喷吹方式对煤粉燃尽率的影响

李永清1, 2,张小辉3,张家元1,闫红杰1,周孑民1

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 湖南工业大学 冶金工程学院,湖南 株洲,412007;

3. 昆明理工大学 冶金与能源工程学院,云南 昆明,650093)

摘要:为研究高炉喷煤采用不同喷吹方式对煤粉燃烧效率、煤焦置换比以及高炉生产的经济效益的影响,以某企业3号高炉为对象,建立回旋区煤粉燃烧过程的计算模型,并基于该计算模型研究不同煤种、喷枪形式和富氧率对煤粉燃尽率的影响。研究结果表明:烟煤的燃尽率高于无烟煤和混煤的燃尽率,双煤枪的燃尽率高于单煤枪和氧煤枪的燃尽率;当喷煤比不超过150 kg/t时,该高炉的最佳富氧率为5%。

关键词:回旋区;燃尽率;喷吹方式;数值仿真

中图分类号:TF536.1 文献标志码:A 文章编号:1672-7207(2014)07-2432-08

Influence of pulverized coal injection pattern on burnout

LI Yongqing1, 2, ZHANG Xiaohui3, ZHANG Jiayuan1, YAN Hongjie1, ZHOU Jiemin1

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. School of Metallurgical Engineering, Hunan University of Technology, Zhuzhou 412007, China;

3. Faculty of Metallurgical and Energy Engineering, Kunming University of Science and Technology,

Kunming 650093, China)

Abstract: To research the influence of different pulverized coal injection ways on combustion efficiency, coal tar replacement ratio and economic benefit in blast furnace, the mathematical model of pulverized coal combustion process in the raceway was established based on the No.3 blast furnace in an iron and steel company. The influences of different types of coal, spray gun and oxygen enrichment rate on pulverized coal burnout were studied based on this mathematical model. The results show that the burnout of bituminous coal and double coal spray gun are the highest in different types of coal and spray gun, and the best oxygen enrichment rate is 5% when the coal injection rate is less than 150 kg/t.

Key words: raceway; burnout; pulverized coal injection pattern; numerical simulation

随着高炉大型化的发展,以喷吹煤粉代替部分焦炭已成为炼铁过程节能降耗的重要技术措施[1],喷吹煤粉对于降低焦比和燃料比、促进高炉炉况的顺利运行以及对经济效益和社会效益的促进作用越来越大,喷煤比也逐渐增加,但煤粉在回旋区内的燃尽率成为限制喷煤比增加的关键因素[2-3]。煤粉一经喷入高炉直风管中,即在极短的时间内被迅速地加热,随即发生快速的热解和燃烧反应,煤粉种类、喷煤枪形式和富氧率均能影响回旋区内煤粉的燃尽率。本文作者在建立回旋区煤粉燃烧过程的计算模型基础上,以数值仿真的方式考察以上3种因素对煤粉燃尽率的影响。

1 计算模型的建立

1.1 物理模型

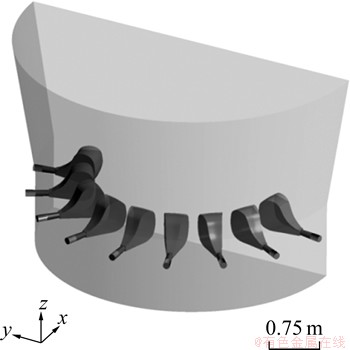

将直风管及回旋区视为相连空腔,焦炭床层视为多孔介质[4],整个计算区域为3部分:回旋区、滴落带和死料区,后2部分的孔隙率分别为0.50和0.25,如图1所示。

图1 计算区域示意图

Fig. 1 Schematic diagram of computational area

根据某钢铁企业3号高炉实际尺寸建立物理模型,根据经验公式[5]计算回旋区大小。由于高炉炉型的对称性,所建立模型为实际的1/2,如图2所示。采用分块非结构化网格并结合局部加密进行网格划分,如图3所示。

对回旋区内煤粉燃烧过程的计算进行以下简化假设[5-6]:

