DOI: 10.11817/j.issn.1672-7207.2016.06.008

触变模锻Al-7%Si/Al-30%Si合金双金属的数值模拟

黄宏华,杨昭,王光旭,史晓成,贺小龙

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:采用有限元软件DEFORM-3D对半固态模锻Al-7%Si/Al-30%Si(质量分数,下同)合金复合材料过程进行数值模拟,研究复合成形过程双金属坯料的充型特征,同时探讨工艺参数对复合成形的影响规律。模拟结果表明:单金属触变模锻具有整体性变形特征,双金属触变模锻充型性能受界面传力影响,其非动模侧充型能力比单金属的弱;随着下坯料初始温度提高,界面传力增强,底部充型能力增强;下坯料初始温度过高,会导致复合界面偏靠下侧、弯曲程度大、底部出现飞边;坯料与模具之间的摩擦因素越大,复合界面弯曲和边部向上倾斜越严重;Al-7%Si和Al-30%Si合金初始温度分别为585 ℃和575 ℃,当坯料与模具之间摩擦因数较小时,上、下坯料变形协调,锻件充型饱满,复合界面水平居中,双金属模锻复合效果良好。

关键词:半固态成形;双金属复合;触变模锻;数值模拟;DEFORM-3D软件

中图分类号:TG316.3 文献标志码:A 文章编号:1672-7207(2016)06-1872-06

Numerical simulation of thixo-forging Al-7%Si/Al-30%Si alloys bimetal

HUANG Honghua, YANG Zhao, WANG Guangxu, SHI Xiaocheng, HE Xiaolong

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The forming process of thixo-forging Al-7%Si/Al-30%Si alloy composite in the semi-solid state was simulated by finite element software DEFORM-3D.The filling characteristics of bimetal billets in the composite forming process and the effects of process parameters on composite forming were investigated. The results show that single metal thixo-forging has integrity forming feature. And the filling capacity of bimetal thixo-forging is greatly affected by the efficiency of the stress transfer through interface, which results in the fact that the filling capacity of the bottom billet on the opposite side of moving die is worse than that of the single metal. The filling capacity of bottom billet would improve with the increase of the initial temperature of bottom billet or the efficiency of the stress transfer. However, when the initial temperature of the bottom billet is too high, the interface will deviate to bottom die and bend badly, and flash will appear on the bottom. The greater the friction coefficient between billets and molds, the more serious the composite interface bends and edge tilts upward. When the initial temperatures of Al-7%Si alloy and Al-30%Si alloy are 585 ℃ and 575 ℃, respectively, and the friction coefficients between billets and dies are small, top and bottom billets are deformed harmonically, forged pieces fill fully, interface of composite is well located in the center of the work pieces. The filling character is good.

Key words: semi-solid forming; bimetal composite; thixo-forging; numerical simulation; DEFORM-3D software

双金属复合材料既可以克服2种金属材料本身的不足,又能发挥2种金属材料的优点,其不同部位能实现不同的性能,被越来越多地应用于航空、航天、机械、化工、电力和电子等工业领域[1-3]。Al-7%Si(质量分数,下同)合金属于亚共晶铝硅合金,其综合力学性能好,耐腐蚀性能强,特别是抗疲劳性能优异,常用于汽车汽缸、悬挂件、活塞曲臂、轮毂等[4];Al-30%Si合金属于过共晶铝硅合金,其膨胀系数小,耐磨性好,具有很好的导热性能,在活塞等耐磨件和电子封装材料上有广泛用途[5-6]。半固态成形技术具有金属流动性好、变形力小、锻件性能优良等诸多优点,可以实现近净成形薄壁复杂零件[7-8]。利用半固态成形方法制备亚/过共晶铝硅合金双金属复合材料,可获得集亚、过共晶铝硅合金优点于一体的高性能、高精度产品[9],例如外形复杂的高性能轻质耐磨制动片,高导热、高尺寸稳定性的导电散热元件,外科用高强耐磨活动支架部件等。双金属坯料在半固态成形过程中流动行为复杂。由于成形时间极短,不易进行观察分析,还没有实验对双金属半固态成形过程进行有效观察。随着有限元技术的迅速发展,可利用数值模拟方法研究坯料在半固态成形过程中的温度场、应力场、应变场等分布规律,预测其充型行为和优化工艺参数等,为观察双金属复合流体流动研究提供了有力工具。唐培 等[10]采用DEFORM-2D模拟软件研究了半固态A356铝合金在微凸台阵列触变成形过程中的流动特性和充型行为,分析了触变成形工艺参数和模具结构参数对微凸台阵列充型效果的影响。杜艳梅等[11]采用ABAQUS有限元软件对Al/Mg双层复合管在半固态多坯料挤压工艺下进行数值模拟研究,确定了界面比为3:7时的挤压速度和初始温度,优化了挤压模具,同时结合速度分析了结合界面的结合情况。然而,半固态触变模锻双金属复合材料的数值模拟研究还未见报道。DEFORM-3D软件提供一个方便的材料特性输入接口窗口,同时它能很好地模拟双金属变形。这些功能赋予它具备分析半固态成形Al-7%Si/Al-30%Si合金双金属制品坯料流动行为的能力。工艺参数对半固态双金属的模锻复合至关重要,如2种坯料的初始温度决定各自的固液相率,若控制不好,则将引起双金属变形抗力悬殊大、变形不协调,导致最终充填不完全、复合界面情况差等不良后果。本文作者利用DEFORM-3D体积成形软件,对半固态触变模锻双金属复合材料的成形规律进行研究,对不同坯料初始温度、摩擦因数下的半固态模锻复合成形进行模拟和比较,以便为制定优异的工艺参数提供依据。

