文章编号: 1004-0609(2006)05-0775-06

黄铜H62搅拌摩擦焊接头的微观组织及性能

王希靖1, 达朝炳1, 2, 李 晶1, 张忠科1

(1. 兰州理工大学 甘肃省有色金属新材料省部共建国家重点实验室, 兰州 730050;

2. 青海油田建设有限责任公司, 敦煌 736202)

摘 要: 针对H62黄铜进行搅拌摩擦焊实验研究, 初步分析工艺参数对接头的组织及力学性能的影响。 结果表明:当焊接速度与搅拌头旋转速度的比值保持在0.09~0.15之间, 压入深度在0.1~0.2mm之间时, 可得到组织致密、 无孔洞的搅拌摩擦焊接头; 用搅拌摩擦焊得到的黄铜接头的力学性能比母材低, 但比熔化焊得到的接头性能要高, 其平均抗拉强度可达到母材的88%。

关键词: 黄铜; 搅拌摩擦焊; 焊接参数; 动态再结晶 中图分类号: TG407

文献标识码: A

Microstructures and properties of

joint by friction stir welding for H62 brass alloys

WANG Xi-jing1, DA Chao-bing1, 2, LI Jing1, ZHANG Zhong-ke1

(1. State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials,

Lanzhou University of Technology, Lanzhou 730050, China;

2. Qinghai Oilfield Construction Co., Ltd., Dunhuang 736202, China)

Abstract: The welding of H62 brass alloys in friction stir welding was investigated. The influence of welding parameters on the microstructures and properties of joint was also studied. The results show that good microstructures and properties of joint can be attained when the ratio of the welding velocity to rotating speed is in the range of 0.09-0.15 and the press depth of the rotating shoulder is 0.1-0.2mm. It is also discovered that the mechanical properties of the friction stir welded H62 brass alloys joint are lower than those of parent metal, but are higher than those of joints by other conventional fusion welding processes. The average value of tensile strength of the joint can achieve 88% of strength of the parent metal.

Key words: brass alloys; friction stir welding; welding parameters; dynamic recrystallzation

黄铜具有比紫铜高得多的强度、 硬度和耐腐蚀能力, 并保持有一定的塑性, 又能承受冷热加工, 因而作为结构材料在工业中得到广泛的应用[1]。 对于铜合金的焊接目前主要使用熔焊、 压焊和钎焊方法, 但焊接质量都不太理想。 由于黄铜的导热系数比普通碳钢大7~11倍, 导致熔化焊接时容易出现基材难于熔合、 焊不透和表面成形差等外观缺陷; 而钎焊时一方面强度不高、 塑性差, 另一方面成本太高限制了它的应用; 压力焊时, 因加压温度范围窄, 使压力焊的工艺难度增大。

搅拌摩擦焊(简称FSW)是基于摩擦焊技术的一种固相塑性连接技术。 与常规焊接方法相比, 具有明显的优越性: 焊接接头力学性能良好, 焊后变形小, 不需要填充材料和保护气体, 没有烟尘与飞溅, 不需要加工坡口, 大大降低了焊接成本。 它的出现为焊接铝、 铜合金提供了一种新的工艺。 目前国内外研究的热点主要是铝合金搅拌摩擦焊[2-6], 在铜及其合金方面, 多集中在对紫铜的搅拌摩擦焊工艺及接头力学性能的研究等方面[7-10], 对黄铜的搅拌摩擦焊进行的研究还很少。 本文作者针对常用黄铜H62进行了FSW工艺实验, 在选用不同转速、 焊接速度的情况下, 对其塑性连接时的焊缝成形、 焊缝组织形态及接头的力学性能进行了分析。

1 实验

选用5mm厚的H62黄铜为实验材料。 在FSW-3LM-015搅拌摩擦焊机上进行FSW实验。 焊前将两待焊件表面离焊缝中心20mm以内用砂纸打磨出金属光泽后放置在工作台上并压紧。 实验时, 通过改变焊接规范参数, 观察焊缝成形分析规范参数对焊缝成形的影响。

焊后沿焊缝横截面切断分别制作金相和拉伸试样。 制作好的金相试样采用氯化高铁盐酸酒精溶液(FeCl3 5g、 HCl 2mL、 C2H5OH 95mL)腐蚀后用光学显微镜观察显微组织并进行照相; 拉伸实验在AG-10TA数控拉伸机上进行。 通过这些结果来分析研究工艺参数对接头性能的影响。

2 结果与分析

2.1 不同工艺参数下接头的宏观形貌

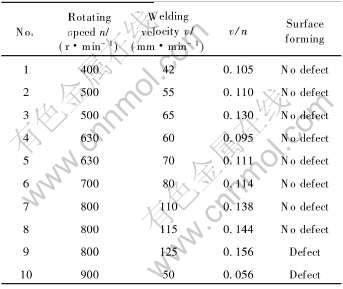

整个搅拌摩擦焊接可分为3个过程: 搅拌头旋转进入施焊材料待定深度及指针停留时间(即预热时间); 搅拌头正常焊接过程; 焊接结束时搅拌头从焊缝中回抽时间。 表1所列为本实验所选用的焊接规范。

