文章编号:1004-0609(2012)09-2588-06

氧化-沉淀法合成高振实密度球形LiFePO4/C正极材料

王文琴1,郭志猛 1,姜 冰1,叶 青1,陈 文2

(1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 莱芜市粉末冶金先进制造重点实验室,山东 271100)

摘 要:采用氧化-沉淀法,以FeSO4·7H2O、H3PO4和H2O2为原料通过合成球形前驱体FePO4·2H2O来制备高密度球形LiFePO4/C复合材料。结果表明:当溶质浓度为0.1 mol/L,搅拌速度为500 r/min,陈化时间为36 h时,可合成振实密度高、球形度好的球状前驱体FePO4·2H2O;采用超声波浸渍液法将制备的FePO4与LiOH·H2O、蔗糖混合,通过碳热还原法合成球形LiFePO4/C。该球形LiFePO4/C正极材料的振实密度为1.68 g/cm3,在0.05 C、0.1 C和0.5 C倍率下的首次放电比容量分别为138.9、128.7和113.2 mA·h/g,经20次循环后,容量的保持率分别为99%,98.7%和98.6%。

关键词:氧化-沉淀法;LiFePO4/C;FePO4;球形;正极材料

中图分类号:TM912.9 文献标志码:A

Synthesis of spherical LiFePO4/C cathode material with

high tap density by oxygen-precipitation method

WANG Wen-qin1, GUO Zhi-meng1, JIANG Bing1, YE Qing1, CHEN Wen2

(1. School of Materials Science and Engineering, University of Science and Technology Beijing,

Beijing 100083, China;

Key Laboratory of Powder Metallurgy in Advanced Manufacturing of Laiwu, Laiwu 271100, China)

Abstract: A high tap density LiFePO4/C composite material was prepared from spherical FePO4·2H2O powder via an oxygen-precipitation method by FeSO4·7H2O and H3PO4 with hydrogen peroxide as the oxidizing agent. The results show that, when the concentration of reactants is 0.1 mol/L, stirring speed is 500 r/min and deposite time is 36 h, the spherical FePO4·2H2O powders with high tap density and good sphericity are obtained. The original materials of FePO4, sucrose and LiOH·H2O are mixed by steep ultrasonic oscillation. Spherical anode materials LiFePO4/C are synthesized by carbothermal reduction method. The spherical LiFePO4/C cathode material with tap density of 1.68 g/cm3 achieves high initial discharge capacities of 138.9, 128.7 and 113.2 mA·h/g at 0.05 C, 0.1 C and 0.5 C rates, respectively, and after 20 cycles discharges, the capacity retention rates are 99%, 98.7% and 98.6%, respectively.

Key words: oxygen-precipitation method; LiFePO4/C; FePO4; spherical; cathode material

自从1997年GOODENOUGH小组[1]首次报道橄榄石结构的磷酸铁锂(LiFePO4)能可逆嵌入和脱嵌锂离子以来,由于LiFePO4理论比容量(170 mA·h/g)高[2],放电平台(3.4 V)稳定,循环性能良好、成本低廉、环境友好[3-4],因此被视为最具发展前景的锂离子二次电池正极材料[5-6]。然而,LiFePO4的倍率性能差、低温性能低、振实密度低等缺点极大地限制了其实际应用。