1 有限元模型的建立

1.1 材料模型的建立

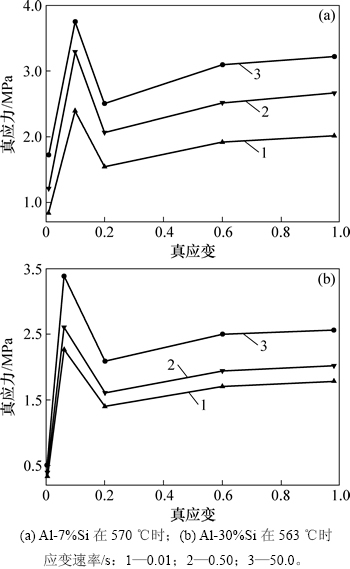

铝合金半固态材料流变应力没有十分确切的函数表达式,随着固相率或剪切速率的改变,真应力-应变曲线呈现不同的变化趋势。在一般情况下,当温度和应变速率都确定时,随着应变增加,应力先迅速增至1个极大值,然后稍有下降至1个极小值,最后又持续而缓慢地上升。本文借鉴KANG等[12-13]的研究结果,获得Al-7%Si合金的真应力-应变曲线。经过修整,选取曲线中极大值、极小值等几个关键点,导入DEFORM-3D软件材料库,得到不同温度时不同应变速率下的真应力-应变曲线,如图1(a)所示。借鉴HOGG等[14]的研究结果,经过类似修整得到Al-30%Si合金在不同温度时不同应变速率下的真应力-真应变曲线,部分曲线如图1(b)所示。

图1 使用者数据库中的真应力-真应变曲线

Fig. 1 True stress-true strain curves in user’s database

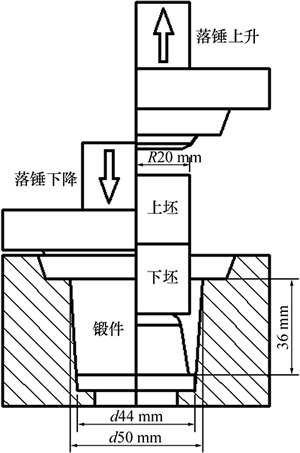

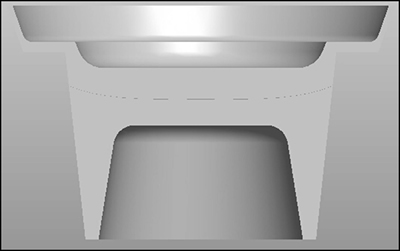

1.2 几何模型的建立

实体模型通过Pro/E三维造型软件建立和装配,保存为“.stl”格式,然后通过前处理器中的模型输入接口导入得到有限元软件中的三维实体模型。2种坯料工件的尺寸均为直径×高为40 mm×26 mm的圆柱体。半固态模锻双金属的示意图如图2所示,右边为锻压前的状态,左边为锻压结束时的状态。最后的锻件剖面效果图如图3所示。

