DOI: 10.11817/j.issn.1672-7207.2019.03.002

钠盐强化某低品位铁矿含碳球团还原机理

钟荣海,黄柱成,易凌云,汉合童

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:采用内配煤造球还原焙烧的方法对某高硅低品位铁矿进行处理,并加入钠盐强化还原,研究温度、时间和添加剂质量分数对还原的影响,并采用烟气分析仪研究含钠盐对还原过程的影响。计算CO体积分数对FeO还原和铁橄榄石(Fe2SiO4)生成反应的热力学影响,并采用SEM和XRD等分析还原球团的微观结构和成分。研究结果表明:还原中间产物FeO可与SiO2反应生成难以再还原的铁橄榄石(Fe2SiO4);提高还原反应体系中CO的体积分数可以促进FeO的还原和减少铁橄榄石(Fe2SiO4)的生成;钠盐能够有效地促进球团中碳的气化反应,提高球团内CO的体积分数,从而促进FeO的还原,减少Fe2SiO4的生成,进而改善还原效果;当内配煤质量分数(即C与Fe质量比m(C)/m(Fe))为0.4,钠盐质量分数为3%,焙烧时间为30 min以及焙烧温度为950 ℃时,还原效果最佳,还原球团的金属化率为56.74%,磨矿、磁选后精矿铁品位和铁回收率分别为74.16%和74.57%。

关键词:低品位铁;钠盐添加剂;内配煤球团;还原焙烧

中图分类号:TF551 文献标志码:A 文章编号:1672-7207(2019)03-0506-08

Reduction enhancement mechanisms of low iron grade ore-coal composite pellets by sodium salt

ZHONG Ronghai, HUANG Zhucheng, YI Lingyun, HAN Hetong

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: Method of reduction roasting with iron ore-coal composite pellets was adopted to deal with high silicon content-low iron grade ore, and sodium salt was used to enhance the reduction process. Effects of temperature, reduction time and mass fraction of sodium salt on reduction behavior were researched. Gas analysis was used to investigate effect of sodium salt on the reduction process. Effects of CO volume fraction on thermodynamic of reduction of FeO and formation of fayalite were analyzed, and SEM and XRD were applied to analyse microstructures and composition of reduced pellets. The results show that FeO may react with SiO2 and form fayalite which can hardly be reduced again. Increasing CO volume fraction can improve the reduction of FeO, and thus decrease the formation of fayalite. Reduction of iron oxide can be facilitated effectively by sodium salt, which can be attributed to the fact that sodium improves the gasification reaction of carbon and increases CO volume fraction, which promotes the reduction of FeO. Reduced pellets with metallization ratio of 56.74% can be obtained with ratio of m(C)/m(Fe) 0.4, mass fraction of sodium salt 3% and reduces at 950 ℃ for 30 min. TFe in the magnetic separation concentrate and iron recovery are 74.16% and 74.57%, respectively.

Key words: low grade iron ore; sodium salt additive; composite pellets; reduction roasting

低品位赤铁矿是我国难选铁矿资源中的一种,具有铁品位低、硅酸盐质量分数高、铁氧化物晶粒粒度小(平均粒度在0.045 mm以下)以及铁氧化物与含铁硅酸盐脉石矿物共生紧密、物理化学性质相近等特点,难以采用常规选矿方法进行有效富集[1-4]。该类赤铁矿石总储量将近30亿t,若这部分铁矿资源能得到有效利用,则对缓解我国铁矿石资源压力具有重要意义。采用直接还原-磁选方法处理该类铁矿石是目前研究热点之一,在还原温度为1 000~1 200 ℃和还原时间为60~120 min条件下,还原产品的金属化率在85%以上,磨矿、磁选后精矿铁品位、铁回收率分别在85%~95%和80%以上[5-8]。但该类铁矿石硅质量分数较高,在还原过程中生成的FeO会与SiO2生产铁橄榄石(Fe2SiO4)。铁橄榄石易与其他化合物形成低熔点体系[9],在高温下转变为液相,阻碍铁氧化物进一步还原。此外,铁橄榄石本身难以被还原[10-11],从而造成铁元素流失,因此,如何使氧化铁快速还原成为金属铁,避免生成过多的铁橄榄石在直接还原过程中至关重要。研究表明,碱金属及碱土金属化合物对铁氧化物的还原反应有一定的促进作用。Na2CO3,Na2SO4,K2CO3以及NaCl等碱土金属盐被广泛用于促进铁氧化物的还原,且效果显著[12-17]。对于碱土金属促进铁氧化物的还原机理,有研究认为碱土金属盐添加剂可以破坏矿石结构,使某些与脉石有复杂嵌布关系的物质从束缚态中释放出来,从而促进铁氧化物还原[13]。也有研究认为碱土金属盐可以弱化FeO中Fe—O键,促进铁氧分离,加快还原[12]。此外,碱土金属盐可以大力促进碳的气化反应[18-20],这对加快铁氧化的还原是有利的。鉴于碱土金属盐对铁氧化物的还原具有显著促进作用,本文采用某钠盐作为添加剂强化某还原低品位铁矿还原,从而提高对该类铁矿资源的利用效率。目前,人们对碱土金属盐促进铁氧化物还原作用的机理研究众多,但其作用机理随原料变化而存在较大差异,因而,深入研究钠盐对低品位铁矿还原的作用机理,对采用直接还原法还原该类铁矿资源具有重要的指导意义。本文以某高硅低品位微细粒嵌布赤铁矿石为研究对象,采用内配煤造球后进行还原焙烧,并添加钠盐强化还原效果。研究温度、时间、内配煤质量分数和添加剂质量分数对还原过程的影响,采用烟气分析的方法以及SEM-EDS和XRD研究钠盐促进还原作用的机理。

