文章编号:1004-0609(2015)12-3422-08

再生WC-Co复合粉及高耐磨性硬质合金涂层的制备

刘雪梅,王海滨,宋晓艳,范金莲

(北京工业大学 材料科学与工程学院,北京 100124)

摘 要:以WC-6Co废旧硬质合金块体和Co3O4粉末为原料,采用氧化-还原碳化法制备再生WC-12Co复合粉,将复合粉经过造粒和热处理制备再生热喷涂喂料,进而采用超音速火焰喷涂(HVOF)制备再生WC-Co硬质合金涂层,比较再生硬质合金涂层和商业购买热喷涂喂料制备涂层的显微组织、耐磨性及其机制。结果表明:当配碳量为16.70%(质量分数)时,再生复合粉的碳含量适中;制备的再生热喷涂喂料由WC和Co相组成,热喷喂料球形度好,粒径分布均匀,平均粒径为23 mm;再生WC-12Co硬质合金涂层的结构致密,WC晶粒尺寸分布均匀。与商业化热喷涂粉制备涂层显微组织和性能相比,再生涂层的磨粒磨损性能明显优于商业喷涂粉制备涂层的,其根本原因是两者的磨损机制不同。

关键词:再生WC-Co复合粉;硬质合金涂层;磨损性能;配碳量;热喷涂粉末

中图分类号:TF124 文献标志码:A

Preparation of recycled WC-Co composite powder and high wear resistance cemented carbide coating

LIU Xue-mei, WANG Hai-bin, SONG Xiao-yan, FAN Jin-lian

(College of Materials Science and Engineering, Beijing University of Technology, Beijing 100124, China)

Abstract: Using the cemented carbides WC-6Co scraps and Co3O4 powder as the raw materials, the recycled WC-12Co composite powder was prepared by a short-term recycling technique which contains the oxidation and reduction- carbonization procedures. The thermal spray feedstock powder was fabricated by the process consisting of spray drying and heat-treatment. The recycled WC-Co cemented carbide coating was fabricated by high velocity oxy fuel (HVOF) method. Moreover, the microstructure, wear resistance and its mechanism of the coating prepared by the recycled composite powder and the commercial feedstock powder were compared. The results show that when the carbon addition is 16.7% (mass fraction), the recycled WC-Co composite has the appropriate carbon content. The fabricated feedstock only contains WC and Co phases, with homogeneously distribution of spherical particles and average particle size of 23 mm. The recycled WC-12Co coating has a high density and a homogeneous WC grain distribution. Compared the microstructure and properties of the coating fabricated by commercial feedstock powder, the recycled coating has better wear resistance, which is caused by different wear mechanisms.

Key words: recycled WC-Co composite powder; cemented carbide coating; wear resistance; carbon addition; thermal spray feedstock

废旧硬质合金因含有大量的极为重要的战略元素钨和稀有金属钴已成为宝贵的二次资源,其回收再利用与开采新矿石相比可减少约75%的能耗和40%二氧化碳污染[1],尤其是可有效降低矿产开采造成自然生态环境的破坏[2]。因此,废旧硬质合金的回收再利用对促进钨产业的可持续健康发展具有非常重要的经济和社会意义。目前,硬质合金的回收再生受到相关企业的极大关注,已有多种再生工艺应用于硬质合金的回收,如锌熔法[3]、机械破碎法[4]、电化学法[5]、高温处理法[6]和氧化-还原碳化法[7]等。其中,氧化-还原碳化法是将废旧WC-Co硬质合金在空气中加热氧化得到钨钴氧化物粉,与炭黑混合后,经原位还原碳化反应合成再生WC-Co复合粉的硬质合金再生技术。本文作者课题组采用氧化和还原碳化技术制备出钴含量与废旧硬质合金原料一致的再生WC-Co复合粉末,并通过烧结致密化获得高性能的再生硬质合金块体材料[8]。因此,氧化-还原碳化技术可制备出适合高性能硬质合金块体制备的高品质再生WC-Co粉末。