目前,有关研究主要集中在提高LiFePO4材料的电子电导率从而提高其倍率性能和实际比容量,但是,高能量密度的锂离子二次电池要求正极材料既要有高

收稿日期:2012-01-20;修订日期:2012-07-13

通信作者:郭志猛,教授,博士;电话:010-62334376;E-mail: zmguo@ustb.edu.cn

的比容量,又需要高的振实密度,以提高材料的能量密度。合成球形的LiFePO4可以提高材料的振实密度,因而高密度球形LiFePO4的研究是提高电池体积比能量的重要发展方向。目前,合成球状LiFePO4方法主要包括控制结晶法共沉淀法、熔盐法、固相合成法和喷雾热解法。应皆荣等[7]采用控制结晶法制备的球形LiFePO4材料振实密度达1.8 g/cm3,在0.1 C下首次放电比容量为142 mA·h/g;WANG等[8]采用共沉淀法合成FePO4·2H2O球形前驱物,将其与Li2CO3和苯酚甲醛树脂球磨混合后合成粒径2~12 μm,振实密度为1.6 g/cm3的球状LiFePO4/C复合材料,在1 C下放电比容量为130 mAh/g;ZHOU等[9]采用KCl熔盐法合成球形LiFePO4/C,材料的振实密度由1.2 g/cm3提高到1.55 g/cm3,在0.1 C下首次放电比容量为130.3 mA·h/g,循环40次后放电比容量可达137.2 mA·h/g;赵新兵和谢健[10]以高分子聚合物为碳源,通过原位碳包覆固相合成法,得到了颗粒尺寸为300~600 nm的球形Li0.99Fe0.01PO4/C,在2 C倍率下的放电比容量为130 mA·h/g,100次循环后无衰减;孙学磊等[11]用湿法球磨-喷雾干燥法制备球状LiFe0.98Mg0.02PO4/C复合正极材料,振实密度达1.67 g/cm3,在0.1 C、0.5 C和1.0 C倍率下的首次放电比容量分别为151、143和132 mA·h/g;KONSTANTIONV等[12]通过喷雾热解法制备了碳含量不同的球形LiFePO4/C粉体,首次放电比容量为140 mA·h/g。

目前,沉淀法制备球状LiFePO4/C一般以Fe(III)为铁源,先制备球状前驱体FePO4·XH2O,其中X=2[13],再合成LiFePO4/C。本文作者使用Fe(II)为铁源,采用氧化沉淀与碳热还原结合的方法制备高振实密度球形LiFePO4/C,探讨制备球状前驱体工艺对LiFePO4/C材料的影响,以期得到球形度好、振实密度高和电化学性能优良的LiFePO4/C复合材料。

1 实验

1.1 材料的制备

本实验以FeSO4·7H2O、H3PO4和H2O2为原料,用氧化-沉淀法先制备球状前驱体FePO4·2H2O。将一定浓度、一定配比的FeSO4·7H2O和H3PO4溶液分别通计量泵滴入烧杯中,严格控制反应体系中的反应物浓度、搅拌速度、pH值和温度。反应一段时间后加入过量的H2O2 (30%,质量分数),用氨水调节pH值,直至出现大量白色沉淀。搅拌15 min后过滤洗涤,最后加入去离子水使其在150 ℃中陈化一段时间后干燥。其反应如下:

2FeSO4 + 2H3PO4 + H2O2 = 2FePO4·2H2O↓ + 2H2SO4 (1)

无定形的FePO4·2H2O经520 ℃预烧10 h后得到球状FePO4晶体,并将其加入到按化学计量比的LiOH·OH溶液中,同时加入10%(质量分数)的蔗糖,在超声波中分散一段时间后在50℃中干燥,得到前驱体混合物。将混合物置于管式炉中,在N2 (95%,体积分数) + H2 (5%,体积分数)的气氛中于700℃中烧结20 h,得到LiFePO4/C复合材料。其反应如下:

2FePO4 + 2LiOH·H2O + C12H12O11 = 2LiFePO4 + 12CO + 9H2O (2)

为了获得振实密度高、球形度好的FePO4·2H2O前驱体,必须要对实验中反应物浓度、搅拌速度、pH值、反应温度及陈化时间加以有效控制,其中文献[14]报道在pH值为2左右合成的FePO4前驱体所制备出的LiFePO4/C具有良好的电化学性能,因此,pH值控制为2。其他固定的反应条件如下:m(FeSO4·7H2O): m(H3PO4)= 1:1,体系温度为55 ℃,滴加速度为5 mL/min,陈化温度为150 ℃。

1.2 材料的表征

采用日本Rigaku公司生产的X射线衍仪对物相进行分析,以Cu靶为辐射源,工作电压40 kV,工作电流150 mA,波长为1.540 6 ?,2θ为10°~100°。采用JEOL公司的JSM-5600 LV扫描电子显微镜,在20 kV下对样品的表面形貌进行观察。通过将10 g样品置入量筒中并振实至体积不再有明显变化时得到体积V,运用公式ρ = 10/V(g/cm3)进行计算得到样品振实密度。

1.3 电池的组装与充放电测试

将制备的复合材料与导电碳黑、聚偏二氟乙烯(PVDF)按照质量比为8:1:1称量,在溶剂N-甲基吡咯烷酮(NMP)中混合成均匀浆料,涂布于铝箔上。在120℃的真空箱中干燥制成正极片。以锂片为负极,Cellgard 2400聚丙烯多孔膜为隔膜,l mol/L的LiPF6/(EC/EMC/DMC)为电解液(V(EC):V(EMC): V(DMC)=1:1:1),在充满氩气的手套箱中装配成LIR2032型扣式电池。组装好的扣式电池在LAND CT 2001A (武汉蓝电电子设备有限公司生产)上测试材料的充放电性能,截止电压为2.5~4.3 V。