1 原料性能与试验方法

1.1 原料性能

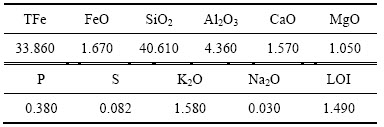

铁矿来自湖南某地,其化学成分如表1所示,X线衍射结果如图1所示。

表1 铁矿化学成分分析结果(质量分数)

Table 1 Chemical composition of iron ore (mass fraction) %

图1 铁矿的X线衍射分析图谱

Fig. 1 XRD analysis spectrum of iron ore

由表1可知:该铁矿铁品位仅为33.860%;脉石主要为SiO2(品位为40.610%),其次是Al2O3,有害元素P和 S质量分数较低。由图1可知:铁矿中主要含铁矿物为赤铁矿;主要脉石为石英,并伴生有少量绢云母和绿泥石。

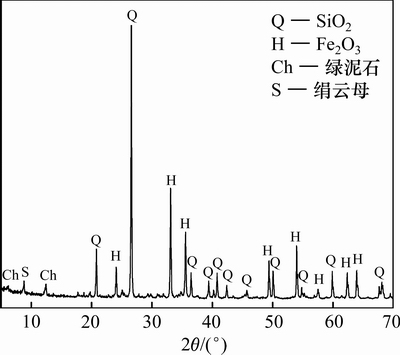

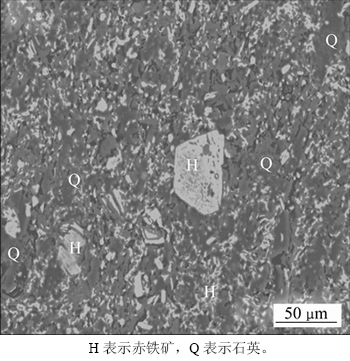

图2所示为铁矿的扫描电镜分析图谱,表2所示为矿石中铁氧化物的嵌布粒度分析结果。由图2和表2可知:矿石中主要含赤铁矿(Fe2O3)和石英(SiO2)这2种矿物,两者呈浸染状相互交生,嵌布关系十分复杂;赤铁矿粒度很小,粒度小于0.01 mm部分赤铁矿的质量分数为39.94%,分散程度高,主要呈星点状无规则地分布。将铁矿石破碎、磨细(粒度小于0.037 mm的铁矿石质量分数占71.20%)用于造球。

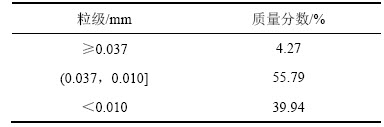

表2 原矿中铁矿物的粒度组成(质量分数)

Table 2 Particle size distribution of hematite in iron ore

图2 铁矿扫描电镜图谱

Fig. 2 SEM image of iron ore

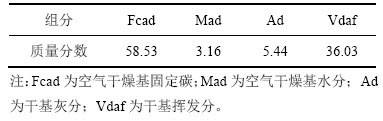

实验所用的还原煤工业分析结果如表3所示。将还原煤破碎、磨细(粒度小于0.037 mm的铁矿石质量分数占58.89%)用于造球。

表3 还原煤工业分析结果(质量分数)