(1) 煤粉和焦炭粒度均匀;

图2 物理模型示意图

Fig. 2 Diagram of physical model

图3 网格结构示意图

Fig. 3 Diagram of grid structure

(2) 忽略煤粉和焦炭颗粒的破碎和凝聚;

(3) 忽略空腔内液相流动;

(4) 各工况下的回旋区形状稳定。

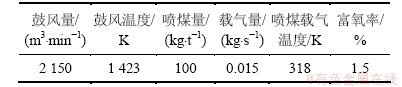

该高炉的基本参数以及高炉稳定运行时的基本操作参数如表1和表2所示。

表1 高炉的基本参数

Table 1 Basic parameter of blast furnace

表2 高炉的操作参数

Table 2 Operating parameter of blast furnace

1.2 数学模型

回旋区内煤粉燃烧过程的数学模型,主要包括气、固两相流动以及煤粉、焦炭的燃烧反应模型。

对于气体在回旋区空腔内的流动,采用标准k-ε双方程湍流模型计算。

对于气体在焦炭床层内(滴落带和死料区)的流动,假定焦炭床层各向同性。对于流体在均匀多孔介质内的流动,需要考虑多孔介质对流体黏性和惯性的影响,即需要对动量方程的源项作出增加一个阻力源项的修正[7],本文利用Ergun方程计算阻力系数[8],计算式为

(1)

(1)

(2)

(2)

式中: 为黏性阻力系数;C2为惯性阻力系数;dp为炭颗粒粒径;φ为孔隙率。

为黏性阻力系数;C2为惯性阻力系数;dp为炭颗粒粒径;φ为孔隙率。

对于煤粉颗粒在计算区域内的运动及由煤粉颗粒与气体之间相互耦合引起的能量变化,采用基于欧拉-拉格朗日法的离散相模型来描述[9]。

单位质量煤粉颗粒的运动方程为

(3)

(3)

式中:up为颗粒速度;u为气相速度;gi为i方向的重力加速度; 为颗粒密度;

为颗粒密度; 为气相密度;Fi为颗粒在i方向上所受到的附加力;FD(u-up)为煤粉颗粒所受到的质量曳力。

为气相密度;Fi为颗粒在i方向上所受到的附加力;FD(u-up)为煤粉颗粒所受到的质量曳力。

煤粉颗粒的能量方程为:

(4)

(4)

式中:mp为颗粒质量;cp为颗粒比热容;Tg和Tp分别为气体和颗粒温度;Nu为对流换热强度准数;Hreac为反应热;Ap为颗粒表面积;I为辐射强度;εp为颗粒的发射率; 为Stefan–Boltzmann常数。

为Stefan–Boltzmann常数。

煤粉颗粒的燃烧过程包括干燥(水分蒸发)、热解析出挥发分以及残炭的燃烧过程。

对于煤粉的干燥,采用液滴蒸发扩散模型来描述[10],水分蒸发速率为

(5)

(5)

式中:D为扩散系数,m2/s;ww,g为气相中水分质量分数;ww,s为颗粒中水分质量分数。

对于煤粉颗粒的热解析出挥发分,采用双平行竞争模型[11],挥发分生成速率为

(6)

(6)

式中:mo为原煤的质量;k1和k2为双平行竞争模型中的频率因子;α1为挥发分的干燥无灰基含量。

对于残炭和焦炭的燃烧过程,采用扩散-动力学燃烧模型[12],燃烧速率为

(7)

(7)

式中:wss为颗粒表面氧化剂的质量分数。

另外,对于高炉内发生的剧烈燃烧反应,必须要考虑炉内的辐射换热过程,本文采用P-1模型对炉内煤粉燃烧的辐射进行计算。

1.3 边界条件

对于热风入口与喷煤枪入口根据实际流量设置为质量流量入口。直风管热风入口的水力直径为120 mm,湍流强度为0.039 7,热风速度方向与入口截面垂直;喷煤枪煤粉入口的水力直径为10 mm,湍流强度为0.048 5,气体和煤粉混合物速度方向与直风管轴线夹角为11°。质量流量入口的压力、温度和气体组分等条件均为高炉稳定运行时的实际平均值。

