DOI: 10.11817/j.issn.1672-7207.2017.03.034

叶片失速延迟控制垂直轴风力机气动性能

高强1,蔡新1, 2,潘盼1,郭兴文1,舒超1

(1. 河海大学 力学与材料学院,江苏 南京,210098;

2. 河海大学 水利水电学院,江苏 南京,210098)

摘要:以麦克马斯特大学H型垂直轴风力机为基础,在叶片上加设射流管,设计一种叶片失速延迟控制垂直轴风力机。基于CFD方法计算典型工况下叶片失速延迟控制垂直轴风力机的功率,分析风场的涡强和风速分布特性。研究结果表明:在相同几何尺寸和工况下叶片失速延迟控制风力机的风能利用系数比麦克马斯特大学H型垂直轴风力机的高,在尖速比为1.3时,最大风能利用系数达到0.33。在叶片上加设射流管对于延迟层流分离具有显著作用。

关键词:失速延迟控制;射流管;垂直轴风力机;风能利用率;气动性能

中图分类号:TK83 文献标志码:A 文章编号:1672-7207(2017)03-0830-07

Aerodynamic characteristics of blade stall delay control vertical axis wind turbine

GAO Qiang1, CAI Xin1, 2, PAN Pan1, GUO Xingwen1, SHU Chao1

(1. College of Mechanics and Materials, Hohai University, Nanjing 210098, China;

2. College of Water Conservancy and Hydropower Engineering, Hohai University, Nanjing 210098, China)

Abstract: Through adding a jet pipe on the blade, a blade stall delay control vertical axis wind turbine was designed on the basis of McMaster university H-type vertical axis wind turbines. Employing CFD method, the power of blade stall delay control vertical axis wind turbine was calculated under the typical working conditions, and the vorticity and wind speed distribution characteristics were analyzed. The results show that with the same geometry size and the working conditions, the wind energy utilization coefficient of blade stall delay control wind turbine is higher than that of McMaster H-type vertical axis wind turbines. The maximum wind energy utilization coefficient reaches 0.33 when the tip speed ratio is 1.3. Adding jet pipe on blade has significant effects on delaying laminar flow separation.

Key words: stall delay control; jet pipe; vertical axis wind turbine; wind energy utilization coefficient; aerodynamic characteristics

伴随着世界化石能源的消耗殆尽,温室气体过度排放引起的温室效应,人类正面临着资源枯竭、环境恶化的困境。找到一种新型能源替代传统能源,又不会造成环境污染是全人类的共同梦想。风能作为一种无污染和可再生的新能源正日益受到重视,风力发电设备的研究在我国方兴未艾[1]。相对于水平轴风力机,垂直轴风力机具有无需对风机构、启动风速较低、方便维护、气动噪声低等诸多优势[2]。国内外学者对垂直轴风力机气动性能开展了大量的研究[3-7]。李岩[8]对垂直轴风力机的设计与实验进行了阐述,指出垂直轴风力机气动方面存在一个不可避免的问题,即是失速现象。梅毅等[9]基于CFD计算了垂直轴风力机不同弦径比和叶片数对气动性能的影响,指出过低的尖速、过大的弦径比和4个以上的叶片数会加剧叶片动态失速和气流分离现象,削弱风机发电效率。高伟等[10]基于CFD对H型垂直轴风力机流场进行瞬态计算,研究了翼型附近涡从形成到脱落的过程,指出当尖速比较小时更容易发生动态失速。王虎彬等[11]对非对称翼型正反4°安装角下的垂直轴风力机分别进行了二维非定常数模拟,结果表明翼型反装可以缩小失速范围,提高风能利用率。姚兴佳等[12]认为叶片旋转过程中由于扰流致使层流分离从而产生涡流,进而导致失速,叶片升力骤然下降,风力机做功减少。叶正寅等[13]利用风洞试验研究了翼型振动对流场的影响,结果表明翼型振动会导致失速提前发生。伍艳等[14]提出考虑三维旋转效应下非定常气动荷载的计算方法,建立了预测分离点位置的计算模型,可计算三维旋转效应对叶片附面层气流分离的影响。FERREIRA等[15]的研究表明气流攻角随着垂直轴风力机叶片方位角的变化而时刻变化,变化范围较大,失速现象无法避免。由此可见,研究新型垂直轴风力机叶片使其能够适应大范围变化的攻角,进而延缓失速现象具有非常重要的意义。为此,本文作者在传统直叶片基础上研究加设射流管,设计出一种叶片失速延迟控制垂直轴风力机,提高了垂直轴风机的风能利用系数。

