中国有色金属学报 2004,(10),1677-1682+6-7 DOI:10.19476/j.ysxb.1004.0609.2004.10.010

铝型材推弯工艺

杨玉英

哈尔滨工业大学材料科学与工程学院,哈尔滨工业大学材料科学与工程学院 哈尔滨150001 ,哈尔滨150001

摘 要:

通过铝型材圆环的推弯实验, 研究了推弯工艺原理、变形过程, 结合有限元模拟得到了和实验结果相吻合的型材厚度分布、成形零件卸载回弹后的曲率半径及型材截面畸变。结果表明:推弯零件曲率及截面畸变一致性高, 成形模具结构简单且便于调整, 数值模拟可以用于推弯工艺的优化分析。

关键词:

铝型材;推弯工艺;数值模拟;

中图分类号: TG386

收稿日期:2004-03-17

Push-bending process of aluminum profile

Abstract:

The push-bending process of aluminum profile was investigated experimentally and numerically. The technical principle and deformation process were researched. The thickness distribution, the curvature after unload and the section distortion of push-bending parts were gotten. The results show that the curvature consistence and section distortion consistence of push-bending parts are high. The forming die is simple and the adjustment is convenient, and the numerical simulation represents the observed response in the laboratory tests fairly well.

Keyword:

aluminum profile; push-bending process; numerical simulation;

Received: 2004-03-17

型材推弯工艺即借助简单的模具 (模具尺寸远小于零件尺寸) , 在型材轴向施压, 毛坯沿轴向逐点逐渐成形, 能够制造其它方法难以成形的复杂形状零件 (例如360°型材圆环) 。 由于推弯成形易于实现零件制造的轻量化、 强韧化、 高效和低耗, 而必将在汽车门框及窗框、 摩托车刹车板及缓冲器、 航空及机械结构件制造业有广泛的应用。 对于传统型材弯曲成形, 文献

[

1,

2]

对压弯、 文献

[

3]

对绕弯、 文献

[

4,

5]

对拉弯、 文献

[

6]

对滚弯等型材弯曲工艺进行了详细的研究, 文献

[

7,

8,

9,

10,

11]

对截面型材诸如压弯、 绕弯、 拉弯、 滚弯等成形工艺进行了综合分析和评述。

推弯工艺与其它弯曲工艺相比, 模具结构简单, 曲率一致性好, 能成形更为复杂的结构件。 但是推弯成形过程中包含复杂截面型材的弹性—塑性—弹性变形过程, 变形机理复杂, 毛坯截面形状、 尺寸、 毛坯长度、 成形件曲率半径、 模具间隙及润滑等参数均对成形过程产生影响, 因此难以用解析关系式描述成形过程。 若完全由实验来确定相关工艺参数, 则会造成较大的实验消耗及增加生产成本, 因而将实验和有限元数值模拟结合起来, 无疑对推弯工艺的研究与应用有较大的指导作用。

本文作者在同一模具上试验研究了2种截面铝型材推弯成形, 研究了推弯工艺原理、 变形过程、 推弯力—行程曲线、 曲率回弹、 截面畸变, 并对推弯过程及曲率回弹和截面畸变进行了数值模拟, 试验结果和有限元数值模拟结果有较好的一致性。

1 推弯工艺实验

1.1 推弯工艺与原理

图1所示为型材推弯成形原理, 型材在轴向压力p作用下, 被推入浮动导向装置内, 经过动轮和扇形静轮之间的导正型槽, 进入靠模与扇形静轮间的圆弧弯曲型槽, 在型槽的强制作用下连续将型材推出。 塑性变形区集中在弯曲型槽内, 型材毛坯逐点稳定变形。 随着型材连续推出, 其始端由推顶机构逐渐顶起, 使连续推出的型材圆环以小螺旋上升, 当推出型材圆环位置靠近扇形静轮上部时, 型材圆环螺旋上升形成的辟让空间可以越过扇形静轮, 既象卷弹簧一样将原为平直的型材坯料逐渐卷弯成卷簧状, 转过360°后, 退回推顶机构, 取下工件, 卷簧状零件自动卸载回弹为平直的型材圆环。 型材毛坯推弯需经历弹性—塑性—弹性的变形过程。