对于回旋区出口,定义为压力出口,压力由测试值确定。

对于直风管、炉腹及炉缸的各壁面设定为非滑移壁面边界条件,壁面的温度值由测试值确定。

2 喷吹方式对燃尽率的影响

根据所建立的计算模型,以高炉稳定运行时的工况作为基准工况,基于FLUENT对在不同煤粉种类,喷枪形式以及富氧率条件下的回旋区煤粉燃烧过程进行数值模拟计算,考察不同喷吹方式下煤粉燃尽率的变化情况。

2.1 煤种的影响

不同的煤粉具有不同的燃烧特性,是影响回旋区煤粉燃尽率的重要因素。竺维春等[13]基于不同煤样的理化性能检测,计算得到了喷吹混煤最佳配比,并经工业试验验证了计算结果。赵晓明等[14]对4种无烟煤的混合喷吹工艺性能的变化规律进行了研究,并得到了混煤有利于提高煤粉喷吹性能的结论。郁建宁[15]结合实际生产,对8种煤样进行工业分析和多项喷吹性能研究,得到最佳的煤粉配比和最大含水量。孔德文等[16]利用热重实验对非等温燃烧条件下的无烟煤、贫煤与高挥发分烟煤进行了不同配比混煤的挥发分初析温度、着火温度、最大燃烧速率和燃尽特性研究。研究结果表明混煤的挥发分初析温度、着火温度、燃尽温度、活化能以及指前因子均随着烟煤配比的增加而降低。

为考察不同的煤粉种类对回旋区内煤粉燃尽率的影响,本文结合该企业用煤情况,选用3种煤粉进行研究:第1种为低挥发分的无烟煤,记为A煤;第2种为高挥发分的烟煤,记为B煤;第3种为前2种煤的混合,配比(即质量比)为1:1,记为C煤。

表3所示为以上3种煤粉的物性参数。

根据表3修改计算过程中不同材料所对应的物性参数,然后进行模拟计算。

表3 3种煤粉的工业与元素分析(质量分数)

Table 3 Ultimate and proximate analysis data of three kinds of pulverized coal %

不同煤种的燃尽率变化曲线由不同粒径的煤粉颗粒沿直风管轴线方向的燃尽率变化曲线加权平均得到,并且选取煤粉颗粒在沿直风管轴线方向1.4 m处(如图1所示,为回旋区边界端点)不同粒径煤粉燃尽率的加权平均值进行统计与分析。其中,回旋区边界端点处的燃尽率为煤粉在直风管、风管嘴和回旋区空腔中的燃尽率之和。

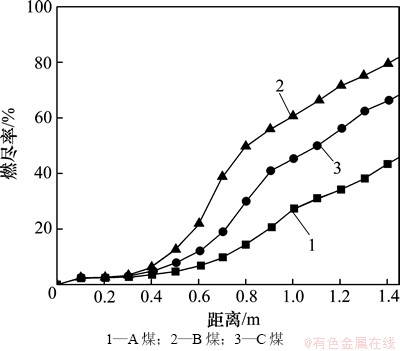

图4所示为不同煤种沿直风管轴线方向上的燃尽率变化情况。

图4 不同煤种的燃尽率变化

Fig. 4 Burning rate change of different coal

由图4可知:A,B和C 3种煤粉的燃尽率随着与风管嘴距离的增加而升高,在0.4 m以内,燃尽率的变化较小,且3种煤粉的燃尽率较接近;大于0.4 m时,燃尽率快速升高,在0.9 m以后燃尽率升高的幅度逐渐降低。在距离风管嘴0.4~1.4 m的范围内,3种煤粉在同一距离时的燃尽率大小顺序关系为:B,C,A,这是因为3种煤粉中所含挥发分含量不同。煤粉从喷煤枪进入直风管后,随气体流动并被迅速加热,挥发分在距离风管嘴0.4~0.9 m的范围内快速大量析出,煤粉颗粒质量迅速减小,挥发分快速燃烧,使得在这一距离范围内的煤粉燃尽率快速升高;在大于0.9 m时,挥发分析出较完全,此时煤粉燃尽率的提高主要受到残炭燃烧速率的影响,而残炭的燃烧速率小于挥发分的析出以及燃烧速率,故在大于0.9 m时,煤粉燃尽率的升高幅度降低。

