DOI: 10.11817/j.issn.1672-7207.2019.02.011

蒸馏水中TC4合金微动磨损特性

宋伟,孙璐,景鹏飞,俞树荣

(兰州理工大学 石油化工学院,甘肃 兰州,730050)

摘要:针对TC4合金在蒸馏水中的微动磨损行为,采用典型微动磨损试验分析不同摩擦配副材料下法向载荷与磨损形貌、摩擦因数和磨损性能的关系。研究结果表明:蒸馏水中TC4合金微动磨损机制是疲劳脱层、磨粒磨损;蒸馏水中的摩擦因数曲线呈上下持续波动;在蒸馏水中GCr15/TC4摩擦因数比Si3N4/TC4的大,而且后者摩擦因数曲线突变的峰值远比前者的大;载荷增加磨损体积和磨损率均会增大,并且两者的变化趋势与摩擦因数的变化趋势一致;在50,80和100 N这3种载荷下,GCr15/TC4磨损体积和磨损率均比Si3N4/TC4的大,Si3N4/TC4耐磨性比GCr15/TC4的耐磨性强,蒸馏水中Si3N4球作摩擦副材料时耐磨性较强;蒸馏水中TC4合金的腐蚀和磨损交互作用的比率非常小且为负值,说明蒸馏水只有润滑作用,TC4合金的材料流失量主要由机械磨损控制。

关键词:TC4合金;微动磨损;蒸馏水;交互作用

中图分类号:TG115.5 文献标志码:A 文章编号:1672-7207(2019)02-0328-08

Fretting wear characteristics of TC4 alloy in distilled water

SONG Wei, SUN Lu, JING Pengfei, YU Shurong

(College of Petrochemical Technology, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The characteristic of fretting wear of TC4 alloy in distilled water were studied and typical fretting wear experiments were made to analyze the relationship between loading, wear scars, the friction coefficient and the wear resistance under different friction counterparts. The results show that the wear mechanism is fatigue delamination and abrasive wear. The friction coefficient curves fluctuate in distilled water. The friction coefficient of GCr15/TC4 is larger than that of Si3N4/TC4 and the peak mutation of Si3N4/TC4 is greatly higher than that of GCr15/TC4 in distilled water. The wear rate and wear volume increases with the increase of load and their variation trend is consistent with that of friction coefficient curve. The wear rate and wear volume of GCr15/TC4 is larger than that of Si3N4/TC4 under different loads(50,80 and 100 N),which means that the abrasion performance of Si3N4/TC4 is better than that of GCr15/TC4, and Si3N4 ball performs the best wear properties in distilled water. The interaction ratio between corrosion and wear in distilled water is negative and accounts for a very small proportion, which indicates that distilled water only acts as lubrication and the material losses of TC4 alloy are determined by mechanical wear.

Key words: TC4 alloy; fretting wear; distilled water; synergy

微动是指发生在两接触表面之间的局部相对运动,其振幅不超过300 μm [1-4]。零部件之间的长期微动会造成微动损伤,这种损伤形式在铁建、核反应堆、石油化工、生物医学等领域广泛存在[5]。根据微动的作用机理,微动可以分为微动磨损、微动腐蚀和微动疲劳共3类,每种微动都可显著降低构件的服役寿命[6-7],因其具有危害的隐蔽性、复杂性等特点,已成为关键零部件失效的主要原因,也成为人们研究的热点和难点[8-9]。TC4合金因具有很多优良性能以及极好的生物相容性成为钛合金家族中研制最早、工艺最成熟、应用最广泛的合金,是航空航天领域最常用的金属材料;但TC4合金因其自身局限性和缺点,在使用过程中极容易造成损伤[10-11],导致某些构件的疲劳寿命降低30%~80%,如:输送工程管道里的球阀在微幅振动时,球体与阀体面间存在微动磨损;油田的锚泊钢索因微动腐蚀而失效[12-13]。只要存在液体介质,微动磨损产生的影响便与干空气产生的影响不同,即润滑和腐蚀起协同作用,因此,对液体介质下的微动磨损行为和机制进行研究有重要意义。为此,本文作者采用球/平面接触方式,并与质量分数为3.5% NaCl溶液中的微动腐蚀机理进行对比,探讨钛合金在水介质下的微动磨损机制和磨屑的演化过程,分析其在蒸馏水中TC4合金腐蚀磨损的交互作用。

