文章编号:1004-0609(2013)05-1262-07

直流电弧原位冶金制备粗晶碳化钨块体复合材料

迟 静,李惠琪,王淑峰,李 敏,李建楠,王 梅,高旭杰

(山东科技大学 材料科学与工程学院,青岛 266590)

摘 要:利用直流电弧原位冶金技术制备粗晶碳化钨块体复合材料,并利用X射线衍射仪、电子探针等对其物相组成、微观组织、W与C反应过程和WC生长形态演变机制进行研究。结果表明:碳化钨复合材料的主要硬质相为WC和W2C;当自耗电极长度增加时,WC含量降低,但晶粒尺寸增大,最大晶粒尺寸约为100 μm。在原位冶金过程中,W和C元素通过溶解进入熔池发生扩散反应,逐步形成W2C和WC。WC生长形态由六棱柱演变为三棱柱,生长方式为小平面晶体台阶侧向长大;当达到临界过冷度时,WC晶粒迅速生长。

关键词:碳化钨;复合材料;粗晶;直流电弧原位冶金;生长形态

中图分类号:TB331 文献标志码:A

Coarse-grain bulk WC composites prepared by direct current arc in-situ metallurgy

CHI Jing, LI Hui-qi, WANG Shu-feng, LI Min, LI Jian-nan, WANG Mei, GAO Xu-jie

(College of Materials Science and Engineering, Shandong University of Science and Technology, Qingdao 266590, China)

Abstract: Coarse-grain bulk WC composites were prepared by direct current arc in-situ metallurgy. The examination of phase composition and microstructure for the materials, reaction process of W and C as well as transformation mechanism for WC morphologies was carried out by X-ray diffractometry and electron probe micro-analysis. The results show that WC and W2C are the main hard phases in the composites. Furthermore, the WC content decreases but the grain sizes of WC increase with increasing the length of consumable electrode, and the largest WC grains can reach about 100 μm. During the process of in-situ metallurgy, W and C dissolve and interdiffuse in the molten pool. As a result, W2C and WC form successively. The WC growth morphology is triangular prism that transforms from hexangular prism, and the growth pattern of WC is lateral growth layer by layer of the facet crystals. The WC grains can grow rapidly when undercooling reaches the critical value.

Key words: WC; composites; coarse-grains; direct current arc in-situ metallurgy; growth morphology

碳化钨(WC)基硬质合金具有较高的硬度、较小的热膨胀系数和优良的耐磨及耐腐蚀性能,被广泛用于采煤、采矿、石油勘探和金属切削等领域。其中,由于粗WC晶粒对裂纹的偏转和分叉作用增强,能有效提高硬质合金的韧性,因此,世界范围内的矿山工具均采用粗晶WC硬质合金[1-2]。

传统粉末冶金技术是制备WC硬质合金的最主要方法[3-4],但该方法工序复杂,时间长,能耗高。近年来,有高能束流参与的快速制造技术逐渐应用于WC增强复合材料的制备。ZHAO等[5]以WC-17%Co为原料粉末,采用等离子熔注技术在Q235低碳钢上制备了WC增强表面金属基复合材料。LIU等[6]以铸造WC粉末作为增强颗粒,采用激光熔注技术制备了WC/Fe复合涂层。李松林等[7]采用超音速火焰喷涂工艺制备了微米结构WC-10Co4Cr涂层,并对涂层的微观结构和滑动磨损行为进行了分析。但目前研究主要集中于利用高能束流制备WC表面增强材料,而对于块体WC材料的快速制备方法的研究报道较少。同时,值得注意的是,在已有文献中多以WC作为原始粉末,研究WC在熔池中的溶解以及与基体作用生成其他合金碳化物的行为[8-11]。但对于高能束流作用下W与C的原位反应过程以及WC生长形态演变机制研究较少。

