DOI: 10.11817/j.issn.1672-7207.2020.04.027

复合热源热泵集热/蒸发器的结构优化模拟

方雷,李舒宏,许成城

(东南大学 能源与环境学院,江苏 南京,210096)

摘要:为了提升直膨式太阳能-空气复合热源热泵的性能,需要优化集热/蒸发器的结构,为此,建立集热/蒸发器的一维稳态传热数学模型和热泵系统模型,并利用已有实验装置验证其准确性。利用模型计算的集热效率作为评价指标,通过正交试验法和数值模拟分析翅片管的结构参数对集热/蒸发器热力性能的影响;选取单位翅片面积集热量作为经济评价指标,对比不同换热面积下采用最佳结构时的集热性能;采用南京地区典型气象年参数,在空气侧总换热面积相同的条件下选取9种结构,模拟计算不同结构下集热/蒸发器的集热效率和系统全年能效比。研究结果表明:翅片间距、铜管内径和翅片高度对集热效率影响最大,且在一定范围内这3个结构参数的影响规律一致,即在所选取的范围内集热效率可以取得最大值;随着翅片总换热面积增大,空气侧总热阻逐渐减小,翅片的总集热量逐渐增大,单位翅片面积集热量为13.22 m2时取得最大值,此时,既可以增加集热/蒸发器的集热量,又有较好的经济性;在不同季节工况下,当空气侧换热总面积为13.22 m2,铜管内径为9 mm,翅片间距为1.7 mm,翅片高度为10.3 mm时的优化效果最好,与原结构相比,集热效率提升11.77%,全年能效比提升9.36%。

关键词:复合热源热泵;集热/蒸发器;结构优化;热力性能

中图分类号:TK519 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)04-1125-10

Structural optimization simulation of collector/evaporator for hybrid heat source heat pump

FANG Lei, LI Shuhong, XU Chengcheng

(School of Energy and Environment, Southeast University, Nanjing 210096, China)

Abstract: In order to improve the performance of the direct-expansion solar-air source heat pump water heater, the structure of the heat collector/evaporator needs to be optimized. Based on the existing experimental equipment, one-dimensional steady-state heat transfer mathematical model of the heat collector/evaporator and a heat pump system model were established. The accuracy of the models was verified by experiment. The heat collection efficiency calculated by the model was used as evaluation index, and the influence of the structural parameters on the thermal performance of the heat collector/evaporator was analyzed by orthogonal test and numerical simulation. The heat collection per unit fin area was selected as the economic evaluation index, and the heat collection performance was compared to determine the appropriate heat exchange area for the optimal structure at different heat exchange areas. Using the typical meteorological year parameters in Nanjing, 9 structures were selected at the same total heat exchange area on the air side. The heat collection efficiency of the heat collector/evaporator with different structures and the annual energy utilization of the system were calculated by simulation. The results show that the fin spacing, the inner diameter of the copper tube and the fin height have the greatest influence on the heat collection efficiency, and the influence of three structural parameters is consistent within a certain range. The heat collection efficiency can reach the maximum value in the selected range. As the total heat transfer area of the fins increases, the total heat resistance on the air side gradually decreases, and the total heat collection amount of the fins gradually increases. The heat collected per unit fin area can get maximum amount at 13.22 m2, with can increase the heat collection of the heat collector/evaporator and is economical. Under different seasonal operating conditions, the optimization effect is the best when the total heat exchange area on the air side is 13.22 m2, the inner diameter of the copper tube is 9 mm, the fin spacing is 1.7 mm, and the fin height is 10.3 mm. Compared with the original structure, the heat collection efficiency increases by 11.77%, and the annual energy efficiency ratio of the system increases by 9.36%.

Key words: composite heat source heat pump; collector/evaporator; structural optimization; thermal performance

