Hot deformation mechanism and microstructure evolution of

TC11 titanium alloy in b field

CHEN Hui-qin(陈慧琴)1, 2, CAO Chun-xiao(曹春晓)1, GUO Ling(郭 灵)1, LIN Hai(林 海)1

1. Beijing Institute of Aeronautical Materials, Beijing 100095, China;

2. School of Materials Science and Engineering, Taiyuan University of Science and Technology,

Taiyuan 030024, China

Received 6 December 2007; accepted 12 June 2008

Abstract: Hot deformation behaviors of TC11 alloy with b-annealed lamellar structure and forged equiaxed structure were investigated in the b field in the temperature range of 1 090-1 030 ℃ and strain rate of 0.001-0.1 s-1 by means of isothermal compression tests. Hot deformation characteristics and microstructure evolutions of the two starting structures were analyzed. And hot processing power dissipation efficiency maps were established. EBSD technique was used for testing grain boundary characteristic of deformation structures. The results indicate that hot deformation mechanism of TC11 alloy in b field is dynamic recovery accompanied by geometric dynamic recrystallization at large strains, or discontinuous dynamic recrystallization based on the starting structure states and deformation parameters. Accordingly, there are two different grain refining patterns. One is characteristic of new fine grains in the interior of elongated prior b grains that have serrated grain boundaries; and the other is that of new fine grains along elongated prior b grain boundaries.

Key words: TC11 titanium alloy; hot deformation; microstructure evolution

1 Introduction

TC11 alloy is a heat-resisting a+b titanium alloy with good mechanical properties, which is extensively used in the aerospace industry. The primary processing of TC11 ingots generally involves hot working in the b field, cooling to obtain a transformed b microstructure, and mechanical working in the a-b field to obtain fine grained equiaxed a+b structure. Such a microstructure results in good strength and ductility. Conversely, the transformed b microstructure consists of acicular or lamellar morphology depending on the cooling rate from the b-solutionizing temperature, and this type of microstructure can provide very attractive creep resistance and fracture properties such as toughness and fatigue crack propagation resistance. However, the attractive comprehensive properties are obtained only with the fine prior b grain sizes below about 200 μm[1]. In practice, large reduction in the b field is utilized to obtain the microstructure consisting of elongated grains whose boundaries are decorated by fine recrystallized grains. Higher preheating temperature results in structure comprising elongated b grains alone. SEMIATIN et al[2] suggested that these results can be rationalized by findings of NORLEY who concluded that alpha/beta alloys dynamically recover during hot working in the b field, but may subsequently statically recrystallize if sufficient hot working has been imposed. SESHACHARYULU et al[3-5] investigated the hot deformation behavior and microstructure evolution mechanisms of Ti-6Al-4V with different sized starting prior b grains by constant strain rate isothermal hot compression tests in the b field. For the b-transformed starting structure with prior b grain sizes of 2-3 mm and intergranular a thickness of 5 μm, the microstructure evolution mechanism is large grain superplasticity controlled by diffusion, but dynamic recrystallization controlled by diffusion in the b field (>1 100 ℃, <0.1 s-1) [3-4]. And in the b field (>1 050 ℃), dynamic recrystallization occurred for the equiaxed starting structure[5]. PRASAD et al[6] have reported that the preform microstructure has an effect on the hot working mechanism in Ti-6Al-4V[6]. Therefore, microstructure microstructure evolution mechanism of titanium alloy deformed in the b field varies with perform structure and thermal-mechanical parameters. The objective of the present work is to investigate hot deformation mechanism and microstructure evolution of TC11 alloy with different perform structure and thermal-mechanical parameters deformed in the b field.