图1 推弯成形原理

Fig.1 Mechanism of push-bending process

推弯工艺实验在WD-1C型电子万能实验机上进行, 通过该试验机可以测量推弯力—行程曲线。 成形材料力学性能如表1所示。 成形零件如图2所示, 其截面形状尺寸如图3所示, 零件外径均为d 153 mm。

1.2 工艺分析

分析图4所示推弯力—行程曲线, 可将推弯变形过程分为3个阶段: 在压头作用下, 型材在导正型槽内作刚性平移至圆弧弯曲型槽入口处, 型材毛坯克服摩擦而使推弯力略有上升; 型材进入圆弧弯曲型槽, 在型槽约束下产生弯曲塑性变形, 随着压头下行, 变形区域不断扩大, 直至型材流过圆弧弯曲型槽为止, 为克服型材弯曲变形及其与型槽的摩擦, 推弯力上升达到最大值; 型材逐点经过圆弧弯曲型槽后进入自由悬空时为稳定变形阶段, 塑性变形和摩擦区域不再扩大, 推弯力基本达到稳定状态。 由图4所示的推弯力—行程曲线可知, 润滑可以使推弯力显著降低。

表1 材料力学性能

Table 1 Mechanical properties of material

| E/MPa |

υ |

σ0.2/MPa |

σb/MPa |

n |

r |

70 000 |

0.33 |

83.89 |

96.28 |

0.046 |

0.7

|

推弯成形是型材弯曲的一种加工方法, 其特点是沿着型材推弯方向逐点逐渐成形。 型材由一端推入, 型材与圆弧弯曲型槽接触点逐渐增多, 随着推弯型材的不断推入, 型材表面与模具紧密接触并不断移动, 变形逐步向型材另一端扩展, 直至型材进入端与圆弧弯曲型槽脱离接触才进入稳定变形阶段, 此时变形区不再扩大。 推弯成形与模具压弯成形过程的一个重要区别在于模具压弯成形过程中, 型材与工具接触点数是递增的及交替变化的, 这将不利于型材曲率分布的均匀化和变形的均匀化。 而型材在推弯成形过程中与模具型槽始终保持接触, 因此型材截面受力状态在推弯过程中对每个截面都保持一致, 能够实现曲率分布的均匀化、 变形的一致性及回弹的均匀性。

推弯成形塑性变形区容易诱发外层拉应力开裂及内层压应力失稳起皱, 由于推弯件是在推力作用下成形, 型材内层受压应力作用失稳起皱的情况经常发生。 较小的间隙容易抑制起皱, 但间隙过小又可能使推弯力急剧上升, 使推入段毛坯失稳, 因此必须严格控制型槽与毛坯之间的间隙, 间隙的控制还必须考虑推弯件内层毛坯增厚的问题。 毛坯推入段容易诱发坯料失稳, 是否发生失稳主要取决于毛坯截面抗失稳刚度及推弯力。

曲率回弹和截面畸变是卸载后弹性应力释放引起的缺陷, 回弹量主要取决于型材截面几何尺寸、 材料力学性能、 模具几何尺寸和推弯力。 推弯成形最大的特点是毛坯逐点逐渐成形, 变形区域稳定, 属于稳定成形。 零件沿周边各点变形区的一致性, 使得卸载后零件的曲率和截面畸变一致性高, 这也是推弯成形的优势所在。 为此, 在推弯工艺模具设计阶段, 通过数值模拟优化确定模具的形状尺寸, 可以得到尺寸精度较高的成形件。

