文章编号:1004-0609(2010)09-1716-08

Mg2Cu基储氢合金的表面复相改性

陈玉安1, 2, 杨丽玲1, 林嘉靖1, 程 绩1

(1. 重庆大学 材料科学与工程学院,重庆 400044;

2. 重庆大学 国家镁合金材料工程技术中心,重庆400044)

摘 要:采用机械球磨法制备Mg2Cu合金,并以该合金为基础,添加质量分数为5%的单质(C、Co、Ni、Cu)或氧化物(Cr2O3、Fe3O4、TiO2、V2O5),通过机械球磨对合金进行表面复相改性。采用p—c—T测试仪测定合金的储氢性能,研究添加不同单质和氧化物对Mg2Cu合金储氢性能的影响。结果表明:在200 ℃和300 ℃下,添加C或Fe3O4能够有效提高Mg2Cu合金的活性,使其易与氢气反应,并缩短吸氢时间,增大吸氢量,改善放氢效果;在400 ℃下,添加Co、Ni、TiO2或Fe3O4能够有效缩短吸氢时间,改善合金的综合储氢性能。

关键词:储氢合金;Mg2Cu;机械球磨;表面复相改性;储氢性能

中图分类号:TG146.2;TB34;TK91 文献标码:A

Multi-phase surface modification of

Mg2Cu-based hydrogen storage alloys

CHEN Yu-an1, 2, YANG Li-ling1, LIN Jia-jing1, CHENG Ji1

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China)

Abstract:Mg2Cu alloys were prepared by mechanical grinding. In order to modify the surface performance of the alloys, 5%(mass fraction) of simple substances such as C, Co, Ni and Cu or oxides such as Cr2O3, Fe3O4, TiO2, V2O5 were added into Mg2Cu alloys by mechanical grinding. The hydrogen storage properties of the alloys were determined by p—c—T apparatus. The effects of simple substances and oxides on the hydrogen storage properties of the alloys were investigated. The results show that the addition of C or Fe3O4 into Mg2Cu alloys can improve the reactivities of the alloys at 200 ℃ and 300 ℃. At those temperatures, the alloys containing C or Fe3O4 can react easily with hydrogen, resulting in that the hydriding times of the alloys can be shortened and the hydriding/dehydriding capacities of the alloys can be improved. The hydrogen absorption times of Mg2Cu alloys with Co, Ni, TiO2 or Fe3O4 can be effectively shortened and the comprehensive hydrogen storage properties of the alloys can be improved at 400 ℃.

Key words:hydrogen storage alloy; Mg2Cu; mechanical grinding; multi-phase surface modification; hydrogen storage property

镁基储氢合金具有质量轻、储氢量高、资源丰富等优点,在新能源开发与应用领域前景广阔。但这类合金吸放氢温度较高,吸放氢速度较慢以及循环稳定性差,因而严重影响了它的实际应用[1-2]。

研究表明,镁基储氢合金可以通过下述途径改善其储氢性能:1) 采用新的方法制备合金,即探索传统方法以外新的材料合成或制备方法来改善其性能[3-4];2) 表面处理改性,即采用有机溶剂、酸或碱处理合金表面,使之具有高的催化活性及抗腐蚀性能,加快吸放氢速度[5];3) 元素取代改性,即通过添加元素来降低合金氢化物的分解温度,同时保持较高的吸氢 量[5-6];4) 与单质、氧化物或有机物组成复配体系,以改善其吸放氢动力学和热力学性能[7-9]。

