DOI:10.19476/j.ysxb.1004.0609.2018.10.12

先进超超临界汽轮机叶片用镍基合金的热变形行为

龚志华1, 2,杨 钢2,殷会芳2,定 巍1

(1. 内蒙古科技大学 材料与冶金学院,包头 014010;

2. 钢铁研究总院特殊钢所,北京 10081)

摘 要:利用Gleeble-3800热模拟试验机,在温度为950~1150 ℃、应变速率为0.01~10 s-1、变形量为60%条件下,研究汽轮机叶片用GY200镍基合金的高温塑性变形及动态再结晶行为,并绘制了合金的热加工图。结果表明:GY200合金的真应力–应变曲线具有动态再结晶特征,峰值应力随变形温度的降低或应变速率的升高而增加,发生动态再结晶的临界应变随温度增加而降低。在真应力–应变曲线的基础上,建立了材料热变形本构方程,其热激活能为353.792 kJ/mol,表明利用W替代合金中的Mo后,降低了合金的热激活能。合金的最佳热加工的温度区间为1000~1150 ℃,应变速率0.01~0.1 s-1,效率值达到0.3以上。

关键词:叶片;GY200镍基合金;本构方程;热激活能;热加工图

文章编号:1004-0609(2018)-10-2050-08 中图分类号:TG142.7 文献标志码:A

先进超超临界火电技术(蒸汽参数700℃、37.5 MPa)是未来火电机组发展的必然趋势,不仅能提高电厂热效率,降低CO2等污染气体的排放量,降低煤耗,而且还具有很高的经济性[1-3]。蒸汽温度达到700℃,传统Fe基耐热合金无法满足电站材料持久强度的要求,需要应用Ni基合金或Fe-Ni基合金来替代[4-5]。叶片做为蒸汽轮机的主要部件,欧、美、日本都有针对性的选材及研究计划,但Waspaloy、Nimonic105、USC141等变形高温合金是目前各国的首要备选材料[6-7]。Waspaloy有作为烟气轮机在650 ℃温度下使用15年以上的经验[8],Waspaloy合金是否满足700 ℃下长期服役的要求,需要进一步研究。杨钢等[9-10]在Waspaloy合金中加入了W元素,开发了一种新型叶片用镍基合金GY200,研究发现W能提高合金的高温持久强度。但W的原子半径比Mo的大,W的加入将提高合金固溶强化效果,从而影响合金的热加工性能[11]。

本文作者依据镍基合金锻造过程中变形温区窄,变形抗力大的特点,利用Gleeble-3800型热模拟试验机对试验用GY200镍基合金进行了高温单道次压缩实验。获得了该材料不同条件下的真应力-应变数据,求得了合金的高温本构方程,并分析合金的软化行为,研究了W替代Mo后合金的热加工区间,为工业生产提供实验数据支持。

1 实验

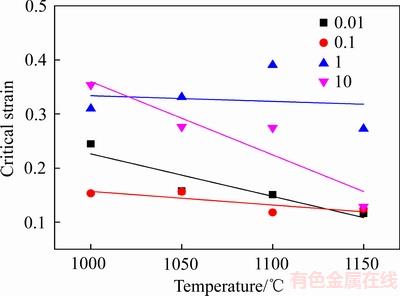

本次试验用镍基合金采用25 kg真空感应炉熔炼而成,合金锭为25 kg,锻造成d 16 mm圆棒。锻造温度1150 ℃,终锻温度不小于950 ℃,利用化学相分析的方法对合金各元素含量进行定量分析,结果如表1所示。

热模拟试样尺寸为d 8 mm×15 mm,利用Gleeble-3800型热模拟试验机对试样进行单次轴向压缩,实验开始前在试样两端均匀涂敷润滑剂(70%石墨+25%机油+5%硝酸三甲苯脂(摩尔分数)),以减小摩擦。试样以20 ℃/s升温到1250 ℃,保温200 s,以10 ℃/s冷却到预设温度保温10 min后开始压缩。变形温度分别为950、1000、1050、1100、1150 ℃,应变速率分别为0.01、0.1、1、10 s-1,压缩量为60%,变形后立即水冷。

表1 试验合金成分的质量百分数

Table 1 Chemical composition of alloy (mass fraction, %)