2 有限元数值模拟和分析

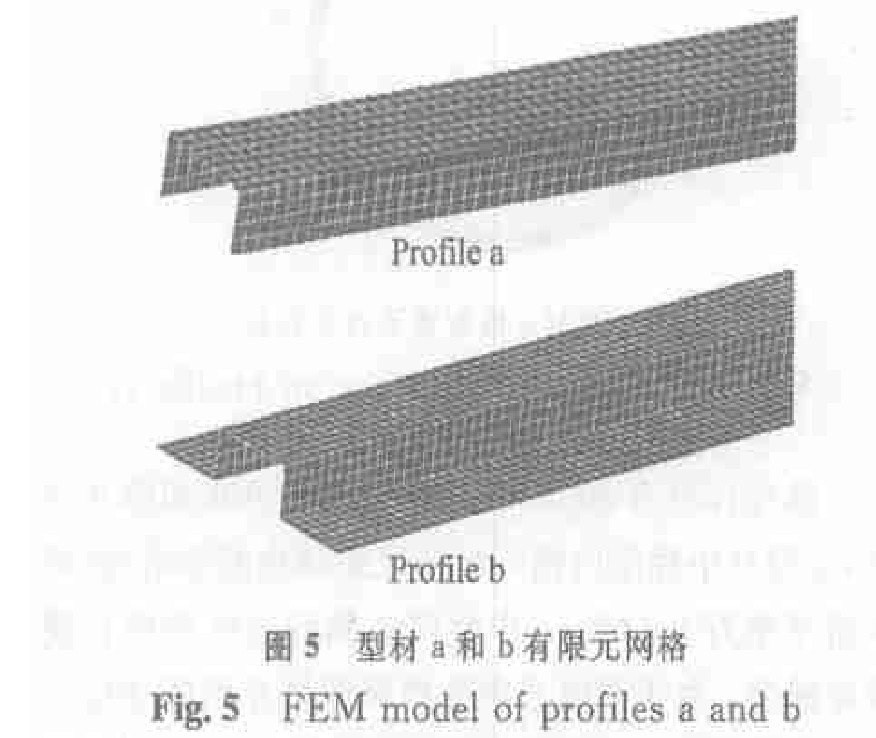

运用有限元软件PAM-STAMP2000对a和b两种截面型材推弯成形进行数值模拟, 采用的有限元模型如图5所示。 a型材截面尺寸由图3 (a) 给出, 长度取500 mm, 按1.5 mm×1.5 mm划分单元, 截面方向共16个单元, 长度方向共334个单元, 采用4节点Mindlin壳体单元进行描述, 高斯积分点为5个; b型材截面尺寸由图3 (b) 给出, 长度取500 mm, 按1.5 mm×1.5 mm划分成4节点Mindlin壳单元, 截面方向共30个单元, 长度方向共333个单元, 高斯积分点为5个。 将毛坯沿推弯方向置于动轮和靠模之间。 导向块、 动轮、 靠模及扇形静轮采用刚性体描述。 图6所示为a型材毛坯及模具有限元网格模型。

计算时应用Hill厚向异性等向强化屈服函数 (面内各向同性) :

式中 r为板厚方向异性指数。

纯铝材料性能参数由表1给出。

成形模拟中, 材料模型定义后, 检查模具型槽的法线方向, 并根据型材壁厚设定初始模具与型材之间的间隙; 虚拟推弯速度设定为3 m/s, 行程500 mm; 扇形静轮、 靠模和型材之间接触摩擦因数设为0.2, 导向块、 动轮和型材之间忽略摩擦作用。

在PAM-STAMP中将型材推弯过程分成2个阶段来模拟: 推弯成形和成形后的回弹。 其中, 成形后回弹的模拟是以成形模拟结果为基础的, 即需要读入前一步的结果文件。 模拟中采用显式算法和隐式算法相结合的方法, 推弯成形过程用动力显式算法, 而回弹采用静力隐式算法。

