房柱法矿柱合理尺寸设计及矿块结构参数优选

赵国彦1,周礼1, 2, 3,李金跃1,余佩佩1

(1. 中南大学 资源与安全工程学院,湖南 长沙,410083;

2. 长沙矿山研究院有限责任公司,湖南 长沙,410083;

3. 国家金属采矿工程技术研究中心,湖南 长沙,410083)

摘要:为科学设计矿柱,分析矿柱的承载机理,指出矿柱承受的荷载为顶板围岩塑性区内岩体的自身重力。针对矿柱尺寸过大的问题,运用普氏理论并考虑埋深的影响,推导出新的矿柱尺寸计算公式。结合某磷矿工程实例,计算得到2种不同的矿柱尺寸,并得到对应的2种矿块结构参数方案:方案A中矿柱长×宽为3.00 m×3.00 m,矿房跨度为12.75 m;方案B中矿柱长×宽为2.50 m×2.50 m,矿房跨度为10.00 m。采用数值模拟方法对包括原设计方案在内的3个方案进行优选,最终确定方案A为最优方案,矿石损失率由5.0%下降到1.8%,具有显著的经济意义。

关键词:采矿工程;房柱法;矿柱;结构参数

中图分类号:TD80 文献标志码:A 文章编号:1672-7207(2014)11-3943-06

Reasonable pillar size design and nugget structural parameters optimization in room-and-pillar mining

ZHAO Guoyan1, ZHOU Li1, 2, 3, LI Jinyue1, YU Peipei1

(1. School of Resources and Safety Engineering, Central South University, Changsha 410083, China;

2. Changsha Institute of Mining Research Co. Ltd, Changsha 410083, China;

3. National Research Center of Metal Mining Engineering and Technology, Changsha 410083, China)

Abstract: In order to reasonably design pillars, the bearing mechanism of pillars was clarified firstly. Load acting on the pillars is the gravity of rock masses in the plastic zone of the roof. In respect to the oversized pillars, a new formula was developed to calculate the geometric parameters of pillars secondly. Promojiyfakonov theory was used and the influence of mining depth was taken into consideration. With the engineering practice of one phosphate mining, two different schemes of pillar size and constructional parameters of nugget were calculated and obtained using the new formula. The pillar’s length×width is 3.00 m×3.00 m and the width of stope is 12.75 m in scheme A. The pillar’s length×width is 2.50 m×2.50 m and the width of stope is 10.00 m in scheme B. Three different schemes including scheme A, scheme B and the original scheme were optimized using the numerical simulation method. The results show that scheme A is the optimal one. The ore loss ratio decreases from 5.0% to 1.8% in scheme A, which has significant economic value.

Key words: mining engineering; room-and-pillar method; pillar; structural parameters

地下矿床开采大量使用房柱法或房柱嗣后充填采矿法。在回采过程中,为确保采场安全,常留设矿柱以支撑顶板围岩[1-3]。矿柱的稳定性直接关系到矿山开采安全,一旦矿柱失稳,会引发顶板围岩冒落,可能引发以下事故[4]:砸毁采场内作业设备,造成人员伤亡;矿体开采难度变大,采矿损失贫化率增大;压缩空气形成冲击气流,威胁作业人员安全等。相关研究表明,矿柱承载能力与矿柱尺寸成正比,矿柱尺寸越大,矿柱稳定性越好。另一方面,为提高矿山经济效益,减小矿石永久损失,在确保安全的前提下要求矿柱尺寸尽可能小。因此,合理的矿柱尺寸设计选取显得尤为重要。一般来说,矿柱尺寸设计是基于矿柱强度理论和矿柱载荷理论进行的[5-6]。研究人员就矿柱设计及采场结构参数优化进行了一系列调查、统计和研究,取得了许多成果,如:Bardy等[6]得到了矿柱强度与矿柱大小、几何形状的经验指数公式;王晓军等[7]分析了深部回采时人工连续矿柱的承载机理,提出了人工矿柱合理宽度计算公式;姚高辉等[8]研究了矿柱稳定性对其影响因素的敏感度,用数值模拟方法确定了圆形矿柱的合理直径及回采高度;刘学曾等[9]提出了矿柱可靠度设计方法;李俊平[10]应用材料力学推导了矿柱间距的计算公式,提出硬岩矿山矿柱设计新理论;刘钦等[11]应用数值模拟和混沌优化方法设计优化了采场结构参数。但在矿山开采过程中,矿柱设计往往没有考虑其承载机理,没有充分利用岩体的自稳能力而盲目加大矿柱尺寸。随着开采水平的加深,矿柱尺寸越来越大,矿柱积压矿石越来越多,资源浪费严重。为此,本文作者首先分析房柱法开采过程中矿柱的承载机理,然后运用普氏理论并计入埋深的影响,得到方形矿柱尺寸的计算公式。将该公式运用于某磷矿开采实例,计算得到2种矿柱尺寸及矿块结构参数,采用数值模拟方法对包括原结构参数在内的3个方案进行优选,得到最优矿块结构参数,确保顶板及矿柱的稳定,降低矿石损失率。