在可再生能源的开发和利用领域,太阳能热泵系统能有效提升太阳能品位,高效制取热水,受到众多关注[1-2]。针对太阳能利用的不稳定性和易导致直膨式太阳能热泵效率降低的问题,XU等[3]提出将平板太阳能集热器与螺旋翅片管相结合,可同时吸收太阳能和空气热能,克服太阳能流密度低及不稳定的缺点;张月红等[4]在此基础上通过启停风机实现热泵系统在不同运行模式下的切换,但热泵系统安装了风机设备,不仅增加电量消耗,且翅片管与集热板在同一侧,空气流动时会带走集热板的热量;LI等[5-6]改进集热/蒸发器的结构,将螺旋翅片管安装在集热板背面,翅片管通过自然对流吸收空气热量,研究不同制冷工质和变容量控制对系统性能的影响,但没有深入分析集热/蒸发器的热力性能,也未对结构参数进行定量分析和优化;李郁武等[7]结合实验数据分析直膨式太阳能热泵热水器的系统及主要部件,发现集热/蒸发器的节能潜力较大。对于平板太阳能集热器的结构优化,主要集中在提升吸热板吸收效率[8-10]、减小热损失系数[11-13]以及优化集热管结构尺寸[14-16]等方面。但目前的研究通常是分析结构参数对集热/蒸发器热力性能的影响规律,没有进一步探究其对热泵系统运行性能的影响。对于翅片管蒸发器的结构优化,主要是研究集热管径、集热管间距、翅片间距、翅片厚度和翅片高度等单个结构参数[17-21]对集热器集热效率的影响,而多参数间的耦合未进行研究。在对多种结构因素[22-23]同时进行研究和分析时,没有保证换热面积相同或者没有考虑集热器的经济性,导致结构优化的前提条件不严谨。目前对于复合热源热泵系统的集热/蒸发器结构参数缺少定量分析和优化。首先,本文利用Visual Basic软件根据实验装置建立集热/蒸发器的稳态传热数学模型和热泵系统模型,并通过实验验证模型的准确性;其次,以集热效率为评价指标,通过正交试验法对翅片高度、翅片厚度、翅片间距、铜管内径和铜管间距进行影响程度分析;最后,根据南京地区典型气象年数据,在空气侧总换热面积相同的条件下,确定不同季节工况下集热/蒸发器集热效率和系统全年能效比最佳的结构。

1 系统模型的建立

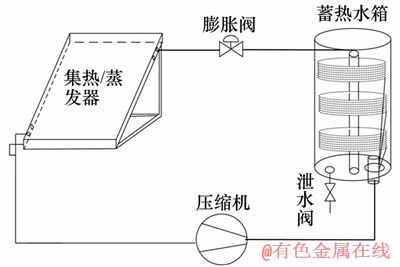

本文采用的直膨式太阳能-空气复合热源热泵热水器(direct-expansion solar air source heat pump water heater,DX-SASHPWH)系统主要由集热/蒸发器、压缩机、蓄热水箱和电子膨胀阀等部件组成,制冷剂R134a作为系统循环工质。

1.1 集热/蒸发器数学模型

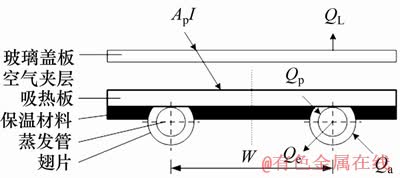

集热/蒸发器是DX-SASHPWH系统的吸热部件,图1为改进后的太阳能集热/蒸发器结构示意图。由图1可见:吸热板下方与蒸发管之间铺设保温材料(岩棉),减少集热板背部向空气的散热。投射到集热/蒸发器上的太阳辐射能,一部分QL散失到环境中,另一部分透过玻璃盖板和空气层后被吸热板吸收,然后转化热能被制冷剂吸收。

图1 改进后的集热/蒸发器结构示意图

Fig. 1 Structure diagram of improved collector/evaporator

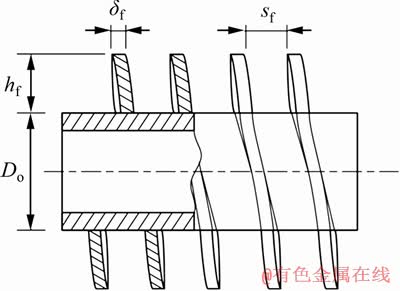

图2所示为本系统的集热/蒸发器采用螺旋翅片管,吸热板背面焊接12根平行布置的蒸发管,蒸发管外胀接铝制螺旋翅片,其结构参数如表1所示。

图2 螺旋翅片管结构示意

Fig. 2 Structure diagram of spiral finned tube

表1 集热/蒸发器结构参数

Table 1 Structure parameters of collector/evaporator mm

在系统稳定运行时,蒸发温度始终低于环境温度,保证制冷剂可以同时吸收太阳能和空气热能。假定制冷剂在管内均匀流动,且忽略轴向传热,只存在径向传热,则管中制冷剂的热量来源Qe有2个部分,即

(1)

(1)

式中:Qp为吸热板吸收的太阳能,W;Qa为翅片吸收的空气热能,W。

1.1.1 吸热板侧的传热数学模型

对于管板结合形式的吸热板,可将吸热板单元当成1个翅片来处理,假设忽略集热管与集热板之间的接触热阻,引入集热器热迁移因子FR:

(2)

(2)

(3)

(3)