图5所示为距离风管嘴1.4 m处,3种煤粉在不同喷煤比条件下的燃尽率变化情况。

图5 3种煤粉在不同喷煤比的燃尽率变化

Fig. 5 Burning rate change for different injection ratio of three kinds of pulverized coal

由图5可知:各煤种的燃尽率均随喷煤比的增加而降低,这是因为喷煤比的增加导致煤粉颗粒周围O2含量以及热风温度均降低,使得煤粉颗粒温度升高和热解速度降低,延长了着火时间和煤粉的燃尽时间。另一方面,当喷煤比在100~150 kg/t的范围内时,不同煤种的燃尽率差距较大,在同一喷煤比时燃尽率由大至小的煤种顺序关系为:B,C,A。在数值上,B煤种的燃尽率平均值比C煤种的高约35.32%,比A煤种的高约14.49%。这主要与煤粉中挥发分含量不同有关。经试验测试,B煤种的挥发分含量比C煤种的高约23.45%,比A煤种的高约11.72%。

2.2 喷枪形式的影响

不同的喷枪形式对煤粉的着火、燃烧以及对动力学条件和传质扩散条件的改善效果均不同。目前常用的喷枪形式主要有单煤枪、双煤枪和氧煤枪,结构如图6所示。

图6 不同的喷枪结构示意图

Fig. 6 Schematic spray gun structures

陈国元等[17]试验研究了4种喷枪形式以及改变喷枪位置对煤粉燃尽率的影响,结果表明喷枪形式的不同对煤粉燃尽率有较明显的影响。吴铿等[18]对不同形式的喷枪进行热态模拟试验,发现采用交叉式氧煤双枪和双煤枪可以获得比单枪较高的燃尽率。苏允隆等[19]试验研究了单煤枪、同轴氧煤枪和双煤枪对煤粉燃尽率的影响,结果表明双煤枪的燃尽率高于单煤枪及氧煤枪。

本文以单煤枪物理模型为基础,当采用氧煤枪和双煤枪进行喷煤时,重建喷枪区域的物理模型,并进行网格划分,在计算过程中根据喷枪形式设置相应的边界条件。

图7所示为不同喷枪沿直风管轴线方向上的燃尽率变化情况。

图7 不同喷枪的燃尽率变化

Fig. 7 Burning rate change of different spray guns

由图7可知:3种喷枪沿直风管轴线方向上的燃尽率均随着距离的增加而升高,这与图4所得到的结论一致;在0~0.4 m范围内燃尽率受喷枪形式的影响较小,主要是该距离范围内煤粉的挥发分析出较少,煤粉温度未达到着火点;在0.4~1.4 m范围内双煤枪的燃尽率高于单煤枪和氧煤枪的燃尽率,在0.4~1.1 m范围内单煤枪的燃尽率高于氧煤枪的燃尽率,在1.1~1.4 m范围内氧煤枪的燃尽率高于单煤枪的燃尽率,这是因为采用双煤枪时煤粉分别喷出,湍流加强,使得煤粉颗粒在气流中更容易扩散,颗粒周围的O2浓度也较高,改善了煤粉颗粒与高温气流间的传热效果,而且在同一喷煤比条件下,双煤枪与单煤枪相比,减小了供煤负荷,使煤粉在热风中的分布更均匀,有利于煤粉温度的提高。采用氧煤枪时,相当于以集中的方式富氧,使得喷枪出口附近的富氧风与周围煤粉混合后局部O2浓度较高,有利于传质过程和煤粉燃尽率的提高,但是,喷枪出口附近温度较低,不利于煤粉与热风的传热过程。从整体上看,氧煤枪为煤粉的燃烧过程提供了良好的动力学条件,因此,可以达到比单煤枪更好的燃烧效果。