1 试验

上试样分别是直径为10.0 mm的GCr15球(维氏硬度约680)和Si3N4球(维氏硬度约1 500),下试样是直径×高为24.0 mm×7.8 mm的TC4合金圆柱(维氏硬度约300),化学成分见表1。对试验所需试样的制备过程如下:用180~7000号 SiC金相砂纸手工抛磨、机械抛光、用100 mL自制的腐蚀剂(质量分数为40%氢氟酸、质量分数为69%的硝酸、蒸馏水的体积比为1:3:16)擦拭腐蚀约20 s、清洗干燥备用。在SRV-IV摩擦磨损试验机(德国Optimol油脂公司)上作球/平面接触方式的微动磨损试验。主要试验参数如下:微动循环周次1.8×105;载荷分别为50,80和100 N;振幅D=-100~100 μm;频率为50 Hz;实验温度为25 ℃;相对湿度为20%~25%。用注射器每隔15 min将蒸馏水注射到接触区,使接触区域完全被液体封闭。

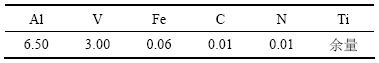

表1 TC4合金的化学元素成分(质量分数)

Table 1 Chemical element composition of TC4 alloy %

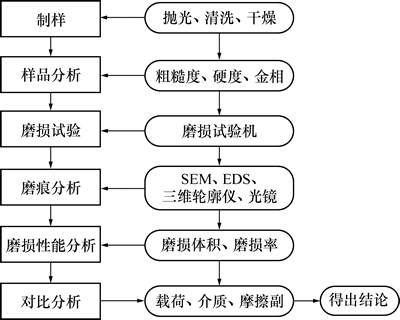

试验前对上、下试样用酒精擦拭清洗,保证接触面洁净。试验完毕后保持试样原貌,用酒精清洗、干燥后用Quanta FEG 250场发射扫描电子显微镜(SEM)分析磨痕表面形貌。在试验过程中由计算机实时采集摩擦因数;用三维轮廓仪测量磨损体积。本文所采用的技术路线图见图1。

图1 技术路线

Fig. 1 Technology road

2 结果分析

2.1 表面形貌分析

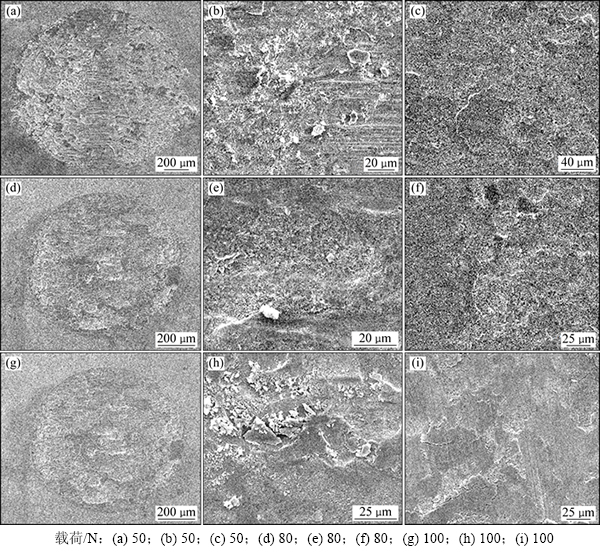

GCr15/TC4在蒸馏水中的磨痕形貌SEM图见图2。从图2(a),(d)和(g)可知:蒸馏水中磨损产生的磨痕形貌总体比较完整,边缘轮廓清晰,在增大接触载荷的同时,接触区域承受挤压和剪切应力的双重作用,从而在亚表面产生许多微裂纹并向表面扩展,最终TC4合金产生疲劳脱落,加剧表面磨损破坏程度;当载荷为50 N时,表面形貌中心存在与相对运动方向一致的划痕,边缘则出现黏着磨损现象,有连续的磨屑压实区。从图2(b),(e)和(h)可知:增大接触载荷时,大量堆积的磨屑在挤压和剪切的双重作用下促使黏着磨损逐渐转变为磨粒磨损,TC4合金大面积脱落,局部区域存在浮雕特征的黏着磨损;当载荷增加到100 N时,有大量的絮状磨屑散落在接触表面,说明此时磨损完全由磨粒磨损主导。从图2(h)可以看到龟裂和基体材料脱落所形成的凹坑,在材料剥落的区域常常聚集很多微动裂纹,这不仅说明该区域应力过度集中,更进一步证实微动裂纹是疲劳脱落的基础。由图2(b),(e)和(h)可以看出在微动接触区域的磨屑以颗粒状、层片状以及摩擦热烧结而成的块状存在。这可用磨屑的演化过程来描述:大尺寸磨屑经过上试样的碾压变成细小的颗粒状磨屑,接触区域产生的摩擦热使这些聚集的颗粒状磨屑烧结成块,此过程可延续至试验终止;随着载荷增加,颗粒状和层片状磨屑数量显著增加,形成2种磨屑混合的聚集区,该聚集区域因压力增加,导致两相磨屑发生焊合而重新形核,通过上试样反复挤压而覆盖在接触表面,从而形成连续的第三体压实区,这时,接触区域很明显从二体接触转变成二、三体混合接触,接触区域存在因磨屑被磨损产生犁沟,此时,微动运行状态为混合滑移状态;边缘形貌则呈现磨屑因上试样推挤变形而产生的层层压实区和疲劳脱落现象,见图2(c),(f)和(i)。