式中:Ap为吸热板面积,m2;mr为制冷剂的质量流量,kg/s;cp为制冷剂的比定压热容,J/(kg·K);UL为总热损失系数,W/(m2·K);F′为集热效率因子;I为太阳辐射强度,W/m2;αo为玻璃盖板的有效透过率-吸收率乘积;Tr,i为集热/蒸发器的制冷剂进口温度,K;Ta为环境温度,K。

1.1.2 翅片侧的传热数学模型

本系统螺旋翅片管使用的是连续型翅片,其翅片效率可按环形翅片计算,则单个翅片效率 和翅片总效率

和翅片总效率 分别为

分别为

(4)

(4)

(5)

(5)

式中: ;αf为翅片表面的换热系数,W/(m2·K);λf为翅片导热系数,W/(m·K);δf为翅片厚度,m;hf为翅片高度,m;hf,e为折算翅片高度,

;αf为翅片表面的换热系数,W/(m2·K);λf为翅片导热系数,W/(m·K);δf为翅片厚度,m;hf为翅片高度,m;hf,e为折算翅片高度, ,m;Do为基管外径,m;Df为翅片外径,m;Af为每米管长翅片的表面积,m2;At为每米管长的总表面积,m2。其翅片侧的热阻Ra为

,m;Do为基管外径,m;Df为翅片外径,m;Af为每米管长翅片的表面积,m2;At为每米管长的总表面积,m2。其翅片侧的热阻Ra为

(6)

(6)

(7)

(7)

式中:A1和A2分别为制冷剂侧和空气侧的换热面积,m2;ro和ri分别为基管的外半径和内半径,m;k为基管的导热系数,W/(m·K);δb为基管的壁厚,m;Trm为管内制冷剂平均温度,K。

1.2 压缩机数学模型

压缩机耗功与实际制冷剂质量流量和总效率有关[24]:

(8)

(8)

式中:Ncom为压缩机耗功,W;ηcom为压缩机总效率;h1和h2分别为压缩机进口和出口的制冷剂焓,J/g。

1.3 蓄热水箱数学模型

蓄热水箱采用沉浸式冷凝盘管结构,假定水箱中水吸收的热量与制冷剂放出的热量相等[25],即

(9)

(9)

式中:Qc为冷凝盘管放热量,W;Qw为水箱内制热量,W;h2和h3分别为冷凝盘管进口和冷凝盘管出口(膨胀阀进口)的制冷剂焓,J/g;Mw为蓄热水箱中水的总质量,kg;Cp,w为水的比定压热容,kJ/(kg·K); 为加热时间内的水温差,K。

为加热时间内的水温差,K。

1.4 膨胀阀数学模型

假定电子膨胀阀节流前后焓不变,则

(10)

(10)

式中:h4为膨胀阀出口处的制冷剂焓,J/g。

2 热泵系统循环模型

2.1 热泵系统

图3所示为复合热源热泵热水系统示意图。蒸发温度Te低于环境温度,压缩机进口的过热度和冷凝盘管出口的过冷度均为5 ℃,在模拟程序中可根据各状态点的温度和压力,调用REFPROP软件得到制冷剂的物性参数。

图3 DX-SASHPWH系统示意图

Fig. 3 System schematic of DX-SASHPWH

为了使系统各部件的模型结合起来,形成完整的热泵系统仿真模型,需要满足能量平衡的约束条件。按照热力学第一定律,热泵系统的各部件之间存在如下能量平衡关系:

(11)

(11)

2.2 评价指标

定义集热/蒸发器的集热效率η为单位时间内制冷剂吸收的热量Qe和集热板表面总太阳辐射量的比:

(12)

(12)

系统平均性能系数ηCOP定义为热水总吸热量和压缩机总耗电量的比:

(13)

(13)

为了更好地评价热泵系统全年的综合性能,本文采用热泵系统全年总能源利用效率 [6]的概念:

[6]的概念:

(14)

(14)

式中:n为全年制取热水次数;Qw,i第i次制取热水时需要的热量,kW·h;Wcom,i为第i次制取热水时压缩机耗电量,kW·h。

3 实验验证

实验平台搭建在没有遮挡的屋顶上,集热/蒸发器朝南倾斜32°安装在支架上。实验过程中所测量的主要实验参数有太阳辐射强度、环境温度、各部件进出口处的制冷剂温度和压力、水箱温度和压缩机功率等。

3.1 误差分析

本实验测量过程中主要有直接测量误差和间接测量误差。直接测量的参数包括太阳辐射强度、温度、压力和功率等,其误差取决于测量仪表的精度[6]。间接测量的参数系统制热量 、集热效率