2 结果与讨论

2.1 反应物浓度的影响

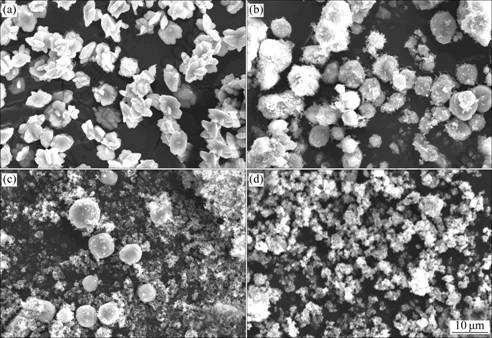

图1所示为反应物浓度分别在0.025、0.1、0.5和2 mol/L时制得的样品形貌,其中搅拌速度为500 r/min,陈化时间为24 h。从图1可以看出,不同浓度下制得的样品的形貌变化很大,当反应物浓度为0.025 mol/L时,形成样品颗粒为细小絮状物(见图1(a));当反应物浓度为0.1 mol/L时,有球状物生成(见图1(b));随着反应物浓度的增加,球状物向片状物发展(见图1(c));当反应物浓度为2 mol/L时,样品为片状的团聚物(见图1(d))。这是因为反应物浓度很低时,容器内溶液分布均匀,晶核的形成速度很快,晶体的生长速度不够,容易形成较小且均匀的颗粒,该絮状物的振实密度很低;当反应物浓度很大时,容易造成溶液局部反应物浓度过高,颗粒倾向于二维生长,易长成片状,团聚在一起的颗粒为花状,其振实密度低。实验中测得样品的振实密度分别为0.52、0.93、1.17和0.86 g/cm3。反应物浓度为0.1和0.5 mol/L时,颗粒的振实密度最高,但反应物浓度为0.1 mol/L时,颗粒的球形度较好,故选择反应物浓度为0.1 mol/L。

2.2 不同搅拌速度的影响

对于一个反应器而言,反应物的滴加速度和搅拌速度对颗粒的形貌有很大的影响,当两者相匹配时,生成的颗粒才具有较好的形貌[15]。图2所示为搅拌速度分别在300、500、700和900 r/min下制备的样品形貌,其中反应物浓度为0.1 mol/L,陈化时间为24 h。由图可以看出,随着搅拌速度的提高,颗粒由花状逐渐变化为球状,最后是细小的絮状。在一定的滴加速度下,过低的搅拌速度使溶液分布不均匀而导致溶液局部浓度过高,从而形成花状。增大搅拌速度使容器内溶液浓度分布均匀而易形成球状颗粒(见图2(b))。当搅拌速度过快时,颗粒还未来得及长大就以过快的速度与其它颗粒猛烈撞击,从而形成细小的絮状颗粒(见图2(b))。当搅拌速度为500 r/min时,颗粒的球形度最好。实验测得样品的振实密度分别为0.94、1.26、1.19和0.34 g/cm3。因此,实验选择搅拌速度为500 r/min。

2.3 陈化时间的影响

将样品洗涤过滤几次后在150 ℃中陈化一段时间,样品的形貌也有很大变化。图3所示为陈化时间分别为12、24和36 h时样品的形貌,其中反应物浓度为0.1 mol/L,搅拌速度为500 r/min。从图3可以看出,随着陈化时间的延长,球状颗粒周围的细小絮状

图1 不同反应物浓度下制备的FePO4·2H2O粉末的SEM像

Fig. 1 SEM images of FePO4·2H2O powders synthesized at various concentrations of reactants: (a) 0.025mol/L;(b) 0.1 mol/L; (c) 0.5 mol/L;(d) 2 mol/L

图2 不同搅拌速度下制备的FePO4·2H2O粉末的SEM像

Fig. 2 SEM images of FePO4·2H2O powders synthesized at various stirring speeds: (a) 300 r/min;(b) 500 r/min; (c) 700 r/min; (d) 900 r/min

