V-N微合金化抗震钢筋高温析出行为分析

吕煜坤,盛光敏,黄振华,薛昊飞

(重庆大学 材料科学与工程学院,重庆,400044)

摘要:采用应力松弛方法,以热动力学为基础研究钒氮(V-N)微合金化抗震钢筋在奥氏体中的应变诱导析出行为。根据J-M-A(Johnson-Mehl-Avrami)理论,结合热力学软件Thermo-Calc定量计算等温过程奥氏体析出热动力学,并与实验测得PTT(precipitation–time–temperature)曲线进行对比,讨论不同V和N质量分数对钢筋V(C,N)析出行为的影响。研究结果表明:高V和低V质量分数抗震钢筋都在870 ℃左右的鼻温区析出动力过程加快,大变形量可缩短析出开始时间,VN(0.04 V-0.0135 N)钢筋实测与计算PTT曲线吻合,采用VFe(0.076 V-0.005 5 N)钢筋计算PTT曲线应该考虑形变储能△Gs的作用。

关键词:V-N微合金钢;应力松弛;碳氮化物;析出

中图分类号:TG151.3 文献标志码:A 文章编号:1672-7207(2014)08-2596-07

Analysis on high-temperature precipitation behavior of V-N microalloyed anti-seismic rebars

L Yukun, SHENG Guangmin, HUANG Zhenhua, XUE Haofei

Yukun, SHENG Guangmin, HUANG Zhenhua, XUE Haofei

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: The strain induced precipitation behavior of V-N microalloyed anti-seismic rebars was studied by using stress relaxation technique based on the theoretical thermo-kinetic. According to J-M-A (Johnson-Mehl-Avrami) theory and combined with the thermodynamic software “Thermo-calc”, precipitation thermo-kinetic theoretical analysis of austenitic in isothermal process was calculated quantitatively and then compared with the experimental measured PTT(precipitation–time–temperature) curve, the influence of V (C, N) precipitation behaviors between different V and N contents was discussed. The results show that the process of precipitation kinetic of high vanadium contents and low vanadium contents rebar are accelerated at nose temperature of 870 ℃. Precipitation starting time is shortened due to the larger deformation. Experimental PTT curve is in agreement with calculated result of VN (0.04 V-0.0135 N) rebar while calculated PTT curve of VFe (0.076 V-0.0055 N) rebar should take account of the role of deformation energy △Gs.

Key words: V-N microalloyed steel; stress relaxation; carbonitride; precipitation

在现代钢铁生产中,通过微合金元素的细晶强化和沉淀强化作用来改善产品性能已是必不可少的工艺。钢筋生产中加钒比加铌具有一定的技术优势,在钢筋在地震载荷下的失效模式以高应变低周疲劳为 主[1],热轧态下的V-N微合金化钢筋由于析出细小、弥散、稳定的第二相V(C,N)质点与位错相互作用而影响其高应变低周疲劳性能。在各种微合金元素中,V是唯一对N有双重影响的元素,V不仅能形成VN抑制N的不利影响,而且可以利用N使析出反应最佳化[2]。国内外已有大量的方法研究碳氮化物的析出热动力学[3],如萃取复形法,间接法和时效法等。析出动力学模型有Kamatsu等[4]基于经典形核理论和扩散控制长大线速度理论以计算NbC的体积分数和尺寸,此外还有国内雍岐龙[5]建立的物理冶金模型等。上述方法实验量大,精度较低,理论模型体系不完整,且分析V(C,N)高温析出动力学的模型较少,尤其对抗震钢筋析出质点的分析未见报道。应力松弛法实验简单,灵敏度高,可以观察松弛过程的回复和再结晶行为,本文借鉴Liu等提出的应力松弛法[6],以析出热动力学为基础,根据J-M-A理论,研究2种不同V和N含量钢筋的析出行为并建立数学模型,定量计算碳氮化物奥氏体析出PTT曲线并与实测结果进行比较。