1 物理数学模型

1.1 物理模型及几何尺寸

2007年麦克马斯特大学对额定功率3.5 kW的H型垂直轴风力机进行了风洞试验,并提取了风机功率曲线,计算了各种工况下的风能利用系数[16]。该风机主要参数见表1。

在McMaster H型垂直轴风力机基础之上,对叶片加设射流管,设计了叶片失速延迟控制垂直轴风力机,主要包括叶片、支撑杆、塔筒、涡轮吸气装置以及导气管,其中,涡轮吸气装置安装在塔筒顶端,沿塔筒、支撑杆以及叶片吸力面内部设置导气管,导气管在叶片吸力面内侧沿展向贯穿设置,间隔一定距离布置射流管。叶片失速延迟控制垂直轴风力机工作时,塔筒顶端安装的涡轮吸气装置被带动高速旋转吸入空气,通过导气管气体由塔筒顶端经支撑杆最终传送到叶片吸力面,在离心力作用下,气流沿叶片表面射流管喷射而出。在喷射气流作用下,叶片层流分离被延迟,翼型升力增加,风力机功率输出增加。

表1 麦克马斯特H型垂直轴风力机几何参数

Table 1 Geometric parameters of McMaster H-type vertical axis wind turbine

在建模软件UG中建立叶片失速延迟控制垂直轴风力机的几何模型,如图1所示。射流管简化为贯穿叶片吸力面的射流槽,射流槽开口位于弦长中点,射流槽与弦线夹角15°。

图1 风力机模型

Fig. 1 Wind turbine model

1.2 数学模型

1.2.1 计算方法

基于不可压缩的连续方程和雷诺平均的 N-S方程,计算叶片失速延迟控制垂直轴风力机的输出功率。不可压缩的连续方程和雷诺平均的 N-S方程用张量描述为:

(1)

(1)

(2)

(2)

式中: 为流体密度;t为时间;v为速度矢量;p为表面压力;

为流体密度;t为时间;v为速度矢量;p为表面压力; 为表面应力矢量;f为单位质量体积力矢量。

为表面应力矢量;f为单位质量体积力矢量。

1.2.2 网格剖分

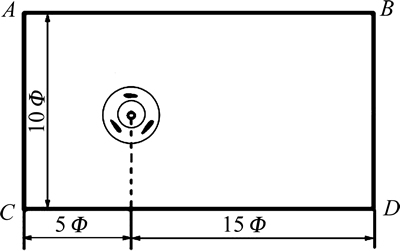

图2所示为风场布置平面示意图,图中Φ为中轮直径。ABCD为风轮叶片和转轴以及风轮旋转域和外流场域组成的区域,AC和BD边长为10Φ,AB和CD边长为20Φ,叶轮回转中心距AC边为5Φ,距BD边为15Φ,距AB和CD边均为5Φ,风轮旋转区域直径为0.8Φ至1.2Φ[10]。

图2 风场布置示意图

Fig. 2 Diagram of wind field

在ICEM网格剖分软件中对风场进行离散化,由于六面体网格精度较高,整个模型全部采用六面体网格。网格尺寸最大为1 m,最小为0.1 mm。离风机较远处的外流场网格较大,最大尺寸达1 m,为了体现叶片边界层黏性流动特征,叶片附面层网格厚度设为0.1 mm。数值模型单元总数645 030,节点总数705 754,如图3所示。

