AlN陶瓷自蔓延高温合成

来源期刊:中国有色金属学报1999年第4期

论文作者:郑永挺 王华彬 韩杰才 杜善义 赫晓东

文章页码:769 - 773

关键词:AlN陶瓷;自蔓延高温合成;致密化

Key words:AlN ceramics; self-propagating high-temperature synthesis; densification

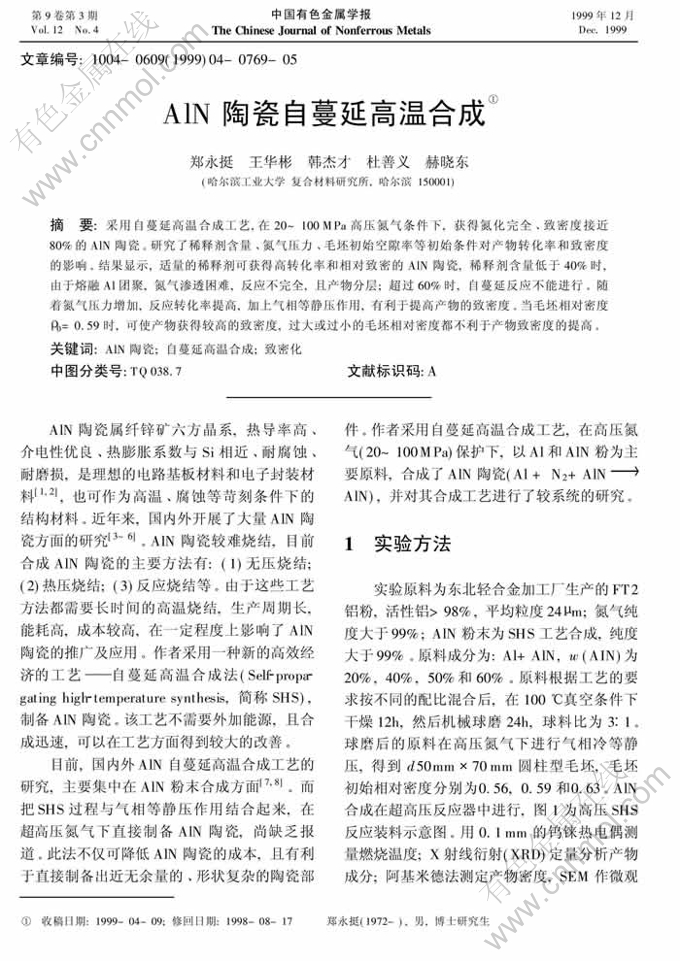

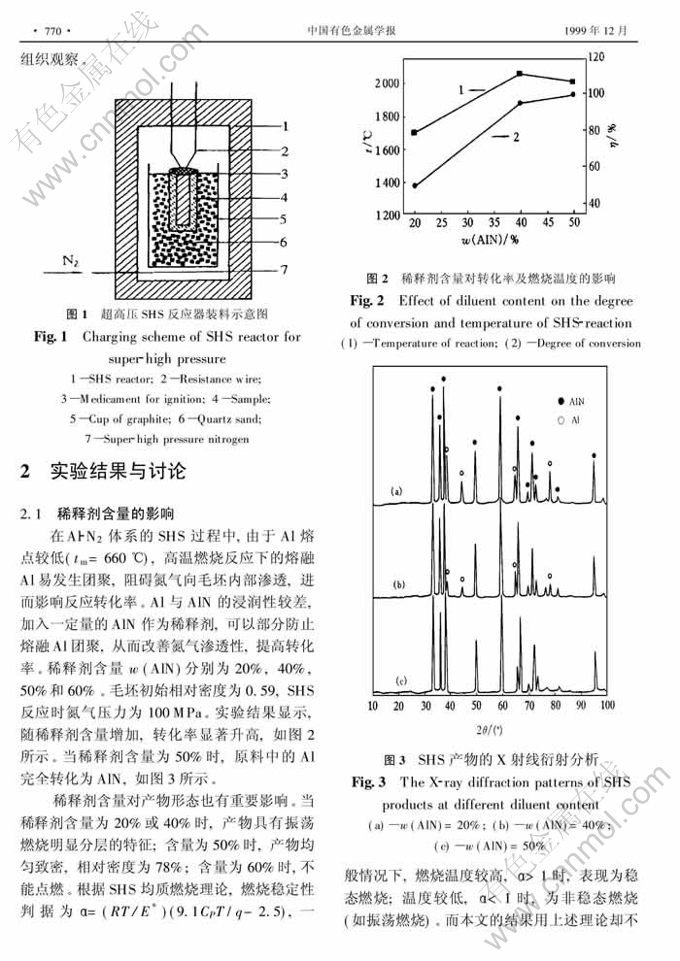

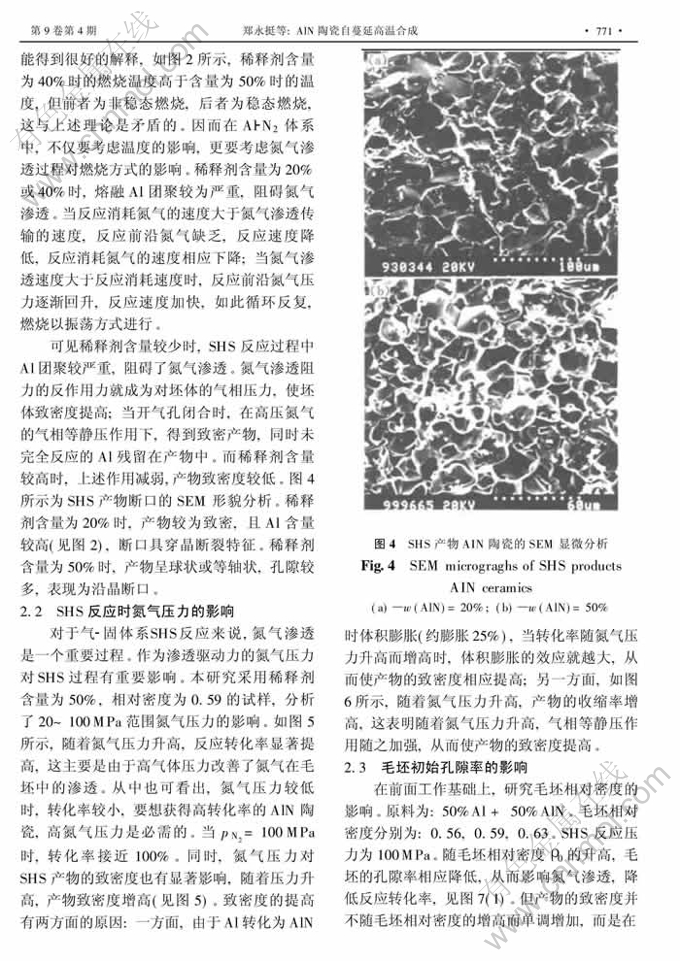

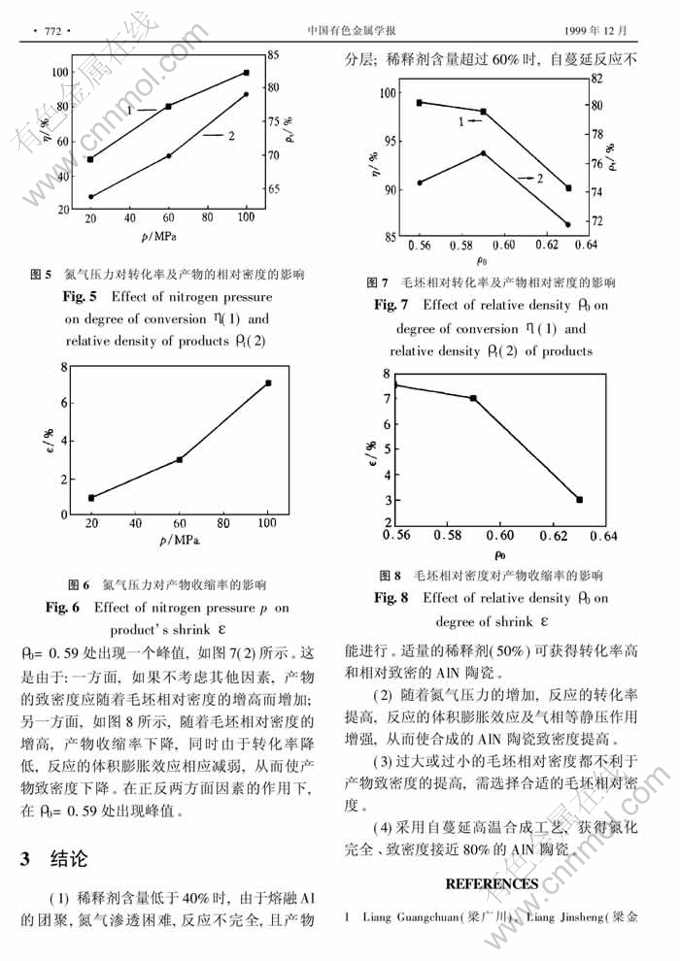

摘 要:采用自蔓延高温合成工艺,在20-100 MPa高压氮气条件下,获得氮化完全、致密度接近80%的AlN陶瓷。研究了稀释剂含量、氮气压力、毛坯初始空隙率等初始条件对产物转化率和致密度的影响。结果显示,适量的稀释剂可获得高转化率和相对致密的AlN陶瓷,稀释剂含量低于40%时,由于熔融Al团聚,氮气渗透困难,反应不完全,且产物分层;超过60%时,自蔓延反应不能进行。随着氮气压力增加,反应转化率提高,加上气相等静压作用,有利于提高产物的致密度。当毛坯相对密度(ρ0= 0.59时,可使产物获得较高的致密度,过大或过小的毛坯相对密度都不利于产物致密度的提高。

Abstract: Full conversion AlN ceramics with approximately 80% relative density were fabricated by self-propagating high-temperature synthesis(SHS) of Al particles in high pressure nitrogen. The effects of initial factors such as the content of diluent, nitrogen pressure and the porosity of compacts on the conversion and relative density of products were discussed in detail. Full conversion and relative density of AlN ceramics were synthesized by addition of appropriate diluents. At the lower level of the diluent in the sample, nitrogen gas is difficult to infiltrate due to aggregation of molten Al, Al cannot completely converse into AlN.As the content of the diluents is up to 60%, self-propagating high-temperature synthesis reaction cannot be self-sustained.With increasing of the pressure of nitrogen, the conversion of product increases and the relative density of the ceramics is improved. The low or high relative density of the sample is not benefit to improve the relative density of the ceramics.