由图7型材a推弯成形过程的模拟可以看出, 有限元数值模拟能够很好的模拟推弯成形。

图7 型材a推弯成形过程模拟

Fig.7 Numerical simulation of profile a

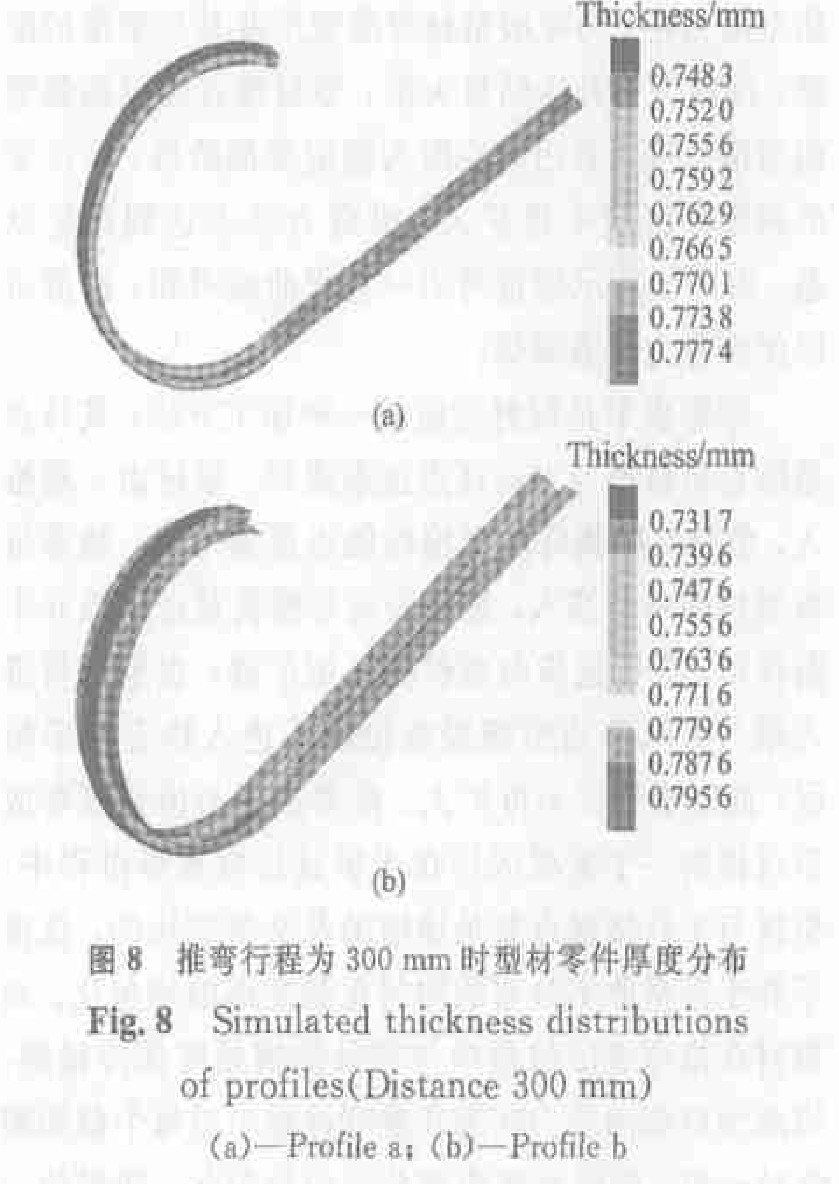

推弯行程为300 mm时型材厚度分布如图8所示, a型材中性层内侧纤维受压缩导致壁厚增加 (最大增厚率为4.14%) , 中性层外侧纤维受拉伸长使壁厚减薄, 由于圆弧弯曲型槽对型材外侧施加较大切向摩擦阻力, 有效地抑制了外侧切向伸长, 模拟得到的型材外侧厚度最大减薄率很小 (最大减薄率仅为0.71%) , 这和试验结果是一致的; b型材中性层内侧受压而使壁厚增加 (增厚率约为1.7%) , 中性层外侧受拉而变薄 (减薄率约为3.4%) , 这与实验测量结果相符。 由图8可见, 已变形区沿圆周方向各截面内层和外层板厚相同, 因此推弯成形沿圆周方向各点变形程度的一致性高。

