文章编号: 1004-0609(2005)12-2047-07

1.35kA TiB2/C阴极泄流式铝电解槽电解实验

冯乃祥, 戚喜全, 彭建平

(东北大学 材料与冶金学院, 沈阳 110004)

摘 要: 介绍了1.35kA新型泄流式电解槽的制作、 筑炉、 焙烧、 启动以及电解实验过程; 电解槽阴极表面倾角为10°, 阴极采用TiB2/C; 电解槽采用干式砌筑方法, 焦粒焙烧, 干法启动; 启动后进入正常生产, 平均电流强度为1.35kA; 对电解槽进行类似实际操作的加料、 出铝和阳极升降过程, 连续运行100h。 结果表明: 泄流式电解槽运行稳定, 槽电压噪声为9mV左右; 电解过程所表现出的现象与实际电解槽完全类似; 根据金属铝产出量和在产铝量计算, 电解效率不低于86%, 接近工业电解槽; TiB2涂层牢固无损, 对阴极起到了较好的保护作用; TiB2涂层的损失速度为1.0g/(h·m2); 证实了预先的理论分析, 证明电解槽的此种结构是合理和可行的。

关键词: 泄流式电解槽; TiB2涂层; 焙烧; 槽噪声 中图分类号: TF801.3

文献标识码: A

Electrolysis test of 1.35kA drained cathode reduction cell with TiB2-coated cathode

FENG Nai-xiang, QI Xi-quan, PENG Jian-ping

(School of Materials and Metallurgy,

Northeastern University, Shenyang 110004, China)

Abstract: For a 1.35kA new-type drained cathode reduction cell, detailed operations of cell building, packing, baking, starting-up and normal operations were presented. Cathode inclination angle was 10°. TiB2-coated cathode was adopted. The cell was drily built, carbon-particulate baked and drily started up. All the operations of feeding, tapping and voltage adjustment were almost the same as those of commercial cells. After 100h of continuous electrolysis, it is found that the cell performs rather steadily. Cell noise is about 9mV and the cell performs exactly like industrial cell. Based on metal production and leftover, current efficiency is not lower than 86% which is approaching that of commercial cells. TiB2 coating is firm without any damage and hence performs good protection for carbon cathode. The dissolution speed of TiB2 into electrolyte is about 1.0g/(h·m2). Test results not only verify the theoretic analysis beforehand, but also prove the feasibility of such kind of cell structure.

Key words: drained cathode cell; TiB2 coating; baking; cell noise

TiB2/C 可湿润性阴极泄流式电解槽, 作为一种以节能降耗为主要目的的新型结构电解槽, 有着如下突出的优点: 1) 电解槽阴极表面只有一薄层铝液, 不存在普通铝电解槽那样的铝液波动, 因而可大幅度降低极距, 节电潜力巨大, 同时由于没有铝液波动, 也可减少铝的溶解损失, 有利于提高电流效率; 2) 电解槽的母线设计上, 不需要对槽内电磁场进行补偿, 因而可减少母线用量。

关于TiB2阴极材料, 国外专家曾进行过许多研究, 并在工业上采用[1-5]。 李劼等[6, 7]和冯乃祥等[8-12 ]都曾对TiB2涂层阴极进行过深入的研究, 并应用于生产中。 本文作者还曾提出生产多层复合阴极, 使其同时具有抗磨蚀、 低电阻率、 高湿润性的特点[9]。