图3 模型网格

Fig. 3 Model grids

1.2.3 边界条件

结合风力机的旋转特性,将流场划分为旋转域和外流场域,并假设当地空气温度为25 ℃。

对于外流场域,入流面设置为速度入口,风速为10 m/s,风场顶面及左右两面设为对称边界,地面和塔架设为无滑移壁面边界,出口设为压力出口,相对压力为0 Pa。

对于旋转域,根据工况设定旋转速度,叶片设为无滑移壁面边界条件,射流管入口速度为10 m/s,射流管两侧为无滑移壁面。

1.2.4 非线性分析求解设置

湍流模型选取SST模型,对流离散格式采用一阶迎风格式,模拟叶轮旋转3圈,叶轮每旋转5°为一个时间步长,收敛残差设为0.000 1。

2 工况选取

BRAVO等[16]对入流速度6,8,10,10.5,12.1,12.4,14.1,14.3和16 m/s,风力机转速20~150 r/min的几十种工况做了风洞试验,得到各工况下风力机功率和风能利用系数。现选取6种典型工况进行叶片失速延迟控制垂直轴风力机的CFD计算。计算工况列于表2。

表2 计算工况

Table 2 Working condition of calculation

3 计算结果

图4所示为叶片交叠布置垂直轴风力机在转速为122 r/min,风速为10 m/s工况下的输出转矩时间历程,在模拟旋转1圈后,风力机转矩进入稳定状态,呈正弦变化规律。取第3圈数据计算风力机平均功率,平均功率计算表达式如下

(3)

(3)

式中:Qi为第i时间步的风力机转矩; 为风轮旋转一圈平均转矩;P为风力机功率。

为风轮旋转一圈平均转矩;P为风力机功率。

图4 输出转矩时间历程

Fig. 4 Time history of twist torque

对McMaster H型垂直轴风力机和失速延迟控制垂直轴风力机在各个尖速比下的功率和风能利用系数进行计算并对比。风能利用系数Cp即为输出功率与总风能之比,表达式如下:

(4)

(4)

式中:P为功率; 为空气密度;v∞为风速;A为风轮扫掠面积,即叶轮直径和叶片长度乘积。

为空气密度;v∞为风速;A为风轮扫掠面积,即叶轮直径和叶片长度乘积。

图5所示为叶片失速延迟控制垂直轴风力机的风能利用系数在各个工况下都高于McMaster H型垂直轴风力机。McMaster H型垂直轴风力机的最佳尖速比为1.6,最大风能利用系数为0.29,而失速延迟控制风力机的最佳尖速比在1.3,最大风能利用系数为0.33。

图5 风能利用系数对比图

Fig. 5 Comparison of wind-energy capture efficiency

4 气动性能分析

尖速比为1.3时风力机风能利用效率最高,在此尖速比下,分析叶片旋转半个周期内位于典型位置的流场特性。图6所示为风机叶片方位图,θ表示叶片1的方位角,设逆时针为正,0°<θ<180°为上风区,180°<θ<360°为下风区,由于上风区属于高能量区,所以对叶片气动性能的分析主要是对上风区叶片扰流特性展开。选取叶片1方位角θ为30°,90°,150°和210°这4个典型位置进行叶片扰流流场分析。

图6 风机叶片方位图

Fig. 6 Azimuth diagram of wind turbine blade

涡量场是描述漩涡运动的物理场,涡量即为流体速度的旋度,其中涡量称之为涡强,对涡量场进行分析,可以确定流场湍流程度。图7所示为不同方位角θ时叶片上中下3个截面涡量场的分布图。当叶片1方位角为30°和150°时,叶片表面附近涡强较小,叶片1方位角为90°和210°时,叶片表面附近涡强较大。在风轮旋转过程中,当上风区只有1个叶片时,叶片附近涡强明显增强,当上风区有2个叶片时,叶片附近涡强随之减弱,是因为当上风区只有1个叶片时,风能只有很小一部分被叶片吸收,多余的风能则激发气流紊动来耗散能量,表明如果垂直轴风力机采用4叶片,保证上风区至少有2个叶片,会取得更高的风能利用率。