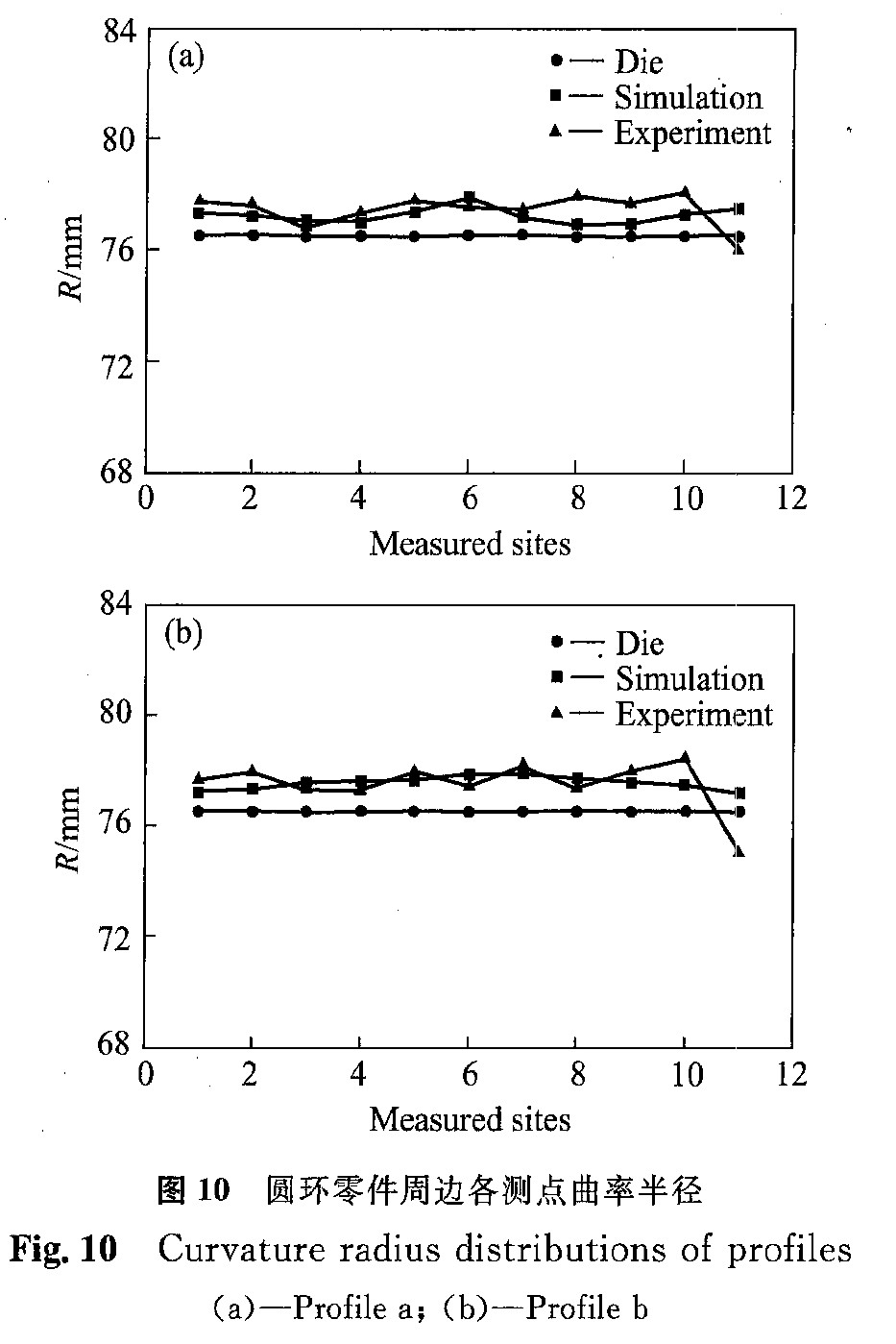

对回弹后曲率半径的测量, 本研究采用如下方法: 1) 用截面对称法截取型材, 获得对称截面线, 在截面上布置若干个测点, 如图9所示 (测点1, 2, …, 10, 11顺时针排列) ; 2) 根据不在同一直线上的3点定圆原理, 计算测点2的曲率半径时, 取相邻测点 (测点1和3) 进行求解。 图10给出了由PAM-STAMP静力隐式模块计算的回弹后曲率半径及实验测量的曲率半径沿周向的分布, 可以看出推弯成形回弹使曲率半径增大, 曲率半径增大幅度较小且沿环向有较好的一致性, 模拟和实测结果符合较好。