近来年,利用机械球磨法进行合金表面复相改性被认为是一种改善镁基储氢合金性能的有效方法。OELERICH等[10]将MgH2与TiO2,V2O5等氧化物一起高能球磨,并指出与纯纳米晶体结构材料相比,一些氧化物会加快合金吸氢时的催化作用,特别是添加0.2%Cr2O3(摩尔分数)时,在0.84 MPa、300 ℃的条件下,合金的放氢量在2 min内即可达到6.7%。SAKIN- TUNA等[11]指出锗元素会使氢化物的分解温度降低50~150 ℃,但随着循环次数的增加,锗会消失;元素钒除了增加合金的储氢量外,还与钛单质一样具有阻止金属表面氧化的作用。而添加氧化物如V2O5、Cr2O3等,可以提高MgH2的动力学性能,且能提高低温下合金形成氢化物的性能。这些氧化物颗粒经过高能球磨后,会在镁的表面生成许多缺陷来促使氢原子通过。此外,Cr2O3可加快吸氢反应的进行,而V2O5和Fe3O4则能促进放氢,TiO2也能提高镁氢化的性能,如加快速度,降低温度,防止氧化等,这为储氢材料的进一步研究奠定了基础。

VIJAY等[12]用机械球磨法制备了Mg-x% Cr2O3(x为质量分数,x=5, 10, 15, 20)纳米储氢材料,并在100、200、300 ℃的温度下进行了相应的性能测试。结果显示,在200 ℃和300 ℃、3 MPa的实验条件下,当Cr2O3的含量为5%时,复合材料储氢量达到最大值,分别为5.67%和6.01%;而100 ℃时吸氢量最大的则是含有15% Cr2O3的合金,其值为3.80%。在同样的温度范围和0.1 MPa下进行放氢实验时,当Cr2O3的含量从5%增加到15%时,随着Cr2O3含量的增大,不同温度下的放氢量均有增加的趋势,其放氢量也可达到最大值,为4.02%;而当Cr2O3的含量从15%增加到20%时,合金的放氢量又会减少。因此,Cr2O3对Mg的吸氢性能具有较大的催化作用,而对其放氢性能的影响不是很大。

在以上研究中一般选用的都是Mg或Mg2Ni来作基体。在此,本文作者通过机械球磨法制备Mg2Cu合金,通过XRD分析确定其完全形成后,以此为基添加质量比为5%的单质或者氧化物,对合金进行表面复相球磨处理,并研究合金在不同温度下的储氢性能,以便为储氢合金进一步的发展提供参考。

1 实验

将纯度不低于99%的Mg、Cu粉末按物质的量比2?1配好料后置于不锈钢罐内,然后装入德国FRITSCH公司生产的Pulverisett-5型球磨机中,在氩气保护下进行球磨,球磨机转速为600 r/min,球料质量比为20?1。在球磨过程中每隔2 h取出少许合金粉末进行XRD分析,以检测Mg2Cu的形成过程并确保其完全形成。将制备好的Mg2Cu储氢合金材料存放在充有氩气的密封袋中备用。依次在玛瑙罐中对Mg2Cu+5%M(M=C, Co, Ni, Cu, Cr2O3, Fe3O4, TiO2, V2O5)进行表面复相球磨处理,球磨气氛仍为氩气,球磨机转速为600 r/min, 球料比为10?1, 球磨时间为1 h。

试验用材料的物相结构分析在Rigaku D/max2500PC X射线衍射仪上进行。其实验条件如下:Cu Kα辐射,石墨单色器,阳极电压为40 kV,阳极电流为150 mA,测角精度为0.02?,扫描速度为4.00 (?)/min,扫描范围为20?~120?。

合金的吸放氢性能在四川大学研制的p—c—T测试仪上进行测试。氢气纯度为99.999%,初始氢压为3 MPa。测试每个合金试样在200、300和400 ℃ 3个温度下的吸氢动力学曲线和放氢p—c—T曲线。

2 结果与分析

2.1 Mg2Cu形成过程及吸氢后的XRD结果与分析

图1所示为Mg和Cu混合粉末经2~8 h球磨后的XRD谱。可以看出,球磨2 h后(见图1(a)),粉末基本上由单质Mg和Cu构成,Mg2Cu的衍射峰强度很弱,说明只是很少的一部分形成了Mg2Cu相。球磨4 h时(见图1(b)),除单质Mg和Cu外,Mg2Cu相的衍射峰逐渐增多,且强度也有所增大。 经过6 h球磨后(见图1(c)),Cu的衍射峰数目已明显减少,Mg的衍