1998年Comalco 铝业公司公布了其在92kA的电解槽上进行泄流式TiB2/C惰性阴极电解槽实验[13]。 电解槽的阴极电流密度为0.97A/cm2, 经150d的实验, 电耗为每吨铝13300kW·h。 阴极电流密度0.99A/cm2; 经700d的实验, 电耗为每吨铝12800kW·h。 这种结构的TiB2/C阴极电解槽及其所取得的初步工业实验结果引起了国内外铝工业和铝冶金工作者的极大关注。 李劼等[14]和LIU等[15]对泄流式电解槽电热场及能量平衡进行了计算, 对阴极结构对槽电热场的影响进行了研究。 但本文作者认为, Comalco泄流式惰性阴极电解槽在结构上也存在着缺点: 由于电解槽纵向中心为聚铝沟, 电解槽中间下料时, 氧化铝沉淀会在聚铝沟内积累而形成结壳, 占据聚铝沟。 同时, 由于阳极向槽边部倾斜, 阳极气体向边部释放, 对电解质没起到必要的搅拌作用。

为了克服Comalco泄流式电解槽的上述缺点, 本文作者提出了一个不同于Comalco泄流式TiB2/C惰性阴极电解槽的阴极结构。 该电解槽的技术特点是泄流式TiB2/C阴极中间高、 边部低式的倾斜[16]。 这种泄流式惰性阴极电解槽在中部打壳下料时, 堆积成的氧化铝沉淀不会对阳极和阴极之间的电解过程造成影响, 而且阳极气体逸出形成的电解质流动有利于氧化铝的溶解。 为此, 对此种结构的泄流式电解槽进行了实验。 本次实验不同于以往实验室的小型实验, 而是按约1∶5的比例制作电解槽, 电解槽的砌筑、 装炉、 焙烧、 启动、 电解、 加料等过程均按实际电解槽的操作过程进行。 平均电解电流强度为1.35kA, 连续生产100h, 得到了大量的实验数据, 为将来泄流式电解槽的应用奠定了基础。

1 电解槽的结构

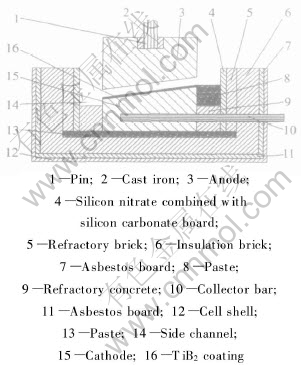

为了能更好地与阳极电流密度为1.2A/cm2左右的泄流式TiB2/C阴极工业电解槽的实际情况接近, 在实验室设计了能够靠自热实现电解槽热平衡的泄流式TiB2/C阴极电解槽, 其结构如图1所示。

图1 泄流式电解槽的结构示意图

Fig.1 Schematic diagram of cell structure

由图1可以看出, 该电解槽的TiB2/C阴极是向一面倾斜的, 电解槽的阴极钢棒从一个侧面插入阴极碳块中, 而阴极聚铝沟在电解槽的另一个侧面, 其优点是便于电解槽母线的布置与排列, 减少母线用量, 降低投资成本; 另一方面由于在聚铝沟一面的底部没有阴极钢棒, 可减少阴极钢棒被漏铝腐蚀的机会, 有利于电解槽寿命的提高。 阴极表面是一层含75%TiB2的TiB2/C复合材料, 其厚度为5mm左右。 阴极基体是以石墨碎为骨料的阴极碳块, 阴极表面的倾斜角为10°(基于作者的理论计算, 另文发表), 电解槽的其它结构设计参数如表1所示。

2 阳极制作

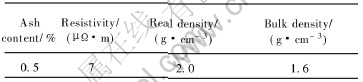

选用抚顺铝厂生产的预焙阳极碳块, 将其进行加工, 使其底部斜面倾角为10°, 与电解槽阴极倾角一致, 阳极上部的导电钢棒直径d60mm, 阳极钢棒与碳阳极之间用磷铁浇铸, 使二者之间得到很好的连接, 此阳极碳块的质量参数列于表2。 加工后的阳极碳块形状如图2所示。