热喷涂WC-Co类硬质合金涂层因其较高的硬度、良好的韧性以及优良的耐磨/耐蚀性而广泛应用于航空航天、钢铁冶金、汽车零件等工业领域[9]。目前,关于原生喷涂粉的制备及喷涂工艺已进行了大量的研究[10-13],并取得重要的研究进展,研究结果表明,原料粉末的碳含量、喷涂粉末的球形度及流动性、喷涂工艺等对涂层的性能有重要的影响。然而,目前针对再生喷涂粉及涂层制备方面的研究鲜见报道。因此,在现有涂层制备理论和经验的指导下,制备高耐磨性再生WC-Co 类硬质合金涂层,将进一步拓展再生硬质合金复合粉的应用范围,具有非常广阔的应用前景。

本文作者以废旧WC-6Co硬质合金块体为原料进行氧化制备钨钴氧化物粉末,根据热喷涂WC-Co硬质合金涂层的钴含量和碳含量的要求,在钨钴氧化物粉末中加入适量钴的氧化物和炭黑,采用还原碳化方法制备再生WC-12Co复合粉,进而制备热喷涂喂料,采用目前喷涂WC-Co 类硬质合金涂层最常用的工艺方法超音速火焰喷涂[14-15]制备再生硬质合金涂层。并在此基础上,进行涂层磨损性能的测试和及其磨损机制的分析。

1 实验

以WC-6Co硬质合金为原料,在空气中加热至900 ℃氧化8 h制备钨钴氧化物粉末;对氧化得到的钨钴氧化物粉末的元素含量进行测定,根据涂层粉末钴含量和碳含量的要求计算出Co3O4和炭黑的需求量,按照配比混合后,在1000 ℃、3 h的条件下进行原位还原碳化反应,制备出再生WC-12Co复合粉;在再生复合粉中加入聚乙烯醇(PVA)、聚乙二醇(PEG)和离子水,经充分搅拌制成料浆,采用高速离心喷雾干燥机进行喷雾造粒,进而对喷雾干燥粉末在氩气保护下进行1200 ℃、1 h的热处理,得到再生WC-12Co热喷涂粉末。随后,利用JP-5000超音速火焰喷涂设备在的40Cr钢基体表面制备再生WC-12Co涂层,具体的喷涂工艺参数为:煤油流量22.0 L/h,氧气流量940 L/min,喷涂距离380 mm。作为对比实验,以商业购买的喷涂粉在相同基体和喷涂工艺条件下制备WC-12Co涂层。

采用X射线衍射仪(XRD)对氧化粉末和再生WC-Co复合粉、热喷涂喂料和硬质合金涂层进行物相分析;通过扫描电镜(SEM)观察粉末和涂层的显微组织;根据GB/T 5124.1和GB/T 5124.2采用燃烧-气体容量法和溶解法分别测定粉末中总碳量和游离碳量,根据相关国家标准进行W、Co和O等元素含量的测定;采用线性截距法测定试样的晶粒尺寸;在MLG-130型干砂橡胶轮式磨损试验机进行涂层磨损性能的评价,满足JBT_7705-1995(松散磨粒磨料磨损试验方法-橡胶轮法)标准的要求,磨粒磨损试样尺寸为56 mm×25 mm×5 mm,磨料为106 μm刚玉,橡胶轮转速为200 r/min,加载载荷为45 N。

2 结果与分析

2.1 废旧WC-6Co合金的氧化

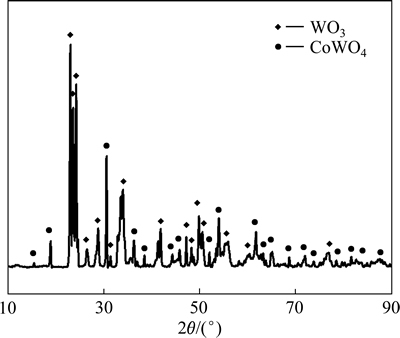

图1所示为废旧WC-6Co合金在空气中进行900 ℃、8 h氧化制备的氧化物粉末的XRD谱。由图1可以看出,氧化物粉末仅由WO3和CoWO4两相组成。表1所列为氧化物粉末中W和Co元素含量的实验测定结果及相组成的计算结果。根据Co元素含量可计算得到氧化物粉末中CoWO4的含量为26.36%(质量分数),其余为WO3(含量为73.64%(质量分数))。相含量的确定为后期配碳量的计算奠定了基础。