、集热效率 和系统性能系数ηCOP,根据间接测量误差传递原理,设间接测量的参数

和系统性能系数ηCOP,根据间接测量误差传递原理,设间接测量的参数 ,其相对误差由直接测量参数x1,x2,…,xn的误差计算得出

,其相对误差由直接测量参数x1,x2,…,xn的误差计算得出

(15)

(15)

表2所示为间接测量参数的最大相对误差,各参数的最大相对误差均在5.00%以内,说明本文的实验结果具有准确性。

表2 间接测量参数的最大相对误差

Table 2 Maximum relative error of indirect measurement parameters

3.2 数学模型的验证

利用实验仪器测得制冷剂各状态的温度和压力,通过REFPROP软件可查出制冷剂的物性参数,从而计算出系统运行过程中的有效集热量、压缩机耗功、制热量和性能系数ηCOP等。为验证数学模型的准确性,利用已搭建的实验装置测量不同环境工况下的系统运行数据,并以相同的太阳辐射强度、环境温度、水初温和水终温作为模拟的输入参数。DX-SASHPWH系统性能模拟结果与实验结果如表3所示,系统平均性能系数ηCOP的最大误差仅8.85%,可见模拟值与实验值吻合良好,数学模型的准确性较高。

表3 DX-SASHPWH系统性能模拟与实验对比

Table 3 Comparison between simulation and experiment of DX-SASHPWH system performance

4 模拟及分析

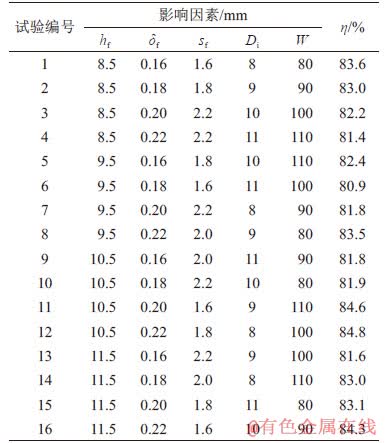

4.1 结构参数的正交试验

对于翅片管的结构优化,主要结构参数有翅片高度 、翅片厚度

、翅片厚度 、翅片间距

、翅片间距 、铜管内径

、铜管内径 和铜管间距

和铜管间距 。为了进一步分析单个结构参数对集热性能影响程度的关系,不考虑因素间的交互作用,这是一个5因素4水平的问题,采用正交试验法建立L16(45)正交试验表[26]。正交试验各因数水平与集热效率

。为了进一步分析单个结构参数对集热性能影响程度的关系,不考虑因素间的交互作用,这是一个5因素4水平的问题,采用正交试验法建立L16(45)正交试验表[26]。正交试验各因数水平与集热效率 模拟结果如表4所示。

模拟结果如表4所示。

表4 正交试验方案及集热效率 模拟结果

模拟结果

Table 4 Orthogonal test plan and numerical simulation results of

表5所示为正交试验直观分析得到的结果。根据各因素在集热效率中的极差可知,各结构参数对集热性能影响的由高到低为 ,

, ,

, ,

, 和

和 。由此可知:翅片间距

。由此可知:翅片间距 、铜管内径

、铜管内径 和翅片高度

和翅片高度 对集热效率影响最大,而翅片厚度

对集热效率影响最大,而翅片厚度 和铜管间距

和铜管间距 影响较小。根据正交试验结果,主要从翅片间距

影响较小。根据正交试验结果,主要从翅片间距 、铜管内径

、铜管内径 和翅片高度

和翅片高度 这3个结构参数优化翅片管结构。这3个主要结构参数的影响规律比较一致,都是先增大后减小,即可以在所选取的范围内取得最大值。

这3个结构参数优化翅片管结构。这3个主要结构参数的影响规律比较一致,都是先增大后减小,即可以在所选取的范围内取得最大值。

表5 集热效率 正交试验的直观分析

正交试验的直观分析

Table 5 Visual analysis of orthogonal experiments of  mm

mm

4.2 空气侧总换热面积的确定

根据正交试验,从铜管内径、翅片间距和翅片高度这3个影响最大的结构参数优化螺旋翅片管的结构,其他结构参数与表1中取值保持一致。结合表5中各因素的集热效率最大值对应的各结构参数如下:铜管内径为9 mm,翅片间距为1.8 mm,翅片高度为10.5 mm,此时,空气侧总换热面积为13.22 m2。因为数据点较少,不能保证这种结构组合最优,且所选面积的合理性也需进一步验证,分别等差值取12.22,12.72,13.22,13.72和14.22 m2共5组换热面积,并计算不同面积下采用最佳结构时集热/蒸发器的集热性能。在空气侧总换热面积相同的情况下,确定了铜管内径和翅片间距,则翅片高度为唯一值。为了简化试验次数,根据正交试验直观分析得到的均值变化规律,选取各结构参数范围:8.5≤ ≤10.0 mm,1.7≤