图2 GCr15/TC4在蒸馏水中的磨痕形貌SEM图

Fig. 2 SEM images of wear scars of GCr15/TC4 in distilled water

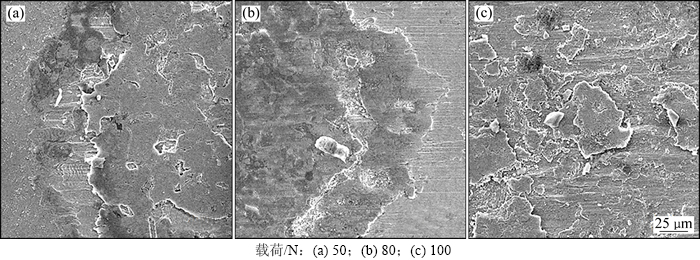

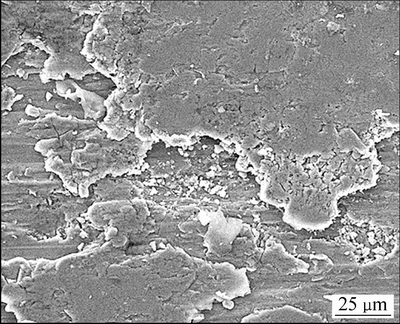

Si3N4/TC4在蒸馏水中的磨痕形貌SEM图见图3。从图3可以看出:当载荷较小时(50 N和80 N),出现黏着磨损现象,边缘有刮擦的痕迹,存在较严重的黏着现象;当载荷为100 N时,在磨粒被磨损的同时,随着载荷增加产生轻微的脆性脱落现象。由于摩擦过程中有大量的摩擦热产生,此外,微动接触区域较小,磨屑很难排出,故在接触区域表面聚集、烧结成块状;Si3N4球中Si与蒸馏水、氧气发生反应生成质软、剪切强度大的SiO2凝胶,同时,由于TC4自身黏着性较强,大量磨屑很难排出,与凝胶膜混合在一起堆积在磨损边缘,并在磨损表面产生沿相对运动方向的划痕,产生的膜层沿短轴方向经上试样挤压最终扩展到整个表面,边缘出现较浅的犁沟及氧化的磨屑/凝胶层,见图3(a);大量黏结的TC4材料在剪切力作用下脱落演变形成磨屑,随后,蒸馏水带走部分磨屑,形成黏结剥落,见图3(b);当载荷增加至100 N时,TC4合金内部拉应力和压应力交替作用的频率加快,产生疲劳损伤,在接触区域与非接触区域的边缘有裂纹萌生,而且TC4合金的内部也出现剪切应力,使得平行于表面的微裂纹快速萌生,并向表面扩展。蒸馏水的分子直径仅为4×10-10 m,但极性极强[14],对于钛合金这种化学活性强的合金来说,水分子容易渗透,这几个因素共同作用使磨损的中心区域产生疲劳脱落。

图3 Si3N4/TC4在蒸馏水中的磨痕形貌SEM图

Fig. 3 SEM images of wear scars of Si3N4/TC4 in distilled water

脱落是逐层发生的[10],疲劳剥落的边缘因塑性变形呈现亮白色。

从图3可以看到表面有些区域颜色比较暗,这是因为制样中有污染物附在表面,在试验过程中有残留的磨屑等物质,这些物质暴露在空气中就会氧化,致使这些区域颜色较深。从图2和图3可知:1) 不管采用何种摩擦副,蒸馏水中所产生的磨痕表面都比较平滑,只发现大量的浅平凹坑以及细微的浅犁沟,在剥落坑内没有发现明显的腐蚀特征,这说明在蒸馏水中TC4合金的主要磨损机理是磨粒磨损和疲劳脱落,Si3N4/TC4表面覆盖散落的颗粒状的磨屑数量要比GCr15/TC4的数量多;2) 水基介质的存在对磨屑的演化具有两面性,既起促进作用,也起抑制作用,这主要取决于具体工况。