图2 触变模锻双金属示意图

Fig. 2 Schematic diagram of thixo-forging bimetal

图3 锻件剖面效果图

Fig. 3 Working sketch of forged piece’s section

1.3 模拟参数的设定

为了简化数值模拟过程中的有限元模型,进行如下假设:1) 当坯料在感应加热终了时,温度均匀分布,几乎没有温度梯度[15];2) 感应加热后的坯料主要由液相和球化的固相颗粒组成,流动性较好,可视为各向同性的均匀材料[16]。Al-7%Si合金固相率可用SCHEIL公式[17]算得,其在585 ℃时固相率为0.45,半固态加工性能较好。半固态成形过程中Al-30%Si合金固相率与温度之间是一种非平衡态关系,不能用SCHEIL公式进行推导,引用HOGG等[15]的实验结果。设定上坯料Al-7%Si合金的初始温度为585 ℃,下坯料Al-30%Si合金的初始温度分别为580,575和570 ℃,进行模拟比较。

将材料属性设置为多孔性,模具属性设置为刚性。网格划分选用相对形式,上、下圆柱体坯料划分网格均为8 000个。由于变形坯料有2个,坯料与坯料之间又有相互作用,成形过程计算比单金属复杂很多,本文选用稀疏矩阵迭代法,既能保证模拟能顺利完成,又能缩减计算时间。上模锻压速度为200 mm/s,模具温度为300 ℃。坯料与模具之间的传热因子为11 N/(s·mm·℃),上、下坯料之间的传热因子为15 N/(s·mm·℃)。上、下坯料之间的摩擦方式设为常数剪切摩擦,摩擦因数为0.3。坯料与模具之间的摩擦方式也设为常数剪切摩擦,摩擦因数分别为0.1,0.3和0.5,进行模拟比较。

2 数值模拟结果分析

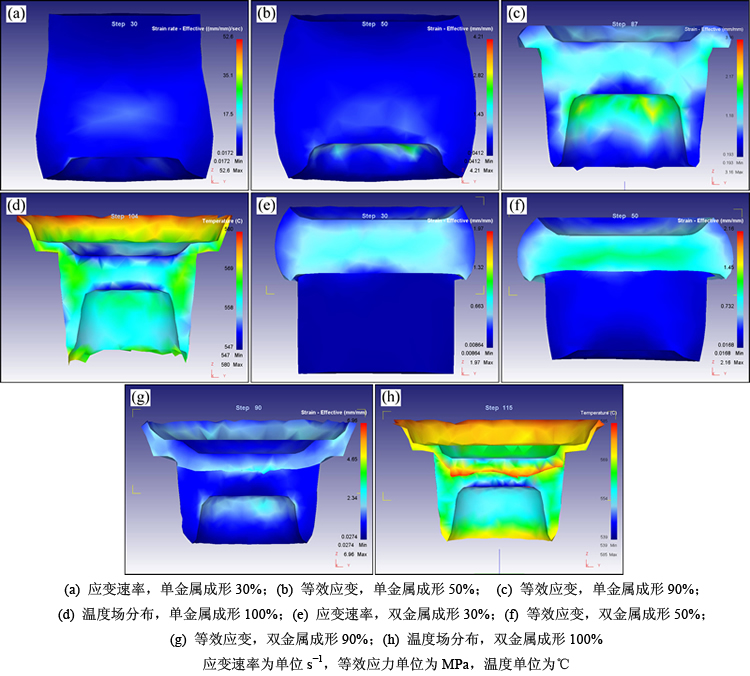

2.1 单、双金属模锻成形过程比较

图4(a)~(e)所示为单金属模锻成形过程剖面图,图4(f)~(j)所示为双金属模锻成形过程剖面图。单金属模锻坯料为Al-7%Si合金,初始温度为580 ℃,坯料与模具之间摩擦因数为0.3。双金属模锻上坯料为Al-7%Si合金,下坯料为Al-30%Si合金,初始温度分别为585 ℃和575 ℃,坯料与模具之间摩擦因数为0.3。