≤10.0 mm,1.7≤ ≤2.0 mm,9.0≤

≤2.0 mm,9.0≤ ≤11.0 mm。以春季平均工况为例,太阳辐射强度I为556.3 W/m2,环境温度Ta为17.9℃,室外风速uw为3.5 m/s,在相同运行参数条件下,分别计算不同面积下各结构的集热性能,得出不同面积下的最佳结构和单位翅片面积集热量

≤11.0 mm。以春季平均工况为例,太阳辐射强度I为556.3 W/m2,环境温度Ta为17.9℃,室外风速uw为3.5 m/s,在相同运行参数条件下,分别计算不同面积下各结构的集热性能,得出不同面积下的最佳结构和单位翅片面积集热量 。单位翅片面积集热量定义为制冷剂从空气中吸收的总热量与空气侧换热面积的比:

。单位翅片面积集热量定义为制冷剂从空气中吸收的总热量与空气侧换热面积的比:

(18)

(18)

为了对比不同换热面积的经济性,本文选取单位翅片面积集热量作为经济评价指标,并对比不同换热面积下分别采用最佳结构时的集热性能,以确定合适的换热面积,结果如表6所示。由表6可见:随着翅片总换热面积增大,空气侧总热阻逐渐减小,翅片的总集热量逐渐增大;但单位翅片面积集热量在面积13.22 m2时采用结构C3能取得最大值57.18 W/m2。因此,空气侧换热面积取13.22 m2比较合理,既可以增加集热/蒸发器的集热量,又能满足一定的经济性。

表6 不同换热面积下各结构的集热性能

Table 6 Heat collecting performance of each structure under different heat exchange areas

4.3 最佳结构的确定

传统的太阳能热泵受太阳辐射强度的影响较大,而热水器需要全年都能高效、稳定地运行,保证生活热水需求。以原结构(M0)作为对照组,在相同的空气侧换热总面积13.22 m2条件下,选择表6中9种不同的结构组合(C1~C9)。根据南京地区“典型气象年逐时参数”数据库见表7。取各月份的平均太阳辐射强度、环境温度和室外风速作为环境参数,并输入各结构参数、水箱初始温度和最终温度,计算出各月份集热/蒸发器的有效集热量、热水加热量以及加热过程中压缩机的耗电量,从而得到不同结构下集热/蒸发器的平均集热效率和系统全年能效比。

表7 不同季节的环境参数和制冷剂入口参数

Table 7 Environmental parameters and refrigerant inlet parameters for different seasons

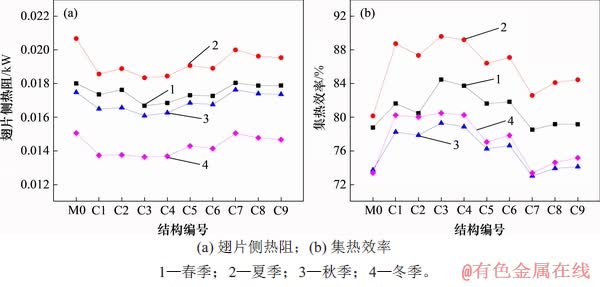

通过优化翅片管结构,提升空气热源利用效率,图4所示为不同季节工况下各结构的翅片侧热阻和集热效率。由图4(a)可知:不同结构下翅片侧热阻有较大差异,主要与翅片总效率和换热系数有关。在空气侧总换热面积相同时,各因素对翅片侧热阻的影响规律如下。

1) 对于翅片高度hf,单个翅片与空气的接触面积随翅片高度增加而增加,换热系数得到提升。但翅片过高时,翅片端部与肋基的距离就会过长,导致单位面积上的换热系数有所下降,所以,翅片高度hf不是越大越好。

2) 对于翅片间距sf,间距越小,翅片越密集,单位长度内翅片面积越大,换热量增加。但翅片与空气处于自然对流换热的情况下,当翅片间距过小时,换热系数会严重衰减,导致换热效果减弱,翅片效率降低。

3) 对于铜管内径Df,当内径增大时,蒸发铜管内制冷剂的流速减小、雷诺数减小,所以,沿程阻力减小,有利于减少压缩机耗功;但两相区制冷剂的对流换热系数也随之减小,管内传热热阻增大,传热效果减弱,造成集热量下降[27]。