3 泄流式TiB2/C阴极的制作

泄流式TiB2/C复合材料阴极碳块的制作方法包括配料、 成型、 焙烧、 加工、 阴极表面的再涂层等步骤。

表1 1.35kA泄流式TiB2/C阴极电解槽结构参数

Table 1 Structure parameters of 1.35kA drained cathode

reduction cell with TiB2/C cathode

表2 泄流式铝电解槽阳极主要指标

Table 2 Main indexes of anodes used

图2 实验采用的阳极照片

Fig.2 Photo of anodes used in test

3.1 配料

按上述泄流式TiB2/C复合材料阴极碳块的特征, 制作本实验泄流式TiB2/C复合材料阴极碳块的原料有如下两组。

1)上表面TiB2/C复合材料层: TiB2、 石墨粉、 热固性酚醛树脂。

2) 阴极碳块基体: 人造石墨碎、 沥青。

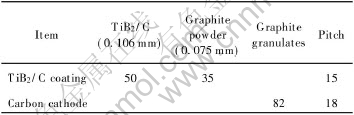

这两组原料的配比及质量标准如表3所示。

3.2 成型

泄流式TiB2/C阴极生坯是在辽阳炭素厂用振动成型的方法成型的。

首先按上述配料比例配好的石墨碎与沥青混合料放入混捏锅中混捏成糊状, 然后倒入振动成型机的模中, 稍加振动后, 再对其进行表面粗糙化处理。 之后将混捏好的TiB2、 石墨粉与沥青的混合物糊料铺平在粗糙后的上述基体的表面, 放下重锤, 再按振动成型电解槽阴极碳块的方法, 使其振动成型在一起。 这样便制成了上表面有一层TiB2/C的阴极碳块的生坯, 其表面的TiB2/C糊层厚度为5mm左右。

表3 阴极表面TiB2/C层和阴极碳块基体配料

Table 3 Proportions of TiB2/C coating and cathode(mass fraction, %)

3.3 焙烧

待上述振动成型好的具有一层TiB2/C糊料的阴极碳块生坯冷却后, 将其放入环式焙烧窑中焙烧。 升温制度如表4所示, 阴极碳块示意图如图3所示。

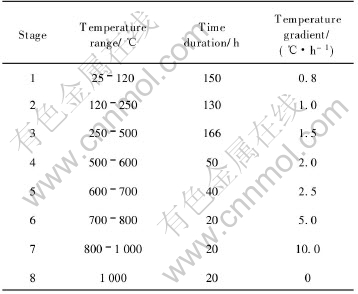

表4 表面具有一层TiB2/C的泄流式铝电解槽阴极碳块的焙烧升温制度

Table 4 Baking theme of carbon cathode with TiB2/C coating

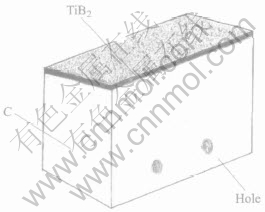

图3 TiB2/C阴极碳块示意图

Fig.3 Cathode with TiB2/C coating

3.4 焙烧品的加工

待炉温冷却后, 取出焙烧品, 用金刚石刀锯加工成如图3所示的表面是一层TiB2/C复合材料, 并具有一定的斜度, 在底下部有两个阴极钢棒孔的阴极碳块。

3.5 阴极表面的再涂层

上述加工好的碳块表面具有厚度为5mm左右的TiB2/C涂层, 但表面在焙烧后不平整, 为此需用50%TiB2(0.106mm)、 32%石墨粉(0.075μm)和18%热固性树脂相混合搅拌成的糊, 对其表面涂抹再处理。 之后加热到100~200℃使其固化。

3.6 阴极钢棒的安装

首先将0.075μm的石墨粉与热固性树脂混成糊状, 置入事先已经加工好的阴极钢棒的棒孔中, 然后将d60mm的两根阴极钢棒直立地插入孔中, 再把阴极碳块放在地面的钢板上, 之后将两根阴极钢棒作一极, 钢板作另一极, 通入低电压、 大电流的直流电进行电加热, 缓慢升温到600℃, 使阴极钢棒与阴极碳块之间烧结在一起。 烧结方法和焙烧装置如图4所示。