变形开始时,单金属模锻坯料下部先变形;成形30%时,坯料上部的应变速率比下部小很多,变形也很微小;成形50%时,坯料中部扩径变形明显,坯料上部的等效应变较小;成形70%时,坯料下部充填完成接近一半,而上部充填才刚开始;成形90%时,坯料下部已经充填饱满,上部充填却还远远不足;成形完成时,锻件上部勉强充满,下部有飞边产生。双金属模锻特征与单金属截然不同,处于上部的上坯料优先变形。成形30%时,上坯料开始向上充填,下坯料的变形速率远远比上坯料的小;成形50%时,上坯料等效应变比下坯料大得多;成形70%时,二者的等效应力整体相差不大,彼此变形趋向协调、同步;成形90%时,上坯料等效应变整体比下坯料稍大,但是二者纵向充填的进度差不多;成形完成时,锻件上、下部充填饱满,几乎没有飞边产生。

比较半固态单金属模锻和双金属模锻得知:单金属触变模锻具有整体性变形特征,整体充型能力强。双金属模锻则兼具了半固态成形的共性和双金属模锻复合的特性,即上、下坯料极软,彼此变形相对独立。上坯料本身变形抗力低,又直接受到上模的锻压作用,变形非常容易;锻压力经过上坯料间接传给下坯料,使得下坯料成形相对困难。双金属触变模锻非动模侧的充型能力比单金属的弱。

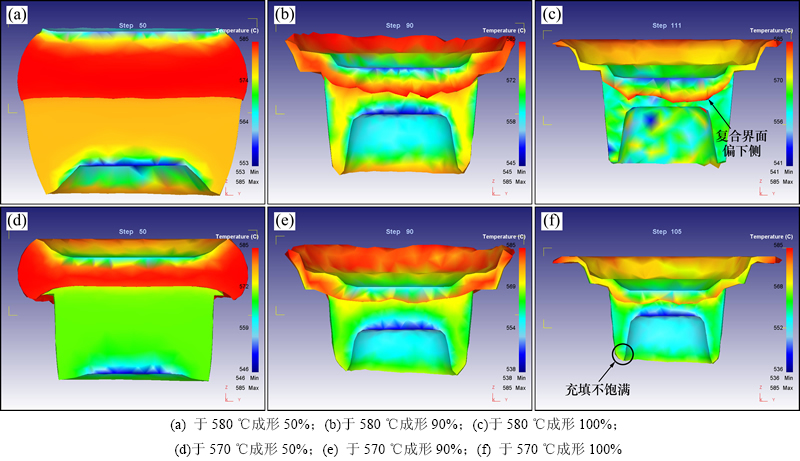

2.2 不同下坯料初始温度对模锻复合成形的影响

固液相率是影响半固态金属加工性能的关键因素,因此,二次加热温度的合理选取至关重要。图5(a)~(c)和图5(d)~(f)所示分别为下坯料初始温度 580 ℃和570 ℃时不同压下量下锻件的温度场剖面图,上坯料初始温度为585 ℃,坯料与模具之间的摩擦因数为0.3。

当下坯料初始温度为580 ℃时,成形开始,上、下坯料几乎同时变形;成形50%时,下坯料竖直向下充填了大约1/3,而上坯料竖直向上充填还未开始;成形90%时,下坯料几乎充填饱满,而上坯料才充填3/4左右;成形结束时,锻件底部有飞边出现,复合界面偏靠下侧、弯曲程度大。当下坯料初始温度570 ℃时,成形开始,上坯料优先变形;成形50%时,上坯料竖直向上充填大约1/4,而下坯料才稍有竖直向下充填的趋势;成形90%时,上坯料充填差不多完全,而下坯料充填还不到3/4;成形结束时,制品底部充填不饱满,顶部飞边较多,复合界面稍微偏靠上侧。

分析结合下坯料初始温度575 ℃结果(图4)可得:下坯料初始温度过高(580 ℃),相应地上坯料固相率相对高,变形抗力相对大,成形困难;上模的锻压力容易通过上坯料传递给下坯料,使得下坯料变形容易;下坯料初始温度过低(570 ℃),相应地上坯料固相率低,变形抗力小,成形容易,上模的锻压力难以通过上坯料传递给下坯料,使得下坯料变形困难。由图5(b),4(i)和5(e)可以看出:随着下坯料初始温度下降,成形90%时锻件下部充填越来越少,上部充填越来越多。这说明下坯料初始温度越高,界面传力效果越好,锻件下部充型能力越强。另一方面,下坯料初始温度过高会导致复合界面偏靠下侧、弯曲程度大和底部出现飞边等不良后果。当下坯料初始温度选取575 ℃时,成形初期上坯料变形比下坯料稍快,慢慢地二者充填速度渐趋同步,最后锻件底部、顶部都充填饱满,复合界面居中,无飞边。