表1 黄铜搅拌摩擦焊的焊接参数

Table 1 Welding parameters of FSW for H62 brass alloys

当搅拌头旋转速度n为400~900r/min, 焊接速度(搅拌头沿焊缝方向的移动速度)v为35~100mm/min, 焊接速度与搅拌头旋转速度v/n值最好保持在0.09~0.15之间时, 能得到上下表面成形良好的焊缝。 焊接时, 搅拌头下压速度保持在10mm/min, 轴肩压入深度在0.1~0.2mm之间。 而压入深度不够时, 在前进边内部出现隧道形缺陷; 压入过深时一是飞边多, 二是搅拌头温升过高, 导致黄铜表面氧化。 另一方面, 黄铜温度过高导致出现熔化现象, 恶化焊缝成形。

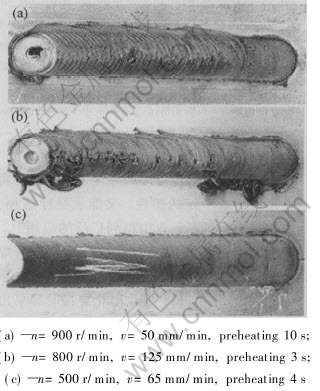

图1所示为采用不同的工艺参数进行焊接时得到的表面成形不同的FSW接头。 焊接时都采用相同的搅拌头及旋转方向, 图上侧为前进边, 下侧为后退边。 由图1(a)可见, 接头表面有粗大的鳞状波纹, 接头前进边明显高于后退边, 接头中间间隔出现孔洞。 这是由于接头输入热量过高导致接头材料温度过高, 被焊材料在搅拌头的带动下流向前进边, 致使后退边流动到中间的材料不足以填充因搅拌针移动而留下的匙孔[2]。 由图1(b)可见, 接头在开始处成形良好, 但随着搅拌头的移动, 焊缝中间出现了因搅拌针撤出而留下的匙孔, 说明接头输入热量不够。 在开始焊接处, 由于搅拌头旋转进入特定深度后有3s的停留时间, 接头初成形较好, 但由于随着焊接速度的增加, 接头单位时间内热量输入不足导致不能形成塑性金属的流动, 引起焊接过程不连续现象。 由图1(c)可见, 接头上下表面成形光滑平整, 证明采用了合适的焊接速度、 旋转速度和下压力及预热时间。

图1 不同工艺条件下黄铜搅拌摩擦焊焊缝的外观像

Fig.1 Welded joint profile images under different welding parameters

2.2 试样显微组织

搅拌摩擦焊接头形成的组织差别较大的区域如图2所示。 焊核区即焊接时搅拌头所处的位置[5], 由于焊接铜合金比焊接铝合金所需温度高400~500℃左右[4], 从显微组织分析可知, 铜合金的焊核区比铝合金的要大一点, 且偏向后退边。 此处金属发生强烈的塑性剪切变形和流动, 相互搅拌和混合, 发生动态回复和动态再结晶等物理冶金和力学冶金过程[2, 11, 12]。 可明显看到焊核区由非常均匀、 细小的等轴晶粒组成, 其晶粒大小比母材、 热影响区及热力影响区晶粒细小得多。 焊核区内晶粒在试件厚度方向上分布也不同, 在靠近上表面处(图2(a))晶粒大小均匀, 没有明显的分层现象, 而在远离上表面处晶粒出现明显的分层(图2(b)), 这表明在焊核区材料受到的塑性剪切力和输入的搅拌摩擦热是随着距搅拌头轴肩的距离增加而减少。 在搅拌针旋转进入焊材后焊缝热量主要由搅拌头轴肩提供[6, 13], 靠近轴肩的材料因为能够得到足够的热量而能充分混合和搅拌, 而远离轴肩的焊核区由于在搅拌针上仅有薄薄一层塑性金属流动, 导致搅拌针在旋转焊接时由于热量输入的不同使离轴肩远的焊核区晶粒出现分层现象, 这也解释了热量输入不够时在搅拌针底层靠近前进边会出现隧道型缺陷。 而热力影响区(图2(c))是近靠焊核区一个非常窄的区域[12, 13]。 该区域由于同时受到热作用及外力拉伸作用, 晶粒沿材料塑性流动方向被拉长, 其分布在焊核区的区域并不对称(如图2(c)所示), 前进边比后退边大, 此区域由于高温停留时间短, 并且在较高变形速度下发生了动态再结晶, 所以晶粒比焊核区晶粒大但比热影响区晶粒小; 热影响区由于仅受到热的影响, 该区组织发生了再结晶, 从图2(d)可看出, 大晶粒间产生新的再结晶晶粒, 由于黄铜为硬态组织, 在焊接前有一定的冷变形量, 并且该区域温度较低, 停留时间很短, 只是部分晶粒发生了再结晶, 导致再结晶晶粒要细于原始组织。

