微波烧结金属纯铜压坯

朱凤霞,易健宏,彭元东

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:分别采用常规电阻加热与微波加热对金属铜压坯进行烧结并比较样品烧结密度、表观硬度以及显微组织分布;微波烧结在功率为1 kW、频率为2.45 GHz微波炉中进行。结果表明:微波烧结样品平均相对密度达97.3%,略高于相同烧结温度下常规烧结样品的平均相对密度;微波烧结可在较短时间内对粉末冶金金属铜样品实现烧结致密化。另外,微波烧结样品表观硬度比常规烧结样品的高。微波烧结样品具有独特孔隙分布规律,样品横截面中心处孔隙率比横截面边缘处的小;并且微波烧结样品孔隙与显微组织较常规烧结样品细小。

关键词:铜;金属压坯;微波烧结;致密度;显微组织

中图分类号:TF124 文献标识码:A 文章编号:1672-7207(2009)01-0106-06

Sintering response of copper powder metal compact in microwave field

ZHU Feng-xia, YI Jian-hong, PENG Yuan-dong

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Sintering responses, including relative density, apparent hardness and microstructure evolution of copper powder compacts sintered by both conventional furnace sintering and microwave processing were studied. The microwave sintering was conducted in a 1 kW, 2.45 GHz, multi-mode microwave furnace. The results show that the average relative density of copper powder compacts sintered in microwave furnace is 97.3%, slightly higher than that sintered in conventional furnace, at the same sintering temperature; good densification of copper powder compact can be realized by microwave sintering for much less processing time. In addition, the apparent hardness of microwave sintered samples are higher than those of the conventional sintered ones. A distinct porosity distribution is obtained in microwave sintered samples, with fewer pores in the inside of the cross section than that in the edge part. And much more refined pores and finer microstructures are observed in the microwave sintered samples as compared to those sintered in conventional furnace.

Key words: copper; metal compact; microwave sintering; relative density; microstructure

微波是波长介于1 mm到1 m,频率在300 MHz到300 GHz之间的电磁波[1]。一般地,用于工业加热的微波频段为915 MHz与2.45 GHz,高频段毫米微波管如28~30 GHz可产生更高功率,更快加热速度[2]。近年来,微波加热在多种材料的高温合成与烧结方面引起越来越多的关注[3-4]。作为一种新型工艺,微波烧结的典型特征是体积加热以及由此引起的工艺时间缩减与节能效应。除此之外,有报道显示微波烧结可细化显微组织,改善样品力学性能[5-10]。目前,微波烧结在陶瓷烧结方面已得到广泛应用[3-4]。不过,在Roy等[11]报道颗粒状金属亦可实现微波场中加热之前,很少有研究者尝试对金属进行微波烧结。在此之后,关于一系列金属以及合金的微波烧结研究较多,包括铝、铅、锡、钢铁、高密度合金、青铜等[5, 7-10, 12-17]。

尽管有很多研究者尝试解释关于微波加热金属机理问题[18-23],但迄今为止尚未形成关于微波-金属耦合机制公认的比较全面的理论。为给微波烧结金属粉体材料机理研究提供一些实验数据,本文作者以金属纯铜压坯作为研究对象,主要对纯铜压坯在微波场下的烧结行为进行观察,并与同温度下常规烧结样品进行比较。

1 实 验

本实验采用平均粒径为38.5 μm的电解铜粉,粉末的具体性能见表1。

表1 实验中铜粉的性能

Table 1 Characteristics of current copper powder

试样成形压制压力为150 MPa,生坯密度约为60%。样品是直径为10 mm的圆柱试样。烧结温度为1 000 ℃,微波烧结保温20 min,常规烧结保温60 min。

图1所示为实验中微波系统示意图。此处采用SiC粉末作辅助加热剂,以便在室温得到较高的升温速率。

金属铜生坯的微波烧结在功率为1 kW、频率为2.45 GHz的多模腔微波烧结炉中进行,烧结过程中通过红外测温计(Optris IR 10)测量样品温度,红外测温计的预设发射率为0.95,金属铜样品的发射率为0.70[24]。红外测温计的起始探测温度为600 ℃,实验时,红外测温计对准样品中心点,同时,通过数据线串口与计算机控制系统相连,屏幕显示温度随时间变化函数,从而可通过计算机软件调节输出功率,实现对样品温度进行智能控制。常规烧结和微波烧结均在流动H2气氛中进行。实验中通过循环水对微波腔体进行冷却。