图1 废旧WC-6Co合金在空气中进行900 ℃、8 h氧化制备的氧化物粉末的XRD谱

Fig. 1 XRD pattern of oxide powder obtained by oxidation of WC-6Co cemented carbides scraps heated at 900 ℃ for 8 h in air

表1 氧化物粉末中W、Co元素含量的测定结果及相组成的计算结果

Table 1 Detected element contents of W and Co and calculated phase contents for oxidation powder (mass fraction, %)

2.2 再生WC-12Co复合粉的制备

将制备的钨钴氧化物粉末(WO3+CoWO4)、炭黑(C)和四氧化三钴(Co3O4)粉末进行原位还原碳化,发生如下反应:

(WO3+CoWO4)+C+Co3O4→WC+Co+CO↑ (1)

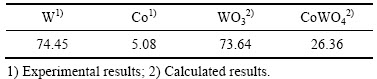

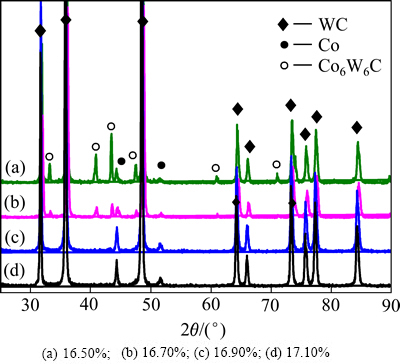

根据再生WC-12Co粉中Co含量的要求,计算出原料中需要添加Co3O4粉与钨钴氧化物粉末的质量比为7.46:100。并在此基础上,根据上述反应过程确定原料粉中所需的理论配碳量,即理论配碳量是原料总质量的16.85%。由于配碳量对再生WC-Co复合粉的相组成和化学成分具有重要的影响,在理论计算结果的指导下,本文作者对4种配碳量(16.50%、16.70%、16.90%、17.00%(质量分数))条件下制备的再生粉末的相组成和化学成分进行研究,其XRD谱和化学成分测定结果分别如图2和表2所示。由图2可知,在实验的范围内,制备的再生复合粉中除了WC、Co相外,还可能出现缺碳相(Co6W6C)。随着配碳量的增加,缺碳相含量明显减少;当配碳量增加为16.90%和17.00%时,复合粉中缺碳相消失,即制备出了只有WC和Co相的再生WC-Co复合粉末。

表2所列为再生复合粉末中不同元素含量的测定结果。由表2可以看出,再生复合粉末中的Co含量均在11.90%~12.10%之间,其O含量均小于0.30%,符合原生WC-12Co粉中Co含量和O含量的要求;总碳量和游离碳含量随着配碳量的增加呈增加的趋势。

综合分析复合粉的XRD谱以及总碳量和游离碳含量可知,当配碳量为16.50%时,复合粉的总碳量只有4.80%,低于WC-12Co粉含碳量的要求,且含有大量的缺碳相,不利于后期制备出相纯净的WC-Co热喷涂喂料;当配碳量为16.90%和17.00%时,复合粉中只含有WC和Co相,其总碳量和游离碳含量高,以此制备的热喷涂喂料碳含量偏高,不利于高性能WC-Co涂层的制备;当配碳量为16.70%时,复合粉中的总碳含量适中,虽然含有少量的缺碳相,但也含有少量的游离碳,缺碳相和游离碳在后期热喷涂喂料的制备过程中可继续反应,生成WC和Co相,有利于相纯净、流动性好的WC-Co热喷涂喂料和高性能涂层的制备[17]。因此,本文作者采用配碳量16.70%时制备的再生WC-12Co复合粉为制备再生热喷涂喂料和硬质合金涂层的原料。

图2 不同配碳量下制备再生WC-12Co复合粉的XRD谱

Fig. 2 XRD patterns of recycled WC-12Co composite powders prepared with different carbon additions