大电流直流电弧能迅速熔化高熔点金属,实现WC在熔凝过程中的原位结晶长大,短流程快速制备块体材料。本文作者以W和C粉末为原料,利用自耗电极直流电弧原位冶金技术制备粗晶WC块体复合材料,研究自耗电极长度对材料物相组成和微观组织的影响,并对W与C原位反应过程和WC生长形态演变机制进行讨论。

1 实验

将W粉和C粉按照质量比93:7配成混合粉末。自耗电极基材为1Cr18Ni9Ti不锈钢管。钢管尺寸:外径10 mm,壁厚1 mm,长度150和300 mm。将混合粉末与适量Na2SiO3·9H2O粘结剂混合均匀,填充于不锈钢管内并压实,低温烘干。

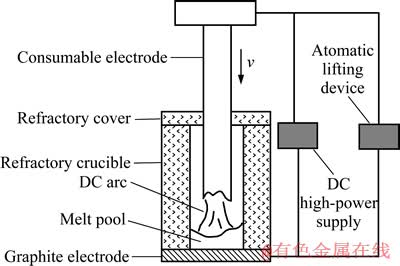

图1 直流电弧原位冶金过程示意图

Fig. 1 Schematic representation of direct current arc in-situ metallurgy process

实验用直流电弧原位冶金系统主要包括:大功率逆变直流电源、自动升降装置以及底部为石墨电极的冶金坩埚。实验过程示意图如图1所示。自耗电极安装在自动升降装置上,接电源负极,石墨接电源正极。实验时,自耗电极匀速下降与石墨电极接触引燃电弧,在直流电弧作用下自耗电极不断熔化,进入坩埚形成熔池,W粉和C粉则在熔池中发生扩散反应。当自耗电极熔化结束时,用保温盖迅速覆盖在熔池上方,使其缓慢降温凝固。采用长度为150和300 mm的自耗电极分别获得试样A(d 20 mm×15 mm)和试样B(d 20 mm×29 mm)。将试样A和B制成标准金相试样后,用RIKAKA D/MAX2500PC型X射线衍射仪进行物相分析;用JXA-8230电子探针观察微观组织,用探针自带波谱仪进行微区成分分析。

2 结果与分析

2.1 WC复合材料物相分析

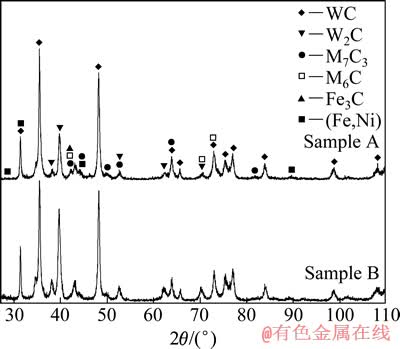

图2所示为试样A和B的XRD谱。由图2可知,两试样的物相组成相同,主要含有WC、W2C、M7C3(M=Fe,Cr,W) 和(Fe,Ni)等物相;其中,WC为最主要衍射峰,表明利用直流电弧原位冶金技术生成了大量WC,获得了以WC和W2C为主要硬质相、Fe基固溶体为粘结相的块体复合材料。以α-Al2O3为内标物质,利用K值法[12]计算了试样中WC和W2C的含量(质量分数),试样A中WC和W2C的含量分别为53.46%和13.83%,试样B中WC和W2C的含量分别为42.34%和25.23%,可以看出,当自耗电极长度增加时,试样中WC含量降低,W2C含量增加。原材料中W粉和C粉的总含量约73.6%,说明反应后约6%的W粉和C粉形成了M7C3(M=Fe,Cr,W)等化合物,因此,合成试样中WC和W2C的含量可以通过改变原材料中W粉和C粉的含量进行调节。