图1 微波装置示意图

Fig.1 Schematic view of microwave system setup in current experiment

对常规烧结和微波烧结样品进行烧结密度、表观硬度测定以及显微组织观察。采用排水法测定试样密度。采用HDI-1875型布洛维硬度计测试样品的硬度,压头直径2.5 mm,加载荷312.5 N,试样在金相制样机上磨出中间横截面,于横截面上取3个点,分别位于试样横截面两边缘处以及中心处(见图4和图5)。

采用MeF3A型光学显微镜观察显微组织分布。抛光未腐蚀样品用于观察2种烧结模式下不同的内部孔隙分布;采用FeCl3对样品进行腐蚀,观察晶粒分布。孔隙度定量分析测试软件为Leica Q520系统。

2 结果与讨论

2.1 微波烧结纯铜压坯的工艺过程

图2所示为常规烧结与微波烧结工艺曲线。除去样品冷却时间,常规烧结时间为5 h左右,而微波烧结总时间仅为1 h,包括将样品冷却到室温并取出炉腔所用时间。通过微波烧结,样品总烧结时间可缩减80%以上。另外,整个常规烧结过程中功率消耗为2~5 kW,而微波烧结最大输入功率仅为0.75 kW(见图3)。

1—常规烧结; 2—微波烧结

图2 常规烧结与微波烧结工艺曲线

Fig.2 Heating profiles of conventional and microwave sintered copper powder metal compact

1—温度; 2—输入功率

图3 微波加热曲线与微波输入功率-时间曲线

Fig.3 Heating profiles and power consumption of microwave sintered copper power metal compact

由图2 及图3可见,微波烧结过程中产生的高加热速率可大大缩减工艺时间,节约能源,有着广阔的工业应用前景。

2.2 试样密度与性能

表2所示为2种烧结工艺以及相应的烧结密度以及表观硬度。表中所列数据均为3~5个同等条件下得到试样的测定平均值,显示了良好的重复性。

表2 烧结工艺与相应的烧结密度及表观硬度比较

Table 2 Comparison of sintering density and sintering parameters between conventional and microwave sintering

由表2可看出,微波烧结保温时间仅为常规烧结的1/3,而微波烧结样品的烧结密度以及表观硬度均略比常规烧结样品的高。这说明对于本实验中金属铜压坯, 微波烧结可与常规烧结一样很好甚至更好地实现致密化。值得注意的是,表中常规烧结样品截面中心与边缘处硬度基本无差异,而微波烧结样品横截面中心处的硬度(HB 52.8)远高于其边缘处硬度(HB 42.6),这要归因于微波烧结中独特的温度梯度分布——体加热导致的内部温度高于外部温度的逆温度分布。

2.3 加热方式对显微组织的影响

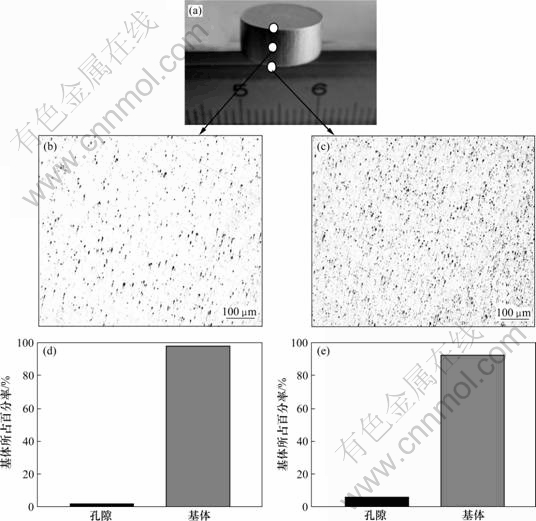

图4和图5分别所示为常规烧结与微波烧结样品照片以及横截面边缘处与中心处微观孔隙分布。可以看出,常规烧结样品与微波烧结样品均得到很好烧结,孔隙率较少;微波烧结样品整体孔隙分布较常规烧结样品的细小,且由图5(b)和(c)以及定量分析图5(d)和(e)可以看出,微波烧结样品内部比外部更加致密,内部孔隙比外部的少,进一步证实了微波烧结体积加热机制,是材料-微波直接耦合产生热量,在快速加热下得到细小孔隙。

(a) 数码照片; (b) 横截面中心处孔隙分布显微照片; (c) 横截面边缘处孔隙分布显微照片;(d) 横截面中心处孔隙率定量分析图,phase01表示孔隙,phase02表示基体;(e) 横截面边缘处孔隙率定量分析图,phase01表示孔隙,phase02表示基体

图4 常规烧结样品

Fig.4 Copper powder sample sintered by conventional furnace

(a) 数码照片; (b) 横截面中心处孔隙分布显微照片; (c) 横截面边缘处孔隙分布显微照片;