表2 再生WC-12Co复合粉中的元素含量

Table 2 Element contents of regenerated WC-12Co composite powders

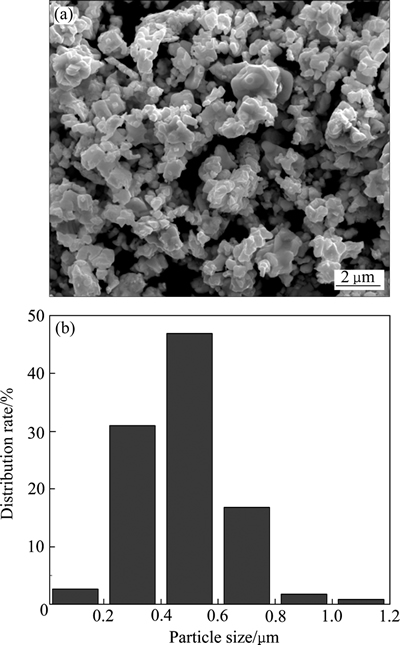

图3所示为配碳量为16.70%时制备的再生WC-12Co复合粉的SEM像及其颗粒尺寸分布图。由图3可以看出,粉末颗粒尺寸较为均匀,且大多数颗粒大小为0.2~0.8 μm,平均颗粒尺寸为0.5 μm。

2.3 热喷涂喂料的制备和再生WC-12Co涂层的制备

图3 配碳量为16.70%时制备的再生WC-12Co复合粉的SEM像及其颗粒尺寸分布

Fig. 3 SEM image(a) and particle size distribution(b) of regenerated WC-12Co composite powder with carbon addition of 16.70% in raw powders

为制备具有高致密度和良好流动性的热喷涂喂料,采用喷雾干燥和热处理相结合的工艺路线对再生WC-12Co复合粉进行团聚造粒。

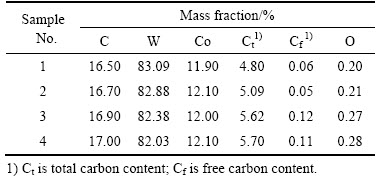

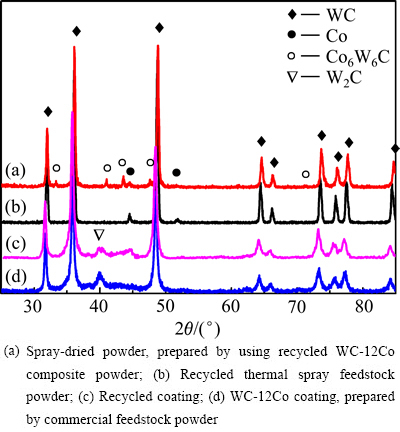

图4(a)和(b)所示为再生WC-12Co复合粉喷雾干燥后和进行热处理后制备的造粒粉和热喷涂喂料的XRD谱。由图4(a)和(b)可以看出,造粒粉与再生复合粉的相组成一致,均由WC、Co和一定量的缺碳相组成,而造粒粉经过热处理后制备的热喷涂喂料仅由WC和Co相组成。

图4(c)和4(d)分别是以再生WC-12Co热喷涂喂料和商业购买热喷涂粉末为原料,经超音速火焰喷涂方法制备的WC-12Co涂层的XRD谱。由图4(c)和(d)可以看出,两者在相组成上基本一致,均由WC、Co相和少量W2C相组成。不同于热喷涂粉的物相,即仅由WC和Co相组成(见图4(b))。究其原因,WC-Co粉末在喷涂过程中,WC颗粒直接与空气中的氧气接触,发生脱碳反应,生成W2C相所致[16]。