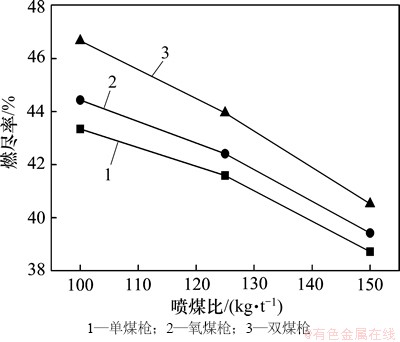

图8所示为距离风管嘴1.4 m处,各喷枪在不同喷煤比时的燃尽率变化情况。

图8 3种喷枪在不同喷煤比时的燃尽率变化

Fig. 8 Burning rate change for different injection ratio of three kinds of spray guns

由图8可知:喷煤比为100~150 kg/t时,燃尽率均随着喷煤比的增加而降低;3种喷枪中,双煤枪的燃尽率最大,单煤枪的燃尽率最小;当喷煤比为100,125和150 kg/t时,双煤枪的燃尽率比氧煤枪分别高约2.23%,1.54%和1.10%,比单煤枪分别高约3.33%,2.36%和1.80%,这说明随着喷煤比的增加,使用不同喷枪时的煤粉燃尽率呈现出逐渐降低并趋于一致的发展趋势。

在一定的高炉运行工况条件下,高炉有其固定的极限喷煤比。通过以上研究可知:调整喷吹煤粉的种类或者改进喷枪形式,可以促进煤粉在回旋区内燃尽率的提高,就能够在保持最初未燃煤粉量的条件下,实现喷煤比的继续提高。

2.3 富氧率的影响

富氧鼓风可以提高喷吹煤粉在高炉风口前的燃尽率,有助于维持合适的理论燃烧温度,并降低生铁成本[20]。沈翃等[21]从维持适宜理论燃烧温度和使富氧效益最大化这两方面,分析探讨了高炉的适宜富氧率。周孑民等[22]针对湖南燃煤资源特性和某高炉喷煤生产现状,对不同煤种的混煤进行优化,并计算得到了与不同混煤匹配的富氧率。沙永志[23]通过对国内外高炉的发展,理论分析了富氧对提高喷煤比的作用,并通过实践分析得到了3%~5%的富氧率是实现200 kg/t以上喷煤比的必要条件。

为考察富氧率对煤粉燃尽率的影响,在其他操作参数相同时,对富氧率分别为0,1.5%,3.0%,5.0%和7.0%回旋区煤粉燃烧过程进行数值模拟计算。图9所示为不同富氧率的燃尽率变化情况。

图9 不同富氧率的燃尽率变化

Fig. 9 Burning rate change of different oxygen enrichment rates

由图9可知:不同富氧率时的煤粉燃尽率均随着与风管嘴距离的增加而升高,在0.4 m以内燃尽率保持稳定,且不同富氧率时的燃尽率较接近;在0.4~1.4 m范围内燃尽率增加较快,且富氧率越大,同一距离处的燃尽率越高,可见富氧率的增加对煤粉燃尽率的提高有极大的促进作用。而随着富氧率的增加,对煤粉燃尽率的提高作用逐渐降低,当富氧率大于5%时,煤粉燃尽率提高的幅度较小,而制氧需要一定的成本,故富氧率应不宜大于5%。

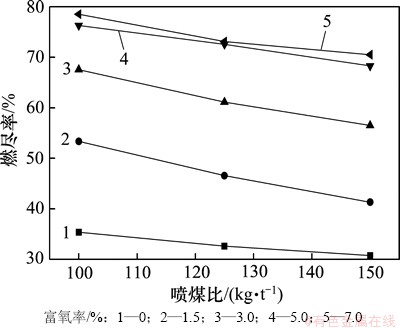

图10所示为距离风管嘴1.4 m处,各富氧率在不同喷煤比时的燃尽率变化情况。

图10 各富氧率在不同喷煤比时的燃尽率变化

Fig. 10 Burning rate change for different injection ratio of different oxygen enrichment rates