1 试验材料和方法

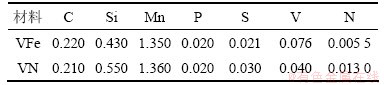

实验材料为HRB400 V-N微合金化热轧带肋钢筋,其化学成分见表1。采用Gleeble1500热模拟试验机,材料加工成直径×长度为10 mm×18 m,同时采用应变量分别为20%,50%和70% 3种变形制度。热膨胀法测试表明2种材料的Ar3都在750 ℃左右,结合实际生产设定变形温度为950,930,900,870,850和830 ℃。为保证V能够全部固溶,试样都加热到1 200 ℃后再降温,采用不锈钢压缩压头降低轴向温度梯度,同时在试样和压头之间加入低导热性的钽片,保证长度方向温度均匀。实验完成后用最快析出温度点的试样制成厚度为50 μm的薄膜样品,双喷后在JEOL-2100F型透射电镜上观察第二相析出物的形貌、分布和组成等。

表1 钢筋的化学成分(质量分数)

Table 1 Chemical compositions of rebar %

2 实验结果及讨论

2.1 沉淀析出自由能的计算

设钢中微合金元素钒及其碳、氮质量分数分别为w(V),w(C),w(N),在全固溶温度下奥氏体中的平衡固溶量分别为ws(V),ws(C),ws(N),大多数情况下是以体积自由能△Gv作为V(C,N)的析出驱动力的,而 ,其中,

,其中, 为摩尔体积(m3/mol)。通常已知MC或MN室温时的摩尔体积,通过线性插值可计算一定温度下的摩尔体积VV(C,N)。

为摩尔体积(m3/mol)。通常已知MC或MN室温时的摩尔体积,通过线性插值可计算一定温度下的摩尔体积VV(C,N)。

利用Hillet等[7]规则溶液亚点阵模型,在热力学温度T时,奥氏体和碳氮化物的平衡方程为:

(1)

(1)

式中:R为气体常数;αM,αC和αN为合金组元的活度; (X为C和N)为纯二元碳氮化物的标准Gibbs形成自由能;

(X为C和N)为纯二元碳氮化物的标准Gibbs形成自由能; 为简化的规则溶液参数;x为化学式系数(0≤x≤1)。

为简化的规则溶液参数;x为化学式系数(0≤x≤1)。

采用固溶度积公式对上式进行简化,可推出第二相的相变自由能△GM公式。本实验中除V外含有Si和Mn等其他合金元素,且2种材料Mn含量有差异,因此需要考虑合金元素对碳氮化钒的固溶度积影响,假设材料中碳化物和氮化物无空位且满足理想化学配比,Mn含量远大于Si含量,所以仅考虑Mn对合金平衡常数的影响[5],考虑Wangner(相互作用系数Ei)。修正第二相在基体中的固溶度公式如下:

(2)

(2)

利用极稀溶液定理可推的第二相相变自由能为

(3)

(3)

式中:A和B为二元相固溶度积公式中的相应常数。

因此,在不同的平衡温度下,V,C和N元素在基体中的平衡固溶量与 的化学式系数x这4个未知量可由下式联立求解:

的化学式系数x这4个未知量可由下式联立求解:

;

;

;

;

;

;

(4)

(4)

其中:AV=50.94,AC=12.01,AN=14.01。当ws(V)=w(V),ws(C)=w(C),ws(N)=w(N)时, 相全固溶,由式(4)可得

相全固溶,由式(4)可得

(5)

(5)