Table 3 Proximate analysis of reductant coal %

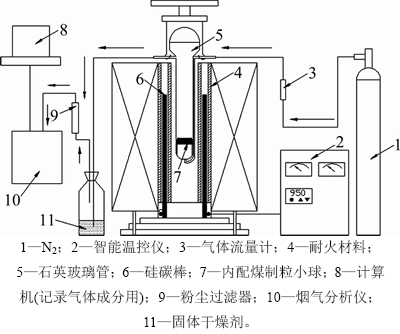

1.2 实验方法

将煤粉和铁矿粉料按固定碳质量和全铁质量比值m(C)/m(Fe)=0.4进行混合,添加一定比例的添加剂,将质量分数为1.5%膨润土和质量分数为8%预配水混匀。然后,在圆盘造球机中(直径为1 m,倾角为45°,转速为28 r/min)制成粒度为5~8 mm的生球,并放入110 ℃的烘箱中干燥2 h以备用。

还原焙烧使用的设备如图3所示。每次取30 g干燥小球置于石英管中,先向玻璃管中通入N2(通气速度为0.18 m3/h),将石英玻璃管中的空气排出。将石英管缓缓放入炉中,待还原炉的温度升至所需温度时开始计时,达到预定时间后将还原小球取出萃冷,以防止再氧化。还原效果用还原球团的金属化率η表征:

η = w(MFe)/w(TFe)×100% (1)

式中:w(MFe)为还原球团中金属铁的质量分数,%;w(TFe)为还原球团中全铁的质量分数,%。

图3 还原焙烧设备示意图

Fig. 3 Schematic diagram of reduction roasting

磨矿实验在XMQ240×90型的锥形球磨机中进行,磨矿时矿浆质量分数为50%,磨矿粒度小于0.045 mm的质量分数为100%。磁选设备为XCGS-73型磁选管, 磁场强度为1 840 kA/m。研究钠盐作用机理时,用烟气分析仪对还原气氛进行分析。将排出的尾气与烟气分析仪连接,分析还原时产生的气体成分与质量分数。烟气分析仪为MUR烟气分析仪,用于分析气体中所含有的O2,CO,CO2,SO2和CxHy体积分数。烟气分析仪与计算机连接,每隔10 s自动记录CO和CO2的体积分数。试验前,烟气分析仪中CO和CO2体积分数为0,O2体积分数小于0.2%。当反应开始后,玻璃管中的气体向外排出,进入烟气分析仪。

据烟气分析仪得出的气体体积分数发现,石英玻璃管中气体成分主要为CO,CO2和N2共3种。由于N2为惰性气体,不参与反应,因此,可以认为使用该方法测出的CO和CO2体积分数能比较真实地反映反应体系中的CO和CO2体积分数。将CO和CO2的体积分数按照下式计算,用于表征还原反应体系中还原气氛体积分数:

(2)

(2)

式中: 为还原反应体系中还原气氛的体积分数,%;

为还原反应体系中还原气氛的体积分数,%; 为气氛中CO的体积分数,%;

为气氛中CO的体积分数,%; 为气氛中CO2的体积分数,%。

为气氛中CO2的体积分数,%。

此外,采用XRD和SEM-EDS等技术对还原焙烧产物进行检测,以分析其还原机理。

2 结果与讨论

2.1 含碳球团的还原行为

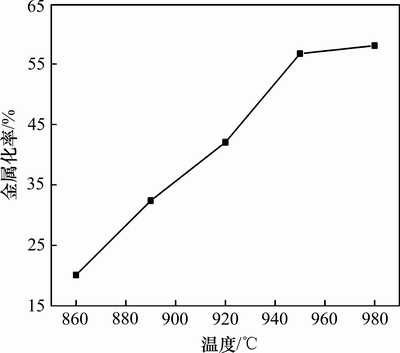

当添加剂钠盐质量分数为3%和还原焙烧时间为30 min时,不同还原温度对还原球团金属化率的影响如图4所示。

图4 还原温度对还原球团金属化率的影响

Fig. 4 Effect of temperature on metallization ratio of reduced pellets

从图4可知:随着还原焙烧温度提高,还原球团的金属化率显著提高,由860 ℃时的20.14%升高到950 ℃时的56.74%;继续提高温度到980 ℃,还原球团的金属化率为58.07%,提高幅度并不明显。因此,较合适的还原焙烧温度为950 ℃。