2 结果与分析

2.1 应力-应变曲线

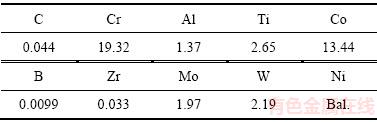

图1所示为不同应变温度和应变速率条件下的真应力-应变曲线。从图1中可以看出,变形开始阶段,应力呈直线急剧增加,主要因为压缩试样经过一段时间的高温保温后,发生了充分的再结晶,晶内位错密度低,压缩变形后位错急剧增殖,发生了加工硬化;但随着变形加剧,晶粒内部的位错通过交互作用而发生重组,发生回复,压缩试样的加工硬化率降低;应变进一步增加,位错密度进一步增加,积累到一定数量后,激发动态再结晶,这时应力达到峰值,应力随应变的进一步增加而呈现降低趋势。在随后的变形过程中,动态再结晶产生的软化效果与应变增加产生的加工硬化效果相抵消,变形进入稳态阶段[12]。

从图1中还可看出,在应变速率较低时(0.01~0.1 s-1),1000 ℃和1050 ℃变形温度下的峰值应力相差较多,主要是在较低变形温度下,位错发生滑移和攀移困难,回复程度较低,体现出了较高的变形抗力。随着应变速率增加,应力增加,主要因为应变速率增加,位错积累程度加剧,虽然位错仍然通过重组来发生回复,但由于加载速度快,回复所带来的软化程度远小于加工硬化程度,因而体现较大的变形阻力。

2.2 热加工过程中的软化及对再结晶的影响

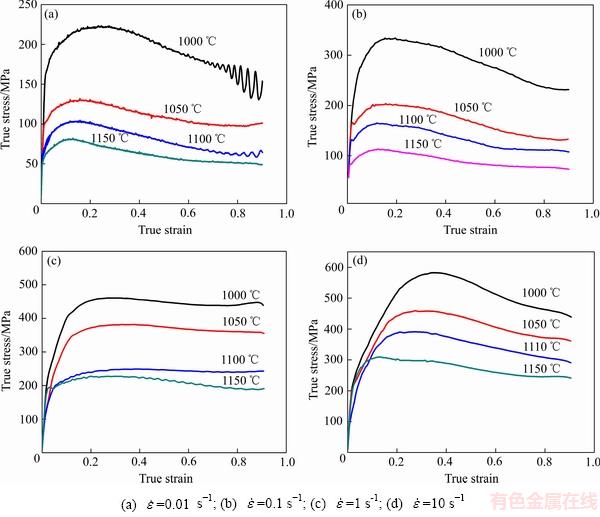

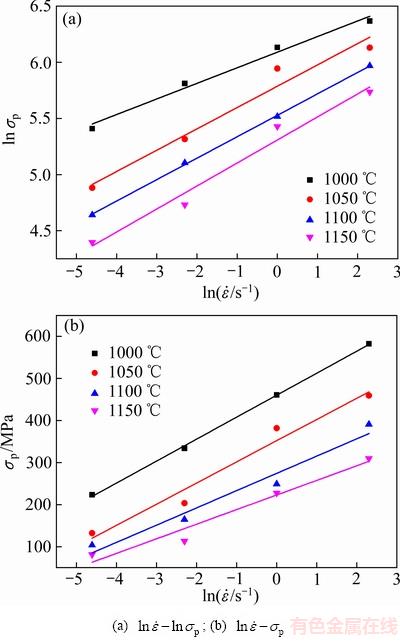

图2所示为GY200镍基合金在不同变形温度和应变速率下的峰值应力。在相同的应变速率下,应力的峰值随变形温度的逐渐增加降低,主要因为变形温度增加,降低了位错和晶界的运动阻力,降低合金的变形抗力。变形温度一定时,应变速率越低,峰值应力越低,主要是因为在应变速率较低时,变形时间增加,更多的位错通过滑移和攀移来进行重组,降低了变形带来的位错增殖效果,加工硬化作用减弱,软化作用增强。

图1 不同变形条件下GY200合金热压缩应力–应变曲线

Fig. 1 True stress–true strain curves of GY200 alloy during hot compression under different deformation conditions