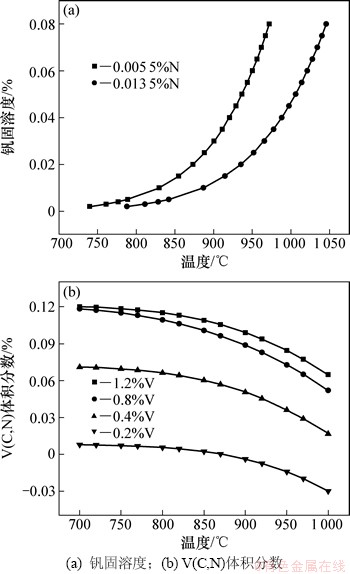

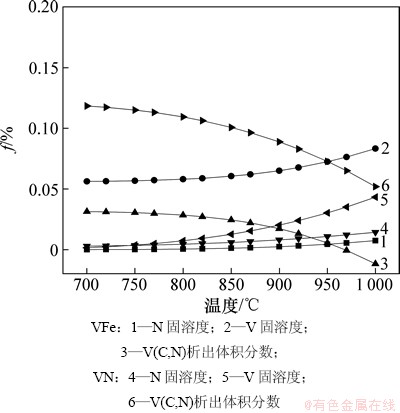

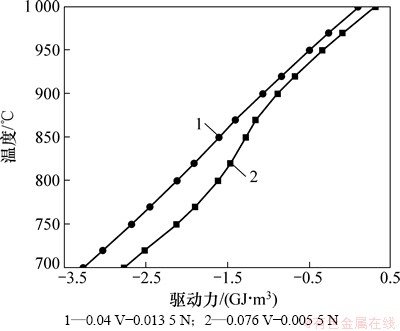

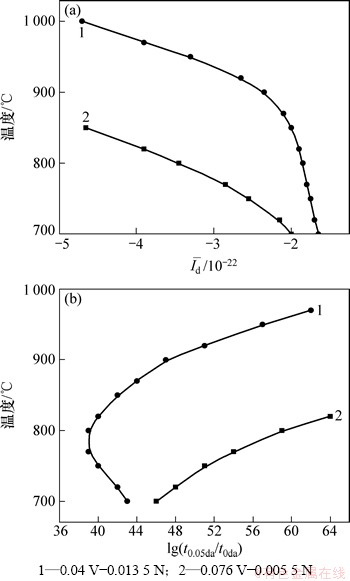

结合Thermo-calc热力学软件可计算V(C,N)的全固溶温度,V,C和N元素随温度变化规律,不同V和N质量分数对析出体积自由能△Gv的影响规律,以及析出体积分数与温度之间的关系并作图,如图1所示。从图1(a)可以看出:V固溶量随温度上升单调递增,随N质量分数的增大而减小。高温时,N质量分数不同,V固溶度差值很大,低温时近似相等,说明高温N质量分数对V在基体中的溶解影响很大,高N更容易促进V(C,N)析出。已有研究表明:C质量分数对高温V(C,N)析出的影响较小[8],但会随N质量分数的增加而增大。本文研究了V的影响,结果如图1(b)所示。随V质量分数增高,V(C,N)析出体积分数增大,图2所示为VN和VFe材料析出体积分数与温度关系。由图2可知:VN抗震钢筋第二相析出体积分数明显比VFe钢筋的大,随着温度的下降,2种材料N的固溶度变化不大,但V的固容度差异很大,且VN材料中750 ℃开始V的固溶量小于N的固溶度,此处为γ→α开始相变点,在相变自由能的驱动下有大量的V开始与C,N结合而析出。N对V(C,N)析出的影响很大,V质量分数高N质量分数低时,高温下不容易析出,V和N达到一定的理想化学配比3.64:1时[9],高温时都会有明显大量析出,高温下析出的V(C,N)明显富N而低温下富C,此时可看成主要为VN。图3所示为VN和VFe材料的△Gv与温度关系。由图3可知: VN的中第二相的析出驱动力明显比VFe中的大,表明在高温下,一定比例的VN可以促使V(C,N) 第二相的大量析出。

图1 C,N,V固溶量与温度之间关系

Fig. 1 Relationship between solid solubility of C, N, V and temperature

图2 VN和VFe材料析出体积分数与温度关系

Fig. 2 Relationship between precipitation volume fraction and temperature for VN and VFe rebars