图8所示为叶轮中部截面在不同方位角θ时的叶片中截面速度分布图。叶片在旋转过程中产生尾流,上风区叶片近场尾流向下游发展,扰动下风区叶片流场,影响其气动特性,同时塔架也会吸收部分风能,影响叶轮流场分布,降低风机做功能力。从图8可以看到:气流经过风轮之后,在风轮右下方位的一定范围内,风速下降较为明显,若安装多个垂直轴风力机,则要合理布置风机位置,使其避开低风速区。

图9所示为叶片1在不同方位角θ时的叶片翼型附近速度矢量分布图。叶片在旋转过程中,气流攻角变化很大,但从图9可以看到:层流并没有从叶片附面层分离,失速现象没有出现。说明射流管喷射气流对于延缓层流分离,提升翼型升力,增加风力机功率具有显著作用。

图7 不同方位角θ时叶片3个截面涡量场

Fig. 7 Vorticity field of three section in blade at different azimuth θ

图8 叶片中截面速度分布图

Fig. 8 Velocity distribution in middle section on blade

图9 叶片1中截面速度矢量分布图

Fig. 9 Velocity vector in middle section on blade 1

5 结论

1) 叶片吸力面增加射流管,在喷射气流作用下,叶片层流分离被延迟,翼型升力增加,风力机功率输出增加。该失速延迟控制风力机具有较高的风能利用率,最大风能利用系数达到0.33。

2) 若风力机的鼓风装置运转完全依赖于自身转动,当叶轮转速变化时,内置涡轮吸气装置的转速也跟着变化,不能保证射流以理想的速度喷出。当叶轮转速较低时,甚至形成不了射流。针对上述问题,可以加设电力助动鼓风装置,当叶轮转速过低或射流速度达不到理想速度时,可以采取电力助动鼓风的方法,以保证射流的稳定性。

参考文献:

[1] 蔡新, 潘盼, 朱杰. 风力发电机叶片[M]. 北京: 中国水利水电出版社, 2013: 4-7.

CAI Xin, PAN Pan, ZHU Jie. Blade of wind turbine[M]. Beijing: China Water Power Press, 2013: 4-7.

[2] 贺德馨. 风工程与工业空气动力学[M]. 北京: 国防工业出版社, 2006: 196-210.

HE Dexin. Wind engineering and industrial aerodynamics[M]. Beijing: National Defense Industry Press, 2006: 196-210.

[3] 徐林, 李学敏, 区家隽. 叶片数及弦长对升力型垂直轴风力机的影响[J]. 可再生能源, 2016, 34(12): 1834-1840.

XU Lin, LI Xuemin, OU Jiajun. The impact of blade number and chord length on lift-type vertical-axis wind turbine[J]. Renewable Energy Resources, 2016, 34(12): 1834-1840.

[4] 张立栋, 毕远瑛, 李少华, 等. 垂直轴风力机叶片与圆柱形塔架相互干涉的数值模拟[J]. 科学技术与工程, 2016, 16(4): 194-199.

ZHANG Lidong, BI Yuanying, LI Shaohua, et al. Interference between the blade and the cylindrical tower vertical axis wind turbine[J]. Science Technology and Engineering, 2016, 16(4): 194-199.

[5] SHARMA S, SHARMA R K. Performance improvement of Savonius rotor using multiple quarter blades–A CFD investigation[J]. Energy Conversion and Management, 2016, 127(1): 43-54.

[6] CASTELLI, M R, MONTE A D, QUARESIMIN M, et al. Numerical evaluation of aerodynamic and inertial contributions to Darrieus wind turbine blade deformation[J]. Renewable Energy, 2013, 51(1): 101-112.