图2 不同变形温度和应变速率下GY200镍合金的峰值应力

Fig. 2 Peak flow stress of GY200 alloy under different conditions of hot compression deformation

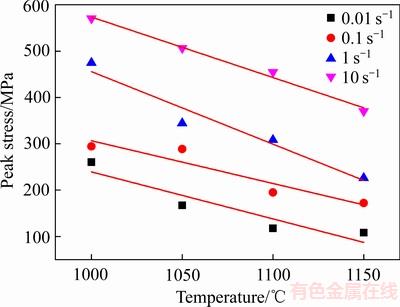

图3所示为GY200镍基合金在不同应变速率和变形温度下,动态再结晶发生的临界应变值,临界应变约等于0.8倍的峰值应变,并对不同应变速率进行线性拟合。从图3可以看出,随应变速率降低,发生动态再结晶的临界应变具有下降的趋势,在较高温度下,临界应变较低,表明在较高温度下,能够在较低应变的时候激发动态再结晶。主要是由于在较高的温度下,原子振动加剧,原子间结合能力降低,可动位错和晶界运动的阻力下降。在应变速率为1 s-1时,发生动态再结晶的临界应变基本在0.3左右,在应变速率为10 s-1时,发生动态再结晶的临界应变随着温度的升高明显降低,主要因为高的应变速率和高的变形温度,提供的再结晶激活能增加,发生再结晶的所需临界应变小。

图3 不同变形条件下GY200镍合金DRX发生的临界应变

Fig. 3 Critical strain of GY200 alloy for onset of DRX under different deformation conditions

2.3 GY200合金的热变形本构方程

金属的高温塑性变形均存在热激活的过程,热激活过程与变形温度、应变速率与流变应力的关系可以用经典的双曲正弦函数来描述[12]:

(1)

(1)

式中:Q为热变形激活能(J/mol);R为摩尔气体常数(8.314 J/(mol·K));T为热力学温度(K); 为峰值应力(MPa);A是与变形温度无关的材料常数;

为峰值应力(MPa);A是与变形温度无关的材料常数; 为应力水平参数;n为应力指数。求出A、α、n、Q即可描述材料的高温流变特征。

为应力水平参数;n为应力指数。求出A、α、n、Q即可描述材料的高温流变特征。

在温度恒定时,并假设激活能为常数,对于应力水平参数 ,在较低应力(

,在较低应力( <0.8)时,式(1)可表述为[13]

<0.8)时,式(1)可表述为[13]

(2)

(2)

在高应力( >1.2)时,式(2)可表述为

>1.2)时,式(2)可表述为

(3)

(3)

式中: 、

、 分别对应图4(a)

分别对应图4(a) 和图4(b)

和图4(b)  直线斜率的倒数。求解后

直线斜率的倒数。求解后 值为0.00424。

值为0.00424。

TEGART等[14]提出并实验验证了热变形过程,通常可以用温度补偿因子Zener-Hollomon参数Z来表示:

(4)

(4)

对式(4)两边取对数,可得

(5)

(5)

由式(1)对1/T求偏导得

(6)

(6)