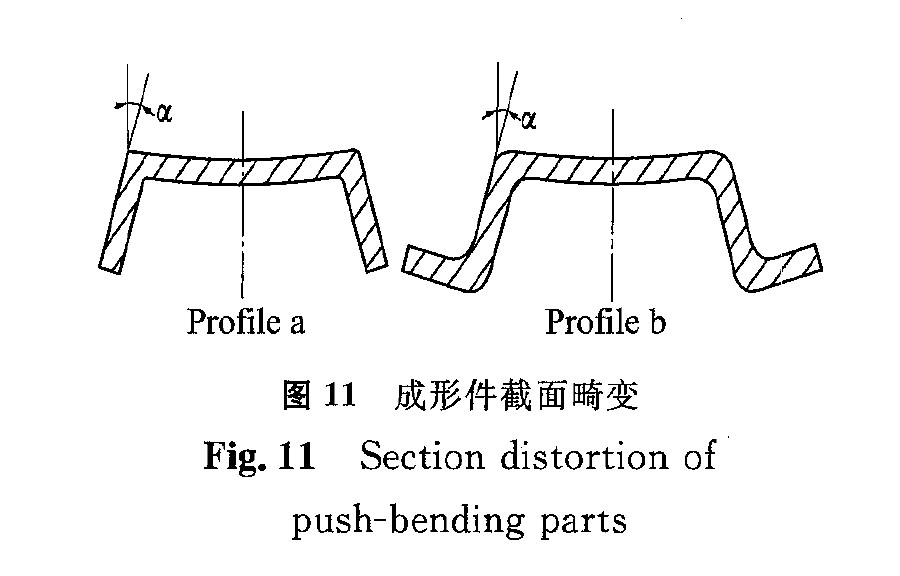

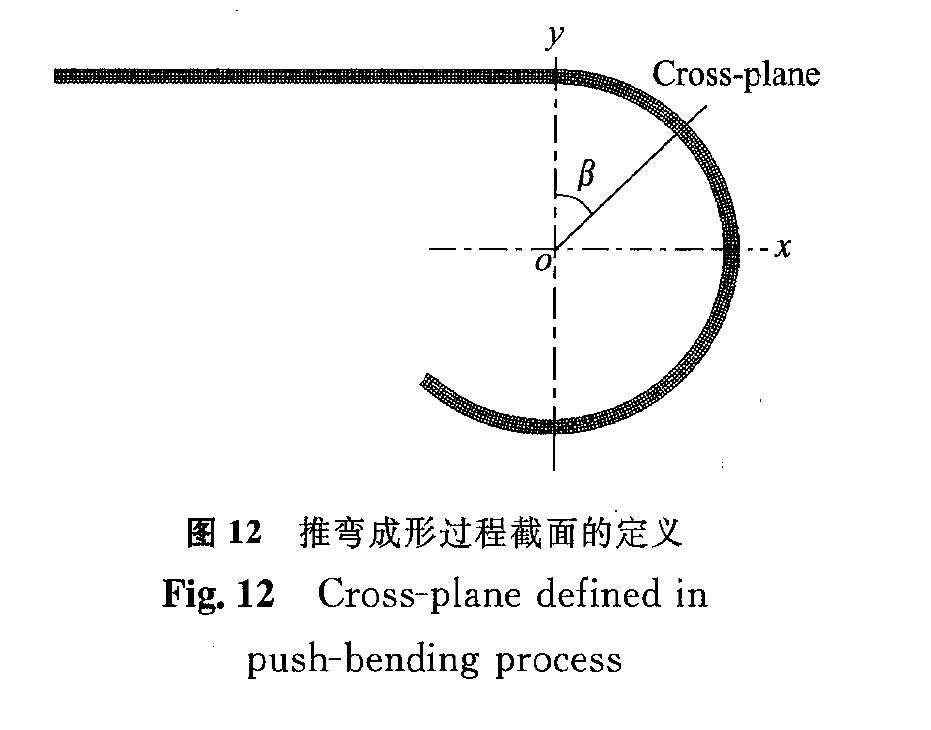

弯曲时, 距离中性层愈远的材料变形阻力愈大, 为了减小变形阻力, 材料有向中性层靠近的趋向, 造成如图11所示的截面畸变, 截面畸变程度由截面畸变角α来反映。 为了测量回弹后的截面畸变, 定义β截面为经过零件轴线o的平面顺时针转动β角度后所在位置, 如图12所示。 沿圆周方向取4个β截面 (β=45°, 90°, 135°及180°) , 测量截面畸变角α, 结果由表2给出。 可以看出畸变角很小, 说明沿零件周向一致性较好。