图2 WC 块体复合材料的XRD谱

Fig. 2 XRD patterns of bulk WC composites

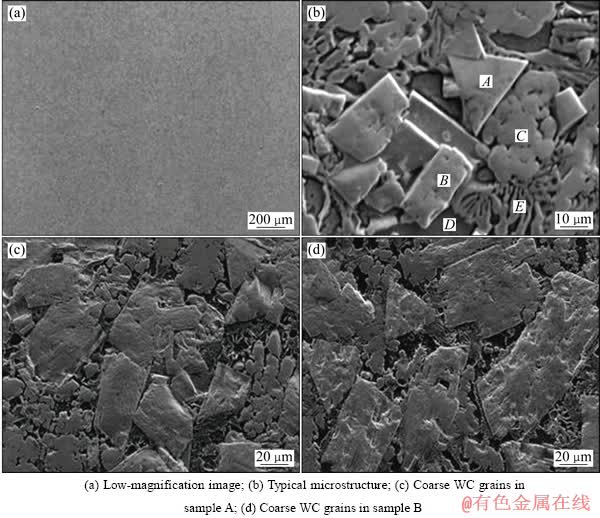

2.2 WC复合材料微观组织分析

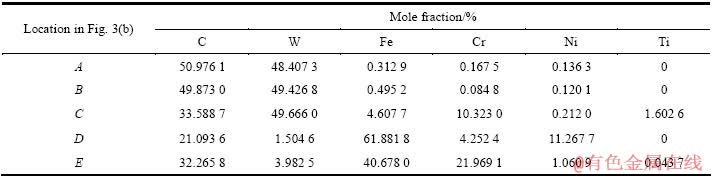

图3(a)所示为直流电弧原位冶金WC复合材料的低倍形貌。可以看出,试样整体致密,没有明显的孔洞和裂纹。图3(b)所示为WC复合材料的典型微观组织形貌,相应的波谱分析结果见表1。其中,三角形和矩形晶粒(图3(b)中位置A和B)含有较多的W(摩尔分数约为49%,质量分数约为94.7%),且C与W的摩尔比接近1:1,其他元素含量极低,可忽略,因此,确定三角形和矩形晶粒为直流电弧冶金过程中原位形成的WC相。花状枝晶(图3(b)中位置C)也具有较高的W含量,同时该相还含有约10%(摩尔分数)的Cr。根据W-C二元相图[13],W和C主要形成两种碳化物WC和W2C,WC是近乎化学计量比化合物,而W2C则具有较宽的非化学计量比范围(C含量范围:26%~34%,摩尔分数)。BERGER等[14]的研究表明,Cr在W2C中具有一定的固溶度,形成的硬质相(W,Cr)2C保持了W2C的晶体结构。因此,试样中形成的花状枝晶为固溶了Cr的W2C相。

图3 WC块体复合材料的组织形貌

Fig. 3 Microstructures of bulk WC composites

表1 WC块体复合材料的波谱分析结果

Table 1 WDS analysis results of bulk WC composites

试样中暗色的基体相(图3(b)中位置D)是Fe基固溶体,作为粘结相存在。图3(b)中位置E处W含量较低(3.98%,摩尔分数),主要含有Fe(40.67%,摩尔分数)和Cr(21.97%,摩尔分数),结合XRD结果确定该相为M7C3 (M=Fe,Cr,W),此处形貌为M7C3碳化物与Fe基固溶体形成的亚共晶组织[15]。当实验中采用不同长度的自耗电极时,试样微观组织形貌相同,但WC晶粒尺寸明显不同,如图3(c)和(d)所示。可以看出,试样A中WC晶粒尺寸为40~70 μm;随着自耗电极长度的增加,试样B中WC晶粒明显粗化,尺寸为60~100 μm。

2.3 W与C反应过程分析

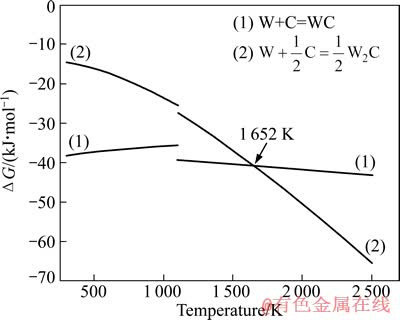

在直流电弧的热量作用下,自耗电极下端不断熔化,滴入冶金坩埚,形成反应熔池。W和C元素主要是通过溶解进入熔池并发生扩散反应,形成WC和W2C两种碳化物,可能的反应如下:

W+C=WC (1)

(2)

(2)

根据热力学数据[16],获得反应(1)和(2)的吉布斯自由能与温度(ΔG—T)关系曲线(ΔG—T曲线不连续是C元素在298~1 100 K和1 100~2 500 K热力学数据不同所致),如图4所示。从图4可以看出,当温度高于1 652 K时,反应(2)的吉布斯自由能低于反应(1)的,表明高温时W2C相更容易生成;当温度低于1 652 K时,反应(1)的吉布斯自由能更低,但此时熔池已经凝固,W和C的固相扩散速度缓慢,在此温度下W与C反应生成WC需要相当长的时间。因此,推断在直流电弧原位冶金过程中,W和C之间的反应主要在高温下进行,且W2C相更容易生成。同时,由于熔体中C的扩散系数远大于W的扩散系数[17],W和C的扩散反应以C向W中扩散为主,因此,富W相即W2C相首先生成,这与热力学计算结果相符。在电弧持续作用以及熔池冷却过程中,随着C原子的进一步扩散,W2C向WC转变,形成的WC依靠固-液界面上原子的附着与脱离而长大。DMITRII等[18]利用第一性原理计算方法证实了W2C在高温下为亚稳相并可向WC相转变。黄新等[19]利用金相显微镜和透射电镜研究了W和C的固态扩散过程,结果表明W颗粒表面首先形成W2C,随着C向W中的扩散,W和W2C逐渐消失,WC逐渐形成。上述结果与本研究所得结果一致。

图4 W 与C 反应的ΔG—T曲线

Fig. 4 ΔG—T curves of W reacting with C

当电流保持恒定、自耗电极长度增加时,电弧作用时间延长,持续的热量输入使熔池温度升高,此时有更多的W2C生成,但随后的熔池凝固过程冷却速 度快,持续时间短,W2C向WC的转变量有限,因此,试样中WC含量降低,W2C含量增加;但对于已经生成的WC,电极长度的增加使熔池保持时间延长,WC长大的时间相对充分,因此WC晶粒尺寸随自耗电极长度的增加而增大,如图3(c)和(d)所示。

2.4 WC生长形态演变机制

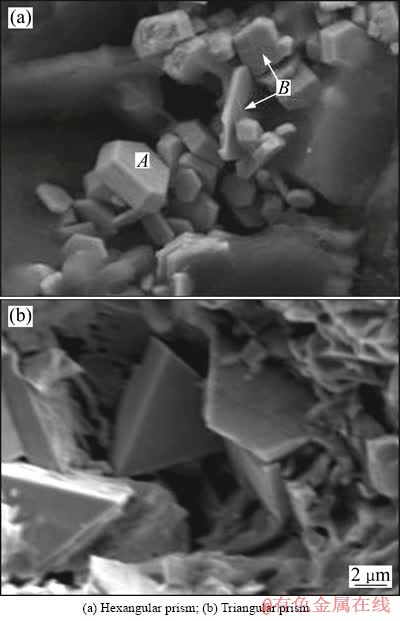

高温下生成的W2C为β-W2C,空间群为P63/mmc,W原子为六方紧密堆积,C原子随机占据W原子构成的八面体空隙中的一半,另一半八面体空隙为结构空位。随着C原子向W2C中扩散,结构空位逐渐减少,当C原子占据所有的八面体空隙时,W2C转变为WC。

WC晶体属于六方晶系, 空间群,晶胞参数a=0.290 6 nm,c=0.283 7 nm。在单位晶胞中,W和C原子的空间坐标分别为(0,0,0)和(1/3,2/3,1/2)。由于C原子位置的不对称性,将WC晶体柱面分成两组不同原子排列的晶面族

空间群,晶胞参数a=0.290 6 nm,c=0.283 7 nm。在单位晶胞中,W和C原子的空间坐标分别为(0,0,0)和(1/3,2/3,1/2)。由于C原子位置的不对称性,将WC晶体柱面分成两组不同原子排列的晶面族 和