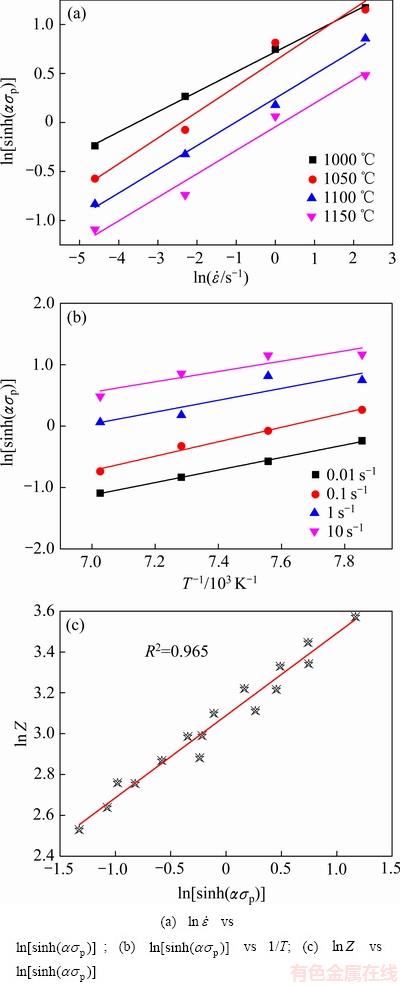

由方程(6)可看出,热激活能Q是关于 –

– 和

和 –1/T的求解过程,

–1/T的求解过程, 为峰值应力。绘制出相应的

为峰值应力。绘制出相应的 –

– 和

和 –1/T图,如图5(a)和(b)所示。直线

–1/T图,如图5(a)和(b)所示。直线 –1/T斜率的平均值设为K,直线

–1/T斜率的平均值设为K,直线 –

– 斜率的平均值设为n,采用最小二乘法线性回归可求得K=1.0015、n=4.249。

斜率的平均值设为n,采用最小二乘法线性回归可求得K=1.0015、n=4.249。

图4 GY200合金峰值应力与应变速率的关系

Fig. 4 Relationship between peak stress and strain rate of GY200 alloy

GY200合金的热变形激活能Q=RnK=353.792 kJ/mol。利用 与T,求出对应的

与T,求出对应的 ,可绘出

,可绘出 –

– 图,如图5(c)所示。其斜率的自然对数即

图,如图5(c)所示。其斜率的自然对数即 =30.886。将上述所求参数值代入式(1),即可得到GY200合金的高温变形流变应力本构方程:

=30.886。将上述所求参数值代入式(1),即可得到GY200合金的高温变形流变应力本构方程:

从峰值应力的Z参数的拟合曲线可以看出,拟合精度为0.965,数据拟合度较高,能够比较真实反映合金的变形过程。

已有研究表明[15],当合金具有高的热激活能时,合金的硬化水平及软化水平都较高。镍基合金中的热激活能与添加元素之间的关系满足以下方程:

(7)

(7)

式中: =8783.23e0.165129wW-8783.23;

=8783.23e0.165129wW-8783.23; = 25638.8e0.1286wMo-25638.8;Q0为纯Ni的热激活能;

= 25638.8e0.1286wMo-25638.8;Q0为纯Ni的热激活能; 是加入元素后热激活能的增量。

是加入元素后热激活能的增量。

图5 GY200合金应变速率、变形温度和峰值应力关系

Fig. 5 Relationships between peak stress, deformation temperature and strain rate of GY200 alloy