3.7 电解槽的焙烧

3.7.1 电解槽焙烧方法的选择

图4 阴极碳块与阴极钢棒之间的烧结示意图

Fig.4 Sketch of baking of cathode assembly

本实验泄流式TiB2/C复合材料阴极电解槽选用焦粉(粒)焙烧, 这是因为焦粉(粒)焙烧不仅升温快, 而且可防止TiB2/C阴极表面被氧化而导致早期破损、 漏炉等情况。

3.7.2 焙烧前的准备及装炉

在泄流式TiB2/C阴极斜坡表面上固定一个内框尺寸为220mm×470mm×30mm的木框。 在木框内均匀铺满粒度为2mm的冶金焦, 考虑到所填冶金焦的松紧程度将直接影响到电阻的大小和均匀度, 所以填充过程中一定尽量使冶金焦均匀铺在阴极表面上, 否则电阻不均匀将会导致电流不均, 产生局部过热现象。

把冶金焦均匀铺满, 厚度为33mm, 然后把阳极小心地放地在冶金焦上。 为了保证阳极的所有重力都由冶金焦支撑, 使焦粉(粒)受力均匀, 在焙烧时阳极首先不固定在阳极升降装置上, 而是实施软连接, 将阳极母线直接连到阳极的钢棒上。

在焙烧前先检查是否会有漏电、 短路情况。 保证阴极钢棒与槽体绝缘, 阳极母线、 阴极母线与槽体绝缘。

上述工作准备好后, 向聚铝沟里添加铝块, 所加的铝量是按照聚铝沟容量的大小计算的, 即所加入的铝在电解温度下的体积能正好与聚铝沟的体积一致, 这样可以在电解过程中用出铝的方法, 使槽中铝在聚铝沟中保持不变的铝水平, 从而可根据出铝量计算电流效率, 另外也可保护聚铝沟处的碳阴极侧表面不直接被电解质熔体腐蚀。

通电焙烧前, 在阳极与槽内衬之间加入粒度为2~20mm的固体电解质块。

3.7.3 电解槽的通电焙烧

开启整流装置的水冷却系统, 并确认调压器、 变压器和整流器各部分连接无误后, 开始通电焙烧。 记录其焙烧过程中的槽电压、 电流情况。

3.7.4 电解槽的启动

启动前将阳极升降装置与阳极挂接, 然后利用阳极升降装置缓慢提高阳极, 用这种方法提高槽电压并提高电解槽的电流强度, 使槽内物料逐渐熔化, 并使电解质温度升到980℃左右, 电解质水平达到25~30cm, 保持此温度一段时间后, 逐渐降低槽电压, 使电解槽进入正常生产条件下的电解温度。

4 电解槽正常电解时的技术条件与工艺操作

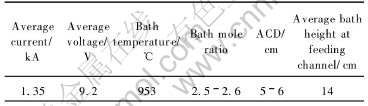

电解槽按上述方法启动转入正常电解阶段, 正常电解时电解槽的工艺技术条件如表5所示。

表5 泄流式TiB2/C阴极电解槽正常电解时的工艺技术条件

Table 5 Process parameters in normal operation

电解过程中, 原料氧化铝从聚铝沟对面的加工面加入, 每小时加入一次, 每次按照法拉第定律的理论量的85%(电流效率)加入, 而出铝是借助一个铁制的焊有铁棒的杯型容器从聚铝沟中取出的。 电解过程中所用的电解质和氟化铝由抚顺铝厂购入。

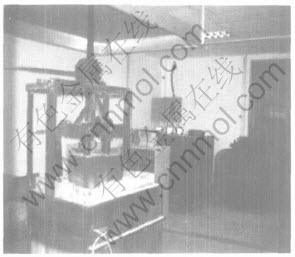

在电解过程中, 需对电解槽的温度、 槽电压和槽电流的变化经常作调整, 使其稳定在给定值, 它是依靠阳极的升降装置对极距的增减, 并配合供电系统的电压和电流调整来实现。 电解槽及其附属的配电和供电装置如图5所示。