图4 不同季节工况下各结构的翅片侧热阻和集热效率

Fig. 4 Fin side thermal resistance and collecting efficiency of each structure under different season conditions

翅片侧热阻越小,单位时间内制冷剂能通过翅片从空气中吸收更多的热量,集热/蒸发器的总集热量增大,集热效率提升。在不同工况下,不同结构的热力性能表现不一样,但大致趋势一致。由图4(b)可知:相比于原结构M0,结构C3提升效果最明显,在春、夏、秋和冬4个工况下,集热效率分别提高7.25%,11.77%,7.56%和9.69%。

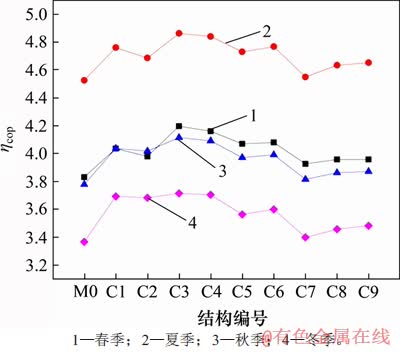

为了研究集热/蒸发器结构对热泵系统的影响,将集热/蒸发器的传热数学模型耦合到热泵系统模型中,模拟计算系统在不同季节工况下将120 L水从15 ℃加热到50 ℃时的平均性能系数ηCOP。图5所示为不同季节工况下各结构的平均性能系数ηCOP,由图5可知:相比于原结构M0,结构C3在春,夏,秋和冬不同季节系统的性能均提升最多,平均性能系数ηCOP分别提升9.53%,7.44%,8.89%和10.34%。集热/蒸发器的集热效率越高,制冷剂单位时间内获得更多的热量,缩短热水加热时间,从而减小压缩机耗电量,提高系统平均性能系数ηCOP。模拟结果表明,结构优化后系统性能得到提升,且在冬季工况下提升效果更明显。

图5 不同季节工况下各结构的平均ηCOP

Fig. 5 Average ηCOP of each structure under different season conditions

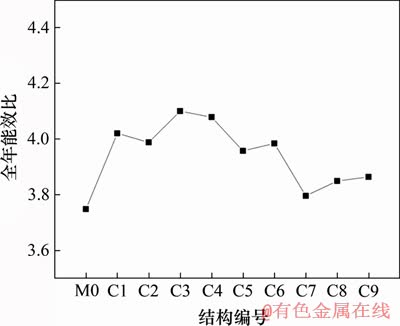

为进一步验证结构C3是否能保证系统全年运行的性能最高效,假设每天需要120 L温度为50 ℃的生活热水,根据各月份的平均环境参数,计算出各月份热泵系统的总制热量和总耗电量,根据式(14)得到系统在不同集热/蒸发器结构下的全年能效比。图6所示为不同结构下系统全年能效比,由图6可知:结构C3的全年能耗利用效率最高,比原结构提升9.36%。采用结构C3时热泵系统在不同季节下的平均ηCOP均最高,即热泵系统在不同环境工况下制取等量热水时所消耗的电能最少。由此可知C3为最佳结构,即铜管内径为9 mm,翅片间距为1.7 mm,翅片高度为10.3 mm。

图6 不同结构下系统全年能效比

Fig. 6 Annual energy efficiency ratio of the system under different structures

5 结论

1) 翅片间距 、铜管内径

、铜管内径 和翅片高度

和翅片高度 对集热/蒸发器的集热效率影响最大;而翅片厚度

对集热/蒸发器的集热效率影响最大;而翅片厚度 和铜管间距

和铜管间距 影响较小。

影响较小。

2) 随着翅片总换热面积增大,空气侧总热阻逐渐减小,翅片的总集热量逐渐增大;单位翅片面积集热量在面积13.22 m2时取得最大值57.18 W/m2。因此,空气侧换热面积取13.22 m2比较合理,即可以增加集热/蒸发器的集热量,又能满足一定的经济性。

3) 铜管内径为9 mm,翅片间距为1.7 mm,翅片高度为10.3 mm时集热效率均最高。相比于原结构,在春、夏、秋和冬季节工况下集热效率分别提升7.25%,11.77%,7.56%和9.69%,系统平均ηCOP分别提升9.53%,7.44%,8.89%和10.34%。

4) 采用最佳结构系统的全年能效比提升了9.36%。相比于原结构,集热/蒸发器结构优化后的系统性能得到进一步提升。

参考文献:

[1] 孔祥强, 李俊枭, 李瑛. 直膨式太阳能热泵热水器不同工质的性能分析[J]. 上海交通大学学报, 2016, 50(4): 506-513.