图1 机械球磨法制备的Mg2Cu的XRD谱

Fig.1 XRD patterns of Mg2Cu prepared by mechanical grinding: (a) 2 h; (b) 4 h; (c) 6 h; (d) 8 h

射峰完全消失,此时Mg2Cu的衍射峰无论从数量上还是从强度上来看均得以显著增多和增大。球磨8 h后(见图1(d)),可认为Mg和Cu粉末已完全合成为Mg2Cu。随着球磨时间的延长,合金的衍射峰逐渐宽化,说明粉末被不断细化。文献[13]认为,当用球磨法制备Mg-Cu二元合金时,首先发生的是Mg在Cu中的固溶,随后形成过饱和固溶体的亚稳相,并引起Cu原子晶格畸变,从而有利于氢原子在合金中的扩散。

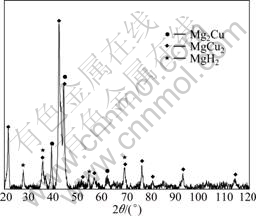

图2所示为机械球磨Mg2Cu合金在400 ℃下吸氢后的XRD谱,可见该合金试样含有Mg2Cu、MgCu2和MgH2这3种物相。一般来说,Mg和Cu能够形成2种金属间化合物Mg2Cu和MgCu2,其中Mg2Cu为吸氢相,在300 ℃、2 MPa的条件下便能够吸氢,而MgCu2则很难与氢气发生反应[14]。在本次实验中,当Mg2Cu在400 ℃下与氢发生反应时,大部分生成了MgH2和MgCu2,其反应式为:2Mg2Cu+3H2 3MgH2+MgCu2。但是由于反应不完全,吸氢后的产物中仍有少量残留的Mg2Cu。

3MgH2+MgCu2。但是由于反应不完全,吸氢后的产物中仍有少量残留的Mg2Cu。

2.2 Mg2Cu+5%M(M =C, Co, Ni, Cu)表面复相球磨处理后的储氢性能

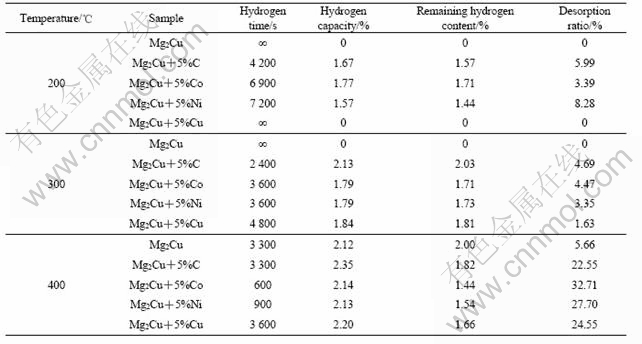

。能,6图3所示为表面复相球磨处理后Mg2Cu+5%M (M=C, Co, Ni, Cu)系列合金在不同温度下的吸氢动力学曲线和放氢p—c—T曲线。其中图3(a)、(b)、(c)

图2 机械球磨法制备的Mg2Cu在400 ℃吸氢后的XRD谱

Fig.2 XRD pattern of Mg2Cu prepared by mechanical grinding after absorbing hydrogen at 400 ℃

是表面复相球磨处理合金分别在200、300、400 ℃下的吸氢动力学曲线,图3(d)、(e)、(f)是在对应温度下的放氢p—c—T曲线。表1所列为该系列合金的吸放氢性能的测试结果。

根据图3和表1的实验结果可知,在200 ℃时,添加C、Co或Ni进行表面复相处理后,Mg2Cu能与氢气反应,其中Mg2Cu+5%C完成吸氢的时间最短,而添加Cu的合金则无吸氢现象。但在此温度下所有

