Sintering of WC-10%Co nano powders containing TaC and VC grain growth inhibitors

M. MAHMOODAN1, H. ALIAKBARZADEH1, 2, R. GHOLAMIPOUR3

1. Department of Material Science, Saveh Branch, Islamic Azad University, P.O.Box 39187366, Saveh, Iran;

2. Department of Material Engineering, Maham Science and Technology Center,

P.O.Box 1668918479, Tehran, Iran;

3. Department of Material Science, Iranian Research Organization for Science and Technology,

P.O.Box 15815/3538, Tehran, Iran

Received 22 July 2010; accepted 2 November 2010

Abstract: WC-10%Co (mass fraction) nanocomposite was synthesized by high energy planetary ball milling at balls to powder mass ratio of 15. For inhibition of growth of WC grains during sintering, TaC and VC were used as inhibitors. Hardness and fracture toughness results reveal that the addition of TaC increases the toughness of hard metal and VC increases the hardness of the sample due to the effective reduction of WC grain size. The effect of co-addition of 0.6% TaC and 0.7% VC on physical and mechanical properties of WC-10%Co sintered sample was investigated. The hardness of the sample is increased to HV30 1 787, which is 24% more than that of the inhibitor-free sample; the fracture toughness achieves 8.7 MPa?m1/2, 35% higer then that of the inhibitor-free sample; the grain growth is inhibited and grain size achieves 0.38 μm.

Key words: WC-10%Co; TaC; VC; inhibitor; cemented carbides

1 Introduction

WC-Co based cemented carbides are materials typically used for metal cutting, milling, turning and rock drilling[1]. These types of materials produced by powder metallurgy can be densified by liquid phase sintering. The mechanical properties of these materials depend on their composition and microstructure, especially on the grain size of the carbide phase[2]. One of the production methods of the nanostructured WC-Co powders is high energy ball milling. This method is a simple and efficient way to manufacture the fine powder with nanostructures[3-6].

It is well known that the properties of the milled powders, such as the particle size distribution, affect strictly the final product properties[4-5]. It is important to control the growth of WC grains during sintering since the average grain size and size distribution have a critical effect on hardness, strength, wear resistance and so on[7]. The most commonly used grain growth inhibitors in the cemented carbide industry are chromium, tantalum carbide or vanadium carbide. The choice of inhibitors is based on the overall effectiveness which has been shown to be VC>Cr3C2>NbC>TaC>TiC>Zr/HfC in order from the most to the least[8-9]. Also MORTON et al[9] suggested that a mixture of VC with at least one of the other grain growth inhibitors may be the best way to control the grain growth throughout the entire sintering.

In the present work, 0.6% TaC and 0.7% VC were added to WC-10%Co composite and the effect of them on the sintering behavior, microstructure, physical and mechanical properties of the sintered samples were studied.

2 Experimental

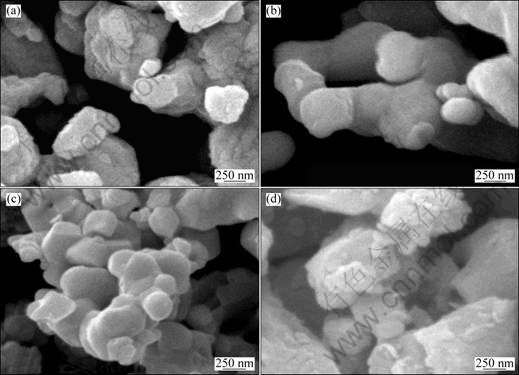

WC (99.50%, mass fraction), Co (99.87%, mass fraction), TaC (99.50%, mass fraction), VC (99.79%, mass fraction) with average particle sizes of 0.52, 0.48, 0.47 and 0.47 μm, respectively, were used as starting materials. Figure 1 shows SEM images of the powders. 0.6% TaC and 0.7% VC were added to WC-10%Co powders as grain growth inhibitor. The powders were mixed in a sealed WC hard metal vial and ball milled in a glove box containing inert atmosphere of high pure Ar

Fig.1 SEM images of starting powders: (a) WC; (b) Co; (c) TaC; (d) VC

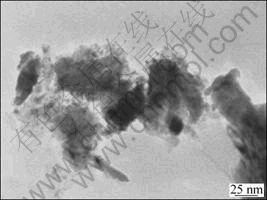

in order to minimize contaminations. The milling process was continued for 10 h with the ball to powder mass ratio of 15 on a high energy ball mill of Retsch PM400-MA type model with a selected rotation velocity of 200 r/min and 1:-3 rotation ratio to produce WC nano powders with size less than 50 nm. Figure 2 shows TEM micrograph of the powders. After milling, the powders were dried in an oven in a rough vacuum at 100 °C for 24 h.