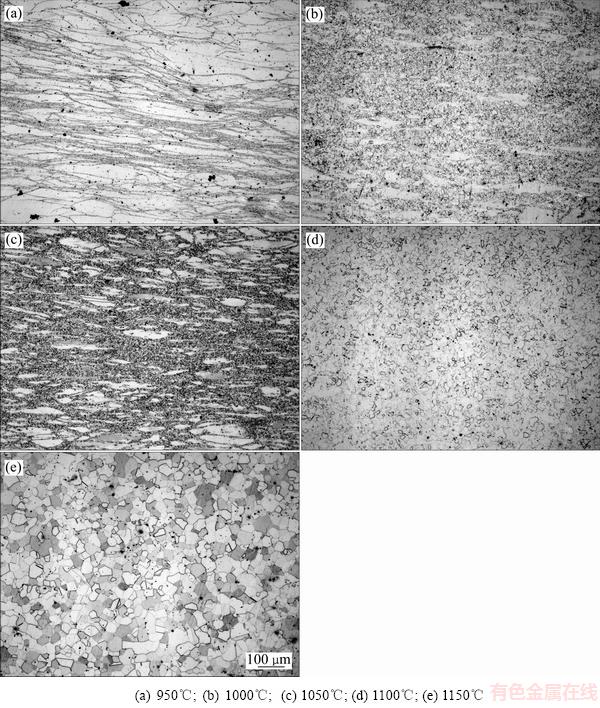

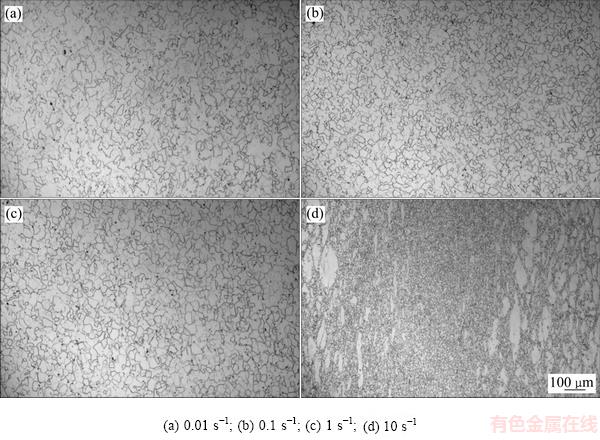

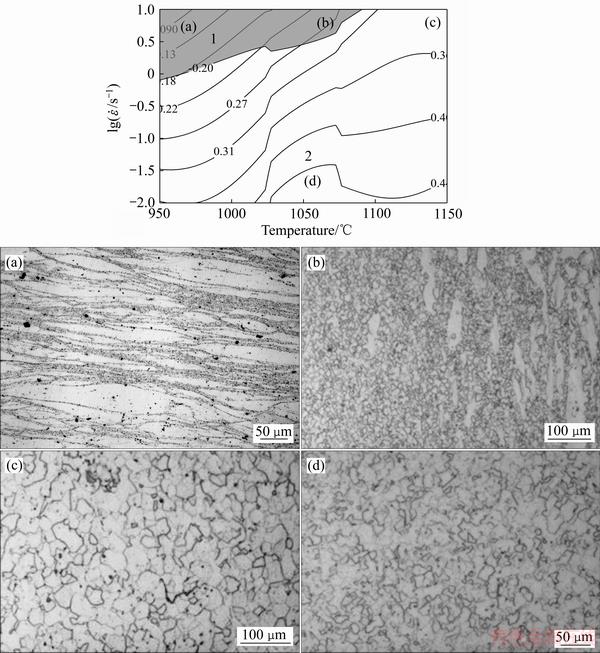

从方程(7)可以看出,在Waspaloy合金中利用相同质量的W替代Mo,将降低合金总的热激活能。本文通过实验数据线性拟合计算的GY200合金热激活能为353.792 kJ/mol,低于传统的Waspaloy合金热激活能的398 kJ/mol[15],表明W替代Mo后,降低了GY200镍基合金的热激活能,合金再结晶所需要积累的能量降低,在较低的应变速率和温度下能够发生再结晶,如图6所示。图6所示为应变速率为1 s-1时不同温度压缩后GY200合金的组织形貌图。从图6(a)可以看出,经950 ℃压缩时,中心区域有极少量的再结晶晶粒,晶粒在压缩过程中被拉长,变形带明显;图6(b)和(c)分别为1000和1050 ℃下的变形后的组织,在1 s-1应变速率下,再结晶都没有完全,压缩变形中主要是动态再结晶和动态回复的过程;图6(d)所示为1100 ℃变形,再结晶完全,再结晶晶粒非常细小,在1150 ℃压缩后晶粒发生长大。图7所示为1100 ℃不同应变速率的组织,在较低应变速率下,能够获得完全的再结晶组织,当应变速率为10 s-1时,组织中有动态回复区,主要是由于应变速率高,变形时间短,再结晶不够充分。

2.4 热加工图的建立

PRASAD等[16]通过大塑性连续流变介质力学、不可逆热力学理论和物理系统模拟建立了动态材料模型(Dynamic material model, DMM)。基于DMM模型建立的热加工图,能够准确的描述特定形变区域间微观组织的形变机制,同时还能给出加工过程中应该避免的不稳定流变区域,获得优化的加工温度和应变速率。

利用m来表示材料的应变硬化敏感指数,可以通过 得到。利用ξ来表示热加工过程中的失稳判据,可用以下方程描述[16]:

得到。利用ξ来表示热加工过程中的失稳判据,可用以下方程描述[16]:

<0 (8)

<0 (8)

能耗图上 值为负数的区域为流变失稳区。已有的研究表明,镍基合金的能量消耗效率值在0.3~0.5间为最佳[15]。图8所示为GY200合金在应变量为0.6时的热加工图。该图由阴影区和白色区两部分组成,阴影区1区代表失稳区,在该区域变形,效率值低,是变形潜在危险区,如图8(a)和(b)所示,部分区域发生再结晶,但仍有大片动态回复组织出现。2区为安全区域,其显微组织如图8(c)、(d)所示,这些区域变形,获得了完全的动态再结晶组织。从图8可以看出, 1区的温度在950~1080℃区间,应变速率高于1 s-1,能量消耗效率值低,容易发生流变失稳。温度区间为1000~1150 ℃,应变速率0.01~0.1 s-1时,为2区中的效率值大于0.3的位置,也是GY200镍基合金的最佳加工区间。