表1 Mg2Cu+5%M(M =C, Co, Ni, Cu)储氢合金表面复相球磨处理后的吸放氢性能

Table 1 Absorption/desorption properties of Mg2Cu+5%M(M=C, Co, Ni, Cu) synthesized by multi-phase surface modification of ball milling at different temperatures

图3 表面复相球磨处理后Mg2Cu+5%M(M=C, Co, Ni, Cu)系列储氢合金在不同温度下的吸氢动力学曲线和放氢p—c—T曲线

Fig.3 Hydrogen absorption kinetic curves and desorption p—c—T curves of Mg2Cu+5%M(M=C, Co, Ni, Cu) synthesized by multi-phase surface modification of ball milling at different temperatures: (a), (a′) 200 ℃; (b), (b′) 300 ℃; (c), (c′) 400 ℃

合金放氢均很困难,仅Mg2Cu+5%Ni有放氢迹象。当吸放氢温度在300 ℃时,Mg2Cu+5%M(M=C, Co, Ni, Cu)均能与氢气发生反应,且吸氢时间较200 ℃时缩短,吸氢量也有所增大,其中C对合金储氢性能的改善最为明显。但添加单质的合金在中、低温度(200~300 ℃)下放氢仍很困难。当温度升高至400 ℃时,几乎所有合金均表现出较好的储氢性能,吸氢量达到最大,同时有明显的放氢现象。尤其是添加了碳的合金在该系列合金中具有最高的吸氢容量,达到2.35%。

值得注意的是,未经表面复相球磨处理的Mg2Cu合金在200 ℃和300 ℃的中、低温度下均不吸氢,400 ℃时Mg2Cu的吸氢量仅为2.12%,同时合金在该温度下放氢率仅为5.66%,且放氢平台较窄,可认为几乎不放氢。而经过表面复相球磨处理后,Mg2Cu的储氢性能得到了较明显的改善,并且随着温度的升高,其吸氢量、放氢率不断增大,放氢平台亦逐渐增宽。在200 ℃和300 ℃时,添加碳的合金活性相对较高,表现为易与氢气反应,吸氢时间较短,吸、放氢量有所增加。400 ℃时,Co和Ni对提高合金的表面活性有明显的效果,有效地缩短了合金吸氢的时间,提高了放氢率,也在一定程度上提高了合金的吸氢量。