图5 正常电解时电解槽及其整流装置

Fig.5 Drained cathode cell and rectifiers in normal operations

5 结果及讨论

在实验室准备很长时间进行如此大的电流强度的泄流式TiB2/C阴极电解槽的电解实验, 是为了考查电解槽电解的稳定性、 电解的电流效率和TiB2/C层在较长时间的抗腐蚀情况, 即TiB2/C的寿命, 以便为今后工业规模的泄流式TiB2/C阴极电解槽的设计和工艺操作提供可参考数据。

5.1 电解槽的电流效率

电解时间按电解质水平达到20cm、 电解槽转入正常生产开始, 一共进行了100h, 较为准确地计算本电解实验的电流效率是困难的。 这是因为, 实验采用焦粒焙烧和干法启动技术, 这两个过程实际上是连续进行的, 很难判断什么时间产生电解质, 什么时间熔化电解质达到足够的量将阳极和阴极之间的焦粒漂离出去, 电解是从什么时候开始的。 不过对本实验电解槽来说, 电解运行非常稳定, 在整个电解过程中, 电解质的温度、 电压和电流都非常稳定。 实验电解槽的运行情况与现在电解铝厂工业电解槽的运行情况没有两样, 电解质的沸腾情况, 阳极气体从表面的逸出情况, 火眼冒出来的火焰的喷射情况, 都与现在电解铝厂的工业电解槽一样, 没有差别, 只是槽子的大小不同而已, 因此按经验估计本实验电解槽的电流效率不会太低。 如果从电解槽电解质的水平达到20cm时作为电解的起始时间算起, 并根据槽内铝量和这一阶段的正常出铝量(在出铝计算电流效率期间, 保持聚铝沟中的铝水平不变), 计算得实验电解槽在电解期间的电流效率为86%。

5.2 槽电压噪声

所谓电解槽槽电压的噪声, 是指目前电解铝厂电解槽槽电压的波动。 一般认为它是由于铝电解槽铝液波动引起的, 也有的认为电解槽阳极气体的形成、 长大和逸出的过程也会引起槽电压的噪声。 本文在电解过程中, 借助于计算机记录了电压变化情况, 并与某铝厂170kA电解槽上测得的槽电压随时间变化数据进行了对比。 标准偏差(Rs)的意义为实际槽电压Vi偏离目标控制电压V0的平方和, 可表示为:

式中 m为总的采样次数。

本实验中泄流式电解槽所记录的槽电压标准偏差为0.0094V, 某铝厂170kA电解槽槽电压标准偏差为0.028V。

由两种电解槽槽电压标准差可以得出, 泄流式TiB2/C阴极电解槽, 没有出现如目前工业电解槽的那种剧烈的槽电压波动, 这也可以间接地说明, 目前的工业铝电解槽槽电压噪声是由于电解槽内阴极铝液的波动引起的。 泄流式TiB2/C阴极电解槽由于阴极表面只有电解生成的薄薄一层铝液, 没有铝液的波动, 因此槽电压比较稳定。

5.3 TiB2/C阴极的寿命

这里所说的泄流式TiB2/C阴极的寿命是指TiB2/C阴极稳定性, 即在电解过程中抗铝液和熔融电解质腐蚀的能力。 有了这个数据, 就可以按照对电解槽寿命的要求, 设计和确定泄流式电解槽要求TiB2/C阴极表面层的厚度。 因此它对泄流式TiB2/C阴极电解槽来说是非常重要的。 TiB2/C阴极抗铝和电解质腐蚀的情况, 可以通过铝中钛浓度的增加来判断。 表6所示为不同时间阶段从电解槽中取出的铝中钛含量的分析结果。 此分析是在郑州轻金属研究院用全谱直读等离子体光谱仪ICP方法测定的。 铝中钛浓度的改变可以判断TiB2/C阴极表面的腐蚀速度。