图3 VN和VFe材料的△Gv与温度关系

Fig. 3 Relationship between △Gv and temperature for VN and VFe rebars

2.2 相变动力学模型

Yi等[10-11]研究指出,形变促进微合金元素析出的原因主要是形成大量位错,不但位错为微合金元素的扩散提供了快速通道,而且位错缠结为第二相的析出提供了大量优先形核位置。本文基于J-M-A 方程[12-13]仅考虑位错线上形核且形核率迅速衰减为零的形核机制。碳氮化钒主要在位错线上析出,在位错线上形核可松弛一部分位错的畸变能,使形核功减小。此外,位错管道作为快速扩散通道对形成富溶质的核心提供了有利条件。

假设析出第二相核胚形状为球形,单位长度位错能量为D,由此得到形成半径为r的核胚的自由能变化△Gd (忽略弹性应变能的影响),位错线上形核的临界形核功为

(6)

(6)

式中: ;S为临界核心的表面积;σ为椭球状V(C,N)析出物比界面能;△GV为体积自由能;△G均*为均匀形核的临界形核功。

;S为临界核心的表面积;σ为椭球状V(C,N)析出物比界面能;△GV为体积自由能;△G均*为均匀形核的临界形核功。

显然,位错线上形核的位置取决于母相中位错的密度,令位错密度为ρ,位错核心管道直径为2b,则位错在母相中所占体积分数大致为πρb2,考虑到由此可得位错线上形核率Id为

(7)

(7)

其中: 为溶质偏聚系数,r0为位错核心半径,可取为柏氏矢量大小b;Kv为难以确定的常数,与温度无关;Qd为原子扩散激活能;k为玻尔兹曼常数。可以将式(7)左右两边都除以Kv,得到相对形核率

为溶质偏聚系数,r0为位错核心半径,可取为柏氏矢量大小b;Kv为难以确定的常数,与温度无关;Qd为原子扩散激活能;k为玻尔兹曼常数。可以将式(7)左右两边都除以Kv,得到相对形核率 。计算可得NrT(形核率-温度)曲线见图4(a)。

。计算可得NrT(形核率-温度)曲线见图4(a)。

由于开始形核的绝对零点难以确定,将不同温度下析出相对开始时间(析出5%沉淀量)和析出相对结束时间(95%沉淀量)作成PTT曲线:

(8)

(8)

式中:β=1/4α;d*为均匀形核尺寸。

由式(8)可以计算出不同形核机制下的碳氮化钒析出开始的相对时间t0.05/t0随着温度T的变化关系,而将该曲线平行右移1.7664 4/n个数量级即可以得到析出完成时t0.95/t0随温度T的变化曲线[14](均质形核n=2/3,晶界形核n=2,位错线上形核 n=1)。

通常认为当N质量分数较低时,NrT和PTT曲线都会出现双峰即呈现S型[15]。但本文中计算和实际测试结果都没有S型曲线出现,这主要考虑了C的影响。当C和N质量分数较低时,低温或γ→α相变时C都会促进析出,高的含碳量可以补偿N含量的不足而形成VC使其在780 ℃以下析出孕育期缩短,低温下可富C。但在780 ℃以上,C质量分数从0.05%增加到0.3%,V(C,N)在奥氏体中析出的PTT曲线较接近,不同成分钢的析出时间差异一般不超过1个数量级,即N质量分数低时,C对析出动力学曲线有一定的影响,N质量分数高时,C对析出动力学曲线的影响较小。

图4 计算NrT(a)和PTT(b)曲线

Fig. 4 Calculated result of NrT(a) and PTT(b) curve

以往的应力松弛实验都会得出应力对数时间曲线,以通过“拐点”确定析出开始点Ps和结束点Pf,但通常“拐点”不明显,尤其对于高温下析出较少的钒微合金化材料来说很难找到,所以结果的误差会比较大。本文把应力对数曲线分2阶段,第一阶段是回复和再结晶的应力软化阶段[16],曲线符合Avrami方程 ;第二阶段是析出强化引起的应力再次上升。拟合Avrami方程,计算得到其与第二段的交点并作为Ps,将第二段曲线上升结束点作为Pf。这种通过拟合计算而确定的“拐点”更加准确。