图3 不同陈化时间下制备的FePO4·2H2O粉末的SEM像

Fig. 3 SEM images of FePO4·2H2O powders synthesized at various deposite times: (a) 12 h; (b) 24 h; (c) 36 h

颗粒逐渐消失,颗粒的球形度也更好。因为高温中陈化时,颗粒的溶解度更高,小颗粒能重新溶解,而大颗粒则长大,颗粒成长更完全,球形度最好。实验测得的样品的振实密度分别为0.98、1.26和1.46 g/cm3。因此,选择陈化时间为36 h。

综上所述,实验得出合成球形前驱体的最优条件如下:反应物浓度为0.1 mol/L,搅拌速度为500 r/min,陈化时间为36 h。在该工艺下制备的FePO4·2H2O的振实密度为1.46 g/m3,颗粒大小为6 μm左右,如图3 (c)所示。

2.4 LiFePO4/C复合材料的性能

图4所示为以最优工艺条件下所得球形FePO4作为前驱体。通过碳热还原法合成的LiFePO4/C的形貌。由图4可以看出,LiFePO4/C经高温烧结后仍保持球状,且颗粒尺寸分布比较均匀,大多在6 μm左右,最终得到的LiFePO4/C的振实密度为1.68 g/cm3。

图5所示为最佳条件下制备的球状前驱体FePO4及LiFePO4/C的XRD谱。与标准卡片PDF#29—0715中的衍射峰谱对照发现,所得的FePO4为纯相,无杂质相。LiFePO4/C PDF#40—1499衍射峰谱为单一的橄榄石型晶体结构,且样品衍射花样中未观察到杂相峰, 物相纯净。同时,图5(b)中并未出现碳的衍射峰,说明蔗糖热分解成无定形碳,对LiFePO4衍射峰没有影响。

图6所示为在不同倍率下LiFePO4/C样品的首次放电曲线和循环性能。从图6(a)可以看出,样品在0.05 C、0.1 C和0.5 C倍率下的首次放电比容量分别为

图4 球状LiFePO4/C的SEM像

Fig. 4 SEM images of spherical LiFePO4/C (a) LiFePO4/C powders; (b) Spherical LiFePO4/C particle

图5 FePO4和LiFePO4/C的XRD谱

Fig. 5 XRD patterns of FePO4 (a) and LiFePO4/C (b)

图6 不同倍率下LiFePO4/C 样品的首次放电曲线和循环性能

Fig. 6 Initial discharge curves (a) and cyclic performances (b) of LiFePO4 samples at different current rates

138.9、128.7和113.2 mA·h/g,具有较好的电化学性能。同时,样品的振实密度为1.68 g/cm3,在0.05 C、0.1 C和0.5 C倍率下的体积比容量分别为233.4、216.2和190.2 mA·h/cm3,远高于其它非球形的LiFePO4/C材料。从图6(b)可以看出,在该条件下合成的LiFePO4材料具有良好的循环性能,在0.05 C、0.1 C和0.5 C倍率下经20次循环后,容量的保持率分别为99%、98.7%和98.6%。

3 结论

1) 以FeSO4·7H2O、H3PO4和H2O2为原料,通过氧化-沉淀法制备球状前驱体FePO4·2H2O,其最优制备工艺如下:反应物浓度为0.1 mol/L,搅拌速度为500 r/min,陈化时间为36 h。所制备的前驱体颗粒大小为6 μm左右,振实密度为1.46 g/cm3。

2) 以球形FePO4·2H2O为前驱体通过碳热还原法合成的LiFePO4/C复合材料保持了良好的球形,且其振实密度达到1.68 g/cm3,颗粒大小为6 μm左右。LiFePO4/C复合材料的电化学性能较好,在0.05 C、0.1 C和0.5 C倍率下的首次放电比容量分别为138.9、128.7和113.2 mA·h/g,体积比容量分别为233.4、216.2和190.2 mA·h/cm3,经20次循环后,容量的保持率分别为99%、98.7%和98.6%。

REFERENCES

[1] PADHI A K, NANJUNDASWAMYK S, GOODENOUGH J B. Phospho-olivines as positive-electrode materials for rechargeable lithium batteries [J]. J Electrochem Soc, 1997, 144(4): 1188-1194.

[2] 陈 宇, 王忠丽, 于春洋, 夏定国, 吴自玉. 掺杂Mo的LiFePO4正极材料的电化学性能[J]. 物理化学学报, 2008, 24(8): 1498-1502.