值为负数的区域为流变失稳区。已有的研究表明,镍基合金的能量消耗效率值在0.3~0.5间为最佳[15]。图8所示为GY200合金在应变量为0.6时的热加工图。该图由阴影区和白色区两部分组成,阴影区1区代表失稳区,在该区域变形,效率值低,是变形潜在危险区,如图8(a)和(b)所示,部分区域发生再结晶,但仍有大片动态回复组织出现。2区为安全区域,其显微组织如图8(c)、(d)所示,这些区域变形,获得了完全的动态再结晶组织。从图8可以看出, 1区的温度在950~1080℃区间,应变速率高于1 s-1,能量消耗效率值低,容易发生流变失稳。温度区间为1000~1150 ℃,应变速率0.01~0.1 s-1时,为2区中的效率值大于0.3的位置,也是GY200镍基合金的最佳加工区间。

图6 应变速率为1 s-1时不同温度压缩后GY200合金的显微组织

Fig. 6 Microstructures of GY200 alloy deformed at different temperatures and strain rate of 1 s-1

图7 1100 ℃时不同应变速率下GY200合金的显微组织

Fig. 7 Microstructures of GY200 alloy at temperature of 1100 ℃ and strain rate of 0.01-10 s-1

图8 GY200合金的热加工图

Fig. 8 Hot working maps of GY200 alloy

3 结论

1) GY200合金在950~1150 ℃变形温度范围内都发生动态再结晶,1100 ℃以下温度变形,组织由动态回复和动态再结晶构成,增加变形温度,将得到完全的再结晶组织,1150 ℃变形,晶粒明显长大。在应变速率为10 s-1时,发生动态再结晶的临界应变随着温度的升高明显降低。

2) 利用等质量的W替代合金中的Mo元素,会降低合金的热激活能。GY200的热激活能为Q=353.792 kJ/mol,本构方程为

3) GY200合金失稳区位于950~1100 ℃,应变速率为1~10 s-1区间,应变速率越高,效率越低,在该区域变形得到动态回复和动态再结晶混合组织。合金最佳热加工的温度区间为1000~1150 ℃,应变速率0.01~1 s-1。

REFERENCES

[1] MA Long-teng, WANG Li-min, LIU Zheng-dong. Hot deformation behavior of F6NM stainless steel[J]. Journal of Iron and Steel Research, International, 2014(11): 1035-1041.

[2] 迟成宇, 于鸿垚, 谢锡善. 世界700 ℃等级先进超超临界电站关键高温材料[J]. 世界钢铁, 2013, 13(2): 42-59.

CHI Cheng-yu, YU Hong-yao, XIE Xi-shan. Critical high temperature materials for 700 ℃ A-USC power plants[J]. World Iron & Steel, 2013, 13(2): 42-59.

[3] ABE F, KUTSUMI H, HARUYAMA H, OKUBO H. Improvement of oxidation resistance of 9 mass% chromium steel for advanced-ultra supercritical power plant boilers by pre-oxidation treatment original research article[J]. Corrosion Science, 2017, 114: 1-9 .

[4] KERMANPUR A. Improvement of grain structure and mechanical properties of a land based gas turbine blade directionally solidified with liquid metal cooling process[J]. Materials Science & Technology, 2008, 24(1): 100-106 .

[5] ABE F, KERN T U, VISWANATHAN R. Creep-resistant steels[M]. North America: CRC Press, 2008: 12.

[6] MASUYAMA F. History of power plants and progress in heat resistant steels[J]. ISIJ International, 2001, 42(6): 612-625.

[7] LASALMONIE A. Why is it so difficult to introduce them in gas turbine engines?[J]. Intermetallics, 2006, 14: 1123-1129.

[8] 郭建亭. 高温合金材料学(上册): 应用基础理论[M]. 北京: 科学出版社, 2008: 332.

GUO Jian-ting. Materials Science and Engineering for Superalloys[M]. Beijing: Science Press, 2008: 332.