1 矿柱承载机理分析

矿柱面积承载理论认为矿柱承受的载荷为其支撑的开采空间范围内直达地表的上覆岩层重力,该矿柱支撑的面积为分摊的开采面积与自身面积之和。随着开采深度的加大,基于该理论设计的矿柱尺寸越来越大,积压的矿石越来越多。岩体工程实践表明,岩体开挖后顶板围岩中存在普氏拱,即顶板围岩中会形成一个自然平衡拱[12-14]。作用在支护上的载荷为拱内岩体的自重,而与拱外上覆岩体无关。普氏理论给出了地压计算公式、地压受开挖断面跨度并分析了岩石普氏系数的影响,但普氏地压计算公式没有考虑埋深的影响,而近年来深部井巷的地压显现规律、破坏范围表明,地压与埋深有紧密联系。因此,为克服普氏理论的不足,在计算地压时需计入埋深的影响。

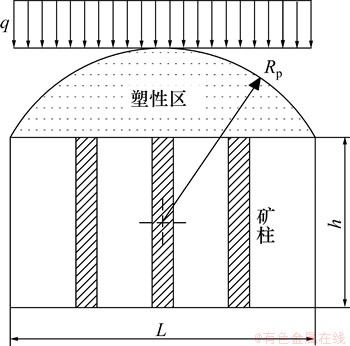

根据上述分析,矿柱承受的荷载仅为某一范围内岩体的重力。事实上,岩体开挖后,围岩中应力重新分布,在地应力作用下围岩中会形成1个半径为Rp的塑性区。Rp不仅与开挖断面跨度、岩体物理性质有关,而且受埋深H的影响。现代地压学说认为支护承受的载荷就是上部塑性区内岩石的全部重力,而与上覆岩层无关,因此,矿房开挖后,只要矿柱能承受顶板围岩塑性区范围内全部岩体的重力,就可保证顶板和矿柱整个系统的长期稳定。矿柱承载机理如图1 所示。

图1 矿柱承载机理示意图

Fig. 1 Schematic diagram of pillar bearing mechanism

2 矿柱尺寸计算公式

矿块回采后,忽略矿柱对顶板围岩中塑性区范围的影响,解卡斯特纳方程[15]即可得到顶板围岩中塑性区半径:

(1)

(1)

式中:R0为开挖半径;P0为开挖处的垂直自重应力;c为岩体内聚力;φ为岩体内摩擦角。

实验证明,塑性区半径Rp受开挖断面形状的影响很小,计算中可近似采用等效开挖半径即不同断面形状的外接圆半径代替。对于矿块,等效开挖半径R0为

(2)

(2)

式中:L为开采空间跨度,即矿块沿走向长度;h为开采空间高度。

开挖处的垂直自重应力P0为

(3)

(3)

式中:γ为顶板围岩的容重;H为开挖处埋深。

根据上述分析,矿柱承受的压力为顶板围岩塑性区内岩石的自身重力,而与塑性区外上覆岩层无关。为方便计算作用在矿柱上的荷载,将塑性区岩石顶压近似处理成为高为Rp的矩形均布顶压,此时,顶压集度为

(4)

(4)

整个开采空间跨度上的顶压为

(5)

(5)

当矿体倾角较小或近似水平、矿柱均匀布置时,塑性区半径Rp范围内岩体重力由开采范围内矿柱均匀承担。对于方形矿柱,有

(6)

(6)

式中:M为矿柱布置排数;N为单排矿柱个数;Wp为矿柱宽度;σ为矿柱中压应力;s为矿块倾向斜长。矿柱未发生失稳破坏时,有

(7)