CHEN Yu, WANG Zhong-li, YU Chun-yang, XIA Ding-guo, WU Zi-yu. Electrochemical properties of Mo-doped LiFePO4 cathode material [J]. Acta Physico-Chimica Sinica, 2008, 24(8): 1498-1502.

[3] 卢俊彪, 唐子龙, 张中太, 金永拄. 镁离子掺杂对LiFePO4/C材料电池性能的影响[J]. 物理化学学报, 2005, 21(3): 319-323.

LU Jun-biao, TANG Zi-long, ZHANG Zhong-tai, JIN Yong-zhu. Influence of Mg ion doping on the battery properties of LiFePO4/C [J]. Acta Physico-Chimica Sinica, 2005, 21(3): 3l9-323.

[4] BELHAROUAK I, JOHNSO C, AMINE K. Synthesis and electrochemical analysis of vapor-deposited carbon-coated LiFePO4 [J]. Electrochemistry Communication, 2005, 7(10): 983-988.

[5] YAMADA A, CHUNGS C. Optimized LiFePO4 for lithium battery cathodes [J]. J Electrochem Soc, 2001, 148(3): A223-A229.

[6] HUANG H, YIN S C, NAZAR L F. Approaching theoretical capacity of LiFePO4 at room temperature at high rates [J]. Electrochemical and Solid-State letters, 2001, 4(10): A170-A172.

[7] YING Jie-rong, LEI Min, HE Xiang-ming. Preparation and characterization of high-density spherical Li0.97Cr0.01FePO4/C cathode material for lithium ion batteries [J]. Power Sources 2006, 158(1): 543-549.

[8] XIE Hai-ming, WANG Rong-shun, YING Jie-rong, ZHANG Ling-yun, JALBOUT A F, YU Hai-ying, YANG Gui-ling, PAN Xiu-mei, SU Zhong-min. Optimized LiFePO4-polyacene cathode material for lithium-ion batteries [J]. Adv Mater, 2006, 18: 2609-2613.

[9] NI Jiang-feng, ZHOU Heng-hui, CHEN Ji-tao, ZHANG Xin-xiang. Molten salt synthesis and electro- chemical properties of spherical LiFePO4 particles [J]. Mater Lett, 2007, 61(4/5): 1260-1264.

[10] 赵新兵, 谢 健. 新型锂离子电池正极材料LiFePO4在研究进展[J]. 机械工程学报, 2007, 43(1): 69-76.

ZHAO Xin-bing, XIE Jian. Recent development of LiFePO4 cathode materials for lithium-ion batteries [J]. Chinese of Mechanical Engineering, 2007, 43(1): 69-76.

[11] 孙学磊, 戴永年, 姚耀春. 球形磷酸铁锂正极材料制备中试研究[J]. 中国有色金属学报, 2011, 21(1): 125-130.

SUN Xue-lei, DAI Yong-nian, YAO Yao-chun. Pilot scale production of spherical LiFePO4/C cathode material [J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 125-130.

[12] KONSTANTINOVA K, BEWLAY S, AHN J H. New approach for synthesis of carbon-mixed LiFePO4 cathode materials [J]. Electrochim Acta, 2004, 50(2/3): 421-426.

[13] SONG Yan-ning, YANG Shou-feng, ZAVALIJ P Y, WHITTINGHAM M S. Temperature-dependent properties of FePO4 3cathode materials [J]. Mater Res Bull, 2002, 37(7): 1249-1257.

[14] 郑俊超, 李新海, 王志兴, 郭华军, 王丹琴. 制备过程pH值对FePO4·xH2O及LiFePO4性能的影响[J]. 中国有色金属学报, 2008, 18(5): 867-872.

ZHENG Jun-chao, LI Xin-hai, WANG Zhi-xing, GUO Hua-jun, WANG Dan-qin. Effect of pH value on performance of FePO4·xH2O and LiFePO4 in synthesis process [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(5): 867-872.

[15] 胡国荣, 刘艳君, 高旭光, 杜 柯, 高旭光. 控制结晶法合成球形正极材料LiNi0.8Co0.2O2及其电化学性能[J]. 中国有色金属学报, 2007, 17(1): 59-67.

HU Guo-rong, LIU Yan-jun, GAO Xu-guang, DU Ke, GUA Xu-guang. Synthesize and properties of spherical cathode materials LiNi0.8Co0.2O2 by controlled crystallization method [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 59-67.

(编辑 何学锋)