[9] WANG Li, YANG Gang, LEI Ting, YIN Shu-biao, WANG Lu. Hot deformation behavior of Waspaloy for A-USC turbine blades[J]. Journal of Iron & Steel Research, International, 2015, 22(11): 1043-1048.

[10] 龚志华, 杨 钢, 马龙腾, 定 巍. 不同Mo、W含量叶片用GY200镍基合金中碳化物的析出行为[J]. 材料热处理学报, 2017, 38(9): 83-88.

GONG Zhi-hua, YANG Gang, MA Long-teng, DING Wei. Precipitation behavior of carbides in GY200 Ni-based alloy for blade with different W and Mo contents[J]. Transaction of Materials and Heat Treatment, 2017, 38(9): 83-88.

[11] MIRZADEH H, CABRERA J M, NAJAFIZADEH A. Constitutive relationships for hot deformation of austenite[J]. Acta Mater, 2011, 59: 6441-6448.

[12] 陈 潮, 严红革, 陈吉华, 夏伟军, 苏 斌, 曹梦馨, 宋 旼. 热压缩过程中的组织演变和流变行为[J]. 中国有色金属学报, 2016, 26(8): 1597-1606.

CHEN Chao, YAN Hong-ge, CHEN Ji-hua, XIA Wei-jun, SU Bin, CAO Meng-xin, SONG Min. Microstructure evolution and flow behaviour of Mg-5Zn-1Mn alloy during high strain rate hot compression[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(8): 1597-1606.

[13] ZENER C, HOLLOMON H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

[14] JONAS J, SELLARS C M, TEGART J M. Strength and structure under hot-working conditions[J]. Metallurgical Reviews, 1969, 14: 1-24.

[15] WANG Jue, DONG Jian-xin, ZHANG Mai-cang, XIE Xi-shan. Hot working characteristics of nickel-base super alloy 740H during compression[J]. Materials Science and Engineering A, 2013, 566: 61–70.

[16] PRASAD Y V R K, SESHACHARYULU T. Modelling of hot deformation for microstructural control[J]. Metall Rev, 1998, 43: 243-258.

Hot deformation behavior of Ni-based alloy used for advanced ultra-supercritical steam turbine blades

GONG Zhi-hua1, 2, YANG Gang2, YIN Hui-fang2, DING Wei1

(1. Inner Mongolia University of Science and Technology, Baotou 014010, China;

2. Special Steel Institute of Central Iron and Steel Research Institute, Beijing 100081, China)

Abstract: The hot deformation characteristics of the GY200 Ni-based alloy at the temperature range of 950-1150 ℃ and strain rate range of 0.01-10 s–1 under deformation of 60% were investigated by means of hot compression tests with Gleeble-3800. The results show that the softening mechanism of the dynamic recrystallization is a feature of high-temperature flow stress-strain curves of the GY200 Ni-based alloy, the peak stress increases with the decrease of deformation temperature or the increase of strain rate, and the critical strain reduces with the decrease of deformation temperature. The constitutive equation for GY200 alloy was established on basis of the true stress–strain curves. The activation energy(Q) of the alloy is obtained as about 353.792 kJ/mol. Using W to replace Mo, the thermal activation energy of GY200 alloy is reduced. The processing map is developed based on the peak stress at different strain rate and showing variations of the efficiency of power dissipation related to temperature and strain rate. The instability zone on the processing map is located at the temperature range of 1030-1170 ℃ and stain rates of 1-10 s-1. The optimum hot working temperature and strain rate interval are 1000-1150 ℃ and 0.01-0.1 s-1, respectively.

Key words: blades; GY200 Ni-based alloy; constitutive equation; thermal activation energy; processing map

Foundation item: Project(2016YFB0300203) supported by the National Basic Research Development Program of China

Received date: 2018-03-28; Accepted date: 2018-07-25

Corresponding author: YANG Gang; Tel: +86-10-62183615; E-mail: yanggang@ nercast. com

(编辑 李艳红)

基金项目:国家重点研发计划项目(2016YFB0300203)

收稿日期:2018-03-28;修订日期:2018-07-25

通信作者:杨 钢,教授,博士;电话:010-62183615;E-mail: yanggang@ nercast. com