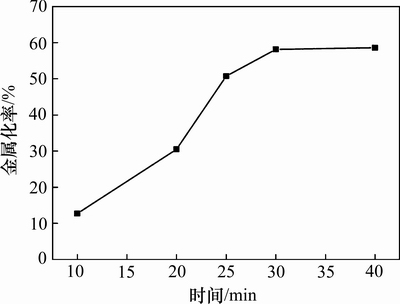

当添加剂质量分数为3%以及还原焙烧为950 ℃时,还原焙烧时间对还原球团金属化率的影响如图5所示。

图5 还原时间对还原球团金属化率的影响

Fig. 5 Effect of reduction time on metallization ratio of reduced pellets

从图5可以看出:还原球团金属化率随着还原时间的延长而增大;当还原时间为10 min时,还原球团的金属化率为12.73%;当还原时间延长到30 min时,还原球团的金属化率提高到56.74%;进一步延长还原时间对还原球团的金属化率提高不明显。综上可知,取还原时间为30 min较合适。

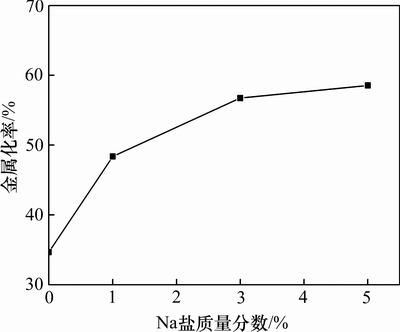

当还原温度为950 ℃和还原时间为30 min时,不同质量分数的钠盐对还原球团金属化率的影响如图6所示。从图6可知:加入钠盐可以有效提高还原球团的金属化率;当不添加钠盐时,还原球团的金属化率仅为34.68%;添加质量分数为1%的钠盐后,还原球团的金属化率提高到48.38%;当钠盐质量分数为3%时,还原球团的金属化率为56.74%,继续提高钠盐质量分数到5%,还原效果变化不明显。研究表明:影响碳的气化反应的主要因素为温度,而当温度低于1100 ℃时,含碳球团中铁氧化物的还原受碳气化反应限制的影响[21]。本研究中还原温度在1100 ℃以下,因而,铁氧化的还原受碳气化反应限制的影响,即使加大钠盐的质量分数,其作用效果也有限。以上结果说明该钠盐可以有效促进铁氧化物的还原。

图6 钠盐质量分数对还原球团金属化率的影响

Fig. 6 Effect of sodium salt mass fraction on metallization ratio of reduced pellets

2.2 钠盐强化含碳球团还原机理

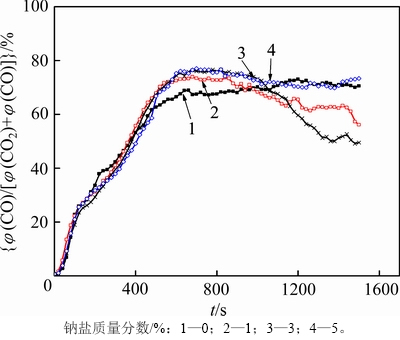

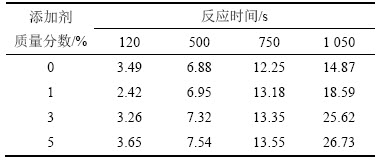

在温度为950 ℃,时间为30 min时,采用烟气分析仪对钠盐还原气氛进行分析,结果如图7所示。不同还原时间下球团的金属化率如表4所示。

由图7可见:还原体系中还原气氛CO的体积分数随着还原时间的延长快速提高,当还原时间为0~500 s时,不同钠盐质量分数的球团气相组成大致相同且钠盐质量分数对还原球团的金属化率影响不明显(见表4);当还原时间为500~1 050 s时,CO体积分数保持在最大值;当不含钠盐时,还原体系中还原气氛CO的体积分数为65%左右;在还原时间为1 050 s时金属化率为14.87%。而添加质量分数为1%和3%的钠盐后,还原体系中还原气氛CO的体积分数分别提高到70%和75%左右,在1 050 s时,金属化率则分别提高到18.59%和25.62%;当钠盐质量分数为5%时,还原体系中还原气氛CO的体积分数基本上与钠盐质量分数(3%)的一致;当还原时间超过1 050 s时,不含钠盐的体系中CO体积分数基本保持不变,而加入钠盐后CO的体积分数则不断降低。

图7 不同钠盐质量分数下还原反应的气相组成

Fig. 7 Atmosphere composition of reduction reaction with different mass fractions of sodium salt