2 Experimental

2.1 Materials

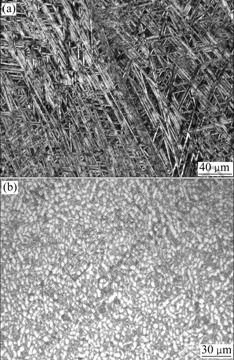

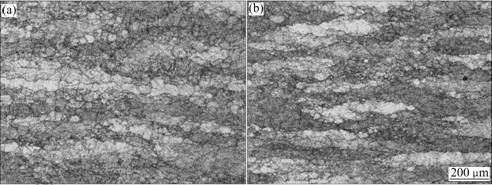

TC11 having the following composition (mass fraction, %) was used in this study: 6.42 Al, 3.29 Mo, 1.79 Zr, 0.23 Si, 0.025 C, 0.077 Fe, 0.96 O, 0.004 4 N, 0.003 4 H and balance Ti. The b transus for this material is about 1 008 ℃. The two starting micro- structures of TC11 alloy used for testing are shown in Fig.1. One is b-annealed lamellar structure (Fig.1(a)), and the other is forged equiaxed structure (Fig.1(b)).

Fig.1 Starting microstructures of TC11 alloy: (a) b-annealed lamellar structure; (b) Forged equiaxed structure

2.2 Hot compression

Compression specimens of 12 mm in height and 8 mm in diameter were machined for hot compression. Concentric grooves of 0.2 mm in depth were made on the top and bottom surfaces of the specimens to trap lubricant. Thermocouples welded in the middle surface of the specimens were used to measure the actual temperature of the specimens. Isothermal hot compression tests were conducted using a Thermecmastor-Z thermo-mechanical simulator.

The test temperature ranged from 1 030 ℃ to 1 090 ℃ and strain rates were kept at 0.001 s-1, 0.01 s-1 and 0.1 s-1. The specimens were deformed to about 50% and quenched immediately after deformation. The true stress—true plastic strain curves at different temperatures and strain rates were obtained. Deformed specimens sectioned parallel to the compression axis were prepared for metallographic examination and EBSD testing. The microscopy specimens were etched with Kroll’s reagent and optical micrographs by ZEISS-AXIO were recorded. EBSD testing was conducted on TESCAN- 5136XM SEM, and the scan step is 1 μm.

3 Results and discussion

3.1 Stress—strain behaviors

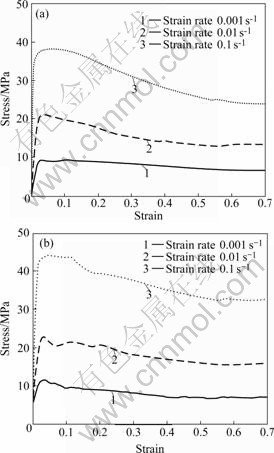

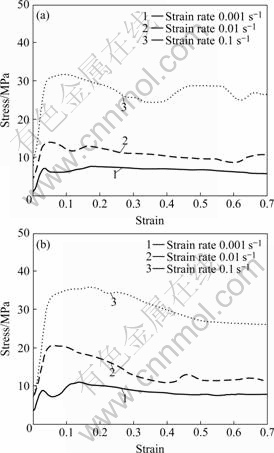

The shape of stress—strain curves indicates some features that help in identifying the mechanism of hot deformation. The stress—strain curves of TC11 alloy with the b-annealed lamellar starting structure (Fig.2) and the forged equiaxed starting structure (Fig.3) in the b phase field are similar. At 1 030 ℃, these curves exhibit a continuous flow softening behavior at all strain rates, especially at higher strain rates. At 1 090 ℃, these curves also exhibit a continuous flow softening behavior at 0.01 s-1 and 0.1s-1, but the curves are of steady-state type at strain rate of 0.001 s-1. The steady-state type curves indicate that softening is sufficiently fast to balance the rate of work hardening and mechanism like dynamic recovery or super-plastic deformation is suggested. Flow softening behavior is observed for dynamic recrystallization or flow instability due to flow localization.

Fig.2 Stress—strain curves of TC11 alloy with b-annealed lamellar structure: (a) At 1 090 ℃; (b) At 1 030 ℃

Fig.3 Stress—strain curves of TC11 alloy with forged equiaxed structure: (a) At 1 090 ℃; (b) At 1 030 ℃

In addition, the stress–strain curves indicate that the flow stress increases with increase of strain rate and decrease of temperature. And the flow stress of the b-annealed lamellar starting structure is higher than that of the forged equiaxed starting structure at the same deformation parameters.