由此可见,对Mg2Cu进行添加C、Co、Ni或Cu的表面复相球磨,能够在一定程度上改善合金的储氢性能。

2.3 Mg2Cu+5%M(M=Cr2O3, Fe3O4, TiO2, V2O5)表面复相球磨处理合金的储氢性能

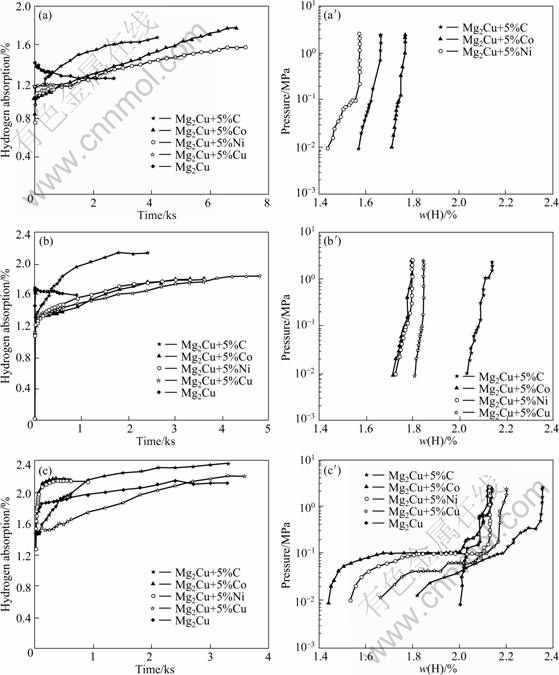

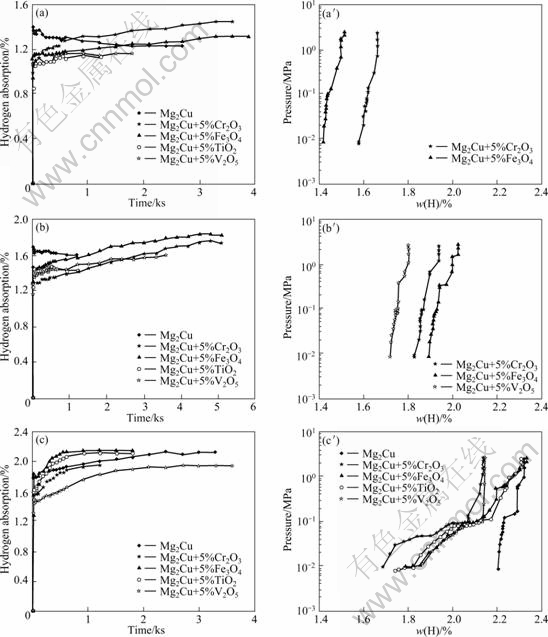

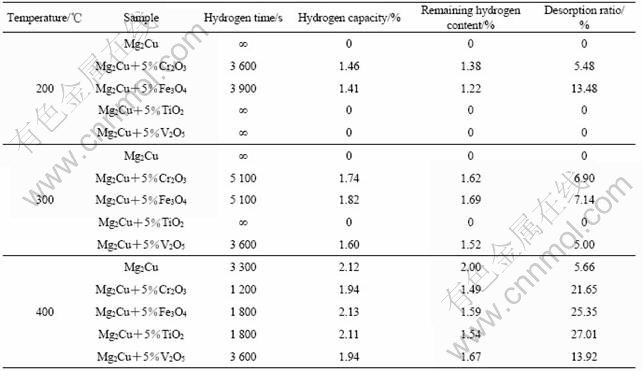

图4所示为Mg2Cu中分别添加5%的Cr2O3、Fe3O4、TiO2、V2O5经复相球磨处理后在200、300和400 ℃下的吸氢动力学曲线和放氢p—c—T曲线。表2所列为该系列合金在对应温度下的储氢性能。

由图4和表2可知,在200 ℃时,除添加Cr2O3、Fe3O4的合金外,其余合金未发现与氢气发生反应,同时在该温度下,所有合金的放氢p—c—T曲线上均没有明显的放氢平台,即无放氢迹象。在300 ℃时,合金的吸放氢性能与200 ℃时的类似,但吸氢量有所增大。当温度升高至400 ℃时,所有合金的吸氢量均达到最大,吸氢时间也最短,同时除Mg2Cu外,添加氧化物的合金均有明显的放氢现象,在放氢p—c—T曲线上可以观察到较宽的放氢平台(见图4(c′)),说明添加氧化物对Mg2Cu进行复相球磨处理后,合金的储氢性能得到了改善。

图4 表面复相球磨处理后Mg2Cu+5%M(M=Cr2O3, Fe3O4, TiO2, V2O5)系列储氢合金在不同温度下的吸氢动力学曲线和放氢 p—c—T曲线

Fig.4 Hydrogen absorption kinetic curves and desorption p—c—T curves of Mg2Cu+5%M(M=Cr2O3, Fe3O4, TiO2, V2O5) synthesized by multi-phase surface modification of ball milling at different temperatures: (a), (a′) 200 ℃; (b), (b′) 300 ℃; (c), (c′) 400 ℃

表2 Mg2Cu+5%M(M=Cr2O3, Fe3O4, TiO2, V2O5)系列储氢合金表面复相球磨处理后的吸放氢性能

Table 2 Absorption/desorption properties of Mg2Cu+5%M(M=Cr2O3, Fe3O4, TiO2, V2O5) synthesized by multi-phase surface modification of ball milling at different temperatures