KONG Xiangqiang, LI Junxiao, LI Ying. Performance analysis of three different refrigerants in a direct-expansion solar-assisted heat pump water heater[J]. Journal of Shanghai Jiao Tong University, 2016, 50(4): 506-513.

[2] BUKER M S, RIFFAT S B. Solar assisted heat pump systems for low temperature water heating applications: a systematic review[J]. Renewable and Sustainable Energy Reviews, 2016, 55: 399-413.

[3] XU Guoying, ZHANG Xiaosong, DENG Shiming. A simulation study on the operating performance of a solar-air source heat pump water heater[J]. Applied Thermal Engineering, 2006, 26(11/12): 1257-1265.

[4] 张月红, 徐国英, 张小松. 太阳能与空气复合源热泵热水系统多模式运行实验特性[J]. 化工学报, 2010, 61(2): 484-490.

ZHANG Yuehong, XU Guoying, ZHANG Xiaosong. Experimental characteristics of solar-air source heat pump water heating system operating in different modes[J]. Journal of the Chemical Industry and Engineering Society of China, 2010, 61(2): 484-490.

[5] LI Shanshan, LI Shuhong, ZHANG Xiaosong. Comparison analysis of different refrigerants in solar-air hybrid heat source heat pump water heater[J]. International Journal of Refrigeration, 2015, 57: 138-146.

[6] 赵伟强, 李舒宏, 张小松. 复合热源热泵热水器变工况运行特性分析[J]. 化工进展, 2017, 36(11): 3977-3985.

ZHAO Weiqiang, LI Shuhong, ZHANG Xiaosong. Analysis of the operating characteristics of hybrid heat sources: heat pump water heater under variable conditions[J]. Chemical Industry and Engineering Progress, 2017, 36(11): 3977-3985.

[7] 李郁武, 王如竹, 王泰华, 等. 直膨式太阳能热泵热水器热力性能分析及优化设计[J]. 太阳能学报, 2007, 28(5): 464-471.

LI Yuwu, WANG Ruzhu, WANG Taihua, et al. Experimental performance analysis and optimization of a direct expansion solar assisted heat pump water heater[J]. Acta Energiae Solaris Sinica, 2007, 28(5): 464-471.

[8] ALVAREZ A, CABEZA O, MUNIZ M C, et al. Experimental and numerical investigation of a flat-plate solar collector[J]. Energy, 2010, 35(9): 3707-3716.

[9] 高留花, 赵军, 高腾. 吸热板参数对平板太阳集热器热性能的影响[J]. 太阳能学报, 2014, 35(10): 2054-2059.

GAO Liuhua, ZHAO Jun, GAO Teng. Effect of absorber plate parameter on thermal performance of flat plat solar collector[J]. Acta Energiae Solaris Sinica, 2014, 35(10): 2054-2059.

[10] 梁子伟, 简林桦, 闫金州, 等. PV/T集热器优化设计及实验[J]. 化工进展, 2016, 35(5): 1326-1331.

LIANG Ziwei, JIAN Linhua, YAN Jinzhou, et al. Optimization design and experimental study on collector of photovoltaic/thermal[J]. Chemical Industry and Engineering Progress, 2016, 35(5): 1326-1331.

[11] CADAFALCH J. A detailed numerical model for flat-plate solar thermal devices[J]. Solar Energy, 2009, 83(12): 2157-2164.

[12] 裴刚, 李晶, 季杰. 玻璃盖板对光伏-太阳能热泵冬季综合性能的影响[J]. 太阳能学报, 2010, 31(3): 323-327.

PEI Gang, LI Jing, JI Jie. Energy and exergy analysis of photovoltaic solar assisted heat pump system in winter[J]. Acta Energiae Solaris Sinica, 2010, 31(3): 323-327.

[13] SUBIANTORO A, OOI K T. Analytical models for the computation and optimization of single and double glazing flat plate solar collectors with normal and small air gap spacing[J]. Applied Energy, 2013, 104: 392-399.

[14] DAGDOUGUI H, OUAMMI A, ROBBA M, et al. Thermal analysis and performance optimization of a solar water heater flat plate collector: Application to Tétouan (Morocco)[J]. Renewable and Sustainable Energy Reviews, 2011, 15(1): 630-638.

[15] 朱绘娟, 裴刚, 符慧德, 等. 不同管间距热管PV/T系统中光电/光热性能的对比研究[J]. 太阳能学报, 2013, 34(7): 1172-1176.

ZHU Huijuan, PEI Gang, FU Huide, et al. Comparative research between two different heat pipe spaces pv /t systems[J]. Acta Energiae Solaris Sinica, 2013, 34(7): 1172-1176.