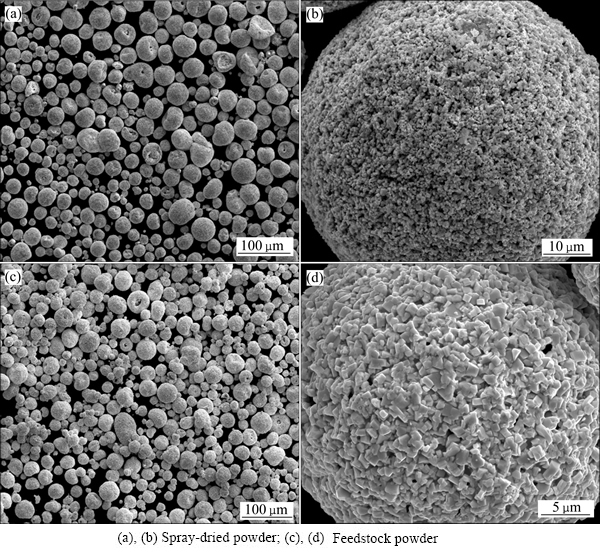

由造粒粉和热喷涂喂料的SEM像(见图5)可以看出,两种粉的颗粒基本呈球形,造粒粉的颗粒尺寸略大于热处理后制备的热喷涂喂料的颗粒尺寸(平均颗粒尺寸为23 μm)。但造粒粉颗粒上孔洞较多,结合松散,其WC 晶粒尺寸细小(见图5(b));与造粒粉相比,图5(d)所示热喷涂喂料的颗粒内部则结合紧密,孔隙少,且由棱角分明的WC晶粒组成,且尺寸明显增大。分析可知,在热处理过程中粉末颗粒发生了如下变化:造粒过程中掺入的有机粘结剂(PVA)的分解、挥发;粉末的致密化及局部烧结和WC晶粒的长大;粉末中的游离碳与未反应完全的缺碳相发生化合反应,生成WC和Co相,即消除缺碳相。

图4 不同粉末和涂层的XRD谱

Fig. 4 XRD patterns of different powders and coatings

综上所述,再生WC-12Co复合粉末经过喷雾干燥和热处理相结合的工艺可制备出仅由WC和Co相组成的、颗粒结构致密的热喷涂喂料。

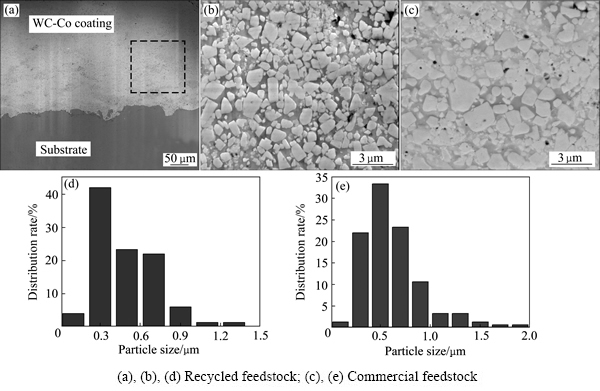

图6所示为再生和商业购买WC-12Co粉末制备涂层的断面形貌。由图6可以看出,制备的再生硬质合金涂层与基体结合紧密、组织致密、空隙细小,但存在个别较大的孔洞。可以推断,喂料中的颗粒在喷涂过程中充分熔融、变形,具有良好的填充孔隙的能力且颗粒之间相互咬合作用强,使得涂层致密,层与层间结合能力增强所致[17]。涂层中的WC晶粒和Co相分布均匀,其晶粒尺寸大部分为0.3~0.9 μm,平均尺寸为0.5 μm,硬度为1310HV0.3;而商业购买喷涂粉制备涂层中晶粒平均尺寸为0.6 μm,并含有较多较小的孔洞,晶粒尺寸的增大和孔洞的存在会降低涂层的耐磨性[18]。

图5 再生WC-12Co复合粉造粒后粉末和喷涂喂料的SEM像

Fig. 5 SEM images of different powders prepared by regenerated WC-12Co composite powder

图6 不同热喷涂粉制备WC-12Co涂层的断面形貌及粒径分布率

Fig. 6 Cross section morphologies((a)-(c)) and particle size distributions((d), (e)) of WC-12Co coatings sprayed by different feedstocks

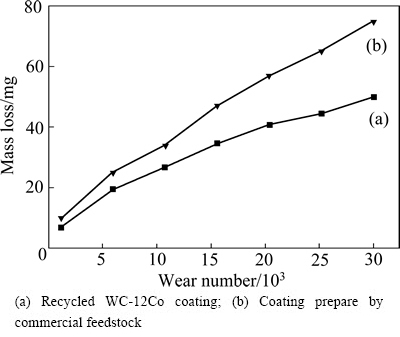

图7 不同喷涂粉制备WC-12Co涂层的磨损量与磨损次数的关系

Fig. 7 Relationship between wear resistance and wear number of WC-12Co coatings sprayed by different feedstocks