(d) 横截面中心处孔隙率定量分析图;(e) 横截面边缘处孔隙率定量分析图

图5 微波烧结样品

Fig.5 Copper powder sample sintered by microwave furnace

将样品用FeCl3溶液进行腐蚀,得到如图6所示的常规烧结样品和微波烧结样品的晶粒分布。

(a) 常规烧结(1)与微波烧结(2)样品数码照片; (b) 常规烧结样横截面中心处晶粒分布显微照片;

(c) 微波烧结样横截面中心处晶粒分布显微照片;(d)常规烧结样横截面边缘处晶粒分布显微照片;

(e) 微波烧结样横截面边缘处晶粒分布显微照片

图6 样品晶粒分布

Fig.6 Microstructure evolution of copper powder sample sintered by conventional method

由图6可以看出,微波烧结样品晶粒较常规烧结样品细小而均匀。这是因为微波烧结过程中产生的高加热速度与较少的保温时间,使得晶粒来不及长大,导致最终得到较细的晶粒组织。

2.4 微波烧结金属机制

关于电介质材料如陶瓷材料与微波的耦合加热机理已经得到相关研究者比较系统的解释:当电介质材料处于微波场中时,材料内部原本无规律分布偶极子在微波电磁场作用下发生旋转,趋向某一方向排列,在旋转过程中各偶极子之间由于摩擦生热,在宏观上就表现为实验过程中样品的体积加热效应[25]。这就是所谓的“电介质损耗机制”。

而对于金属导体材料,引入趋肤深度(δ)的概念。趋肤深度(δ)可定义为微波衰减到表面的1/e(即0.368)时的深度。

趋肤深度(δ)的数学定义式如下[25]:

由式(1)可得块体铜的趋肤深度约为1.3 μm。这意味着微波尚未到达样品内部时强度已经衰减很多,大部分微波被反射,块体样品吸波能力差,不会被加热。不过,粉末态松散结构生坯的初始趋肤深度与块体金属的初始趋肤深度存在很大不同,研究者通过实验测定金属生坯电导率随微波加热时间变化曲线,由式(1)计算得出,生坯趋肤深度约为0.05 m[25];随微波加热过程进行,松散接触粉末颗粒间发生团聚粘接,电导率显著增加,但温度高达500 ℃时计算趋肤深度仍有0.02 m,与样品尺寸(直径为 0.01 m,0.05 m)处于同一数量级,更远远大于单个粉末颗粒尺寸(38.5 μm),最终样品得以升至1 000 ℃高温保温,并实现良好致密化。

从微观角度来看,金属生坯中粉末颗粒间最初为松散接触,电接触与热传导均很弱,当生坯置于微波场中时,金属表面电子在微波电磁场作用下将发生定向移动,即产生所谓的涡流,由此产生的焦耳热效应称为“涡流损耗”。颗粒间的热传导使得原本松散接触的颗粒间开始形成连接颈,颗粒的紧密接触使得压坯电导率呈上升趋势,趋肤深度亦随样品电导率的升高而呈下降趋势,当样品被加热到接近全致密时,绝大部分微波将会被样品反射而非吸收。

3 结 论

a. 微波烧结样品相对密度高达97.3%,高于常规烧结样品;通过微波烧结工艺可实现金属铜压坯在较少时间内实现烧结致密化。

b. 微波烧结样品表观硬度比常规烧结样品的高。

c. 微波烧结样品具有独特的显微孔隙分布:与常规烧结样品正好相反,微波烧结样品横截面中心处比边缘处孔隙少,且微波烧结样品整体孔隙与微观组织均较常规烧结样品的细小。

参考文献:

[1] 张 瑜, 郝文辉, 高金辉. 微波技术及应用[M]. 西安: 西安电子科技大学出版社, 2006: 206-207.

ZHANG Yu, HAO Wen-hui, GAO Jin-hui. Microwave technologies and applications[M]. Xi’an: Electronic Science and Technology University of Xi’an, 2006: 206-207.

[2] Eremeev A G, Plotnikov I V, Holoptsev V V, et al. Absorption of millimeter waves in composite metal-ceramic materials[C]// Porada M W. Advances in Microwave and Radio Frequency Processing. Berlin: Springer Berlin Heidelberg, 2006: 591-597.

[3] Thostenson E T, Chou T W. Microwave processing: fundamentals and applications[J]. Composites, Part A: Applied science and manufacturing, 1999, 30: 1055-1071.

[4] Clark D E, Folz D C, West J K. Processing materials with microwave energy[J]. Materials Science and Engineering A, 2007, 287: 153-158.