[16] CHATURVEDI S K, GAGRANI V D, ABDEL-SALAM T M. Solar-assisted heat pump–a sustainable system for low-temperature water heating applications[J]. Energy Conversion and Management, 2014, 77: 550-557.

[17] ZHANG Jiandong, TAO Hanzhong, CHEN Susu. Numerical simulation for structural parameters of flat-plate solar collector[J]. Solar Energy, 2015, 117: 192-202.

[18] BORRAJO-PELAEZ R, ORTEGA-CASANOVA J, CEJUDO-LOPEZ J M. A three-dimensional numerical study and comparison between the air side model and the air/water side model of a plain fin-and-tube heat exchanger[J]. Applied Thermal Engineering, 2010, 30(13): 1608-1615.

[19] TANG Linghong, MIN Zeng, XIE Gongnan, et al. Fin pattern effects on air-side heat transfer and friction characteristics of fin-and-tube heat exchangers with large number of large-diameter tube rows[J]. Heat Transfer Engineering, 2009, 30(3): 171-180.

[20] PONGSOI P, PIKULKAJORN S, WONGWISES S. Effect of fin pitches on the optimum heat transfer performance of crimped spiral fin-and-tube heat exchangers[J]. International Journal of Heat and Mass Transfer, 2012, 55(23/24): 6555-6566.

[21] 高晶丹, 吴伟, 丁国良, 等. 空调器用小管径翅片管蒸发器的优化设计方法[J]. 化工学报, 2012, 63(S2): 42-48.

GAO Jingdan, WU Wei, DING Guoliang, et al. Principle of designing fin-and-tube evaporator with small diameter tubes for air conditioner[J]. CIESC Journal, 2012, 63(S2): 42-48.

[22] 杨文静, 王赫, 丛培武, 等. 翅片管换热器的结构优化[J]. 金属热处理, 2017, 42(4): 208-211.

YANG Wenjing, WANG He, CONG Peiwu, et al. Structure optimization of fin-tube heat exchanger[J]. Heat Treatment of Metals, 2017, 42(4): 208-211.

[23] 费继友, 田士博, 王枫, 等. 平直翅片管式换热器结构参数的优化[J]. 大连交通大学学报, 2018, 39(6): 40-44, 91.

FEI Jiyou, TIAN Shibo, WANG Feng, et al. Optimization of structural parameters for plate-fin-tube heat exchanger[J]. Journal of Dalian Jiaotong University, 2018, 39(6): 40-44, 91.

[24] 张政, 李舒宏. 光伏太阳能热泵/环形热管复合热水系统性能模拟[J]. 中南大学学报(自然科学版), 2017, 48(12): 3392-3399.

ZHANG Zheng, LI Shuhong. Performance simulation of photovoltaic solar assisted heat pump/loop heat pipe hybrid water heater system[J]. Journal of Central South University(Science and Technology), 2017, 48(12): 3392-3399.

[25] 何宏宇, 李舒宏, 董科枫. 光伏一体化太阳能热泵热水器的实时变容量控制[J]. 中南大学学报(自然科学版), 2018, 49(12): 3095-3104.

HE Hongyu, LI Shuhong, DONG Kefeng. Real-time variable capacity control strategy of photovoltaic integrated solar heat pump water heater[J]. Journal of Central South University(Science and Technology), 2018, 49(12): 3095-3104.

[26] 何立博, 姜涛, 李志峰, 等. 多翼离心风机叶轮的正交设计与试验分析[J]. 流体机械, 2016, 44(9): 7-11, 30.

HE Libo, JIANG Tao, LI Zhifeng, et al. Orthogonal design and experiment analysis of multi-blades centrifugal fan impeller[J]. Fluid Machinery, 2016, 44(9): 7-11, 30.

[27] 董科枫, 李舒宏. 铜铟镓硒光伏管板式集热器的模拟与性能分析[J]. 制冷技术, 2016, 36(5): 24-30.

DONG Kefeng, LI Shuhong. Modeling and performance analysis on CuInGaSe photovoltaic/thermal tube-sheet collector[J]. Chinese Journal of Refrigeration Technology, 2016, 36(5): 24-30.

(编辑 秦明阳)

收稿日期: 2019 -07 -12; 修回日期: 2019 -09 -22

基金项目(Foundation item):“十三五”国家重点研发课题(2017YFC0702501-3); 国家自然科学基金资助项目(51876033) (Project(2017YFC0702501-3) supported by the 13th Five-year National Science and Technology Key Project of China; Project(51876033) supported by the National Natural Science Foundation of China)

通信作者:李舒宏,博士,教授,从事太阳能热利用研究;E-mail:equart@163.com