和 。所以,WC的初生形貌是由底面{0001}及柱面

。所以,WC的初生形貌是由底面{0001}及柱面 和

和 构成的六棱柱,如图5(a)中位置A所示。WC的密堆积形式为AB类型紧密堆积,即沿<0001>方向,W和C原子的密堆积层在{0001}面交替出现,W原子位于由最近邻的6个C原子构成的变形八面体内,形成6个W—C键。而在WC与粘结相的界面,由于C原子的不对称位置,

构成的六棱柱,如图5(a)中位置A所示。WC的密堆积形式为AB类型紧密堆积,即沿<0001>方向,W和C原子的密堆积层在{0001}面交替出现,W原子位于由最近邻的6个C原子构成的变形八面体内,形成6个W—C键。而在WC与粘结相的界面,由于C原子的不对称位置, 和

和 柱面则分别只形成2个和4个W—C键,

柱面则分别只形成2个和4个W—C键, 的界面能高于

的界面能高于 的界面能[20]。界面能越高,晶面法向生长速率越快,在晶体形貌上保留的面积越小,越容易消失,而法向生长速率慢的晶面将构成晶体生长的最终形态[21]。高能量柱面

的界面能[20]。界面能越高,晶面法向生长速率越快,在晶体形貌上保留的面积越小,越容易消失,而法向生长速率慢的晶面将构成晶体生长的最终形态[21]。高能量柱面 具有较快的生长速率,在生长过程中晶面面积逐渐缩小(图5(a)中位置B);当