为进一步观察材料脱落区域的形貌,将100 N下的表面形貌进行局部放大,见图4。从图4可以看到块状磨屑层层压实在基体表面,形成台阶状的第三体层。由于上下试样的反复挤压,在块状磨屑的表面可以看到有细小的裂纹和磨屑脱落,在块状磨屑没有覆盖的地方可以看到沿运动方向划过的较浅犁沟痕迹,氧化后的磨屑成分复杂,硬度较高,可以充当磨粒,从而在TC4合金的表面形成擦伤或者犁沟形貌;块状磨屑在往复运动过程中产生较严重的塑性变形,在表面和内部进一步产生垂直和平行的裂纹,裂纹交汇扩展,最终产生疲劳脱落形成凹坑。在凹坑的内部可以看到许多大颗粒状的磨屑弥散其中而其周围存在疏松的块状磨屑层,这些块状磨屑层有的表面颜色较深,其原因是:试样放置时间较长,导致被氧化;有杂质覆盖其上。

图4 Si3N4/TC4在蒸馏水中的磨痕形貌SEM图

Fig. 4 SEM image of wear scars of Si3N4/TC4 in distilled water

2.2 摩擦因数分析

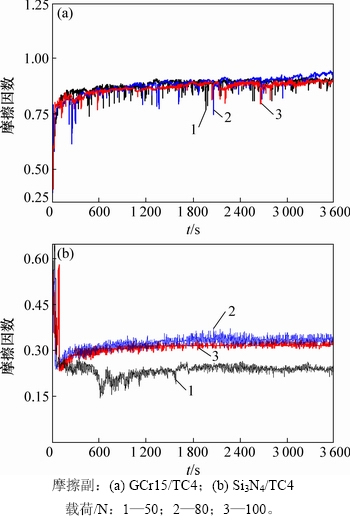

摩擦副对摩擦因数的影响见图5。从图5可知:蒸馏水中摩擦因数曲线的变化主要集中在微动磨损初期,即大约在试验开始后的600 s内,此后曲线会趋于稳定直至试验结束。这是因为当试验刚开始时,在所施加的载荷作用下,上、下试样相互接触,TC4合金表面所覆盖的一层薄膜(包含氧化物、污染物等)被破坏,新鲜金属裸露,使得上、下试样之间直接接触,而且在小位移往复运动的过程中,由于接触表面凹凸不平,接触点之间不可避免地会产生相互交错,使得运动阻力增加[15],从而摩擦因数突然增大。

随着磨损过程进行,蒸馏水经过上试样的碾压进入接触区域,起到润滑减摩的作用,同时,磨屑不断产生—溢出,起到第三体润滑作用;此外,接触表面上大量的磨屑堆积可以使应力分布比较均匀,并使其有所减弱;当试验进行到中后期时,磨屑的产生—溢出达到动态平衡,微动磨损进入相对稳定阶段,摩擦因数自然会下降且趋于平稳。由此可以得出在蒸馏水中进行微动磨损试验所得到的摩擦因数曲线可以分为2个阶段即初始阶段和稳定阶段,从图5可以看出稳定时间占整个磨损时间的2/3。

图5 摩擦副对摩擦因数的影响

Fig. 5 Effect of friction counterparts on friction coefficient

对比图5(a)和(b)可知:

1) 在蒸馏水中,Si3N4/TC4的摩擦因数要低于GCr15/TC4的摩擦因数。这是因为Si3N4球在有蒸馏水和氧气的环境中进行摩擦磨损时会与周围的介质发生摩擦化学反应生成SiO2凝胶,这层凝胶柔软、有弹性且抗剪切强度大,在上试样球的反复碾压和推挤下,会与产生的磨屑形成混合物覆盖在接触表面,从而降低摩擦因数,具体反应式为:

,

, ;此外,Si3N4球本身具有良好的耐磨性和自润滑性[16],与TC4合金相互磨损过程中能减小磨损,这也说明与GCr15/TC4相比,Si3N4/TC4所形成磨屑的速度快且数量多;GCr15球中含有Fe,在水分子的作用下会使生成的磨屑大量聚集,从而摩擦因数增大[17]。

;此外,Si3N4球本身具有良好的耐磨性和自润滑性[16],与TC4合金相互磨损过程中能减小磨损,这也说明与GCr15/TC4相比,Si3N4/TC4所形成磨屑的速度快且数量多;GCr15球中含有Fe,在水分子的作用下会使生成的磨屑大量聚集,从而摩擦因数增大[17]。