表4 不同还原时间下球团的金属化率

Table 4 Metallization ratio of reduction products at different time %

本研究中使用的钠盐在高温下会迁移挥发[22]。当只加入质量分数为1%的钠盐时,在高温下较快挥发,因而,在1 050 s后碳气化作用减弱,且钠盐促进了碳的消耗,所以,还原体系中还原气氛CO的体积分数下降明显;但添加质量分数为3%和5%的钠盐时,在相同时间内球团中残余钠盐较多,仍存在较强的促进作用。因此,尽管前期碳消耗较多,但由于残余钠盐的促进作用,还原体系中还原气氛CO的体积分数比只加入质量分数为1%的钠盐时的CO体积分数高。含质量分数为5%的钠盐时,气相中CO的体积分数比质量分数为3%钠盐时下降较慢。不含钠盐时气相中CO体积分数保持稳定,但对铁氧化的还原作用较弱。

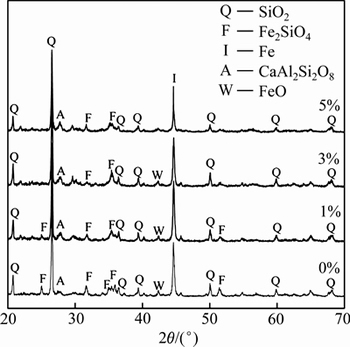

取不同钠盐质量分数还原球团,制样后进行XRD检测,结果如图8所示。由图8可知:当不添加钠盐时,还原球团中主要含有SiO2,Fe2SiO4和金属铁,此外,还含有少量长石(CaAl2Si2O8)和未被还原彻底的Fe3O4;当添加质量分数为1%的钠盐后,还原球团中的Fe2SiO4大量减少,Fe3O4被彻底还原;继续增加钠盐质量分数到3%,Fe2SiO4的特征衍射峰明显减小,说明钠盐对Fe2SiO4的生成有显著的抑制作用。

图8 不同钠盐质量分数时焙砂的XRD分析图

Fig. 8 XRD analysis of samples with different sodium salt mass fraction

在本研究过程中,还原温度大于570 ℃。在Fe2O3还原过程中,按Fe2O3 ,Fe3O4, FeO和Fe逐级进行,而FeO还原为Fe较难[23]。

FeO+CO=Fe+CO2; J/mol (3)

J/mol (3)

式中: 为反应的标准吉布斯自由能,J/mol;T为热力学温度,K。

为反应的标准吉布斯自由能,J/mol;T为热力学温度,K。

本文试验所用的矿石为高硅赤铁矿,原矿的脉石成分中含有大量的SiO2。在还原过程中,中间产物FeO与SiO2反应,生成铁橄榄石:

2FeO+ SiO2=Fe2SiO4; (4)

(4)

在用碳直接还原Fe2O3的体系中,一般认为直接还原作用较弱,而主要是间接还原反应[23]:

C+CO2=2CO (5)

FexOy+CO=FexOy-1+CO2 (6)

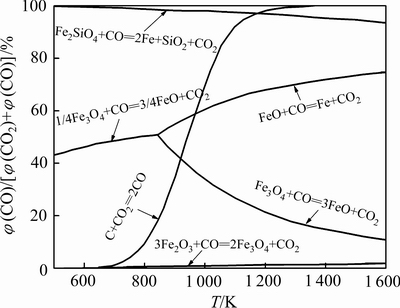

由式(3)~(6)可以得出铁氧化物还原反应的气相平衡图如图9所示。

图9 Fe2O3-SiO2体系煤基还原反应气相平衡图

Fig. 9 Coal-based reduction gas phase equilibrium diagram of Fe2O3-SiO2 system

由图9可知:在相同温度下,Fe2SiO4还原成Fe相比FeO还原成Fe需要更高的CO体积分数,当FeO转化为Fe2SiO4后,再还原为Fe较难。因而,需减少Fe2SiO4的生成,这在用直接还原法处理该类铁矿石中至关重要。

非标准态下的吉布斯自由能计算式为

(7)

(7)

式中:R为理想气体常数,8.314 4 J/(mol·K);KP为反应平衡常数。反应平衡常数可以按下式进行计算:

KP=φ(CO2)/φ(CO) (8)