由图10可知:不同富氧率条件下的燃尽率均随着喷煤比的增加而降低,在同一喷煤比时,富氧率越高,燃尽率越大,但当富氧率大于5%时,不同喷煤比时的燃尽率较为接近。可见:当富氧率大于5%时,富氧率的提高对燃尽率提高的促进作用快速降低。

由以上对在不同喷煤比时的燃尽率研究分析可知:在一定的高炉运行工况条件下,高炉有其固定的极限喷煤比。

综合以上研究分析可知:调整喷吹煤粉的种类、改进喷枪形式或者适当提高富氧率,均可以促进煤粉在回旋区内燃尽率的提高,这样就能够在保持最初未燃煤粉量的条件下,实现喷煤比的继续提高。

3 对计算模型的验证

通过半工业化的煤粉燃烧实验设备测量气体组分和煤粉的燃尽率,图11所示为该实验装置工作原理图。根据该实验装置构建物理模型,并利用所建立的数学模型来计算煤粉燃烧过程的烟气成分和燃尽率,通过与该实验测试值的对比来验证数学模型的可靠性。

所建立的物理模型如图12所示(由于是对称结构,模型为1/2区域),其中喷煤入口位于圆筒中心,喷煤入口流速U为10 m/s,载气温度T为293 K,喷煤量 为12 kg/h;高温富氧空气入口为外圆环,流速为50 m/s,温度为1 393 K。

为12 kg/h;高温富氧空气入口为外圆环,流速为50 m/s,温度为1 393 K。

计算初始条件与实验工况一致,具体如图8所示。边界条件为:入口为速度入口,出口为自由出流边界,壁面为绝热无滑移边界。测试点距离载气入口中心点分别为0.330,0.626和1.030 m(A,B和C点),煤粉颗粒平均粒径为40 μm,煤粉的物性参数如表4所示。

图11 煤粉燃烧实验装置工作原理图

Fig. 11 Schematic diagram of pulverized coal combustion experimental device

图12 煤粉燃烧实验装置的模拟示意图

Fig. 12 Physical model of pulverized coal combustion

表4 煤粉的工业分析与元素分析(质量分数)

Table 4 Ultimate and proximate analysis data of pulverized coal %

在煤粉燃烧稳定之后,通过烟气分析仪对3个测试点进行多次采样测试,对每个测试点的烟气成分浓度取平均值;并收集相应测试点处的煤粉颗粒,分析煤粉的燃尽率。表5所示为O2和CO2质量分数的计算值与测试值的对比及相对误差。

由表5可知:O2质量分数相对误差的最大值为8.8%,CO2质量分数相对误差的最大值为7.1%,且计算值与测试值的变化趋势较为一致。

表5 O2和CO2质量分数的计算值与测试值对比

Table 5 Comparison of calculated and tested mass fraction of O2 and CO2

表6所示为煤粉燃尽率的计算值与测试值的对比及相对误差。

表6 煤粉燃尽率计算值与测试值的对比

Table 6 Comparison of calculated and tested burnout of pulverized coal

由表6可知:相对误差随着离载气入口距离的增加而降低,最大值为7.4%,最小值为0.3%,计算值与测试值的变化趋势一致。

由以上计算值与测试值的对比可知:最大相对误差小于9%,且变化趋势一致,吻合较好,可认为该计算模型是准确和可靠的。

4 结论

(1) 建立了高炉回旋区内煤粉燃烧过程的计算模型,根据某钢铁企业3号高炉的实际尺寸构建物理模型并进行网格划分,对气、固两相流动,煤粉、焦炭的燃烧以及辐射建立相应的数学模型,通过半工业化试验测试值与基于流体计算软件FLUENT进行数值仿真的计算值对比,验证了计算模型的可靠性。

(2) 采用烟煤喷吹的燃尽率高于无烟煤和混煤的燃尽率,采用双煤枪喷吹的燃尽率高于单煤枪和氧煤枪的燃尽率,富氧率越高,燃尽率越大;燃尽率随着喷煤比的增加而降低。

参考文献:

[1] 沙永志, 腾飞, 曹军. 我国炼铁工艺技术的进步[J]. 炼铁, 2012, 31(1): 7-11.