图7所示为采用磨粒磨损测试得到的再生与商业购买喷涂粉末制备涂层的磨损量随磨损次数(转数)的变化曲线。由图7可知,随磨损次数的增加,涂层的磨损量均逐渐增加。相比于商业购买涂层粉制备的硬质合金涂层,再生WC-12Co涂层具有更好的耐磨性,随着磨损次数的增加,这种优势更加明显。当磨损次数达到30000次时,再生涂层的磨损量为50 mg,与商业涂层粉制备涂层的磨损量下降了33.3%。由此可见,采用再生WC-12Co复合粉为原料,采用喷雾干燥和热处理工艺制备的喂料粉,经超音速火焰喷涂可制备出与基体结合良好、涂层组织致密、耐磨性优良的硬质合金涂层。

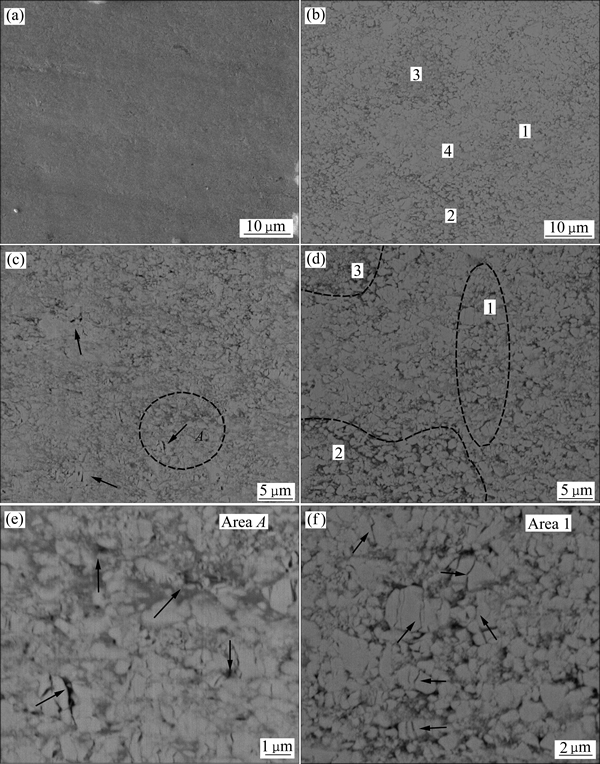

为了分析再生WC-12Co涂层的耐磨性优于商业购买喷涂粉制备涂层的原因,对两种涂层的相组成和涂层磨损后的形貌进行了观察。图8所示为涂层经30000 r磨损后试样的表面形貌。

图8 制备的WC-12Co涂层磨损后的表面形貌和商业购买粉末制备涂层的表面形貌

Fig. 8 Worn surface morphologies of WC-Co coatings prepared with recycling WC-12Co powder((a), (c), (e)) and commercial feedstock powder((b), (d), (f))

由图8(a)可知,再生硬质合金涂层磨后出现了明显的划痕沟、塑性变形沟和少量的剥落坑,由放大后可知(见图8(c)和(e)),涂层中少量的WC颗粒与周边颗粒间形成的裂痕与孔洞(如图8(e)中实线箭头所示)。由此可见,涂层的磨损主要以塑性变形和微切削为主,伴有少量的WC颗粒剥落。由商业购买的涂层粉制备的涂层磨损后,磨损表面存在明显的剥落现象(如图8(b)和8(d)中所示的已剥落区域3、正在剥落的区域1、2和未剥落区域4),WC颗粒和基体间存在明显裂纹,说明涂层颗粒间的结合强度较低。由图8(f)可知,正在剥落区域涂层中存在大量的WC颗粒及与周边颗粒间形成的裂纹与孔洞(图8(f)中虚线箭头所示),WC颗粒的破碎会加剧WC颗粒的脱落,致使磨损加剧。因此,商业购买喷涂粉制备涂层的磨损方式主要是WC颗粒的破碎和剥落。究其原因,刚玉磨粒硬度大,可对涂层内的WC和Co相同时进行切削[19],在切削的过程中,WC晶粒可能被切削成小块和更小的碎屑,晶粒尺寸大和有孔隙的试样更容易在切削过程中产生应力集中而破碎,造成磨损加剧。