图4 单、双金属模锻成形过程剖面图

Fig. 4 Sections of single metal and bimetal during die forging process

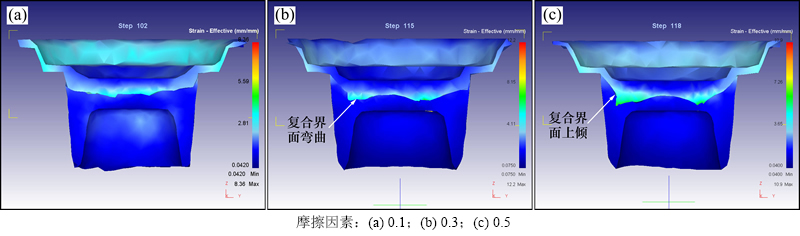

2.3 坯料与模具之间的摩擦因数对模锻复合成形的影响

摩擦因数是影响金属半固态触变模锻性能的1个重要因素,合适的摩擦因素是充型饱满、复合界面情况良好、飞边少等的保障。图6(a),(b)和(c)所示为坯料与模具之间的摩擦因素分别为0.1,0.3和0.5成形完成时锻件的等效应变场剖面图。上坯料初始温度为585 ℃,下坯料初始温度为575 ℃。由图6可以看出:随着坯料和模具之间的摩擦因素增大,复合界面由原来的水平面状转为上下起伏的波浪状,并且弯曲程度越来越大;复合界面边部向上倾斜角度也逐渐增大,如图6中箭头所指处。这是由于摩擦因素增大,模具对坯料流动的阻碍增强,尤其是对下坯料竖直向下流动的阻碍更明显。下坯料受到凹模内壁表面和型芯模侧壁表面摩擦阻力的共同作用,使得其向下充填时中间流动快两侧流动慢,导致复合界面发生弯曲,边部向上倾斜。又由于型芯模侧壁倾斜方向与凹模内壁相反,与凹模内壁相比,型芯模阻碍金属向下流动作用小,因此,凹模给予的摩擦阻碍作用更显著,使得复合界面两侧向上倾斜角度更大。故随着摩擦因素增大,阻碍作用越明显,复合界面呈波浪线状弯曲得更严重,两侧向上倾斜角度也越大。

图5 不同下坯料初始温度下成形过程锻件的剖面图

Fig. 5 Sections of forged pieces during forming process at different initial temperatures of bottom billets

图6 不同坯料与模具之间摩擦因素下锻件的剖面图

Fig. 6 Sections of forged pieces under different friction coefficients between billets and dies

3 结论

1) 单金属触变模锻具有整体性变形特征,整体充型能力好;双金属触变模锻则兼具了半固态成形的共性和双金属模锻复合的特性,上、下坯料极软,彼此变形相对独立,但受接触界面传力的影响,其非动模侧的充型能力比单金属的弱。

2) 下坯料初始温度过高,锻压力易于通过上坯料传给下坯料,下坯料充填速度比上坯料快得多,锻件复合界面偏靠下侧、弯曲程度大,底部出现飞边;下坯料初始温度过低,锻压力难于通过上坯料传给下坯料,下坯料充填速度比上坯料的充填速度慢得多,最终锻件底部稍有未充满、复合界面偏靠上侧,顶部飞边多。

3) 随着坯料与模具之间的摩擦因素增大,凹模和型芯模表面阻碍下坯料流动的作用越显著,导致复合界面发生弯曲起伏的程度增大,边部向上倾斜的角度也增大。

4) Al-7%Si合金初始温度为585 ℃,Al-30%Si合金初始温度为575 ℃、坯料与模具之间摩擦因素较小时,上、下坯料变形协调,锻件充型饱满,复合界面水平居中,双金属触变模锻复合效果良好。

参考文献:

[1] BULENT K, MUSTAFA U. Interfacial microstructure of diffusion bonded inconel 738 and ferritic stainless steel couple[J]. Journal of Material Science & Technology, 2009, 25(4): 527-530.

[2] NAKANO J, MIWA Y, TSUKADA T, et al. Characterization of 316L(N)IG SS joint produced by hot isostatic pressing technique[J]. Journal of Nuclear Materials, 2002, 307: 1568-1572.