对比合金的储氢性能可以发现,在200和300 ℃时,添加Fe3O4的合金活性相对较高,易与氢气反应,吸氢时间较短,吸氢量较高,放氢率也较大。在400 ℃时所有合金均有较明显的放氢现象,但相对来说,添加TiO2和Fe3O4的合金具有较高的吸放氢性能。

3 讨论

根据上述实验结果与分析可知,采用机械球磨法制备的Mg2Cu储氢合金没有良好的储氢性能,只在400 ℃的高温下才能吸氢,且吸氢时间较长、储氢量和放氢率都较低,在中低温度下 (200、300 ℃)则基本无吸放氢趋势。但在引入不同的添加物进行表面复相球磨后,其储氢性能得到了不同程度的改善。

3.1 C、Co、Ni以及Cu对Mg2Cu储氢性能的影响

首先,在Mg-Ni中添加C进行复相球磨,由于镍颗粒硬度较大,镁颗粒的硬度较小,碳颗粒的脆性较大,使得各颗粒在球磨过程中得以充分研磨[15],从而增大合金与氢气接触的表面积。本次实验表明,加入碳进行复相球磨后,合金吸氢量和放氢率均优于Mg2Cu,符合上述论断。

钴可以降低合金在吸放氢过程中的晶格膨胀[16],从而抑制合金的晶格体积变化,因此具有很高的催化活性。而镍除了在球磨过程中的助磨作用以外,亦有催化剂的作用,合金吸氢时氢分子在镍颗粒表面解离为氢原子,而后与镁结合生成MgH2,从而降低了氢化反应的活化能,也有利于改善合金的储氢性能[17]。这也是加入Co、Ni进行复相球磨后,合金的吸氢时间缩短,放氢率增加的主要原因。

SEDER等[18]在对Mg2Cu表面经XPS和AES分析后表明,Mg2Cu表面的镁择优氧化,使铜以金属态的形式存在于表面,催化了氢分子的化学解离,提高了反应速度。本实验也表明,合金中添加铜的Mg2Cu合金吸放氢温度降低、吸氢量提高。只是与添加C、Ni和Co的合金试样相比,性能提升的幅度相对较小。

3.2 Cr2O3、Fe3O4、TiO2以及V2O5对Mg2Cu储氢性能的影响

KANDAVEL和RAMAPRABHU [17]认为,储氢合金的吸氢量易受其晶格体积、合金中氢原子与金属元素之间的电荷转移等因素的影响。与金属氧化物进行复相球磨,可以提高合金与氢分子之间的电子交换反应,加快气-固反应的进行,从而改善合金的储氢性能。通常情况下多价态的过渡族金属的催化作用优于单一价态的[19]。虽然具有可变化合价的不同过渡族金属对镁基储氢合金的具体影响不同,但其效果还是比较明显的[20]。根据在Mg2Cu合金中添加氧化物进行表面复相球磨的结果来看,Fe3O4和Cr2O3改善合金性能的作用较明显。

综合以上研究结果,添加的氧化物中金属元素具有可变的多价态,高价态的金属离子得到氢原子提供的一个电子可被还原成低价态,而由于后者的不稳定性又可重新氧化成高价态的金属离子,这便构成了一种动态平衡,进而在金属和氢分子之间起到传递电子的作用,因此有效地改善了合金的储氢性能。

4 结论

1) 采用机械球磨法制备Mg2Cu储氢合金,Mg、Cu单质粉末在不锈钢罐中球磨8 h后即可完全形成吸氢相Mg2Cu。Mg2Cu在200 ℃和300 ℃下的储氢性能不佳,400 ℃时才能有效吸氢,且吸氢时间长,放氢效果较差。

