒子变为稀土氧化物,相应地,形貌会从规则的长方体变为不规则形状。由于粒子从基体中脱溶,其周围稀土浓度较低,而远离脱溶粒子的地方稀土浓度则比较高,稀土与氧原子的结合能力比镁与氧的结合能力强,所以,粒子首先被氧化,接下来稀土浓度较高的区域即远离粒子的区域被氧化,最后才是方形粒子周围稀土浓度比较低的地方被氧化。而氧化物容易被腐蚀,因此,金相腐蚀后,氧化的部位颜色较深。合金然823 K热处理后,氧化深度为4~8 mm。

从上述实验结果可知,GY73K合金热处理过程中表面氧化分为2个阶段:

(1) 第1个阶段,氧原子向合金扩散,并迅速在稀土元素周围形成一层保护膜。此时,氧化速度减慢,如温度不高或者时间较短,氧化会进行很慢或停止,例如GY73K合金在773 K保温48 h热处理后,表面轻微氧化,并且随着时间的延长,氧化不明显。

(2) 第2个阶段,在高温或长时间条件下氧化层破裂,此时,氧原子扩散速度再次加快,氧化加剧并深入到内层,如合金在823 K保温48 h热处理后表面氧化严重,形貌发生了较大变化,并且影响到距离表层4~ 8 mm处的形貌。

4 结论

(1) GY73K合金在773和823 K空气环境下进行热处理后,合金表面会形成含有Y2O3和Zr2Gd2O7化合物的氧化层。

(2) GY73K合金在773 K无保护气氛下热处理时,试样形成的氧化层厚度小于2 mm,氧化层(表面层)内的微观结构与内部未受氧化区域(次表面层及内部)的微观结构没有本质区别;于823 K无保护气氛条件下热处理时,被氧化的表面层厚度达到4~8 mm,块状的RE-rich相被严重氧化。

(3) GY73K合金在773 K进行热处理时,不需惰性气氛保护;而在823 K热处理时需用惰性气氛保护。

参考文献:

[1] Nie J F, Muddle B C. Precipitation in magnesium alloy WE54 during isothermal ageing at 250 ℃[J]. Scripta Materialia, 1999, 40(10): 1089-1094.

[2] 李德辉, 李志成, 刘路, 等. 时效对Mg-Y-Nd合金的影响[J]. 材料研究学报, 2003, 17(5): 483-488.

LI De-hui, LI Zhi-cheng, LIU Lu, et al. Effect of ageing on Mg-Y-Nd alloys[J]. Chinese Journal of Materials Research, 2003, 17(5): 483-488.

[3] 张新明, 陈健美. 高强耐热稀土镁合金: 中国, ZL200610031169.9[P]. 2008-04-23.

ZHANG Xin-ming, CHEN Jian-mei. Magnesium alloy with high strength and heat resistance: China, ZL200610031169.9 [P]. 2008-04-23.

[4] Anyanwu I A, Kamado S, Kojima Y. Aging characteristics and high temperature tensile properties of Mg-Gd-Y-Zr alloys[J]. Materials Transations, 2001, 42(7): 1206-1211.

[5] Anyanwu I A, Kamado S, Kojima Y. Creep properties of Mg-Gd-Y-Zr alloys[J]. Materials Transactions, 2001, 42(7): 1212-1218.

[6] 彭卓凯, 张新明, 陈健美, 等 Mn, Zr对Mg-Gd-Y合金组织与力学性能的影响[J]. 中国有色金属学报, 2006, 15(6): 917-922.

PENG Zhuo-kai, ZHANG Xin-ming, CHEN Jian-mei, et al. Effects of Mn, Zr on microstructure and properties of Mg-Gd-Y alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 15(6): 917-922.

[7] DENG Zhen-zhen, ZHANG Xin-ming, DENG Yun-lai, et al. Aging behavior of Mg-9Gd-4Y-0.6Mn alloy[J]. Materials Science Forum, 2007, 546/549: 425-428.

[8] 马志新, 张家振, 李德富, 等. 铸态Mg-Gd-Y-Zr镁合金均匀化工艺研究[J]. 特种铸造及有色合金, 2007, 27(9): 659-662.

MA Zhi-xin, ZHANG Jia-zhen, LI De-fu, et al. Homogenizing process for as-cast Mg-Gd-Y-Zr magnesium alloy[J]. Special Casting and Nonferrous Alloys, 2007, 27(9): 659-662.

[9] XIAO Yang, ZHANG Xin-ming, CHEN Bu-xiang, et al. Mechanical properties of Mg-9Gd-4Y-0.6Zr alloy[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S3): 1669-1672.

[10] 张新明, 陈健美, 邓运来, 等. Mg-Gd-Y-Zr耐热镁合金的压缩变形行为[J]. 中国有色金属学报, 2005, 15(12): 1925-1932.

ZHANG Xin-ming, CHEN Jian-mei, DENG Yun-lai, et al. Deformation behavior of Mg-Gd-Y-Zr heat resistant magnesium alloy during hot-compression[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 1925-1932.

[11] XIAO Yang, ZHANG Xin-ming, DENG Yun-lai, et al. Superplasticity of Mg-Gd-Y alloy in tensile test at elevated temperature[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(S1): 372-375.

[12] GUO Yong-chun, LI Jian-ping, LI Jin-shan, et al. Mg-Gd-Y system phase diagram calculation and experimental clari?cation[J]. Journal of Alloys and Compounds, 2008, 450: 446-451.

[13] 姚允斌, 解涛, 高英敏. 物理化学手册[M]. 上海: 上海科学技术出版社, 1985.

YAO Yun-bin, XIE Tao, GAO Ying-min. Handbook of chemistry and physics[M]. Shanghai: Shanghai Science and Technology Press, 1985.

[14] Cahn R W, 丁道云. 非铁合金的结构和性能[M]. 北京: 科学出版社, 1999.

Cahn R W, DING Dao-yun. Structure and properties of nonferrous alloys[M]. Beijing: Science Press, 1999.

[15] 中国机械工程学会铸造专业学会. 铸造手册: 第3卷[M]. 北京: 机械工业出版社, 1993: 183.

Foundry Professional Institute of Chinese Mechanical Engineering Society. Casting manual: Volume 3[M]. Beijing: China Machine Press, 1993: 183.

收稿日期:2009-02-27;修回日期:2009-06-02

基金项目:国家安全重大基础研究项目(5133001E,5233001E)

通信作者:邓运来(1969-),男,湖南常德人,副教授,从事金属材料加工及性能研究;电话:13873152095;E-mail: luckdeng@mail.csu.edu.cn

(编辑 陈爱华)