;第二阶段是析出强化引起的应力再次上升。拟合Avrami方程,计算得到其与第二段的交点并作为Ps,将第二段曲线上升结束点作为Pf。这种通过拟合计算而确定的“拐点”更加准确。

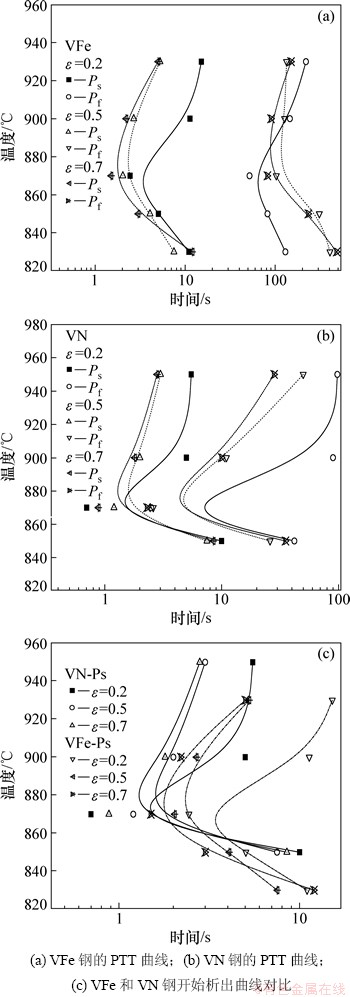

2.3 实验结果分析

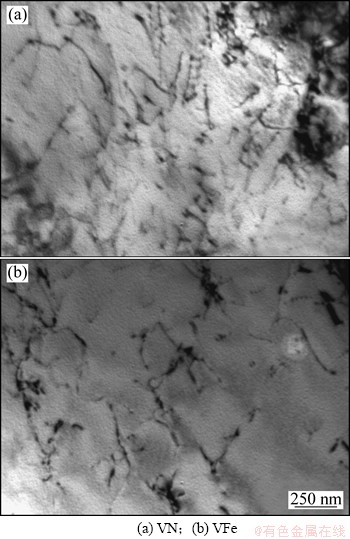

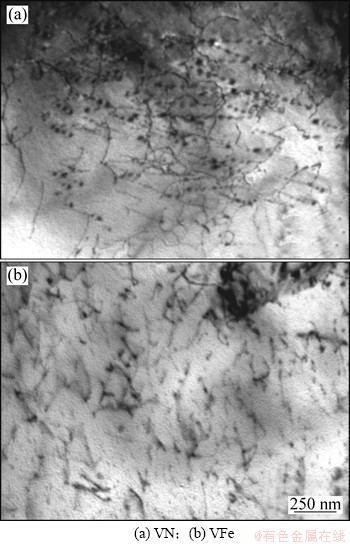

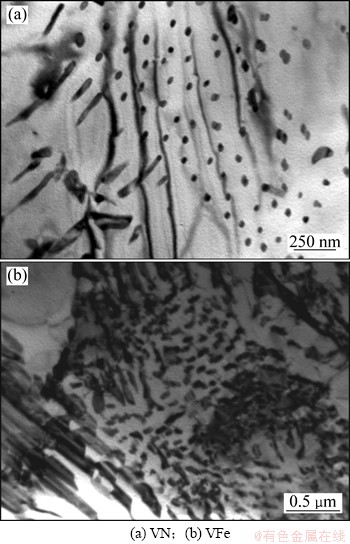

确定VN和VFe材料在不同变形量下及各变形量下不同温度应力松弛曲线的Ps和Pf点得出实测PTT曲线,如图5所示。将图5(a)和(b)与计算PTT曲线(图4(b))进行对比发现:VFe的PTT曲线差别较大,这主要与形变储存能△Gs有关,从图5(a)实测PTT曲线可看出:尽管析出最快开始温度为870 ℃,但可明显看出析出过程都比较长,应力对数时间曲线析出强化峰不明显,尤其是70%和50%应变量时的析出过程比20%时的析出过程还要长,说明高V低N质量分数的微合金化材料高温应变诱导第二相沉淀较困难,且析出量较少,过程较长。图5(b)所示的实测曲线与计算PTT曲线基本吻合,鼻温点都在870 ℃左右,且变形量越大,析出孕育期越短,析出快速而析出量越大。由图5(c)可看出:VN材料析出孕育期明显比VFe材料的小,变形量越大,开始析出越快,最快可达0.7 s;N质量分数越低,鼻温有向下移动的趋势,说明高温主要是VN析出,而对于高V低N质量分数的钢来说,可能主要在铁素体温度区析出。当温度为870 ℃,变形量分别为20%,50%和70%VN和VFe材料的应力松弛后的TEM图片如图6~8所示。从图6~8可看出:位错密度都很高,VN材料析出大量清晰可见的V(C,N)圆形质点,应变量越大,析出越多。这些质点与位错交互作用使位错墙相互扭曲缠绕,通过质点钉扎位错的相互作用可提高材料的强度。图6(b)显示VFe析出质点很少,几乎不能分辨,且都分布在位错和晶界等处,只在70%应变量下观察到较多的大质点,这主要是大变形量下第二相析出形核速度很快,长时间保温时在Ostwald熟化机制作用下长大。同样,VFe材料的位错密度也很高,说明计算模型考虑位错线上形核且形核率迅速衰减为零的形核机制是合理的。

图5 VN和VFe材料的PTT曲线

Fig. 5 PTT curves of VN and VFe rebars

图6 870 ℃变形20%的析出物形貌

Fig. 6 Precipitation morphologies of 20% deformation under 870 ℃

图7 870 ℃变形50%的析出物形貌

Fig. 7 Precipitation morphologies of 50% deformation under 870 ℃

图8 870 ℃变形70%的析出物形貌

Fig. 8 Precipitation morphologies of 70% deformation under 870 ℃