2) 采用添加不同单质或氧化物对Mg2Cu进行复相球磨处理后,合金的储氢性能得到改善。在200 ℃和300 ℃下,添加C和Fe3O4的合金活性较高,易与氢气反应,吸氢时间较短,吸氢量有所增大,放氢效果较好;在400 ℃时,添加Co、Ni或TiO2、Fe3O4改善合金放氢性能的作用较明显。

REFERENCES

[1] 胡秀颖, 周仕学, 王振华, 马怀营, 雷桂芹. 球磨时间对镁碳复合储氢材料结构和性能的影响[J]. 功能材料, 2008, 39(3): 424-425.

HU Xiu-ying, ZHOU Shi-xue, WANG Zhen-hua, MA Huai-ying, LEI Gui-qin. Effect of ball milling time on the structure and properties of Mg-C composites for hydrogen storage [J]. Functional Materials, 2008, 39(3): 424-425.

[2] 陈 军, 朱 敏. 高容量储氢材料的研究进展[J]. 中国材料进展, 2009, 28(5): 2-10.

CHEN Jun, ZHU Min. Progress in research of hydrogen storage materials with high capacity[J]. Materials China, 2009, 28(5): 2-10.

[3] 李松林, 刘 燚, VARIN R A, 刘怀菲, 崔建民, 陈仕奇. 球磨方式对纳米晶Mg2FeH6储氢材料合成与放氢性能的影响[J].中国有色金属学报, 2008, 18(1): 42-47.

LI Song-lin, LIU Yi, VARIN R A, LIU Huai-fei, CUI Jian-min, CHEN Shi-qi. Effect of ball milling methods on synthesis and desorption properties of nanocrystalline Mg2FeH6 hydrogen storage materials [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 42-47.

[4] 王利伟, 金自力, 张羊换. La-Mg-Ni系贮氢合金的研究进展[J]. 金属功能材料, 2009, 16(2): 46-50.

WANG Li-wei, JIN Zi-li, ZHANG Yang-huan. Recent research on La-Mg-Ni system hydrogen storage alloys[J]. Metallic Functional Materials, 2009, 16(2): 46-50.

[5] 钱晓静, 黄国强, 林 波. Mg-Ni系贮氢合金的改性[J]. 稀有金属, 2008, 32(1): 107-114.

QIAN Xiao-jing, HUANG Guo-qiang, LIN Bo. Improvement on Mg-Ni-based hydrogen storage alloy[J]. Chinese Journal of Rare Metals, 2008, 32(1): 107-114.

[6] YOO J H, SHIM G, YOON J S, CHO S W. Effects of substituting Al for Cr in the Ti0.32Cr0.43V0.25 alloy on its microstructure and hydrogen storage properties[J]. International Journal Of Hydrogen Energy, 2009, 34: 1463-1467.

[7] 周惦武, 刘金水, 卢远志, 张楚慧. 镁基储氢材料的吸放氢性能[J]. 机械工程材料, 2008, 32(4): 5-9.

ZHOU Dian-wu, LIU Jin-shui, LU Yuan-zhi, ZHANG Chu-hui. Hydriding and dehydrogenating properties of magnesium-based hydrogen storage materials[J]. Materials for Mechanical Engineering, 2008, 32(4): 5-9.

[8] 冯 艳, 袁华堂, 乔林军, 刘 强. Mg0.9M0.1Ni(M=Cr, Al, Ti, Zr)三元镁基储氢合金的制备及其电化学性能的研究[J]. 南开大学学报, 2005, 38(2): 74-79.

FENG Yan, YUAN Hua-tang, QIAO Lin-jun, LIU Qiang. Preparation and electrochemical characteristics of Mg0.9M0.1Ni(M=Cr,Al,Ti,Zr)[J]. Acta Scientiarum Naturalium Universitatis Nankaiensis, 2005, 38(2): 74-79.

[9] 徐益军, 唐有根, 黄伯云. Mg-Ni基贮氢合金的研究进展[J]. 材料导报, 2003, 17(12): 9-11.