图2 黄铜搅拌摩擦焊接头的微观组织

Fig.2 Microstructures of FSW joint for H62 brass alloy

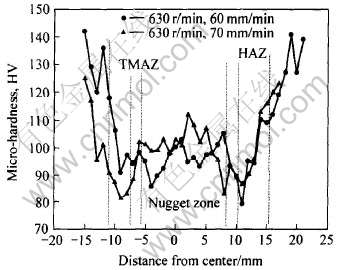

2.3 试样显微硬度

沿垂直于焊缝横截面每隔0.5mm测一次显微硬度(如图3所示)。 图4所示为在搅拌头旋转速度为630r/min, 但焊接速度分别为60、 70mm/min时得到的焊缝横截面显微硬度的分布。 从图4可知, 显微硬度值从热影响区开始急剧下降, 在靠近热力影响区处开始上升, 在焊缝中心处显微硬度变化不大。 黄铜在经过搅拌摩擦焊后焊缝硬度平均值比母材低, 焊缝中心即焊核区的显微硬度只有母材硬度的70%~82%, 而焊接影响区的显微硬度比焊核区和母材区都低, 只有母材硬度的60%。 出现这种现象有两方面的原因: 一是由于黄铜的初始状态是硬态, 焊接时因加热而焊缝区发生了软化; 二是由于焊缝区金属在搅拌摩擦焊中经历了动态回复与再结晶, 虽然这一区域晶粒比母材小, 但是这一区域在回复与再结晶过程中软化程度超过了硬化程度, 使焊缝硬度比母材低[14]。 但从焊缝局部看符合晶粒大小与硬度的关系。

从整个实验分析可知, 显微硬度大小与搅拌头旋转速度与焊接速度的变化有一定的关系。 当旋转速度较小时, 焊核区显微硬度与影响区硬度变化幅度较小。 当旋转速度一定时, 焊接速度增大时, 显微硬度升高; 而旋转速度增加时, 虽然焊接速度也增加, 但焊核区显微硬度与影响区硬度差值变大。

图3 焊缝横截面显微硬度的测量部位

Fig.3 Location of test point for

micro-hardness on transverse section

图4 黄铜搅拌摩擦焊接头的显微硬度分布

Fig.4 Micro-hardness distribution of

FSW joints for H62 brass alloy

2.4 试样拉伸性能分析

对不同焊接参数下得到的表面成形好的试样组分别进行拉伸实验。 图5所示为拉伸试样的焊缝断裂部位。 可见为典型的韧性断裂。

图5 拉伸试样的断裂位置

Fig.5 Failure location of tensile sample

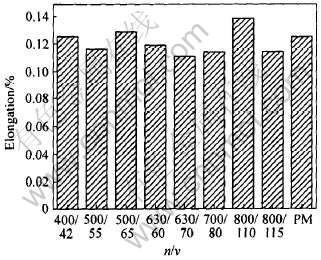

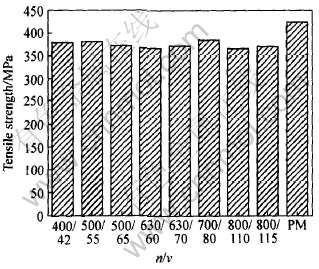

图6、 7所示分别为不同工艺参数条件下获得的焊缝的延伸率及抗拉强度。 可知搅拌头转速为800r/min, 焊速为110mm/min下接头的延伸率最大, 其延伸率超过母材的延伸率。 但当焊速增加到115mm/min时, 其延伸率下降了14.3%, 这是因为焊速为110mm/min的接头断裂部位在焊核区。 而各种工艺参数下接头的抗拉强度几乎保持不变, 当搅拌头转速为700r/min, 焊接速度为80mm/min时焊接得到的接头抗拉强度最大, 为母材抗拉强度的90.5%。 对延伸率、 断裂位置以及抗拉强度的结果进行综合考虑, 认为当搅拌头转速在400~800r/min之间以及焊接速度在42~110mm/min之间时, 得到的焊缝的力学性能各方面都比较好。 焊接接头平均抗拉强度是母材的88%, 最大可达到90.5%。