3.2 Kinetic analysis

The temperature and strain rate dependence of flow stress in hot deformation is generally expressed in terms of a kinetic rate equation given by[3-5]:

where  is the strain rate; σ is the flow stress; A is the material constant; Q is the activation energy; R is the gas constant; T is the temperature in Kelvin and n is the stress exponent. In order to identify the mechanisms of hot deformation, the kinetic parameters, n and Q, are to be evaluated. From Eqn.(1), the stress exponent, n, is defined by

is the strain rate; σ is the flow stress; A is the material constant; Q is the activation energy; R is the gas constant; T is the temperature in Kelvin and n is the stress exponent. In order to identify the mechanisms of hot deformation, the kinetic parameters, n and Q, are to be evaluated. From Eqn.(1), the stress exponent, n, is defined by

And the activation energy, Q, may be defined as:

The value of stress exponent n is estimated to be about 3.32 for the b-annealed lamellar starting structure in the b field, and 4.05 for the forged equiaxed starting structure (Fig.4). The plots for estimating the activation energies for hot deformation in the b field are shown in Fig.5. The activation energies estimated from these plots are 135.4 kJ/mol and 172.3 kJ/mol for the b annealed lamellar and forged equiaxed starting structure, respectively, in the b field. These values are approach to those for self-diffusion in b-Ti (153 kJ/mol)[3], which may suggest that the mechanism in the b field is governed by diffusion related processes. The lower stress exponent and activation energy suggest that the deformation mechanism in the b phase field may be controlled by diffusion creep processes mainly for the b-annealed lamellar starting structure. The higher stress exponent and activation energy suggest that the deformation mechanism in the b phase field may be controlled by dislocation slipping and climbing processes mainly for the forged equiaxed starting structure.

Fig.4 Natural logarithm relationship of strain rate and peak stress: (a) b-annealed lamellar structure; (b) Forged equiaxed structure

Fig.5 Relationship of natural logarithm peak stress and reciprocal temperature: (a) b-annealed lamellar structure; (b) Forged equiaxed structure

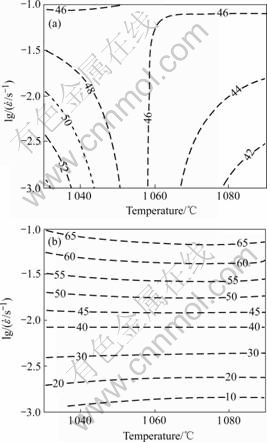

3.3 Processing map

The approach of processing map[7] has been adopted in this study to represent and analyze the deformation behavior of TC11 alloy in the b field. Depicted in a frame of temperature and strain rate, a power dissipation map represents the pattern in which the input power is dissipated by the material through micro-structural changes rather than heat. The rate of this change compared to an ideal linear dissipater is given by the dimensionless parameter called the efficiency of power dissipation:

where m is the strain rate sensitivity of flow stress.

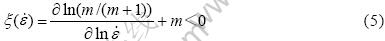

An instability map is developed using the continuum instability criterion given by

Therefore, a processing map can be obtained by superimposing the instability map to the power dissipation map plotted as an iso-efficiency contour map. The processing map developed for TC11 at a strain of 0.5 is shown in Fig.6, in which contour numbers represent the efficiency percent of power dissipation and no unstable region.

Fig.6 Processing maps at 0.5 strain: (a) b annealed lamellar structure; (b) forged equiaxed structure

As interpreted in Ref.[7], the power dissipation efficiency of dynamic recrystallization is 50%-55% for metals with high stacking faulty energy. Super-plasticity with about 60% power dissipation efficiency occurs at strain rates lower than 0.01 s-1. And the power dissipation efficiency of dynamic recovery is slightly lower than that of dynamic recrystallization. In Fig.6(a), the higher power dissipation efficiency domain locates in the lower strain rate of 0.001 s-1 and 1 030 ℃ with an efficiency value of 52%, and in the medium strain rate of 0.01-0.1 s-1 with an efficiency value of 42%-48%, which may suggest that dynamic recovery occurs. In Fig.6(b), the higher power dissipation efficiency domain locates in the higher strain rate of 0.1 s-1 with an efficiency value of 65%, which may suggest that super-plasticity or dynamic recrystallization happens. And the power dissipation efficiency decreases from 65% to 10% with strain rates deceasing from 0.1 s-1 to 0.001 s-1.