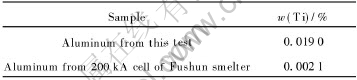

表6 泄流式电解槽与抚顺铝厂电解槽生产出的铝中钛的含量

Table 6 Ti content in aluminum of this test and that from Fushun smelter

为了能定量地评判TiB2/C阴极表面的腐蚀程度, 本文中还对使用相同电解质、 氧化铝原料、 相同阳极、 碳阴极的抚顺铝厂200kA电解槽中生产出来的原铝中的Ti元素进行了对比分析(表6), 二者分析结果的差值即可认为完全是来自泄流式TiB2/C阴极铝电解槽TiB2/C表面TiB2的腐蚀, 在理论上这一差值也可消除由分析仪器引起的系统误差。

由表6的分析结果可以近似计算: 在电解前加入9.09kg铝, 经100h电解后铝中钛的浓度由0.0021%增加到0.0190%, 根据这个数据以及电解槽中的铝量和取出的铝量, 可以算出整个电解期间, 铝中总的钛增加量是8.93g, 此值相当于13.0g的TiB2的腐蚀量, 并由此得出TiB2/C阴极表面TiB2的腐蚀速度为1.0g/(h·m2)。

5.4 电解后阴、 阳极观察

经100h的连续电解过程, 测取了相关数据后, 进行了停槽。 随后将阳极提出电解质。 由当时的阳极实物看, 阳极底掌非常干净, 没有粘结电解质, 而且阳极底面倾斜角度几乎未发生任何变化。 这说明, 电解过程完全按预计的想法进行, 即金属铝生成后流入聚铝沟, 铝液面没有高出阴极表面而进入极间。 因此, 电解过程得以稳定进行。 停槽后, 由于电解质温度太高, 而且液态电解质几乎充满炉膛, 因此无法观测到阴极表面状态。 在电解质温度降到室温后, 对电解槽刨炉处理, 去掉电解质, 取出阴极炭块, 但阴极表面仍粘有较多电解质。 为观察TiB2/C涂层的状况, 从阴极上表面一个角处取下一块阴极。 从断面看, TiB2/C涂层表面有被电解质侵蚀的小坑, 最深小坑不大于1mm, 这可能是由于TiB2/C涂层二次抹平, 两次涂层结合不牢固、 未捣实的缘故。 但TiB2/C涂层没有从阴极表面剥落的现象。 这对保护阴极炭块无疑是很有利的, 也表明阴极碳块表面采用振动成型法固化TiB2/C涂层是可行和成功的。

6 结论

通过100h、 1.35kA电流强度的电解实验发现, 本结构的泄流式电解槽运行非常稳定, 槽噪声很低, TiB2 涂层牢固无脱落。 这完全验证了作者对泄流式电解槽所作的预测和理论分析。 因此, 这种结构泄流式电解槽将大有前途, 会在将来的铝电解工业中发挥重要作用。

REFERENCES

[1]Dionne M, L′Esperance G, Mirtchi A. Wetting of TiB2-carbon material composite[A]. Light Metals[C]. Warrendale, Pennsylvannia, USA: TMS, 1999. 389-394.

[2]Pawlek R P. Aluminum wettable cathodes: an update[A]. Light Metals[C]. Warrendale, Pennsylvannia, USA: TMS, 2000. 449-454.

[3]Keniry J. The economics if inert anodes and wettable cathodes for aluminum reduction cells[J]. JOM, 2001, 53(5): 43-47.

[4]Tabereaux A, Brown J, Eldridege I. The operational performance of 70kA prebake cells retrofitted with TiB2-G cathode elements[A]. Light Metals[C]. Warrendale, Pennsylvannia, USA: TMS, 1998. 257-264.

[5]MacClung M, Browning J, Carte S. Plant experience with an experimental titanium diboride cell[A]. Light Metals[C]. Warrendale, Pennsylvannia, USA: TMS, 2004. 399-404.