综上所述,相比于商业购买喷涂粉制备的涂层,再生WC-Co热喷涂涂层具有更为优异的耐磨性能,其主要原因是再生涂层的磨损机制主要为塑性变形和少量的WC颗粒剥落,不同商业购买喷涂粉制备的涂层以颗粒剥落为主的磨损方式。

采用氧化和还原碳化方法回收制备再生WC-Co粉末,进而采用造粒和热处理工艺获得热喷涂喂料粉末,并进行超音速火焰喷涂的技术路线可制备出硬度高、耐磨性好的再生WC-Co涂层,表明该回收路线可制备出合格的再生热喷涂粉末,并可应用于高耐磨性涂层的制备。

3 结论

1) 采用氧化和还原碳化技术,通过对原料中钴和碳含量的调控,制备出平均颗粒尺寸为0.5mm,化学成分适合制备热喷涂涂层的再生WC-12Co复合粉。

2) 由再生WC-Co复合粉经造粒和1200 ℃、1 h氩气气氛中热处理,制备出仅由WC和Co相组成、平均颗粒尺寸23 mm、颗粒结构致密的再生WC-12Co热喷涂喂料。

3) 以再生WC-12Co热喷涂喂料为原料经超音速火焰喷涂制备出与基体结合紧密、组织致密、WC平均晶粒尺寸约为0.5 μm、硬度达到1310HV0.3的再生硬质合金涂层。

4) 与商业购买热喷涂粉为原料制备涂层相比,再生硬质合金热喷涂涂层具有更好的耐磨损性,在80 N的载荷下其磨损量可降低33.3%,磨损机制的不同是再生硬质合金涂层具备优异耐磨性的根本原因。

REFERENCES

[1] LIN L, LIU K, ATSUSHI S, WANTAI Y, TOYOHISA F, OSAMU S, AKIRA K. Recovery of tungsten and vanadium from tungsten alloy scrap[J]. Hydrometallurgy, 2004, 72(1/2): 1-8.

[2] 左铁镛, 宋晓艳. 我国高端钨制品发展有关问题的思考与探讨[J]. 硬质合金, 2012, 29(6): 337-343.

ZUO Tie-yong, SONG Xiao-yan. Discussions concerning development of high-grade tungsten products in China[J], Cemented Carbide, 2012, 29(6): 337-343.

[3] FREEMANTLE C S, SACKS N, TOPIC M, PINEDA-VARGAS C A. Impurity characterization of zinc-recycled WC-6wt.% Co cemented carbides[J]. International Journal of Refractory Metals and Hard Materials, 2014, 44: 94-102.

[4] 吴子军, 梁小华. “新型破碎法”回收料生产硬质合金的工艺探索[J]. 硬质合金, 2004, 12(4): 241-243.

WU Zi-jun, LIANG Xiao-hua. The tecnniques discussion of producing cemented carbide with recycling materials by the new type crashing method[J]. Cemented Carbide, 2004, 12(4): 241-243.

[5] 张 立, 陈述, 熊湘君, 黄伯云, 张传福. 电化学回收WC粉末质量控制问题的探讨[J]. 硬质合金, 2006, 23(2): 103-106.

ZHANG Li, CHEN Shu, XIONG Xiang-jun, HUANG Bai-yun, ZHANG Chuan-fu. Study on the quality control of tungsten carbide powder reclaimed by electrochemical method[J]. Cemented Carbide, 2006, 23(2): 103-106.

[6] 陈 芃, 李海坤. 硬质合金高温处理回收工艺研究[J]. 硬质合金, 2001, 18(4): 201-204.

CHEN Peng, LI Hai-kun. Study on the technique of reclaiming cemented carbide by high-temperature treatment[J]. Cemented Carbide, 2001, 18(4): 201-204.

[7] JUNG W G. Recovery of tungsten carbide from hard material sludge by oxidation and carbothermal reduction process[J]. Journal of Industrial and Engineering Chemistry, 2014, 20: 2384-2388.

[8] 王 瑶, 刘雪梅, 宋晓艳, 魏崇斌, 王海滨, 王西龙. 高性能再生硬质合金的短流程回收制备[J]. 金属学报, 2014, 50(5): 633-640.