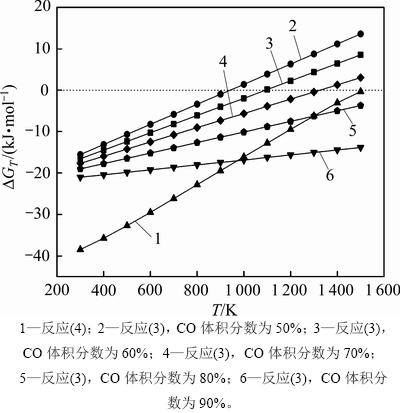

在标准大气压下,根据反应(3)~(4)和反应(6)~(8),计算CO体积分数对反应吉布斯自由能的影响,结果如图10所示。

由图10可见:提高CO的体积分数可以促进FeO的还原;当气氛中CO体积分数达到90%且还原温度大于1 000 K时,反应(3)的吉布斯自由能比反应(4)的小,这说明反应(3)比反应(4)更容易发生,即反应(3)有利于FeO还原为Fe。加入钠盐后,还原球团的金属化率显著提高,这是因为该钠盐具有催化作用,提高了碳的气化反应速度和CO的体积分数,促进了FeO的还原,从而减少了Fe2SiO4的生成。

图10 不同CO体积分数对反应(3)和(4) Gibbs自由能的影响

Fig. 10 Effects of CO volume fractions on Gibbs free energy of reactions (3) and (4)

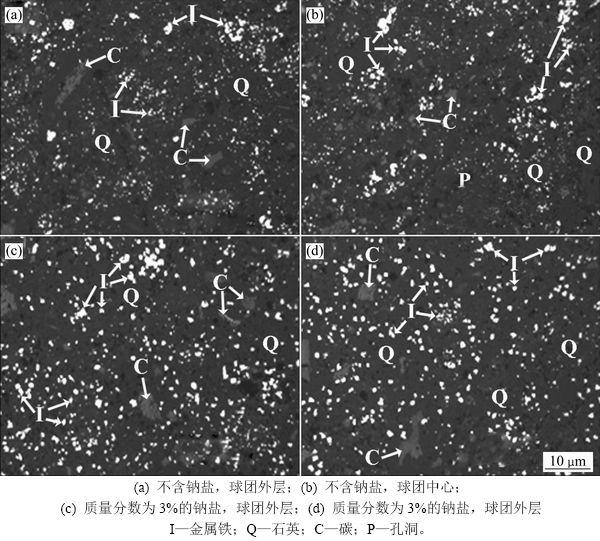

取含钠盐质量分数为0及3%的还原球团进行SEM分析,结果如图11所示。从图11可知:有无添加剂的内配煤还原球团表层与中心的显微结构都较接近,内外还原均匀;与无添加剂的还原球团相比,配加质量分数为3%的钠盐后,还原球团内铁晶粒粒度明显增大,局部出现了聚集现象。

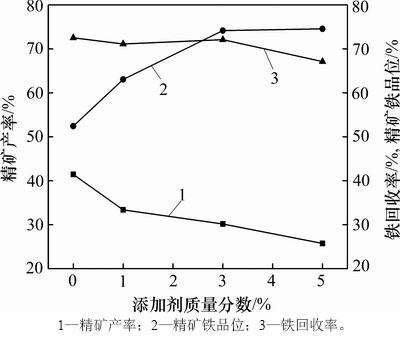

取含不同质量分数的钠盐还原所得球团进行磨矿、磁选,结果如图12所示。从图12可见:不含钠盐时,磨矿、磁选后精矿产率为41.43%,铁品位为52.42%,铁回收率为67.52%;随着钠盐质量分数增加,还原球团的金属化率提高,磨矿、磁选所得精矿铁品位也相应提高;当钠盐质量分数为3%时,精矿铁品位和铁回收率则分别提高到74.16%和74.57%。钠盐促进了还原球团中金属铁的聚集长大(见图11),这有利于磨矿、磁选中的金属铁与脉石矿物分离,从而提高分选指标。继续提高钠盐的质量分数至5%时,还原效果变化不明显,磨矿、磁选结果变化也不明显。

当加入钠盐后,煤的活性提高,在同样温度下,碳的气化反应速度加快,气相中CO体积分数提高,从而加快了铁氧化物的还原速度。由实验结果可知,加入质量分数为3%的钠盐时还原效果较好。

图11 不同添加剂质量分数的还原球团显微结构

Fig. 11 Microstructures of reduced pellets with different sodium salt mass fractions

图12 不同钠盐质量分数时还原球团的磨矿-磁选结果

Fig. 12 Effect of different sodium salt mass fraction on magnetic separation results of reducted products

3 结论

1) 该低品位赤铁矿铁品位仅为33.18%,而SiO2的质量分数则达40.61%。原矿中铁氧化物结晶粒度小于0.037 mm,而小于0.010 mm的氧化物质量分数为39.94%。该类铁矿石难以用传统的选矿方法进行富集。