2) 在试验进行的前300 s内,Si3N4/TC4摩擦因数曲线存在1个显著的突变峰值(从最初的0.6迅速下降到0.2左右),此后保持较稳定的状态直至试验结束。共原因是:一方面,磨屑的存在对Si3N4/TC4摩擦因数的影响比对GCr15/TC4摩擦因数的影响更显著;另一方面,Si3N4球的硬度远比GCr15球的硬度高,试验开始后,在施加法向载荷的瞬间,Si3N4球会将TC4合金的接触区域迅速向下压出凹坑,两者接触区域的表面产生剧烈磨损,使得摩擦因数突然上升;随着试验的进行,磨屑产生,细小颗粒的磨屑在接触区域会充当“滚珠”的作用,使得在磨屑较多之处,接触区域由滑动状态转变为滚动状态,此时,蒸馏水也会被挤入接触区域,两者共同起到润滑的作用,摩擦因数又会大幅度降低,最终表现为Si3N4/TC4摩擦因数曲线突变的峰值远比GCr15/TC4曲线突变的峰值大。

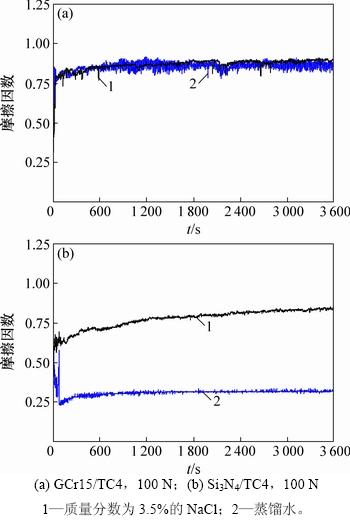

介质对摩擦因数影响的示意图见图6。对比图6(a)和(b)可知:

1) 当摩擦副为Si3N4/TC4时,2种介质下对应的摩擦因数的差值远比GCr15/TC4的大,这主要与所选上试样的材料特性有关。一方面,Si3N4球本身具有良好的自润滑性,在蒸馏水中进行摩擦时与周围的氧等发生化学反应,不断生成SiO2凝胶膜,这层膜与产生的磨屑混合起到减摩的作用;另一方面,Si3N4球的硬度要比TC4合金的硬度大得多,因此,在摩擦磨损过程中Si3N4/TC4的黏着程度远没有GCr15/TC4的黏着程度严重,更多表现为脆性剥落,此时,溶液所起的润滑效果在摩擦因数曲线中表现得更显著。

图6 介质对摩擦因数影响

Fig. 6 Effect of media on friction coefficient

2) 不论采用何种摩擦副,蒸馏水中的摩擦因数小于3.5% NaCl溶液下的摩擦因数,说明蒸馏水在微动磨损过程中所起的润滑效果与质量分数为3.5%的NaCl溶液相比更显著,但是总体来说,质量分数为3.5%的NaCl溶液下所得的摩擦因数曲线较平稳。

由图5和图6可知:1) 在试验进行初期,磨屑的形成速度和数量对摩擦因数曲线的影响很大,但在实验后期,因为磨屑的形成和溢出达到动态平衡,且其他因素的影响显著,故磨屑对摩擦因数的影响反而减弱;2) 不论采取何种摩擦副,在蒸馏水中所得的摩擦因数曲线持续上下波动,这是由于微动磨损过程接触区域面积较小,单位时间内摩擦较剧烈且集中,因此,会有大量的摩擦热产生,出现“闪温”,这会使得蒸馏水蒸发,接触区域处于半干半湿状态,从而使摩擦因数始终在小范围内上下波动;此外,在微动磨损过程中,不可避免地会产生大量磨屑,磨屑一部分被蒸馏水冲出接触区域,还有一部分聚集在接触界面造成磨屑堆积、碾压平铺,这样就避免了上、下试样直接接触,在微动过程中,所形成的膜层不断破坏—修复[18],从而造成摩擦因数曲线不稳定;3) 若在水基溶液中加入其他离子,则会使得相应的摩擦因数曲线比较平稳,但所得到的摩擦因数较高,这说明混合溶液的润滑性能与蒸馏水相比要优良很多,但会加剧TC4合金的磨损。

2.3 载荷对磨损率和磨损体积的影响

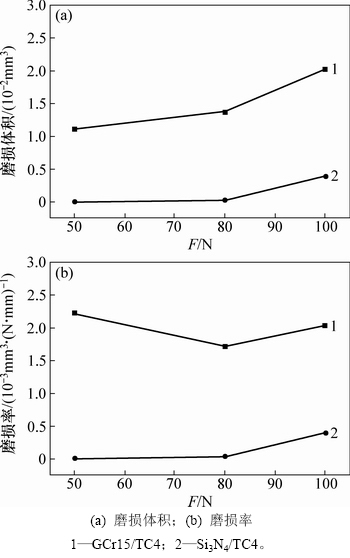

本文以磨损体积和磨损率为指标衡量TC4磨损性能。磨损体积由三维轮廓仪直接测得,磨损率K可以通过位移和载荷以及磨损体积得出[19],载荷对TC4磨损性能的影响如图7所示。