图6 不同工艺参数条件下焊缝的延伸率

Fig.6 Elongation of FSW joints for H62 brass

alloys under different welding parameters

图7 不同工艺参数条件下接头的抗拉强度

Fig.7 Tensile strength of FSW joints for

H62 brass alloy under different welding parameters

3 结论

1) 用搅拌摩擦焊焊接板厚5mm的黄铜H62时, 搅拌头旋转速度为400~900r/min, 焊接速度为35~100mm/min, 焊接速度与搅拌头旋转速度的比值保持在0.09~0.15之间, 压入深度在0.1~0.2mm之间时, 可得到组织致密、 无孔洞的搅拌摩擦焊接头。

2) 由于焊缝金属经历了高温搅拌、 加压作用, 接头组织经历了动态回复与动态再结晶, 焊接接头可分为细小均匀的等轴晶组成的焊核区、 变形拉长的热力影响区、 再结晶不充分的热影响区。

3) 用搅拌摩擦焊进行焊接, 得到的黄铜接头的力学性能比母材要低, 其接头平均抗拉强度可达到母材的88%, 最大可达到90.5%, 而常规焊接方法得到的接头只能达到原母材抗拉强度的40%~60%。

REFERENCES

[1]中国焊接学会. 焊接手册(第2卷)[M]. 北京: 机械工业出版社, 1992. 469-471.

China Welding Association. Welding Handbook (Vol.2)[M]. Beijing: China Machine Press, 1992. 469-471.

[2]Elrefaey A, Takahashi M, Ikeuchi K. Preliminary investigation of friction stir welding aluminum/copper lap joint[A]. Proceeding of IIW Pre-Assembly Meeting on FSW[C]. Nagoya: Osaka University, 2004. 275-285.

[3]Shinoda T. Recent development of friction stir welding process[J]. Light Metal Welding and Construction, 1999, 37(9): 406-412.

[4]Hassan K A A, Norman A F, Price D A, et al. Stability of nugget zone grain structures in high strength Al-alloy friction stir welds during solution treatment[J]. Acta Mater, 2003, 51: 1923-1936.

[5]Schneider J A, Nunes A C Jr. Characterization of plastic flow and resulting microtextures in a friction stir weld[J]. Metallurgical and Materials Transactions, 2004, 35B: 4-13.

[6]王希靖, 郭瑞杰, 阿荣. 搅拌摩擦焊接头的温度检测[J]. 电焊机, 2004(1): 22-23.

WANG Xi-jing, GUO Rui-jie, A Rong. Temperature measure for joint of friction stir welding[J]. Electric Welding Machine, 2004(1): 22-23.

[7]Lee W B, Jung S B. The joint properties of copper by friction stir welding[J]. Materials Letters, 2004, 58: 1041-1046.

[8]刘小文, 薛朝改, 张小剑. 铜板搅拌摩擦焊工艺优化[J]. 焊接, 2003(12): 9-12.

LIU Xiao-wen, XUE Chao-gai, ZHANG Xiao-jian. The optimize friction stir welding process for copper [J]. Welding Joining, 2003(12): 9-12.

[9]肖兵, 柯黎明, 王伟兰. 紫铜的搅拌摩擦焊接头性能测试与组织分析[J]. 电焊机, 2004(增): 125-129.

XIAO Bing, KE Li-ming, WANG Wei-lan. Joint properties and microstructure of copper by friction stir welding[J]. Electric Welding Machine, 2004(suppl.): 125-129.

[10]刘小文, 鄢君辉, 薛朝改, 等. 铜板搅拌摩擦焊接头金相组织及力学性能[J]. 焊接学报, 2003, 24(6): 47-50.

LIU Xiao-wen, YAN Jun-hui, XUE Chao-gai,et al. Microstructure and stress property of copper in friction stir welding[J]. Transactions of the China Welding Institution, 2003, 24(6): 47-50.

[11]Fonda R W, Bingert J F, Colligan K J. Development of grain structure during friction stir welding[J]. Scripta Mater, 2004, 51: 243-248.

[12]Jata K V, Semiatin S L. Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys[J]. Scripta Mater, 2000, 43: 743-749.

[13]Shibayanagi T, Maeda M. Microstructure and hardness in a joint of 7075 aluminum alloy friction stir welded[A]. Proceeding of IIW Pre-Assembly Meeting on FSW[C]. Nagoya: Osaka University, 2004. 205-211.

[14]周纪华, 管克智. 金属塑性变形阻力[M]. 北京: 机械工业出版社, 1989. 2-20.

ZHOU Ji-hua, GUAN Ke-zhi. The Resistance to Metal Plastic Deformation[M]. Beijing: China Machine Press, 1989. 2-20.

[15]Peel M, Steuwer A, Preuss M, et al. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminum AA5083 friction stir welds[J]. Acta Mater, 2003, 51: 4791-4801.

基金项目: 甘肃省科技攻关资助项目(SG012-A52-069)

收稿日期: 2005-11-18; 修订日期: 2006-02-17

通讯作者: 王希靖, 教授; 电话: 0931-2976706; E-mail: wangxj@lut.cn

(编辑陈爱华)