3.4 Microstructure observation

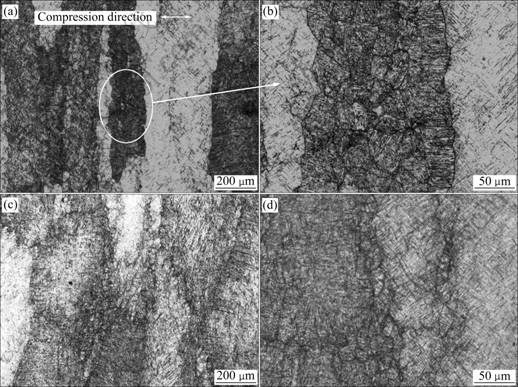

Microstructures of specimens deformed at different temperatures and strain rates are examined and shown in Figs.7 and 8. From these images, it can be seen that different microstructure mechanisms may be operated at different temperatures and strain rates in the b field for different starting structures.

Typical deformation microstructures at steady- state strain in the b field for the b-annealed lamellar starting structure are shown in the Fig.7. It can be seen that microstructure evolution patterns are different with different deformation parameters for the same starting structure. At 1 090 ℃ and 0.1 s-1, prior b grains elongate along the deforming direction (Fig.7(a)). Meanwhile, the prior b-grain boundaries become serrated, and new fine grains appear in the interior of elongated prior b grains (Fig.7(b)). This implies that the microstructure evolution mechanism is dynamic recovery.

Fig.7 Typical deformation microstructures at steady-state strain in b field for b-annealed lamellar starting structure: (a) and (b) 1 090℃, 0.1 s-1; (c) and (d) 1 030 ℃, 0.1 s-1

Fig.8 Deformation microstructures at steady-state strain in b field for equiaxed starting structure: (a) 1 090 ℃, 0.1 s-1; (b) 1 030 ℃, 0.1 s-1

During this deformation process, dislocation density increases with the increase of strain, and dislocations are annihilated and re-arranged by dynamic recovery at the same time. At the steady-state strain, creation and annihilation of dislocations arrive dynamic equilibrium, and uniform fine sub-grains are formed in the deformed and elongated prior grains. At very large strain, prior grains become flatted, and new fine grains form in the interior of elongated prior grains. McQUEEN[8] named this processes as Geometric Dynamic Recrystallization (GDRX). This microstructure evolution mechanism has been proven in Zr and Al alloys[8-13]. At 1 030 ℃ and the same strain rate, prior b grains elongate also along the deforming direction (Fig.7(c)). Meanwhile, new fine grains appear along elongated prior b grain boundaries (Fig.7(d)). This suggests that the microstructure evolution mechanism is discontinuous dynamic recrystallization[14-15]. The above two microstructure evolution patterns indicate that microstructure mechanism changes with different deformation parameters for the same material. And the continuous flow softening behavior of the stress—strain curve (Fig.2) may be caused by discontinuous dynamic recrystallization or dynamic recovery accompanied by geometric dynamic recrystallization.

Deformation microstructure of the equiaxed starting structure in Fig.8 is similar to that in Fig.7(d). Prior b grains elongate along deformation direction, and new fine grains decorate along elongated prior b grain boundaries. Microstructures, as shown in Fig.8, also indicate that partial recrystallized structure is obtained at steady-state strain. This may be due to the lower deformation activation energy (the activation energy of typical dynamic recrystallization is 300-400 kJ/mol[8]). The recrystallized grains are finer at lower deformation temperature.

By comparing Fig.7(a) with Fig.8(a), it can be seen that microstructure mechanism changes with different starting structures at the same deformation parameters.

In order to verify above analysis, EBSD testing for typical structures (Fig.7(b) and Fig.8(b)) were conducted. The results, as shown in Fig.9, indicate that β phase mis-orientation distribution features are similar. Low- angle boundaries have a peak in 3?-5?. High-angle boundaries have two peaks in 30?-40? and 50?-60?, respectively. Transformation from low-angle boundaries to high-angle boundaries is discontinuous. From microstructure observation, processing map and EBSD testing results, conclusions can be drown that the microstructure evolution mechanism in Fig.7(b) is dynamic recovery accompanied by geometric dynamic recrystallization at large strain, and it is discontinuous dynamic recrystallization in Fig.8(b).