WANG Yao, LIU Xue-mei, SONG Xiao-yan, WEI Chong-bin, WANG Hai-bin, WANG Xi-long. Short-term process of recycling cemented carbide scraps and preparation of high performance hard metals[J]. Acta Metallurgica Sinica, 2014, 50(5): 633-640.

[9] 李学伟, 孟 银, 王 鹏, 程浩然. 热喷涂WC-10Co4Cr涂层的研究现状[J]. 中国钨业, 2014, 29(2): 28-31.

LI Xue-wei, MENG Yin, WANG Peng, CHENG Hao-ran. Research status of WC-10Co4Cr coatings prepared by thermal spraying[J]. China Tungsten Industry, 2014, 29(2): 28-31.

[10] ZHAN Q, YU L, YE F, XUE Q, LI H. Quantitative evaluation of the decarburization and microstructure evolution of WC-Co during plasma spraying[J]. Surface and Coatings Technology, 2012 , 206(19/20): 4068-4074.

[11] GHADAMI F, HEYDARZADEH S M, GHADAMI S. Effect of bond coat and post-heat treatment on the adhesion of air plasma sprayed WC-Co coatings[J]. Surface and Coatings Technology, 2015, 261: 289-294.

[12] WANG T, ZHAO S, HUA W, LI J, GONG J, SUN C. Estimation of residual stress and its effects on the mechanical properties of detonation gun sprayed WC-Co coatings[J]. Materials Science and Engineering A, 2010, 527(3): 454-461.

[13] DU H, HUA W, LIU J, GONG J, SUN C, WEN L. Influence of process variables on the qualities of detonation gun sprayed WC-Co coatings[J]. Materials Science and Engineering A, 2005, 408(1/2): 202-210.

[14] WANG H B, SONG X Y, LIU X M, WEI C B, GAO Y, FU J. Effect of heat-treatment of spray-dried powder on properties of ultrafine-structured WC-Co coating[J]. Surface Coating Technology, 2012, 207: 117-122.

[15]  J, RAMS J. Protection of carbon steel against molten aluminum attack and high temperature corrosion using high velocity oxygen-fuel WC-Co coatings[J]. Surface and Coatings Technology, 2015, 262: 123-133.

J, RAMS J. Protection of carbon steel against molten aluminum attack and high temperature corrosion using high velocity oxygen-fuel WC-Co coatings[J]. Surface and Coatings Technology, 2015, 262: 123-133.

[16] DING Z X, CHEN W, WANG Q. Resistance of cavitation erosion of multimodal WC-12Co coatings sprayed by HVOF[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(10): 2231-2236.

[17] 李松林, 向锦涛, 周伍喜, 李玉玺, 陈 文. 超音速火焰喷涂WC-10Co4Cr 涂层的耐滑动磨损行为[J], 中国有色金属学报, 2012, 22(5): 1371-1376.

LI Song-lin, XIANG Jin-tao, ZHOU Wu-xi, LI Yu-xi, CHEN Wen. Sliding wear behavior of high-velocity oxy-fuel sprayed WC-10Co4Cr coatings[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1371-1376.

[18] YANG Q Q, SENDA T, OHMORI A. Effect of carbide grain size on microstructure and sliding wear behavior of HVOF sprayed WC-12%Co coating[J]. Wear, 2003, 254: 23-34.

[19] 王 群, 屈帮荣, 唐瞾肸, 熊浩奇. 超音速火焰喷涂碳化钨-钴涂层磨粒磨损行为[J], 中国有色金属学报, 2015, 25(7): 1920-1928.

WANG Qun, QU Bang-rong, TANG Zhao-xi, XIONG Hao-qi. Abrasive wear behavior of WC-Co coating deposited by high velocity oxygen flame process[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1920-1928.

(编辑 李艳红)

基金项目:国家高新技术研究发展计划主题项目(SQ2013AAJY3168);国家自然科学基金资助项目(51174009);北京市自然科学基金重点资助项目(2131001)

收稿日期:2015-03-31;修订日期:2015-09-28

通信作者:宋晓艳,教授,博士;电话:010-67392311;E-mail: xysong@bjut.edu.cn