SHA Yongzhi, TENG Fei, CAO Jun. The ironmaking technique progress in our country[J]. Ironmaking, 2012, 31(1): 7-11.

[2] Borrego A G, Osório E, Casal M D, et al. Coal char combustion under a CO2-rich atmosphere: Implications for pulverized coal injection in a blast furnace[J]. Fuel Processing Technology, 2008, 89(11): 1017-1024.

[3] 王培平, 陈旺生, 孟康. 高炉喷吹配煤催化燃烧特性的研究[J]. 武汉科技大学学报, 2012, 35(6): 432-436.

WANG Peoping, CHEN Wangsheng, MENG Kang. Injection in the blast furnace of catalytic combustion characteristics of coal blending[J]. J Univ Sci Technol Wuhan, 2012, 35(6): 432-436.

[4] NogamihH, Yamaoka H, Takatani K. Raceway design for the innovative blast furnace[J]. ISIJ International, 2004, 44(12): 2150-2158.

[5] 赵欣. 高炉风口回旋区特征的实验研究与数值模拟[D]. 重庆: 重庆大学材料科学与工程学院, 2008: 31-42.

ZHAO Xin. Numerical simulation and experiment research on the character of tuyereraceway of blast furnace [D]. Chongqing: Chongqing University. College of Materials Science and Engineering, 2008: 31-42.

[6] Shen Y S, Guo B Y, Yu A B, et al. A three-dimensional numerical study of the combustion of coal blends in blast furnace[J]. Fuel, 2009, 88(2): 255-263.

[7] Chen Y C, Sun Y M, Mou J L, et al. Application of orthogonal array tests method to optimize operating conditions for iron ore sintering[J]. ISIJ International, 2009, 49(5): 743-748.

[8] Ergun S. Fluid flow through packed columns[J]. Chemical Engineering Progress, 1952, 48(2): 89-94.

[9] 邹祖桥, 孙学信, 丘纪华, 等. 高炉风口内煤粉颗粒轨迹的数学模拟[J]. 钢铁, 2000, 35(3): 9-11.

ZOU Zuqiao, SUN Xxuexin, QIU Jihua, et al. Numerical simulation of the pulverized coal track in BF tuyere[J]. Iron & Steel, 2000, 35(3): 9-11.

[10] Zhou L X, Li L, Li R X, et al. Simulation of 3-D gas-particle flows and coal combustion in a tangentially fired furnace using a two-fluid-trajectory model[J]. Powder Technology, 2002, 125(2): 226-233.

[11] Shang Q, Zhang J, Zhou L X. Instantaneous response of pulverized coal particles to fluctuating temperature in a hot gas flow[J]. Chemical Engineering Communications, 2006, 193(11): 1397-1413.

[12] 顾明言. 煤粉燃烧空气动力学特性与燃烧过程的数值模拟及其应用[D]. 上海: 上海交通大学机械与动力工程学院, 2008: 17-23.

GU Mingyan. Numerical study on the aerodynamics during pulverized coal combustion process and its application[D]. Shanghai: Shanghai Jiaotong University. School of Mechanical Engineering, 2008: 17-23.

[13] 竺维春, 单洎华, 王自亭, 等. 首钢高炉喷吹煤种优化研究[J]. 中国冶金, 2005(5): 23-26.

ZHU Weichun, SHAN Leihua, WANG Ziting, et al. Shougang blast furnace injection coal optimization research[J]. China Metallurgy, 2005(5): 23-26.