(1)

(1)

式中:K为磨损率(mm3/(N·mm));V为磨损体积(mm3);D为位移(mm);F为载荷(N)。从图7可知:

1) 当振幅一定时,不同摩擦副的磨损量与法向载荷呈正相关增大;随着载荷增加,磨损量也随之增加;前段的增长速率要低于后段的增长速率,这是由于在试验过程中持续滴加蒸馏水,使得磨屑更易溢出接触面,削弱磨屑固体润滑的效果;在微动磨损进行过程中,基体金属表面的减摩膜层破坏—修复不断循环交替,也会加剧TC4的磨损;摩擦因数的变化趋势与磨损量的变化趋势一致。

图7 载荷对TC4合金磨损性能影响

Fig. 7 Effect of loads on wear resistance of TC4 alloy

2) GCr15/TC4的磨损量比Si3N4/TC4的大。这是因为在蒸馏水中,Si3N4球在摩擦磨损过程中会与蒸馏水和周围环境中的氧气发生摩擦化学反应生成SiO2凝胶,造成Si3N4/TC4的黏着程度比较严重,从而加速了TC4合金材料的流失。

3) GCr15/TC4的磨损率比Si3N4/TC4的磨损率大,说明蒸馏水中Si3N4/TC4耐磨性能比GCr15/TC4的耐磨性能优,故Si3N4球在蒸馏水中作摩擦副材料时,TC4磨损性能最好,但因为Si3N4球有自润滑性,对于其本身来说磨损反而加剧。随着载荷增加,TC4合金的磨损率有继续增大趋势,这说明在蒸馏水中,TC4合金的磨损仍然处于部分滑移区,微动磨损随着载荷的增加更加严重,蒸馏水的持续加入使得大量的磨屑冲出,削弱了第三体的调节和保护机制,从而使磨损率持续增加。

2.4 腐蚀磨损的交互作用分析

目前,人们对磨损和腐蚀的交互作用的分析还不够完善,针对金属腐蚀磨损交互作用提出的数学模型都有缺陷[20-21]。由于本试验采用的介质是蒸馏水,必须考虑润滑作用。本试验的腐蚀磨损交互作用的数学模型可采用[22]

(2)

(2)

腐蚀和磨损交互作用比率γ可由下式计算:

(3)

(3)

式中:Wt为微动腐蚀总量,μm3,采用蒸馏水中的微动磨损体积;Wc为单纯腐蚀量,μm3,由静态浸泡腐蚀试验测得;Ww为单纯磨损量,μm3,近似以干空气下所得的磨损体积代替;ΔW为腐蚀和磨损交互作用量,μm3;ΔWl为介质润滑作用量,μm3,由大气环境中的磨损体积Ww减去蒸馏水中的磨损体积Wt可得。其中,Wt和Ww可以由三维轮廓仪直接测量得出,其余参量则可以由相应的公式计算得出。所得腐蚀磨损的交互作用比率γ如表2所示。

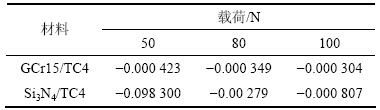

表2 腐蚀磨损的交互作用比率γ

Table 2 Ratio of synergistic effect of corrosion wear

由表2可知:在蒸馏水中,腐蚀和磨损的交互作用比率是负值并且很小。结合表面形貌图(图2~4),γ为负值说明此时摩擦副的微动运行区域处于混合区[20];γ很小说明腐蚀磨损的交互作用很小,由此证明蒸馏水的导电性能差,几乎没有腐蚀作用,在微动腐蚀磨损中只有润滑作用,TC4合金材料的流失量也主要是机械磨损所致。

3 结论

1) TC4合金在蒸馏水中的微动磨损机制为磨粒磨损和疲劳脱落。摩擦因数随时间变化的曲线可分为初始阶段和稳定阶段,其中,稳定时间占整个磨损时间的2/3。在水基介质中加入其他离子会使得润滑性能比蒸馏水的润滑性能优良很多,但会加剧TC4合金的磨损。

2) 在蒸馏水中,摩擦因数曲线存在持续上下波动现象。当载荷一定时,Si3N4/TC4的摩擦因数要低于GCr15/TC4的摩擦因数,但与GCr15/TC4相比,Si3N4/TC4摩擦因数曲线突变的峰值要大得多。