Fig.2 TEM bright field image of WC-10%Co with 0.6%TaC-0.7%VC after high energy ball milling

The nano powders were stacked in a cylindrical steel mould with 10 mm in diameter and were compacted at 200 MPa for 1 min and then sintered at temperature of 1 370-1450 °C for 1 h in a pure H2 atmosphere. The sintered samples were ground and polished by 3 and 1 μm diamond paste. Finally, the samples were etched by Murakami solution for 1 min. The relative bulk densities of the samples were measured by ASTM B311-93 standard. The hardness was measured by Vickers hardness under 294 N load and the fracture toughness was determined by Palmqvist equation[10]. The scanning electron microscopy was carried out by PHILIPS XL-30 to observe the microstructure. Also the microstructure of powders was examined by transmission electron microscopy using PHILIPS-CM200 at 200 kV.

3 Results and discussion

The relative bulk densities of the sintered WC-10%Co samples containing TaC and VC versus sintering temperature are shown in Fig.3. The increase of the sintering temperature enhances the relative bulk density of the samples. The increase of sintering temperature causes the increase of cobalt melt fluidity (during liquid phase sintering), leading to the improvement of the capillary pressure as well as the filling of porosities of samples more completely. This redounds to the increase of the bulk density[11-12].

Figure 3 also shows that the addition of VC to the composite systems decreases the relative bulk density at the whole range of sintering temperature. It may be due to the higher viscosity of liquid phase containing VC and the lower capability to fill the porosities[11-12]. Thus VC-containing sample does not achieve the maximum density even at higher sintering temperature. In contrast, TaC-containing and inhibitor-free samples have easily reached high density at a high temperature. It is indicated that TaC has a little effect on the decrease of viscosity of liquid phase during sintering. The effect of co-addition of TaC and VC on the density of the sintered samples confirms the above description for a single inhibitor sample behavior. VC decreases the density of the sample whereas TaC compensates the degradation of the density of the sample.

Fig.3 Relative bulk densities of samples versus sintering temperature

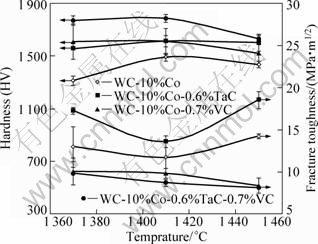

Figure 4 shows the values of hardness and fracture toughness of the samples at various sintering temperatures. WC-10%Co-0.6%TaC-0.7%VC has the highest hardness of HV30 1 787 sintered at 1 410 °C, and has the highest fracture toughness of 8.7 MPa?m1/2 sintered at 1 450 °C, 35% higher than that of the inhibitor-free sample. It is obviously indicated that all additives improve the hardness of the sintered WC-10%Co samples. However, among all samples, co-addition of TaC and VC has the best effect on the hardness. The hardness can be increased by 24% at sintering temperature of 1 410 °C. At low sintering temperatures (1 370 and 1 410 °C), the addition of inhibitors is very effective; but at high sintering temperature (1 450 °C), the hardness cannot be controlled by inhibitors and decreases to some lower values. Two phenomena occur simultaneously during high temperature sintering. The first is the increase of bulk density (Fig.3) as well as the decrease of porosity volume fraction which causes the improvement of the material strength (or hardness). The second is the occurrence of grain growth, which decreases the hardness. Thus the best hardness value can be balanced at 1 410 °C.

Figure 4 also shows an interesting result that TaC-containing samples have the highest fracture toughness at a given sintering temperature, even better than the inhibitor-free sample. On the other hand, Fig.4 indicates that VC-containing samples have low fracture toughness. Therefore, VC as an additive has a negative effect on fracture toughness of a WC-sintered sample. The fracture toughness is affected by Co phase composition and distribution (as a damping site of a crack) and porosity volume fraction (as nucleation sites of cracks)[11].