[14] 赵晓明, 张建良, 任铁军, 等. 混合煤种高炉喷吹工艺性能研究[C]// 2004年全国炼铁生产技术暨炼铁年会. 无锡, 2004: 748-751.

ZHAO Xiaoming, ZHANG Jianliang, REN Toejun, et al. Mixed coal injection in the blast furnace process performance research[C]// The Ironmaking Production Technology and Ironmaking Convention in 2004. Wuxi, 2004: 748-751.

[15] 郁建宁. 马钢2 500 m3高炉烟煤无烟煤混合喷吹的研究[D]. 唐山: 河北理工大学冶金与能源学院, 2005: 9-16.

YU Jianning. 2 500 m3 blast furnace of masteel hybrid anthracite bituminous coal injection[D]. Tangshan: Hebei United University. School of Metallurgical and Energy, 2005: 9-16.

[16] 孔德文, 张建良, 林祥海, 等. 高炉喷吹混合煤的燃烧特性及动力学分析[J]. 钢铁研究学报, 2011, 23(11): 4-9.

KONG Dewen, ZHANG Jianliang, LIN Xianghai, et al. Blast furnace injection mixed coal combustion characteristic and dynamics analysis[J]. Journal of Iron and Steel Research, 2011, 23(11): 4-9.

[17] 陈国元, 杜国萍, 吴铿. 喷枪形式对煤粉燃烧率影响的研究[J]. 炼铁, 2003, 22(2): 36-37.

CHEN Guoyuan, DU Guoping, WU Keng. Research on the effects of spray gun form for pulverized coal combustion rate[J]. Ironmaking, 2003, 22(2): 36-37.

[18] 吴铿, 魏欣, 张向国, 等. 高炉喷煤交叉式双枪的基础研究[J]. 北京科技大学学报, 2003, 25(6): 515-519.

WU Keng, WEI Xin, ZHANG Xiangguo, et al. Blast furnace coal injection intersection two guns for basic research[J]. J Univ Sci Technol Beijing, 2003, 25(6): 515-519.

[19] 苏允隆, 李小静, 金俊, 等. 高炉煤枪结构及形式研究[J]. 钢铁, 2008, 43(10): 13-16.

SU Yunlong, LI Xiaojing, JIN Jun, et al. Blast furnace coal gun structure and form[J]. Iron & Steel, 2008, 43(10): 13-16.

[20] 许莹, 胡宾生. 高炉大喷煤量与富氧率的合理搭配[J]. 钢铁研究学报, 2006, 18(1): 6-8.

XU Ying, HU Binshen. Oxygen-enriched rate of large blast furnace coal injection amount and reasonable collocation[J]. Journal of Iron and Steel Research, 2006, 18(1): 6-8.

[21] 沈翃, 冯捷, 赵会敏. BF喷煤最佳富氧率的研究[J]. 洁净煤技术, 2007, 13(1): 50-52.

SHEN Hong, FENG Jie, ZHAO Huimin. BF best oxygen-enriched coal injection rate[J]. Clean Coal Technology, 2007, 13(1): 50-52.

[22] 周孑民, 王浩, 张家元, 等. 高炉混合配煤及富氧率优化[J]. 冶金能源, 2012, 31(3): 11-15.

ZHOU Jiemin, WANG Hao, ZHANG Jiayuan, et al. Mixed blast furnace coal blending and oxygen enrichment rate optimization[J]. Energy for Metallurgical Industry, 2012, 31(3): 11-15.

[23] 沙永志. 高富氧大喷煤技术分析[J]. 炼铁, 2006, 26(6): 19-22.

SHA Yongzhi. Grosvenor LTD oxygen analysis technology of coal injection[J]. Ironmaking, 2006, 26(6): 19-22.

(编辑 杨幼平)

收稿日期:2013-07-16;修回日期:2013-10-25

基金项目:国家重大产业技术开发专项基金资助项目([2009]1717)

通信作者:张小辉(1982-),男,湖北浠水人,博士,讲师,从事冶金节能减排研究;电话:18487319560;E-mail: xiaohui6064@sina.com