2) 提高还原温度、加入钠盐添加剂可有效促进铁氧化物的还原,改变还原时间对还原效果影响较小。当m(C)/m(Fe)=0.4,添加剂质量分数为3%,还原温度为950 ℃和还原时间为30 min时,可得到金属化率为56.74%的还原球团。

3) 钠盐可以促进碳的气化反应,使气氛中CO的体积分数提高10%~15%,从而促使FeO快速还原为金属铁,减少Fe2SiO4的生成,促进铁晶粒的长大迁移,进而改善还原效果。加入钠盐添加剂可以使还原球团的金属化率提高20%以上。

参考文献:

[1] 张泾生. 我国铁矿资源开发利用现状及发展趋势[J]. 中国冶金, 2007, 17(1): 1-6.

ZHANG Jingsheng. Status and trend of exploitation and utilization of iron ore resources in China[J]. China Metallurgy, 2007, 17(1): 1-6.

[2] 侯宗林. 中国铁矿资源现状与潜力[J]. 地质找矿论丛, 2005, 20(4): 242-247.

HOU Zonglin. Current situation and potential of iron ore resources in China[J]. Contributions to Geology and Mineral Resource Research, 2005, 20(4): 242-247.

[3] 袁致涛, 高太, 印万忠, 等. 我国难选铁矿石资源利用的现状及发展方向[J]. 金属矿山, 2007(1): 1-6.

YUAN Zhitao, GAO Tai, YIN Wanzhong, et al. Status and development orientation of China’s refractory ore resource utilization[J]. Metal Mine, 2007(1): 1-6.

[4] 陈雯, 张立刚. 复杂难选铁矿石技术现状及发展趋势[J]. 有色金属(选矿部分), 2013(增刊): 19-23.

CHEN Wen, ZHANG Ligang. Status and development trend of beneficiation technology on complex refractory ores[J]. Nonferrous Metals Mineral Processing, 2013(Suppl): 19-23.

[5] 朱德庆, 翟永, 潘建, 等. 煤基直接还原-磁选超微细贫赤铁矿新工艺[J]. 中南大学学报(自然科学版), 2008, 39(6): 1132-1136.

ZHU Deqing, ZHAI Yong, PAN Jian, et al. Beneficiation of super microfine low-grade hematite ore by coal-based direct reduction-magnetic concentration process[J]. Journal of Central South University(Science and Technology), 2008, 39(6): 1132-1138.

[6] 陈伟鹏, 王强, 冯志明, 等. 干熄焦除尘灰作还原剂直接还原低品位褐铁矿机理分析[J]. 钢铁钒钛, 2018, 39(1): 78-83.

CHEN Weipeng, WANG Qiang, FENG Zhiming, et al. Analysis on the mechanism of direct reduction of limonite by coke quenching ash as reducing agent[J]. Iron Steel Vanadium Titanium, 2018, 39(1): 78-83.

[7] 陈伟鹏, 王强, 陈晓丹, 等. 干熄焦除尘灰对低品位褐铁矿的直接还原[J]. 矿冶工程, 2018, 38(4): 87-90.

CHEN Weipeng, WANG Qiang, CHEN Xiaodan, et al. Direct reduction of low-grade limonite by coke dry quenching dust[J]. Mining and Metallurgical Engineering, 2018, 38(4): 87-90.

[8] 魏玉霞, 孙体昌, 寇珏, 等. 内配煤质量分数对某难选铁矿石压块直接还原焙烧的影响[J]. 中南大学学报(自然科学版), 2013, 44(4): 1305-1311.

WEI Yuxia, SUN Tichang, KOU Yu, et al. Effect of coal dosage on direct reduction roasting of refractory iron ore briquettes[J]. Journal of Central South University(Science and Technology), 2013, 44(4): 1305-1311.

[9] 付菊英, 姜涛, 朱德庆. 烧结球团学[M]. 长沙: 中南大学出版社, 1996: 127-130, 224-245, 256-259.

FU Jiuying, JIANG Tao, ZHU Deqing. Sintering and pelletizing[M]. Changsha: Central South University Press, 1996: 127-130, 224-245, 256-259.

[10] FAN Duncheng, WEN Ni, WANG Jianyue, et al. Effect of CaO and Na2CO3 on the reduction of high silicon iron ores[J]. Journal of Wuhan University of Technology(Materials Science Edition), 2017, 32(3): 508-516.