[3] 周俊杰, 庞玉华, 苏晓莉, 等. 金属层状复合技术的研究现状与发展[J]. 材料导报, 2005, 19(11): 300-303.

ZHOU Junjie, PANG Yuhua, SU Xiaoli, et al. Development of manufacturing technology for layer-metal composite plate[J]. Materials Review, 2005, 19(11): 300-303.

[4] JACOBSON D M. Spray-formed silicon-aluminum[J]. Advanced Materials & Processes, 2000, 157(3): 36-39.

[5] 杨伏良, 易丹青. Al-Si合金粉末的高能球磨及其表征[J]. 中南大学学报(自然科学版), 2008, 39(1): 29-34.

YANG Fuliang, YI Danqing. High-energy ball milling and characterization of Al-Si alloy powders[J]. Journal of Central South University (Science and Technology), 2008, 39(1): 29-34.

[6] KIM H J. Effect of calcium on primary silicon particle size in hypereutectic Al-Si alloys[J]. Materials Science and Technology, 2003, 19(7): 915-918.

[7] YANG Zhao, DONG Jianxiong, ZHOU Li, et a1. A study of the method of manufacturing bimaterial composite parts through semisolid metal processing[J]. Metallurgical and Materials Transactions A, 2011, 42(6): 1709-1716.

[8] YANG Zhao, ZHOU Li, DONG Jianxiong. Observation of interface of two kinds of bi-metal composite parts prepared by thixo-forging[J]. Trans Nonferrous Met Soc China, 2010, 20(9): 1579-1584.

[9] LI Tianbao, YANG Zhao, LI Bing, et al. Mechanical properties of hypo/hyper-eutectic Al-Si bi-metal composite parts prepared by thixo-forging[J]. Solid State Phenomena, 2013, 192/193: 95-100.

[10] 唐培, 梅德庆, 姚喆赫, 等. 半固态A356铝合金微凸台阵列触变成形充型过程数值模拟[J]. 中国有色金属学报, 2012, 22(12): 3334-3341.

TANG Pei, MEI Deqing, YAO Zhehe, et al. Numerical simulation of carity-filling procedures for micro-pin- finarray thixoforming with semi-solid A356 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3334-3341.

[11] 杜艳梅, 王开坤, 张鹏, 等. 半固态挤压铝/镁合金双金属复合管的有限元模拟[J]. 中国有色金属学报, 2009, 19(2): 208-216.

DU Yanmei, WANG Kaikun, ZHANG Peng, et al. FEM simulation on extrusion of double-layer tube of aluminum and magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(2): 208-216.

[12] KANG C G, CHOI J S, KIM K H. The effect of strain rate on macroscopic behavior in the compression forming of semi-solid aluminum alloy[J]. Journal of Materials Processing Technology, 1999, 88: 159-168.

[13] LIU T Y, ATKINSON H V, KAPRANOS P, et al. Rapid compression of aluminum alloys and its relationship to thixoformability[J]. Metallurgical and Materials Transactions A, 2003, 34(7): 1545-1554.

[14] HOGG S C, ATKINSON H V, KAPRANOS P. Semi-solid rapid compression testing of spray-formed hypereutectic Al-Si alloys[J]. Metallurgical and Materials Transactions A, 2004, 35(3): 899-910.

[15] TANG Pei, MEI Deqing, ZHOU Honghua, et al. Experimental study on the reheating process for A356 alloy in thixoforming[J]. Advanced Materials Research, 2011, 154/155: 1324-1329.

[16] KANG C G, YOUN S W, SEO P K. The effect of globular microstructure size on the mechanical properties in reheating process of aluminum alloys[J]. Journal of Materials Engineering and Performance, 2004, 13(2): 172-184.

[17] FLEMINGS M C. Behavior of metal alloys in the semisolid state[J]. Metallurgical Transactions A, 1991, 22(5): 957-981.

(编辑 陈灿华)

收稿日期:2015-06-15;修回日期:2015-08-18

基金项目(Foundation item):国家自然科学基金面上项目(51474241);中南大学中央高校基本科研业务费专项资金资助项目(2014zzts173)(Project (51474241) supported by the National Natural Science Funds; Project(2014zzts173) supported by the Fundamental Research Funds for the Central Universities in Central South University)

通信作者:杨昭,博士(后),副教授,从事半固态成形研究;E-mail:zyang@csu.edu.cn