具有较快的生长速率,在生长过程中晶面面积逐渐缩小(图5(a)中位置B);当 面最终消失时,WC的生长形貌由六棱柱演变成由底面{0001}和柱面

面最终消失时,WC的生长形貌由六棱柱演变成由底面{0001}和柱面 构成的三棱柱(图5(b))。LAY等[22]通过研究WC晶粒柱面的极化,证明

构成的三棱柱(图5(b))。LAY等[22]通过研究WC晶粒柱面的极化,证明 是WC晶粒生长过程中保留下来的面积最大的柱面,这与上述分析结果一致。

是WC晶粒生长过程中保留下来的面积最大的柱面,这与上述分析结果一致。

图5 块体复合材料中WC的生长形貌

Fig. 5 Growth morphologies of WC grains in bulk composites

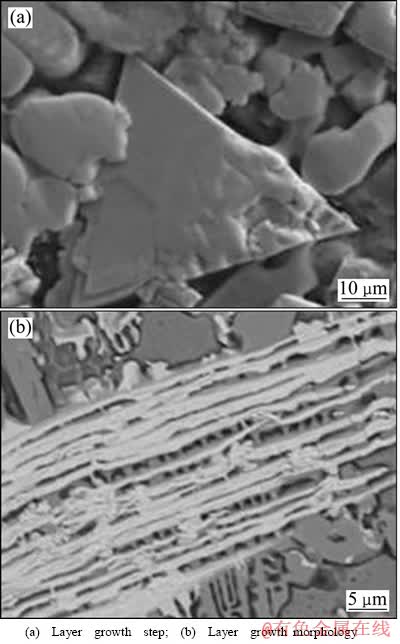

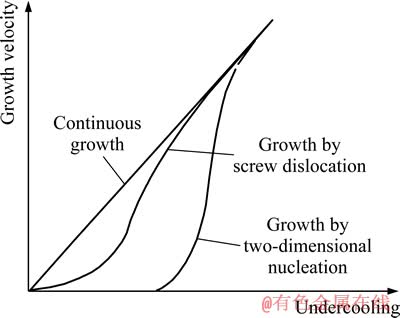

直流电弧原位冶金过程中生成的WC晶粒,棱角分明(图3和5),属于小平面晶体。根据晶体生长理论[21],小平面晶体的生长机制是台阶侧向长大,即依靠二维成核或螺旋位错等缺陷提供的台阶生长。WC的最紧密堆积面{0001}面具有较低的界面能,是WC生长的固-液界面。在生长过程中,首先进入晶体{0001}面的生长基元提供生长台阶,其余基元靠此台阶或螺旋位错等缺陷提供的台阶进入{0001}面,铺满整个晶面后,又在其上产生新的一层台阶,继续长大,形成以{0001}为基面沿<0001>方向的层状生长方式,图6(a)所示为{0001}上的层状生长台阶。通常,随着冷却速度的增加或熔体中过冷度的提高,晶体生长界面上的晶体缺陷密度显著增加[21],从而导致生长台阶密度的增高。在直流电弧原位冶金过程中,较快的冷却速度及局部熔体过冷度的增加,没有改变WC的台阶侧向生长微观机制,但生长界面上的台阶密度增高,因此,在部分WC生长形貌上凝固了大量以{0001}为基面沿<0001>方向的层状生长台阶,如图6(b)所示。

与非小平面晶体的连续长大机制不同,小平面晶体WC长大所依靠的二维成核和位错生长机制中,晶体生长速度并不与过冷度呈直线关系,而是存在临界过冷度。当过冷度小于临界值时,晶体生长缓慢;当过冷度达到临界值后,晶体生长速度突然增大[21,23],如图7所示。直流电弧原位冶金冷却速度快,可提供较大的过冷度,当达到临界值时,WC晶粒得以迅速生长。高能束表面冶金能提供更大的过冷度,但降温速率过快,WC最大晶粒尺寸一般为20 μm[24]。与表面冶金在基材表面形成的熔池相比,直流电弧原位冶金熔池保温时间更长,有利于WC晶粒的进一步长大,因而形成了最大尺寸约为100 μm的粗晶WC。

图6 块体复合材料中WC的层状生长

Fig. 6 Layer-by-layer growth fashion of WC grains in bulk composites

图7 晶体生长速率与过冷度的关系[21, 23]

Fig. 7 Dependence of crystal growth velocity on undercooling[21, 23]

3 结论

1) 以W粉和C粉为原料,利用自耗电极直流电弧原位冶金技术制备了以WC和W2C为主要硬质相、以Fe基固溶体为粘结相的块体复合材料。随着自耗 电极长度的增加,试样中W2C含量增高,WC含量降低,但WC晶粒尺寸增大。

2) 在直流电弧原位冶金过程中,W和C元素通过溶解进入熔池并发生扩散反应,W2C在高温条件下更容易生成,随着C原子的进一步扩散,W2C向WC转变。

3) 直流电弧原位冶金过程中生成的WC,其初生形貌是由底面{0001}和柱面 、

、 构成的六棱柱,高能量柱面

构成的六棱柱,高能量柱面 由于具有较快的生长速率而最终消失,使WC的生长形貌由六棱柱演变成由底面{0001}和柱面

由于具有较快的生长速率而最终消失,使WC的生长形貌由六棱柱演变成由底面{0001}和柱面 构成的三棱柱。WC晶粒生长方式为小平面晶体台阶侧向长大,即以{0001}为基面沿<0001>方向层状生长;当达到临界过冷度时,WC晶粒迅速长大,形成最大尺寸约为100 μm的粗晶WC。

构成的三棱柱。WC晶粒生长方式为小平面晶体台阶侧向长大,即以{0001}为基面沿<0001>方向层状生长;当达到临界过冷度时,WC晶粒迅速长大,形成最大尺寸约为100 μm的粗晶WC。

REFERENCES

[1] 孙东平, 夏斌华. 超粗晶粒凿岩硬质合金研究的新进展[J]. 凿岩机械气动工具, 2009(4): 41-46.

SUN Dong-ping, XIA Bin-hua. New development of super coarse-grains rock drilling cemented carbides[J]. Rock Drilling Machinery and Pneumatic Tools, 2009(4): 41-46.

[2] 迟 静, 李惠琪, 王淑峰, 李 敏. 矿用WC硬质合金的研究进展与趋势[J]. 矿山机械, 2010, 38(8): 23-27.