[11] KIM W H, LEE Y S, SUH I K, et al. Influence of CaO and SiO2 on the reducibility of wustite using H2 and CO as gas[J]. The Iron and Steel Institute of Japan International, 2012, 52(8): 1463-1471.

[12] 白云, 陈德胜, 马文会, 等. 直接还原处理低品位钒钛磁铁精矿[J]. 有色冶金(冶炼部分), 2017(9): 48-53.

BAI Yun, CHEN Desheng, MA Huiwen, et al. Treatment of low grade vanadium-bearing titanomagnetite concentrates by direct reduction[J]. Nonferrous Metals(Extractive Metallurgy), 2017(9): 48-53.

[13] 李永利, 孙体昌, 徐承焱, 等. 高磷鲕状赤铁矿直接还原同步脱磷新脱磷剂[J]. 中南大学学报(自然科学版), 2012, 43(3): 827-834.

LI Yongli, SUN Tichang, XU Chenyan, et al. New dephosphorizing agent for phosphorus removal from high-phosphorus oolitic hematite ore in direct reduction roasting[J]. Journal of Central South University(Science and Technology), 2012, 43(3): 827-834.

[14] 刘牡丹, 刘勇, 李珍珍, 等. 直接还原工艺在稀有金属伴生铁矿综合利用中的应用[J]. 材料研究与应用, 2018, 12(2): 123-128.

LIU Mudan, LIU Yong, LI Zhenzhen, et al. The application of direct reduction process in the comprehensive utilization of rare metal associated iron ores[J]. Materials Research and Application, 2018, 12(2): 123-128.

[15] SHEARER C R, PROVIS J L, BERNAL S A, et al. Alkali-activation potential of biomass-coal co-fired fly ash[J]. Cement and Concrete Composites, 2016(73): 62-74.

[16] 陈伟鹏, 张天睿, 李光为, 等. 添加剂对褐铁矿煤基直接还原强化作用研究[J]. 矿冶工程, 2018, 38(1): 76-80.

CHEN Weipeng, ZHANG Tianrui, LI Guangwei, et al. Strengthening effects of different additives on coal-based direct reduction of limonite[J]. Mining and Metallurgical Engineering, 2018, 38(1): 76-80.

[17] WANG Xiaoping, SUN Tichang, CHEN Chao, et al. Effects of Na2SO4 on iron and nickel reduction in a high-iron and low-nickel laterite ore[J]. International Journal of Minerals, Metallurgy and Materials, 2018, 25(4): 383-390.

[18] COETZEE S,NEOMAGUS H W J P,BUNT J R, et al. Improving reactivity of large coal particles by K2CO3 addition during steam gasification[J]. Fuel Processing Technology, 2013(114): 75-80.

[19] ZHU W K, SONG W L, LIN W G. Catalytic gasification of char from co-pyrolysis of coal and biomass[J]. Fuel Processing Technology, 2008, 89(9): 890-896.

[20] 张松, 汪琦, 李金莲, 等. 氧化物对碳气化反应的影响[J]. 材料导报, 2013, 27(21): 115-116, 125.

ZHANG Song, WANG Qi, LI Jinlian, et al. The effects of oxides on carbon gasification reaction[J]. Materials Review, 2013, 27(21): 115-116, 125.

[21] 杨天钧, 黄典冰, 孔令坛. 熔融还原[M]. 北京: 冶金工业出版社, 1998: 150-151.

YANG Tianjun, HUANG Dianbing, KONG Lingtan. Smelting reduction[M]. Beijing: Metallurgical Industry Press, 1998: 150-151.

[22] 孙进, 李清海, 李国岫, 等. 城市生活垃圾焚烧中NaCl迁移转化的实验和热力学平衡分析[J]. 中国电机工程学报, 2014, 34(2): 272-278.

SUN Jin, LI Qinghai, LI Guoxiu, et al. Experimental and thermodynamic investigation on partitioning and speciation of NaCl during municipal solid waste incineration[J]. Proceedings of the Chinese Society for Electrical Engineering, 2014, 34(2): 272-278.

[23] MAN Y, FENG J X, LI F J, et al. Influence of temperature and time on the reduction behavior in iron-coal composite pellets[J]. Powder Technology, 2014(256): 361-366.

(编辑 陈灿华)

收稿日期:2018-05-10;修回日期:2018-07-21

基金项目(Foundation item):国家自然科学基金资助项目(51504230) (Project(51504230) supported by the National Natural Science Foundation of China)

通信作者:易凌云,博士,副教授,从事绿色冶金、多金属复杂资源综合利用研究;E-mail:ylycsu@126.com