Fig.9 β mis-orientation distribution of different microstructures: (a) With β-annealed lamellar starting structure; (b) With equiaxed starting structure

4 Conclusions

1) For the b-annealed lamellar starting structure, hot deformation stress exponent and activation energies estimated in the b field are 3.32 and 135.4 kJ/mol, respectively, which may suggest that deformation is controlled by diffusion creep processes mainly. According to the deformation parameters, microstructure evolution mechanism can be dynamic recovery accompanied by geometric dynamic recrystallization at large strain or discontinuous dynamic recrystallization, both of which can cause continuous flow softening behavior of the stress—strain curve.

2) For the equiaxed starting structure, hot deformation stress exponent and activation energies estimated in the b field are 4.05 and 172.3 kJ/mol, respectively, which may suggest that deformation is controlled by dislocation slipping and climbing processes mainly. Microstructure evolution mechanism is discontinuous dynamic recrystallization, which causes continuous flow softening behavior of the stress—strain curve.

References

[1] PRASAD Y V R K, SESHACHARYULU T, MEDEIROS S C, FRAZIER W G. Effect of prior b grain size on the hot deformation behavior of Ti-6Al-4V: coarse vs. coarser [J]. Materials Science and Technology, 2000, 16 (5): 511-516.

[2] SEMIATIN S L, SEELHARAMAN V AND WEISS I. Hot working of titanium alloys—an overview [C]// WEISS I ed. Advances in the science and technology of titanium alloy processing. New York, 1997: 3-37.

[3] SESHACHARYULU T, MEDEIROS S C, MORGAN J T, MALAS J C, FRAZIER W G AND PRASAD Y V R K. Hot deformation mechanisms in ELI grade Ti-6Al-4V[J]. Scripta Materialia, 1999, 41(3): 283-288.

[4] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure [J]. Materials Science and Engineering A, 2002, 325: 112-125.

[5] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Hot working of commercial Ti-6Al-4V with an equiaxed a-b microstructure: Materials modeling consideration [J]. Materials Science and Engineering A, 2000, 284: 184-194.

[6] PRASAD Y V R K, SESHACHARYULU T, MEDEIROS S C, FRAZIER W G. Effect of preform microstructure on the hot working mechanisms in ELI grade Ti-6Al-4V: Transformed b v. equiaxed (a+b)[J]. Materials Science and Technology, 2000, 16 (5): 511-516.

[7] PRASAD Y V R K. Hot working guide: a compendium of processing maps [M]. ASM International, Materials Park, OH, 1997.

[8] MCQUEEN H J. Development of dynamic recrystallization[J]. Materials Science and Engineering A, 2004, 387/389: 203-208.

[9] BARRABES S R, KASSNER M E, PEREZ-PRADO M T, EVANGELISTA E. Geometric dynamic recrystallization in a-Zirconium at elevated temperature [J]. Materials Science Forum, 2004, 467/470: 1145-1150.

[10] KAIBYSHEV R, MAZURINA I, SITDIKOV O. Geometric dynamic recrystallization in an AA2219 alloy deformed to large strains at an elevated temperature [J]. Materials Science Forum, 2004, 467/470: 1199-1204.

[11] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena [M]. Oxford: Elsevier, 2004.

[12] MCQUEEN H J. Development of dynamic recovery theory for aluminum [J]. ASM International, 2001, 351-360.

[13] MCQUEEN H J, BLUN W. Dynamic recovery: Sufficient mechanism in the hot deformation of Al (<99.99) [J]. Materials Science and Engineering A, 2000, 290: 95-107.

[14] DING R, GUO Z X, WILSON A. Microstructure evolution of a Ti-6Al-4V alloy during thermo-mechanical processing [J]. Materials Science and Engineering A, 2002, 327: 233-245.

[15] DING R, GUO Z X. Microstructure evolution of a Ti-6Al-4V alloy during β-phase processing: Experimental and simulative investigations [J]. Materials Science and Engineering A, 2004, 365: 172-179.

Corresponding author: CHEN Hui-qin, Tel: +86-13327510620; Fax: +86-351-6998646; E-mail: chqsxty@yahoo.com.cn

(Edited by YANG Bing)