利用PAM-STAMP2000软件可以有效模拟推弯成形, 得到了和实验结果相一致的型材厚度分布、 成形零件卸载回弹后的曲率半径及截面畸变的变化规律, 而且可以对成形中可能出现的缺陷进行预测。 在推弯工艺模具设计阶段, 通过数值模拟优化确定模具的形状尺寸, 是控制回弹和截面畸变等缺陷最有效的方法。 这对于该工艺实际应用有着重要的意义。

表2 回弹后截面畸变角

Table 2 Section distortion after unload

Cross-

plane

positon,

β/ (°) |

Section distortion α/ (°) |

Profile a |

|

Profile b |

Simulated |

Experi-

mental |

Error/

% |

Simulated |

Experi-

mental |

Error/

% |

45 |

1.14 |

1.34 |

14.9 |

|

1.18 |

1.04 |

13.5 |

90 |

1.16 |

1.28 |

9.4 |

|

1.31 |

1.42 |

7.7 |

135 |

1.11 |

1.25 |

11.2 |

|

1.34 |

1.49 |

10.1 |

180 |

1.14 |

1.32 |

13.6 |

|

1.24 |

1.07 |

15.9 |

3 结论

1) 推弯工艺可以用于铝型材的成形加工。 推弯成形需经历弹性—塑性—弹性的变形过程, 其特点是沿着型材推弯方向逐点逐渐成形, 变形区稳定, 能够实现曲率分布的均匀化、 变形的一致性及回弹的均匀性。 卸载后推弯零件沿周向曲率和截面畸变一致性高。 良好的润滑能有效减小摩擦、 降低推弯力。

2) 利用有限元模拟方法研究了推弯成形过程, 得到了和实验结果相吻合的型材厚度分布、 成形零件卸载回弹后的曲率半径及截面畸变。 数值模拟可以用于推弯工艺的分析, 这对于该工艺实际应用有着重要的意义。

参考文献

[1] Perduijn A B, Hoogenboom S M. The pure bending of metal sheet[J]. Journal of Materials Processing Techology, 1995, 51:274 295.

[2] De Vin L J. Curvature prediction in air bending of metal sheet[J]. Journal of Materials Processing Technology, 2000, 100:257 261.

[3] LI Chun-feng, YANG Yu-ying. Research on the section distortion of hat-section profiles in rotary draw bending with stretching force[J]. Journal ofMaterialsProcessingTechnology, 1999, 94:41 44.

[4] Arild HC, Odd S H, Magnus L.Stretch bending of aluminium extrusions for car bumpers[J]. Journal of Materials Processing Technology, 2000, 102:241 248.

[5] El-domlaty A A, ELsharkawy A A. Stretch-bending analysis of U-section beams[J]. Int J Mach Tools Manufacture, 1998, 38:75 95.

[6] HuaM, BainessK, Cole IM. Bending mechanisms, experimental techniques and preliminary tests for the continuous four-roll plate bending process[J]. Journal of Materials Pro-cessing Technology, 1999, 48:159 172.

[7] Frank V, Axel S, Jurgen K, et al. Extrusion, channel, and profile bending:a review[J]. Journal of Materials Processing Technology, 1999, 87:1 27.

[8] Streppel AH, De Vin L J, Brinkman J, et al. Suitability of sheet bending modelling techniques in CAPP applications[J].J Mater Process Technol, 1993, 36:139 156.

[9] De Vin L J, Streppel A H, Singh U P, et al. A processmodel for air bending[J]. J Mater Process Technol, 1996, 57:48 54.

[10] Reid S R. Plastic deformation mechanisms in axially compressed metal tubes used as impact energy absorbers[J]. Int J Mech Sci, 1993, 35:1035 1052.

[11] 吴诗.冲压工艺学[M].西安:西北工业大学出版社