[6]李庆余, 赖延清, 李劼, 等. 应用新一代常温固化TiB2阴极涂层技术提高我国预焙铝电解槽寿命[J]. 轻金属, 2004, 37(10): 34-37.

LI Qing-yu, LAI Yan-qing, LI Jie, et al. Increasing expected service life of pre-baked anode reduction cell by new generation TiB2 cathode painting technology[J]. Light Metals, 2004, 37(10): 34-37.

[7]李劼, 李相鹏, 赖延清, 等. 采用惰性阳极和可湿润性阴极的新型铝电解槽[J]. 轻金属, 2003, 36(8): 36-41.

LI Jie, LI Xiang-peng, LAI Yan-qing, et al. New aluminum cell using inert anodes and wettable cathodes[J]. Light Metals, 2003 , 36(8): 36-41.

[8]冯乃祥. 冰晶石熔体和金属钠在铝电解阴极碳块中的共渗透[J]. 金属学报, 1999, 35(6): 611-617.

FENG Nai-xiang. Co-penetration of cryolite melt and metallic sodium in the cathodes of aluminum cell[J]. Acta Metallurgica Sinica, 1999, 35(6): 611-617.

[9]冯乃祥, 姜东涛. 铝电解槽TiB2/C 阴极材料的研究[J]. 炭素技术, 1992, 10(6): 23-27.

FENG Nai-xiang, JIANG Dong-tao. Study on TiB2/C cathode materials of aluminum cell[J]. Carbon Technology, 1992 , 10(6): 23-27.

[10]冯乃祥. 60kA自焙槽电流效率的研究[J]. 有色金属(季刊), 1998, 50(4): 59-64.

FENG Nai-xiang, Study on the current efficiency of 60kA Soderberg cell[J]. Nonferrous Metals (Quarterly), 1998, 50(4): 59-64.

[11]FENG Nai-xiang, Kvande H. Penetration of sodium and molten bath into high pressure baked cathode block[J]. Aluminum, 1997, 73(4): 836-839.

[12]段学良, 冯乃祥, 吴建国, 等. TiB2/C 符合材料阴极在电解过程中的膨胀和对钠的渗透性研究[J]. 材料与冶金学报, 2004, 3(3): 30-34.

DUAN Xue-liang, FENG Nai-xiang, WU Jian-guo, et al. Expansion study of TiB2/C composite cathode materials during electrolysis and the penetration of sodium in it[J]. Journal of Materials and Metallurgy, 2004, 3(3): 30-34.

[13]Kvande H. The 6th australasian aluminium smelting technology conference and workshop[J]. Light Metal Age, 1999, 57(2): 54-60.

[14]李劼, 李相鹏, 刘业翔, 等. 泄流槽阴极导杆安装方式对阴极表面电流分布的影响[J]. 中国有色金属学报, 2003, 12(4): 1017-1020.

LI Jie, LI Xiang-peng, LIU Ye-xiang, et al. The influence of installation style of cathode collector bar on current distribution at cathode surface for drained-cathode cell[J]. The Chinese Journal of Nonferrous Metals, 2003, 12(4): 1017-1020.

[15]LIU Ye-xiang, LI Xiang-peng, LAI Yan-qing, et al, Heat balance of a drained aluminum reduction cell[J]. Trans Nonferrous Met Soc China, 2003, 13(5): 1199-1202.

[16]冯乃祥. 泄流式TiB2复合材料阴极铝电解槽[P]. CN ZL01248353, 2002.

FENG Nai-xiang. Drained-cathode Aluminum Cell with TiB2 Composite Cathode[P]. CN ZL01248353, 2002.

基金项目: 国家自然科学基金资助项目(50274031)

收稿日期: 2005-03-31; 修订日期: 2005-08-09

作者简介: 冯乃祥(1944-), 男, 教授

通讯作者: 戚喜全, 博士; 电话: 024-83686463; E-mail: fengnaixiang@163.com

(编辑李向群)