VFe材料计算PTT曲线近似单调,且在实测PTT曲线下方,这主要是计算时没有考虑形变储存能△Gs的影响。析出驱动力应该为相变体积自由能△Gv与△Gs之和,而△Gs是位错增值和亚晶界界面能组成的。

(9)

(9)

本次试验中应变引起位错增值,亚晶粒界面能增加,△Gs增大,即使在氮含量很低的情况下,很少的第二相析出与大量位错相互作用便可引起松弛阶段应力升高,所以,实测PTT曲线在计算曲线之上。

3 结论

(1) 高温下VN和VFe材料析出第二相都富N。随温度下降2种材料中N的固溶度变化不大,但在750 ℃以下VN钢筋V固溶度开始小于N的固溶度,大大促进了V(C,N)质点的析出。

(2) 2种抗震钢筋的“鼻温”点都在870 ℃左右,变形量越大,N质量分数越高,V(C,N)析出孕育期越短,析出量越大。一定比例的VN合金增加了第二相的析出行为。

(3) VN钢筋计算曲线与实测PTT曲线都呈C型且较吻合,而VFe钢筋计算曲线与实测PPT曲线差异较大,这主要考虑形变储能△Gs的影响。少量析出质点钉扎大量位错也会引起应力上升,使VFe钢筋实测PTT曲线鼻温在870 ℃左右。

(4) 在50%变形量下,870 ℃时VN钢的析出质点大量均匀,弥散,且呈圆形。VFe钢筋析出量少且不明显。70%应变下由于析出速度较快,保温时在Ostwald熟化机制作用下质点长大。2种材料的析出质点都在位错附近,说明本文基于J-M-A方程的动力学模型且考虑位错线上形核且形核率迅速衰减为零的形核机制是合理的。

参考文献:

[1] SHENG Guangmin, GONG Shihong. Investigation of low cycle fatigue behavior of building structural steels under earthquake loading[J]. Acta Metallur Sin (English Letters), 1997, 10(1): 51-55

[2] Quispe A, Medina S F, Omez M G, et al. Influence of austenite grain size on recrystallisation-precipitation interaction in a V-Microalloyed steel[J]. Materials Science and Engineering, 2007, 447(1): 11-13

[3] CHEN Jun. TANG Shuai. LIU Zhen-yu, et al.Strain-induced precipitation kinetics of Nb(C,N) and precipitates evolution in austenite of Nb-Ti micro-alloyed steels[J]. Journal of Materials Science, 2012, 47(11): 4640-4648.