CHI Jing, LI Hui-qi, WANG Shu-feng, LI Min. Development and tendency of bit-used WC cemented carbides[J]. Mining and Processing Equipment, 2010, 38(8): 23-27.

[3] 吴厚平, 张 立, 王元杰, 黄伯云, 程 鑫. 化学包裹粉工艺制备粗晶粒WC-Co硬质合金[J]. 中国有色金属学报, 2010, 20(4): 701-705.

WU Hou-ping, ZHANG Li, WANG Yuan-jie, HUANG Bai-yun, CHENG Xin. WC-Co cemented carbide from porous spumous cobalt enwrapped WC powders by chemical route[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(4): 701-705.

[4] 张 祎, 马 俊, 狄 平, 朱世根. La2O3对WC-MgO复合材料组织和力学性能的影响[J]. 中国有色金属学报, 2010, 20(10): 1982-1988.

ZHANG Yi, MA Jun, DI Ping, ZHU Shi-gen. Effects of La2O3 on microstructures and mechanical properties of hot-pressing sintered WC-MgO composite material[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1982-1988.

[5] ZHAO Min-hai, LIU Ai-guo, GUO Mian-huan, LIU De-jian, WANG Zhi-jian, WANG Chang-bai. WC reinforced surface metal matrix composite produced by plasma melt injection[J]. Surface and Coatings Technology, 2006, 201(3/4): 1655-1659.

[6] LIU De-jian, LI Li-qun, LI Fu-quan, CHEN Yan-bin. WCp/Fe metal matrix composites produced by laser melt injection[J]. Surface and Coatings Technology, 2008, 202(9): 1771-1777.

[7] 李松林, 向锦涛, 周伍喜, 李玉玺, 陈 文. 超音速火焰喷涂WC-10Co4Cr涂层的耐滑动磨损行为[J]. 中国有色金属学报, 2012, 22(5): 1371-1376.

LI Song-lin, XIANG Jin-tao, ZHOU Wu-xi, LI Yu-xi, CHEN Wen. Sliding wear behavior of high-velocity oxy-fuel sprayed WC-10Co4Cr coatings[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1371-1376.

[8] ZHOU Sheng-feng, ZENG Xiao-yan. Growth characteristics and mechanism of carbides precipitated in WC-Fe composite coatings by laser induction hybrid rapid cladding[J]. Journal of Alloys and Compounds, 2010, 505(2): 685-691.

[9] TOBAR M J,  A. Morphology and characterization of laser clad composite NiCrBSi-WC coatings on stainless steel[J]. Surface and Coatings Technology, 2006, 200(22/23): 6313-6317.

A. Morphology and characterization of laser clad composite NiCrBSi-WC coatings on stainless steel[J]. Surface and Coatings Technology, 2006, 200(22/23): 6313-6317.

[10] ZHONG Min-lin, LIU Wen-jin, YAO Ke-fu, GOUSSAIN J C, MAYER C, BECKER A. Microstructural evolution in high power laser cladding of Stelllite 6+WC layers[J]. Surface and Coatings Technology, 2002, 157(2/3): 128-137.

[11] 王智慧, 杨爱弟, 贺定勇, 蒋建敏. 真空熔覆镍基合金涂层中碳化钨颗粒转变行为[J]. 稀有金属材料与工程, 2008, 37(10): 1869-1871.

WANG Zhi-hui, YANG Ai-di, HE Ding-yong, JIANG Jian-min. The transformation of WC in Ni-based alloy coating by vacuum melting[J]. Rare Metal Materials and Engineering, 2008, 37(10): 1869-1871.

[12] 周 玉. 材料分析方法[M]. 北京: 机械工业出版社, 2004: 1-331.

ZHOU Yu. Materials analysis methods[M]. Beijing: China Machine Press, 2004: 1-331.

[13] 王国栋. 硬质合金生产原理[M]. 北京: 冶金工业出版社, 1988: 1-390.

WANG Guo-dong. Fundamentals of cemented carbides[M]. Beijing: Metallurgical Industry Press, 1988: 1-390.