(7)

式中:[σ]为矿体的抗压强度;f为安全系数,本文中取f=1.5[6]。联立式(1)~(7),解得方形矿柱宽度Wp的计算公式为

(8)

(8)

在工程实际中,应根据矿体实际赋存条件、产状及矿块参数L和s选取不同的M和N组合,运用式(8)计算得到不同的矿柱宽度,并就不同组合进行对比分析,最终确定矿柱尺寸。

3 工程应用

3.1 工程概况

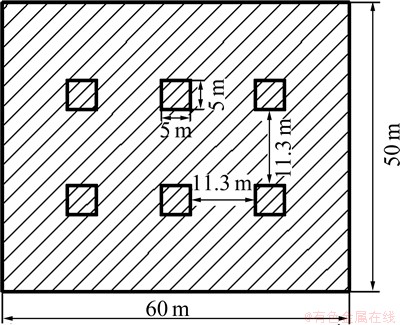

某磷矿矿体平均倾角为10°,平均厚度为10.00 m,设计采用房柱嗣后充填采矿法分盘区开采。目前回采标高为+1 450.00 m,上覆岩层厚约为200.00 m,其矿岩物理力学参数见表1。盘区内布置4个矿块,“采一充一”,单个矿块沿走向长度为60.00 m,倾向斜长为50.00 m,原方案矿块结构参数见图2。

图2 原方案矿块结构参数

Fig. 2 Constructional parameters of original scheme

3.2 合理矿柱尺寸设计

结合表1中矿石、顶板围岩物理力学参数,选取不同的M和N组合,代入式(8)得到2种可能的矿柱尺寸及布置方式。

方案A:M=2,N=3,Wp=2.85,近似取Wp=3.00;

方案B:M=2,N=4,Wp=2.47,近似取Wp=2.50。

据此得到各方案的具体结构参数见表2。

3.3 矿块回采数值模拟

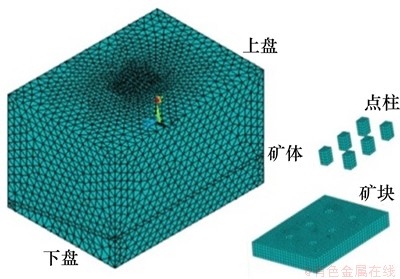

采用ANSYS三维弹塑性有限元软件模拟矿块回

采过程。有限元三维模型参数如下:矿体倾角为10°,分析范围为420.00 m×300.00 m×275.00 m,矿块走向长度为60.00 m,倾向斜长为50.00 m。有限元分析模型如图3所示,单元数量因结构参数不同而不同。计算时采用Drucker-Prager屈服准则,原岩应力按自重应力场处理。

表1 矿岩物理力学参数

Table 1 Physical-mechanical parameters of rock masses

表2 各方案矿块结构参数

Table 2 Nugget constructional parameters of different schemes

图3 有限元分析模型

Fig. 3 Finite element analysis model

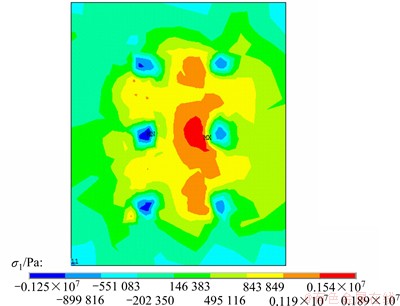

矿块回采后各方案顶板应力分布情况见图4~9。结果表明:矿块回采后,采场顶板围岩中出现拉应力并产生应力集中现象,最大拉应力的位置出现在采场中央;随着矿柱尺寸的减小和矿房跨度的增大,顶板拉应力、压应力均呈上升趋势。各方案顶板最大应力及位移见表3。从表3可见:当矿柱长×宽为2.50 m×2.50 m,矿房跨度为10.00 m(即方案B)时,拉应力与压应力达到最大,分别为2.25 MPa和9.83 MPa。矿块回采后会引起顶板的沉降与变形;当矿柱长×宽为2.50 m×2.50 m,矿房跨度为10.00 m时,顶板垂直位移最大,达到2.86 cm;当矿柱尺寸为5.00 m×5.00 m,矿房跨度为11.25 m(即原方案)时,顶板垂直位移最小,为1.87 cm。