3) 当振幅一定时,不同摩擦副的磨损量与法向载荷成正相关,随着载荷增加,磨损量随之增加,TC4合金的磨损率还有继续增大的趋势。摩擦因数的变化趋势与磨损量的变化趋势一致。

4) GCr15/TC4的磨损率和磨损体积均比Si3N4/TC4的大,说明蒸馏水中Si3N4/TC4耐磨性能优于GCr15/TC4的耐磨性能,Si3N4球在蒸馏水中作摩擦副材料时TC4合金耐磨性能较好。但由于Si3N4球有自润滑性,对于其本身来说磨损反而加剧。

5) 在蒸馏水中,腐蚀和磨损的交互作用比率出现负值且数值很小,说明蒸馏水的导电性能差,几乎没有腐蚀作用,只有润滑作用;TC4合金材料的流失量主要由机械磨损所致。

6) 水基介质的存在对磨屑的演化过程既有促进作用,同时也有抑制作用,这主要取决于具体工况。

参考文献:

[1] AMANOV A, WATABE T, TSUBOI R, et al. Fretting wear and fracture behaviors of Cr-doped and non-doped DLC films deposited on Ti-6Al-4V alloy by unbalanced magnetron sputtering[J]. Tribology International, 2013, 62: 49-57.

[2] HORSWILL N C, LEEN S B, SRIDHARAN K, et al. A fretting wear study of a nitrogen implanted titanium alloy[J]. Journal of Material Science Letters, 1995, 14(19): 1349-1351.

[3] ZHANG Yuanbin, LU Liantao, GONG Yubin, et al. Fretting wear-induced evolution of surface damage in press-fitted shaft[J]. Wear, 2017, 384/385: 131-141.

[4] NICOLAOU P D, SHELL E B, MATIKAS T E. Microstrucutral and surface characterization of Ti-6Al-4V alloys after fretting fatigue[J]. Materials Science & Engineering, 1999, 269(1/2): 98-103.

[5] 徐涛. Inconel690合金表面HVOF喷涂CoCrW和WC-10Co-4Cr涂层的微动磨损特性研究[D]. 成都: 西南交通大学机械工程学院, 2013: 3-4.

XU Tao. Fretting wear behavior of HVOF sprayed CoCrW and WC-10Co-4Cr coatings on the surface of Inconel690 alloy[D]. Chengdu: Southwest Jiaotong University. College of mechanical Engineering, 2013: 3-4.

[6] 屈盛官, 和锐亮, 王光宏, 等. 滚压对碳钢微动磨损性能的影响[J]. 中南大学学报(自然科学版), 2017, 48(4): 896-902.

QU Shengguan, HE Ruiliang, WANG Guanghong, et al. Effect of burnishing on fretting wear behaviors of carbon steel[J]. Journal of Central South University(Science and Technology), 2017, 48(4): 896-902.

[7] 贾国海, 龚金科, 鄂加强, 等. 齿轮轴过盈配合对轴间微动磨损的影响研究[J]. 湖南大学学报(自然科学版), 2013, 40(5): 31-36.

JIA Guohai, GONG Jinke, E Jiaqiang, et al. Effect of interference fit on fretting wear of gear shaft shoulder[J]. Journal of Hunan University(Natural Science), 2013, 40(5): 31-36.

[8] CHEN G X, ZHOU Z R. Study on transition between fretting and reciprocating sliding wear[J]. Wear, 2001, 250: 665-672.

[9] ZEISE B, LIEBICH R, PR L

L M. Simulation of fretting wear evolution for fatigue endurance limit estimation of assemblies[J]. Wear, 2014, 316(1/2): 49-57.

M. Simulation of fretting wear evolution for fatigue endurance limit estimation of assemblies[J]. Wear, 2014, 316(1/2): 49-57.

[10] 俞树荣, 王洁璐, 李淑欣, 等. Ti-6Al-4V燕尾榫结构微动疲劳裂纹萌生及扩展行为研究[J]. 中国机械工程, 2015, 26(24): 3386-3390.

YU Shurong, WANG Jielu, LI Shuxin, et al. Study on the initiation and propagation of fretting fatigue crack on the Ti-6Al-4V alloy dovetail joint[J]. China Mechanical Engineering, 2015, 26(24): 3386-3390.

[11] 周仲荣. 关于微动磨损与微动疲劳的研究[J]. 中国机械工程, 2000, 11(10): 1146-1150.

ZHOU Zhongrong. Study on fretting wear and fretting fatigue[J]. China Mechanical Engineering, 2000, 11(10): 1146-1150.