XU Yi-jun, TANG You-gen, HUANG Bo-yun. The research of Mg-Ni based hydrogen storage materials[J]. Materials Review, 2003, 17(12): 9-11.

[10] OELERICH W, KKASSEN T, BORMANN R. Metal oxides as catalysts for improved hydrogen sorption in nanocrystalline Mg-based materials [J]. Journal of Alloys and Compounds, 2001, 315(1/2): 237-242.

[11] SAKINTUNA B, LAMARI-DARKRIM F, HIRSCHER M. Metal hydride materials for solid hydrogen storage: A review[J]. International Journal of Hydrogen Energy, 2007, 32: 1121-1140.

[12] VIJAY R, SUNDARESAN R, MAIYA M P, SRINIVASA MURTHY S. Hydrogen storage properties of Mg-Cr2O3 nanocomposites: The role of catalyst distribution and grain size[J]. Journal of Alloys and Compounds, 2006, 424: 289-293.

[13] 王晓军, 王晓丽, 陈学定, 夏天东. 球磨法制备Mg-Cu非晶态合金粉末[J]. 粉末冶金技术, 2005, 23(1): 36-39.

WANG Xiao-jun, WANG Xiao-li, CHEN Xue-ding, XIA Tian-dong. On Mg-Cu amorphous alloy powders produced by ball milling[J]. Powder Metallurgy Technology, 2005, 23(1): 36-39.

[14] REILLY J J, WISWALL R H Jr. Reaction of hydrogen with alloys of magnesium and nickel and the formation of Mg2NiH4 [J]. Inorg Chem, 1968, 7(11): 2254-2256.

[15] 吴峻青, 周仕学, 王振华, 吕英海. 镍对镁碳复合储氢材料性能的影响[J]. 矿冶工程, 2008, 28(4): 105-107.

WU Jun-qing, ZHOU Shi-xue, WANG Zhen-hua, L? Ying-hai. Effect of Ni on properties of Mg/C composites for hydrogen storage[J]. Mining and Metallurgical Engineering, 2008, 28(4): 105-107.

[16] PAN H G. Studies on the electrochemical properties of MlNi4.3-xCoxAl0.7 hydride alloy electrodes[J]. Journal of Alloys and Compounds, 1999, 648: 293-295.

[17] KANDAVEL M, RAMAPRABHU S. Correlation between hydrogen storage properties and amount of alloy particles in Mg-based composites [J]. Journal of Alloys and Compounds, 2007, 438: 285-292.

[18] SEILER A, SCHLAPBACH L, von WALDKIRCH T, SHALTIEL D, STUCKI F. Surface analysis of Mg2Ni-Mg, Mg2Ni and Mg2Cu[J]. Less-Common Met, 1980, 73 (1): 193-199.

[19] 蔡 浩, 顾 昊, 朱云峰, 李李泉. 催化剂对镁基储氢材料储氢性能影响的研究进展[J]. 材料导报, 2008, 22(11): 115-119.

CAI Hao, GU Hao, ZHU Yun-feng, LI Li-quan. Research progress in the influence of catalysts on hydrogen storage property of magnesium-based hydrogen storage materials[J]. Materials Review, 2008, 22(11): 115-119.

[20] OELERICH W, KIASSEN T, BORMANN R. Metal oxides as catalysts for improved hydrogen sorption in nanocrystalline Mg-based materials[J]. Journal of Alloys Compounds, 2001, 315(1/2): 237-242.

(编辑 杨 华)

基金项目:重庆市自然科学基金资助项目(CSTC 2006BB4197);重庆大学大型仪器设备开放基金资助项目

收稿日期:2009-11-15;修订日期:2010-02-20

通信作者:陈玉安,副教授,博士;电话: 13996300268;传真: 023-65127306; E-mail: chenyuan@cqu.edu.cn