Fig.4 Hardness and fracture toughness of samples versus sintering temperature

Figure 3 confirms that TaC-containing sample has the highest density or the lowest porosity volume fraction. Based on the fracture toughness and relative bulk density results, it is indicated that the addition of TaC to WC-10%Co system may change the composition of Co liquid phase during sintering, leading to a lower viscosity of the liquid than the sample without inhibitor, so that densification of the TaC-containing samples is in a high level (near 100%). On the other hand, VC has an opposite effect on the physical properties of liquid Co phase. VC increases the viscosity of liquid phase so that the densification level of VC-containing samples cannot achieve 95%. Therefore, the fracture toughnesses of VC-containing samples deteriorate[7].

The solubilities of TaC and VC in Co liquid phase are enhanced with the increase of sintering temperature. Thus, the increase of sintering temperature from 1 370 to 1 410 °C causes the increase of volume fraction of carbide brittle phases at the grain boundaries, leading to the decrease of fracture toughness. This phenomenon may severely occur by co-introduction of VC and TaC to the system. When the sintering temperature is more than 1 410 °C, the Co phase is saturated by TaC but not by VC, therefore, the reduction of fracture toughness continues with temperature by adding VC. But, the increase of temperature to 1 450 °C may cause the improvement of fluidity of the saturated liquid (by TaC) phase to fill the voids, leading to better densification as well as higher fracture toughness for TaC-containing sample.

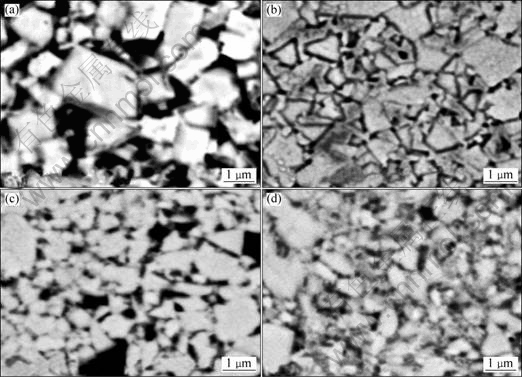

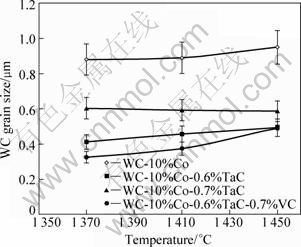

The back scattered SEM micrographs of the samples are shown in Fig.5. As can be seen, the additives are very effective for the reduction of grains size. The analysis results of the images are shown in Fig.6. It is clear that the co-addition of TaC and VC reduces the grain size much more than others. The grain size of the sample reduces to 0.38 μm, 55% lower than that of the sintered inhibitor-free sample sintered at 1 410 °C. Therefore, the addition of 0.6%TaC-0.7%VC improves the hardness of the sintered sample (Fig.4). This results support the claim of MORTON et al[9].

Fig.5 Back scattered SEM images of WC-10%Co (a), WC-10%Co-0.6%TaC (b), WC-10%Co-0.7%VC (c) and WC-10%Co- 0.6%TaC-0.7%VC (d) at 1 410 °C

Fig.6 WC grain size in samples sintered at various temperatures

4 Conclusions

1) The addition of 0.6%TaC is very useful for the improvement of sintered WC-10%Co fracture toughness.

2) The co-addition of 0.6% TaC and 0.7%VC to WC-10%Co sintered at 1 410 °C controls the grain growth of tungsten carbide to 0.38 μm, which is lower than that in the case of the above mentioned inhibitors added alone. Thus, the best hardness of HV30 1 787 for this sample is 24% more than that of the inhibitor-free sample.

3) The fracture toughness of WC-10%Co sample with co-addition of 0.6% TaC and 0.7% VC is 8.7 MPa?m1/2, 35% higher than that of the inhibitor-free sample. The grain size of sample reduces to 0.38 μm.

References

[1] da COSTA F A, de MEDEIROS F F P, da SILVA A G P, GOMES U U, FILGUEIRA M, de SOUZA C P. Structure and hardness of a hard metal alloy prepared with a WC powder synthesized at low temperature [J]. Mat Sci Eng A, 2008, 485(1-2): 638-642.