[5] Anklekar R M, Bauer K, Agrawal D, et al. Improved mechanical properties and microstructural development of microwave sintered copper and nickel steel PM parts[J]. Powder Metakkurgy, 2005, 48(1): 39-45.

[6] Semenov V E, Rybakov K I, Bykov Y V. High temperature microwave processing of materials[J]. J Phys D: Appl Phys, 2001, 34: 55-75.

[7] Agrawal D. Microwave processing of ceramics, composites and metallic materials[J]. High Tech Ceramic News, 2005, 16(12): 9-10.

[8] Saitou K. Microwave sintering of iron, cobalt, nickel, copper and stainless steel powders[J]. Scripta Materialia, 2006, 54(5): 875-879.

[9] Panda S S, Singh V, Upadhyaya A, et al. Sintering response of austenitic (316 L) and ferritic (434 L) stainless steel consolidated in conventional and microwave furnaces[J]. Scripta Materialia, 2006, 54(12): 2179-2183.

[10] Upadhyaya A, Tiwari S K, Mishra P. Microwave sintering of W-Ni-Fe alloy[J]. Scripta Materialia, 2007, 56(1): 5-8.

[11] Roy R, Agrawal D, Cheng J, et al. Full sintering of powdered metal bodies in a microwave field[J]. Nature, 1999, 399(6750): 668-670.

[12] Gedevanishvili S, Agrawal D, Roy R. Microwave combustion synthesis and sintering of intermetallics and alloys[J]. J Materials Science Letters, 1999, 18(9): 665-668.

[13] Sethi G, Upadhyaya A, Agrawal D. Microwave and conventional sintering of premixed and prealloyed Cu-12Sn bronze[J]. Science of Sintering, 2003, 35(2): 49-65.

[14] Sun X, Hwang J Y, Huang X, et al. Effects of microwave on molten metals with low melting temperatures[J]. Journal of Minerals & Materials Characterization & Engineering, 2005, 4(2): 107-112.

[15] Gupta M, Wong W L E. Development of Mg/Cu nanocomposites using microwave assisted rapid sintering[J]. Composites Science and Technology, 2006, 67(7/8): 1541-1552.

[16] Takayama S, Saito Y, Sato M, et al. Sintering behavior of metal powders involving microwave-enhanced chemical reaction[J]. J Appl Phys, 2006, 45(3A): 1816-1822.

[17] Upadhyaya A, Sethi G. Effect of heating mode on the densification and microstructural homogenization response of premixed bronze[J]. Scripta Materialia, 2007, 56: 469-472.

[18] Pinkel D, Dunifer L G, Schultz S. Modes for transmission of microwaves through alkali metals at cryogenic temperature[J]. Physical Review B, 1978, 18(12): 6658-6675.

[19] Nimtz M P. Size-dependent dielectric response of small metal particles[J]. Physical Review B, 1991, 43(17): 14245-14247.

[20] Zhou F, Spivak B, Monod M T B. Mesoscopic mechanism of the photovoltaic effect and the microwave absorption in granular metals[J]. Physical Review B, 1991, 51(19): 13226-13230.

[21] Zhou F, Spivak B, Taniguchi N, et al. Giant microwave absorption in metallic grains: relaxation mechanism[J]. Physical Review Letters, 1996, 77(10): 1958-1961.

[22] Mishra P, Sethi G, Upadhyaya A. Molding of microwave heating of particulate metals [J]. Metallurgical and Materials Transactions B, 2006, 37B(l0): 839-845.

[23] TANG Xin, TIAN Qing, ZHAO Bin-yuan, et al. The microwave electromagnetic and absorption properties of some porous iron powders[J]. Materials Science and Engineering A, 2007, 445/446: 135-140.

[24] 陈北盈, 涂远军, 李晓华, 等. 铜和铜合金[M]. 长沙: 中南工业大学出版社, 1987: 13-22.

CHEN Bei-ying, TU Yuan-jun, LI Xiao-hua, et al. Copper and its alloys[M]. Changsha: Central South University, 1987: 13-22.

[25] Ma J, Diehl J F, Johnson E J, et al. Systematic study of microwave absorption, heating, and microstructure evolution of porous copper powder metal compacts[J]. J Appl Phys, 2007, 101(7): 074906.

收稿日期:2007-12-07;修回日期:2008-03-26

基金项目:国家科技攻关资助项目(MKPT-2004-09ZD)

通信作者:易健宏(1965-),男,湖南株洲人,教授,从事高性能粉末冶金材料的研究;电话:0731-8876420;E-mail: yijianhong2004@yahoo.com.cn