[12] 李瑞冬. TC4钛合金喷丸处理及涂层的微动磨损特性研究[D]. 大连: 大连理工大学材料科学与工程学院, 2016: 9-10.

LI Ruidong. Study on the fretting wear behavior of TC4 titanium alloy after shot peening and coating treatment[D]. Dalian: Dalian University of Technology. College of Materials Science and Enigneering, 2016: 9-10.

[13] 刘学红. 铝合金扭动微动及切扭复合微动磨损行为研究[D]. 成都: 西南交通大学力学与工程学院, 2013: 6-7.

LIU Xuehong. Research on torsional/tangential and torsional fretting wear behavior of aluminum alloy[D]. Chengdu: Southwest Jiaotong University. College of Mechanics and Engineering, 2013: 6-7.

[14] 李晓刚, 高瑾, 张三平, 等. 高分子材料自然环境老化规律与机理[M]. 北京: 科学出版社, 2011: 271-272.

LI Xiaogang, GAO Jin, ZHANG Sanpin, et al. High polymer material principle and mechanism of nature environment[M]. Beijing: Science Press, 2011: 271-272.

[15] 王运动. 碳纤维增强复合材料及钛合金微动磨损特性的研究[D]. 南京: 南京航空航天大学航空宇航学院, 2016: 23-24.

WANG Yundong. Research on fretting wear of carbon fiber reinforced composites and titanium alloy[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Aerospace Engineering, 2016: 23-24.

[16] 吴庆文, 胡丰, 谢志鹏. 高性能氮化硅陶瓷的制备与应用新进展[J]. 陶瓷学报, 2018, 39(1): 13-19.

WU Qingwen, HU Feng, XIE Zhipeng. New progress in the preparation and application of high performance silicon nitride ceramics[J]. Journal of Ceramics, 2018, 39(1): 13-19.

[17] 曾群锋, 董光能, 于飞, 等. Si3N4球/DLC膜摩擦副在真空环境下的摩擦学行为研究[J]. 真空科学与技术学报, 2014, 34(11): 1184-1191.

ZENG Qunfeng, DONG Guangneng, YU Fei, et al. Tribological property in vacuum of high speed steel modified with diamond-like-carbon coatings[J]. Chinese Journal of Vacuum Science and Technology, 2014, 34(11): 1184-1191.

[18] 李杰. 大气及溶液环境下传热管材料微动磨损行为及损伤机制[D]. 北京: 北京科技大学材料科学与工程学院, 2017: 79-81.

LI Jie. The fretting wear behavior and damage mechanism of heat exchange tube materials in air and solution environment[D]. Beijing: University of Science and Technology Beijing. College of Materials Science and Engineering, 2017: 79-81.

[19] 刘明, 王振国, 胡毅. 不同摩擦副条件下Ti-6Al-4V合金的微磨粒磨损行为[J]. 润滑与密封, 2014, 39(7): 88-92.

LIU Ming, WANG Zhenguo, HU Yi. Micro-scale abrasive wear behaviour of Ti-6Al-4V alloy under different friction pairs[J]. Lubrication Engineering, 2014, 39(7): 88-92.

[20] 王勇. 钛及钛合金在三种介质下的微动腐蚀特性[D]. 成都: 西南交通大学机械工程学院, 2002: 36-37.

WANG Yong. Fretting corrosion characteristics of titanium and titanium alloys in three mediums[D]. Chengdu: Southwest Jiaotong University. College of Mechanical Engineering, 2002: 36-37.

[21] 姜晓霞, 李诗卓, 李曙. 金属的腐蚀磨损[M]. 北京: 化学工业出版社, 2003: 271-272.

JIANG Xiaoxia, LI Shizhuo, LI Shu. Corrosive wear of metals[J]. Beijing: Chemical Industry Press, 2003: 271-272.

[22] 王志刚, 李久青, 吴荫顺. 1Cr13不锈钢微动腐蚀中腐蚀与磨损交互作用[J]. 北京科技大学学报, 2000, 22(2): 138-141.

WU Zhigang, LI Jiuqing, WU Yinshun. Synergy of corrosion and wear in the fretting corrosion of 1Cr13 stainless steel[J]. Journal of University of Science and Technology Beijing, 2000, 22(2): 138-141.

(编辑 陈灿华)

收稿日期:2018-05-10;修回日期:2018-07-21

基金项目(Foundation item):国家自然科学基金资助项目(51275225)(Project(51275225) supported by the National Natural Science Foundation of China)

通信作者:宋伟,博士研究生,讲师,从事过程装备结构完整性等研究;E-mail:songwei@lut.edu.cn