[2] QU X, GO J, QIN M, LEI C. Application of a wax-based binder in PIM of WC-TiCCo cemented carbides [J]. Int J Ref Met Mat, 2005, 23(4-6): 273-277.

[3] SIVAPRAHASAM D, CHANDRASEKAR S B, SUNDARESAN R. Microstructure and mechanical properties of nanocrystalline WC-12Co consolidated by spark plasma sintering [J]. Int J Ref Met Mat, 2007, 25(2): 144-152.

[4] SUN J, ZHANG F, SHEN J. Characterizations of ball-milled nanocrystalline WC-Co composite powders and subsequently rapid hot pressing sintered cermets [J]. Materials Letters, 2003, 57(21): 3140-3148.

[5] EL SKANDARANY M S, MAHDAY A A, AHMED H A, AMER A H. Synthesis and characterizations of ball-milled nanocrystalline WC nanocomposite WC-Co powders and subsequent consolidations [J]. J Alloys and Compounds, 2000, 312(1-2): 315-325.

[6] MAHMOODAN M, ALIAKBARZADEH H, GHOLAMIPOUR R. Microstructural and mechanical characterizations of high energy ball milled and sintered WC-10wt% Co-xTaC nanocomposite powders [J]. Int J Ref Met Mat, 2009, 27(4): 801-805.

[7] HASHE N G, NEETHLING J H, BERNDT P R, ANDREN H O, NORGREN S. A comparison of the microstructures of WC-VC- TiC-Co and WC-VC-Co cemented carbides [J]. Int J Ref Met Mat, 2007, 25(3): 207-213.

[8] PETERSSON A, AGREN J. Sintering shrinkage of WC-Co materials with bimodal grain size distribution [J]. Acta Mat, 2005, 53(6): 1665-1671.

[9] MORTON C W, WILLS D J, STJERNBERG K. The temperature ranges of maximum effectiveness of grain growth inhibitors in WC alloys [J]. Int J Ref Met Mat, 2005, 23(4-6): 287-293.

[10] SCHUBERT W D, NEAMEISTER H, KINGER G. Hardness to toughness relationship of fine grained WC-Co hard material [J]. Int J Ref Met Mat, 1998, 16(2): 133-142.

[11] UPADHYAYA G S. Cemented tungsten carbides, production, properties and testing [M]. New Jersey, USA: Noyes Publication, 1998.

[12] RANDALL M G. Powder metallurgy science [R]. Metal Powder Industries Federation, USA, 1984.

含TaC和VC抑制剂的WC-10%Co纳米粉末的烧结性能

M. MAHMOODAN1, H. ALIAKBARZADEH1, 2, R. GHOLAMIPOUR3

1. School of Metallurgy and Material Engineering, Azad University-Saveh Centre, P.O. Box 39187366, Saveh, Iran;

2. School of Metallurgy and Material Engineering, Maham Research Center, P.O. Box 1668918479, Tehran, Iran;

3. Metallurgy and Material Engineering, Iranian Research Organization for Science and Technology,

P.O. Box 15815/3538, Tehran, Iran

摘 要:采用高能球磨法,在球料比为15时合成了WC-10%Co(质量分数)纳米复合材料。为抑制烧结过程中WC颗粒的长大,在粉末中添加TaC和VC作抑制剂。结果表明:由于抑制剂有效减小了WC晶粒尺寸,添加TaC能增加硬质合金的韧性,添加VC增加其硬度;对同时添加0.6%TaC和0.7%VC对材料的物理、力学性能的影响也进行研究。结果表明: WC-10%Co-0.6%TaC-0.7%VC烧结样品的硬度达到了HV30 1 787,比没有抑制剂的样品高24%;断裂韧性达到8.7 MPa?m1/2, 比没有抑制剂的样品高35%;0.6%TaC和0.7%VC共同抑制了晶粒的长大,烧结后晶粒尺寸为3.8 μm。

关键词:WC-10%Co;TaC;VC;抑制剂;硬质合金

(Edited by YANG Hua)

Corresponding author: H. ALIAKBARZADEH; Tel/Fax: +98-2188826692; E-mail: a.akbarzadeh@gmail.com

DOI: 10.1016/S1003-6326(11)60825-X