[7] 祖红亚, 李春, 叶舟, 等. 垂直轴风力机动态流场及其气动性能分析[J]. 能源研究与信息, 2014, 30(4): 199-203.

ZU Hongya, LI Chun, YE Zhou, et al. Aerodynamic performance analysis and dynamic flow field of vertical axis wind turbine[J]. Energy Research and Information, 2014, 30(4): 199-203.

[8] 李岩. 垂直轴风力机技术讲座(五)垂直轴风力机设计与实验[J]. 可再生能源, 2009, 27(5): 120-122.

LI Yan. Lecture of vertical axis wind turbine (Ⅴ) the design and experiment of vertical axis wind turbines[J]. Renewable Energy Resources, 2009, 27(5): 120-122.

[9] 梅毅, 曲建俊, 许明伟. 垂直轴风力机叶片动态失速数值模拟[J]. 农业机械学报, 2014, 45(3): 184-190.

MEI Yi, QU Jianjun, XU Mingwei. Numerical study on blade dynamic stall of vertical axis wind turbine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(3): 184-190.

[10] 高伟, 李春, 叶舟. 基于滑移网格的H型垂直轴动态气动特性分析[J]. 流体机械, 2013, 41(10): 36-40.

GAO Wei, LI Chun, YE Zhou. Analysis of dynamic aerodynamic performance for H-type VAWT based on sliding mesh technique[J]. Fluid Machinery, 2013, 41(10): 36-40.

[11] 王虎彬, 徐志晖. 非对称翼型安装方式对垂直轴风力机性能影响的数值研究[J]. 沈阳航空航天大学学报, 2013, 30(1): 5-8.

WANG Hubin, XU Zhihui. Numerical study of the effect of asymmetric airfoil’s installation on the performance of wind turbine[J]. Journal of Shenyang Aerospace University, 2013, 30(1): 5-8.

[12] 姚兴佳, 王士荣, 董丽萍. 风力机的工作原理[J]. 可再生能源, 2006(2): 87-89.

YAO Xingjia, WANG Shirong, DONG Liping. The working principle of wind turbine[J]. Renewable Energy Resources, 2006(2): 87-89.

[13] 叶正寅, 解亚军, 武洁. 模型振动对翼型流场和气动性能的影响[J]. 工程力学, 2009, 26(4): 240-245.

YE Zhengyin, XIE Yajun, WU Jie. The effects of wind-tunnel model vibration on flow field and aerodynamics of an airfoil[J]. Engineering Mechanics, 2009, 26(4): 240-245.

[14] 伍艳, 谢华, 王同光. 风力机叶片的非定常气动特性计算方法的改进[J]. 工程力学, 2008, 25(10): 54-59.

WU Yan, XIE Hua, WANG Tongguang. Modification of calculating unsteady aerodynamic characteristic of wind turbine blades[J]. Engineering Mechanics, 2008, 25(10): 54-59.

[15] FERREIRA C S, KUIK G, BUSSEL G. Visualization by PIV of dynamic stall on a vertical axis wind turbine[J]. Exp Fluids, 2009, 46: 97-108.

[16] BRAVO R, TULLIS S, ZIADA S. Performance testing of a small vertical-axis wind turbine[C]// 21st Canadian Congress of Applied Mechanics. Toronto, Ontario, Canada, 2007: 3-7.

(编辑 赵俊)

收稿日期:2016-03-04;修回日期:2016-05-29

基金项目(Foundation item):中央高校基本科研业务费专项资金资助项目(2015B37714);江苏风力发电工程技术中心开放基金资助项目(ZK16-03-03);江苏高校首批2011计划项目(苏政办发[2013]56号) (Project(2015B37714) supported by the Fundamental Research Funds for the Central Universities of China; Project(ZK16-03-03) supported by the Open Foundation of Jiangsu Province Wind Technology Center; Project ([2013]56) supported by the First Group of 2011 plan of Jiangsu Province)

通信作者:高强,博士,从事风力机叶片气动性能研究;E-mail: gaoqiang12@126.com