图4 原方案顶板最大主应力s1

Fig. 4 Roof’s max principal stress s1 of original scheme

图5 原方案顶板最小主应力s3

Fig. 5 Roof’s min principal stress s3 of original scheme

图6 方案A顶板最大主应力s1

Fig. 6 Roof’s max principal stress s1 of scheme A

图7 方案A顶板最小主应力s3

Fig. 7 Roof’s min principal stress s3 of scheme A

图8 方案B顶板最大主应力s1

Fig. 8 Roof’s max principal stress s1 of scheme B

图9 方案B顶板最小主应力s3

Fig. 9 Roof’s min principal stress s3 of scheme B

矿块回采后矿柱中也出现了应力集中现象,最大压应力分布在矿柱和底板接触的边界处,最大拉应力则分布在矿柱腰部。矿柱中应力与位移均随矿柱尺寸的减小和矿房跨度的增大呈上升趋势。回采后各方案矿柱应力及位移见表4。从表4可见:当矿柱长×宽为2.50 m×2.50 m,矿房跨度为10.00 m(即方案B)时,最大拉应力为0.17 MPa,最大压应力为23.60 MPa,最大垂直位移为2.86 cm,均为各方案中最大值。

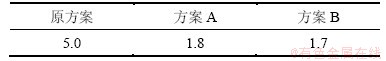

综合上述分析,各方案顶板及矿柱中应力均小于顶板围岩及矿体的抗压、抗拉强度,顶板及矿柱在回采过程中不会破坏失稳,说明原方案中矿柱尺寸设计过大,造成不必要的矿石损失。各方案的矿柱损失率见表5。从表5可见:原设计方案损失率最大,达到5.0%,方案A和B的损失率接近,分别为1.8%和1.7%。因此,在确保顶板与矿柱稳定的情况下,对比各方案矿柱损失率,基于本文公式设计的矿柱尺寸能显著降低矿石的损失量,具有显著的经济意义。

该矿地表大部为荒山,允许产生小规模沉降。从减少矿石损失和降低采场围岩应力的角度出发,确定方案A结构参数为最终合理矿块结构参数,矿柱长×宽为3.00 m×3.00 m,矿房跨度为12.75 m。

表3 各方案顶板应力及位移

Table 3 Press and displacement in roof of different schemes

表4 各方案矿柱应力及位移

Table 4 Press and displacement in pillars of different schemes

表5 各方案矿石损失率

Table 5 Ore loss ratio of different schemes %

4 结论

1) 传统的矿柱面积承载理论认为矿柱承受的载荷为其支撑的开采空间范围内直达地表的上覆岩层的重力。运用普氏理论基本思想,分析了房柱法开采过程中矿柱的承载机理,指出矿柱承受的荷载为顶板围岩塑性区内岩体的重力。

2) 运用普氏理论并考虑埋深的影响,推导出新的矿柱尺寸计算公式,使房柱法矿柱尺寸设计过程得以量化,矿柱尺寸趋于合理,既保证了回采过程中矿柱的稳定,又减少了回采中矿石的永久损失,提高了资源回收率。

3) 针对某磷矿开采工程实例,运用推导的矿柱尺寸计算公式得到2个不同的矿柱尺寸及2个不同的矿块结构参数:方案A中矿柱长×宽为3.00 m×3.00 m,矿房跨度为12.75 m;方案B中矿柱长×宽为2.50 m×2.50 m,矿房跨度为10.00 m。采用数值模拟的方法优选出方案A为最优方案,在此方案下,矿石损失率由原方案的5.0%下降到1.8%,具有显著的经济效益。

参考文献:

[1] 解世俊. 金属矿床地下开采[M]. 北京: 冶金工业出版社, 2008: 55-59.

XIE Shijun. Metal underground mining[M]. Beijing: Metallurgical Industry Press, 2008: 55-59.

[2] Ghasemi E, Ataei M, Shahriar K, et al. Assessment of rock fall risk during retreat mining in room and pillar coal mines[J]. International Journal of Rock Mechanics and Mining Sciences, 2012, 12(54): 80-89.

[3] Ghasemi E, Shahriar K. A new coal pillars design method in order to enhance safety of the retreat mining in room and pillar mines[J]. Safety Science, 2012, 50(3): 579-585.

[4] 赵兴东. 谦比希矿深部开采隔离矿柱稳定性分析[J]. 岩石力学与工程学报, 2010, 29(增刊): 2616-2621.