[14] BERGER L M, SAARO S, NAUMANN T,  Influence of feedstock powder characteristics and spray processes on microstructure and properties of WC-(W,Cr)2C-Ni hardmetal coatings[J]. Surface and Coatings Technology, 2010, 205(4): 1080-1087.

Influence of feedstock powder characteristics and spray processes on microstructure and properties of WC-(W,Cr)2C-Ni hardmetal coatings[J]. Surface and Coatings Technology, 2010, 205(4): 1080-1087.

[15] POWELL G L F, CARLSON R A, RANDLE V. The morphology and microtexture of M7C3 carbides in Fe-Cr-C and Fe-Cr-C-Si alloys of near eutectic composition[J]. Journal of Materials Science, 1994, 29(18): 4889-4896.

[16] 叶大伦, 胡建华. 实用无机热力学数据手册[M]. 北京: 冶金工业出版社, 2002: 1-1210.

YE Da-lun, HU Jiang-hua. Practical inorganic thermodynamics data handbook[M]. Beijing: Metallurgical Industry Press, 2002: 1-1210.

[17] 王淑峰, 李惠琪, 迟 静, 李 敏, 柴 禄, 许 慧. 等离子原位冶金复合碳化钨合金组织特性与结晶机理研究[J]. 材料工程, 2011(8): 72-76.

WANG Shu-feng, LI Hui-qi, CHI Jing, LI Min, CHAI Lu, XU Hui. Microstructure and crystallization mechanism of composite WC alloy produced by plasma in-situ metallurgy[J]. Journal of Materials Engineering, 2011(8): 72-76.

[18] DMITRII V S, IGOR R S, ALEXANDER L I. Structural, electronic properties and stability of tungsten mono- and semi-carbides: A first principles investigation[J]. Journal of Physics and Chemistry of Solids, 2009, 70(1): 64-71.

[19] 黄 新, 孙亚丽, 颜 杰, 唐 凯, 刘清才, 何宪峰, 李 伟. 两步碳化法生产优质粗颗粒WC粉末[J]. 中国钨业, 2007, 22(6): 39-42.

HUANG Xin, SUN Ya-li, YAN Jie, TANG Kai, LIU Qing-cai, HE Xian-feng, LI Wei. The synthesis of high quality coarse WC powder by two-step carbonization[J]. China Tungsten Industry, 2007, 22(6): 39-42.

[20] HERBER R P, SCHUBERT W D, LUX B. Hardmetals with rounded WC grains[J]. International Journal of Refractory Metals and Hard Materials, 2006, 24(5): 360-364.

[21] 胡汉起. 金属凝固原理[M]. 北京: 机械工业出版社, 2000: 1-196.

HU Han-qi. Fundamentals of metal solidification[M]. Beijing: China Machine Press, 2000: 1-196.

[22] LAY S, DONNADIEU P, LOUBRADOU M. Polarity of prismatic facets delimiting WC grains in WC-Co alloys[J]. Micron, 2010, 41(5): 472-477.

[23] 陈 瑶, 王华明. MC碳化物非平衡凝固液/固界面结构及生长机制[J]. 金属学报, 2003, 39(3): 254-258.

CHEN Yao, WANG Hua-ming. Liquid/solid interface structure and growth mechanism of MC carbide under non-equilibrium solidification conditions[J]. Acta Metallurgica Sinica, 2003, 39(3): 254-258.

[24] GU Dong-dong, MEINERS W. Microstructure characteristics and formation mechanisms of in situ WC cemented carbide based hardmetals prepared by selective laser melting[J]. Materials Science and Engineering A, 2010, 527(29/30): 7585-7592.

(编辑 陈卫萍)

基金项目:青岛市科技发展计划项目(12-1-4-6-(4)-jch);山东省博士基金资助项目(BS2010CL038)

收稿日期:2012-07-26;修订日期:2012-12-25

通信作者:迟 静,讲师,博士研究生;电话:0532-86057927;E-mail:chijing79@163.com