[4] Kamatsu S A, Senuma T, Hasebe M. Generalized Nb(C,N) precipitation model applicable to extra low carbon steel[J]. ISIJ International, 1992, 32(3): 275-282.

[5] 雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006: 349-366.

YONG Qilong. Secondary phases in steels[M]. Beijing: Metallurgical Industry Press, 2006: 349-366.

[6] Liu W J, Jonas J J. A stress relaxation method for following carbonitride precipitation in austenite at hot working temperatures[J]. Metall Trans A, 1988, 19(6): 1403-1413.

[7] Hillert M, Staffansson L I. The regular solution model for stoichometric phases and iron metls[J]. Acta Chem Scand, 1970, 24(10): 3618-3626.

[8] 方芳. C、N含量对钢中V( C, N) 析出行为的影响[D]. 北京: 钢铁研究总院, 2009: 35-36.

FANG Fang. Effects of C and N contents on the precipitation of V(C,N)[D]. Beijing: Beijing General Research Institute for Iron and Steel, 2009: 35-36.

[9] 伊桂全, 黄贞益, 杨才富, 等. 氮含量和TMCP对微合金V-N钢显微组织和力学性能的影响[J]. 金属热处理, 2008, 33(3): 4-8.

[10] YI Guiquan, HUANG Zhenyi, YANG Caifu, et al. Effects of nitrogen content and TMCP on microstructure and mechanical properties in V-containing steel[J]. Heat Treatment of Metals, 2008, 33(3): 4-8.

[11] ZHOU Xiaoguang, LIU Zhenyu, YUAN Xiangqian, et al. Modeling of strain-Induced precipitation kinetics and evolution of austenite grains in Nb microalloyed steels[J]. Journal of Iron and Steel Research, 2008, 15(3): 65-69

[12] Dutta B, Palmiere E J, Sellars C M. Modeling the kinetics of strain induced precipitation in Nb microalloyed steels[J]. Acta Metallurgica, 2001, 49(5): 785-794.

[13] 陈睿恺, 顾剑锋, 韩利战, 等. 30Cr2Ni4MoV钢的奥氏体化动力学[J]. 材料热处理学报, 2013, 34(1): 170-174.

CHEN Ruikai, GU Jianfeng, HAN Lizhan, et al. Austenitization kinetics of 30Cr2Ni4MoV steel[J]. Transactions of Materials and Heat Treatment, 2013, 34(1): 170-174.

[14] FANG Fang, YONG Qilong, YANG Caifu, et al. A model for precipitation kinetics in vanadium microalloyed steel[J]. Journal of Iron and Steel Research (International), 2010, 17(2): 36-42.

[15] Vervynckta S, Verbekena K, Thibauxc P, et al. Recrystallization–precipitation interaction during austenite hot deformation of a Nb microalloyed steel[J]. Materials Science and Engineering A, 2011, 528(16): 5519-5528.

[16] WANG Zhenqiang, MAO Xinping, YANG Zhigang, et al. Strain-induced precipitation in a Ti micro-alloyed HSLA steel[J]. Materials Science and Engineering A, 2011, 529(25): 459-467.

[17] Michaud P, Delagnes D, Lamesle P, et al. The effect of the addition of alloying elements on carbide precipitation and mechanical properties in 5% chromium martensitic steels[J]. Acta Materialia, 2007, 55(14): 4877-4889.

(编辑 何运斌)

收稿日期:2013-04-16;修回日期:2013-09-25

基金项目:国家科技支撑计划项目(2007BAE30B05)

通信作者:盛光敏(1958-),男,湖北仙桃人,教授,博士生导师,从事高抗震性能建筑结构钢的研究;电话:15923026226; E-mail:gmsheng@cqu.edu.cn