ZHAO Xingdong. Stability analysis of insulating pillar of excavation of Chambishi copper mine in depth[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(Suppl): 2616-2621.

[5] 杨明春. 矿柱尺寸设计方法研究[J]. 采矿技术, 2005, 5(3): 10-12.

YANG Mingchun. Study on size design method of pillars[J]. Mining Technology, 2005, 5(3): 10-12.

[6] Brady B G H, Brown E T. Rock mechanics for underground mining[M]. LI Xibing, DONG Longjun, trans. Beijing: Science Press, 2010: 326-328.

[7] 王晓军, 冯萧, 杨涛波, 等. 深部回采人工矿柱合理宽度计算及关键影响因素分析[J]. 采矿与安全工程学报, 2012, 29(1): 54-59.

WANG Xiaojun, FENG Xiao, YANG Taobo, et al. Reasonable width calculation and analysis of artificial pillar in deep mining[J]. Journal of Mining & Safety Engineering, 2012, 29(1): 54-59.

[8] 姚高辉, 吴爱祥, 王贻明, 等. 破碎围岩条件下采场留存矿柱稳定性分析[J]. 北京科技大学学报, 2011, 33(4): 400-405.

YAO Gaohui, WU Aixiang, WANG Yiming, et al. Stability analysis of stope retention pillars in broken rock conditions[J]. Journal of University of Science and Technology Beijing, 2011, 33(4): 400-405.

[9] 刘学曾, 翟德元. 矿柱可靠度设计[J]. 岩石力学与工程学报, 2000, 18(6): 85-88.

LIU Xuezeng, ZHAI Deyuan. The reliability design of pillar[J]. Chinese Journal of Rock Mechanics and Engineering, 2000, 18(6): 85-88.

[10] 李俊平. 缓倾斜采空场处理新方法及采场地压控制研究[J]. 岩石力学与工程学报, 2004, 23(2): 356-356.

LI Junping. Study on new disposing method and ground pressure control for gently inclined abandoned stope[J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(2): 356-356.

[11] 刘钦, 刘志祥, 刘爱华, 等. 金矿采场结构参数混沌优化[J]. 采矿与安全工程学报, 2010, 27(4): 548-552.

LIU Qin, LIU Zhixiang, LIU Aihua, et al. Chaotic optimization of structural parameters in gold mining field[J]. Journal of Mining & Safety Engineering, 2010, 27(4): 548-552.

[12] 李鸿博, 郭小红. 公路连拱隧道土压力荷载的计算方法研究[J]. 岩土力学, 2009, 30(11): 3429-3434.

LI Hongbo, GUO Xiaohong. Research on calculation methods of earth pressure on muti-arch tunnel for highway[J]. Rock and Soil Mechanics, 2009, 30(11): 3429-3434.

[13] 陈庆, 杨文喜, 卢珂. 深埋砾石层隧道围岩压力计算方法[J]. 施工技术, 2011, 40(增刊): 242-243.

CHEN Qing, YANG Wenxi, LU Ke. Calculating methods for the pressure of wall rock of immerged tunnel in gravel stratum[J]. Construction Technology, 2011, 40(Suppl): 242-243.

[14] 蔡美峰, 何满潮, 刘东燕. 岩石力学与工程[M]. 北京: 科学出版社, 2002: 63-70.

CAI Meifeng, HE Manchao, LIU Dongyan. Rock mechanics and engineering[M]. Beijing: Science Press, 2002: 63-70.

[15] 季卫东. 矿山岩石力学[M]. 北京: 冶金工业出版社, 1991: 36-41.

JI Weidong. Mining rock mechanics[M]. Beijing: Metallurgical Industry Press, 1991: 36-41.

(编辑 陈灿华)

收稿日期:2013-11-12;修回日期:2014-01-14

基金项目(Foundation item):国家重点基础研究发展计划(“973”计划)项目(2010CB732004);国家重点实验室开放基金资助项目(SKLGDUEK0906) (Project(2010CB732004) supported by Major State Basic Research Development Program; Project (SKLGDUEK0906) supported by Open Fund of State Key Laboratory)

通信作者:赵国彦(1963-),男,湖南沅江人,博士,教授,从事采矿工程、矿山安全和岩石力学与工程等研究;电话:13507311842;E-mail: gy.zhao@263.net