新型SPD工艺对AM60镁合金性能不均匀性的影响

来源期刊:中国有色金属学报(英文版)2021年第3期

论文作者:Siroos AHMADI Vali ALIMIRZALOO Ghader FARAJI Ali DONIAVI

文章页码:655 - 665

Key words:cyclic extrusion compression angular pressing; AM60 alloy; strain distribution; mechanical properties; grain refinement

摘 要:利用新型大塑性变形(SPD) 技术提高镁合金的冶金性能。在此过程中,先进行循环挤压-压缩-角挤压(CECAP)过程,再在出口处进行挤压,起到附加背压的作用。因此,与等径角挤压(ECAP)相比,期望获得更加均匀和优异的力学性能。为了评价这种新方法的有效性和能力,对AM60镁合金进行加工。有限元分析表明,新方法的应变值和均匀应变分布均显著提高。此外,与传统的ECAP相比,新方法的压应力增加约110%。实验结果表明,经新工艺处理后,试样的硬度和强度均有显著提高,这是由于其晶粒细化,显微组织更加均匀,并且细化的β相沿晶界均匀分布。因此,该新工艺在未来镁合金生产中具有广阔的应用前景。

Abstract: A new severe plastic deformation (SPD) technique for improvement of the metallurgical properties of the magnesium alloys is presented. In this process, a cyclic extrusion compression angular pressing (CECAP) process is followed by an extrusion step in the outlet playing the role of additional back pressure. Therefore, more uniform and enhanced mechanical properties are expected in comparison with equal channel angular pressing (ECAP). In order to evaluate the effectiveness and capabilities of this new method, an AM60 magnesium alloy was processed. Finite element results exhibited a significant increase in strain values as well as uniform strain distribution for the new method. In addition, ~110% increase in compressive stress was observed in new method compared to the conventional ECAP. Experimental results revealed a noticeable increase in the hardness and strength of the specimens processed by the new technique as a result of the formation of finer grains and more homogeneous microstructure with good distribution of refined β-phase along the boundaries. It may be concluded that the new process is very promising for future magnesium alloy products.

Trans. Nonferrous Met. Soc. China 31(2021) 655-665

Siroos AHMADI1, Vali ALIMIRZALOO1, Ghader FARAJI2, Ali DONIAVI3

1. Department of Mechanical Engineering, Urmia University, Urmia 57153165, Iran;

2. School of Mechanical Engineering, College of Engineering, University of Tehran, Tehran 11155-4563, Iran;

3. Department of Industrial Engineering, Urmia University, Urmia 57153165, Iran

Received 21 April 2020; accepted 30 December 2020

Abstract: A new severe plastic deformation (SPD) technique for improvement of the metallurgical properties of the magnesium alloys is presented. In this process, a cyclic extrusion compression angular pressing (CECAP) process is followed by an extrusion step in the outlet playing the role of additional back pressure. Therefore, more uniform and enhanced mechanical properties are expected in comparison with equal channel angular pressing (ECAP). In order to evaluate the effectiveness and capabilities of this new method, an AM60 magnesium alloy was processed. Finite element results exhibited a significant increase in strain values as well as uniform strain distribution for the new method. In addition, ~110% increase in compressive stress was observed in new method compared to the conventional ECAP. Experimental results revealed a noticeable increase in the hardness and strength of the specimens processed by the new technique as a result of the formation of finer grains and more homogeneous microstructure with good distribution of refined β-phase along the boundaries. It may be concluded that the new process is very promising for future magnesium alloy products.

Key words: cyclic extrusion compression angular pressing; AM60 alloy; strain distribution; mechanical properties; grain refinement

1 Introduction

Recently, magnesium (Mg) alloys have attracted the attention of several researchers regarding their superior properties, including high specific strength, good recyclability, resistance to heat changes as well as biocompatibility and corrosion resistance in body fluids [1-3]. In addition, the improved biocompatibility and mechanical properties of the material as a consequence of microstructure refinement through ECAP process have resulted in the potential usage for medical applications [4-7]. The significant reduction in grain size in this process may be attributed to the recrystallization phenomenon of AM60 Mg alloy [8-10]. Moreover, the increased strength and improved fatigue behavior of Mg alloys in ECAP process enable its application in various industries [11-13]. However, the low plasticity especially at low temperatures due to the compressed hexagonal close-packed (HCP) structure and low slip system, has restricted its application [14]. Considering the HCP structure and ductility restrictions, Mg alloys have often been fabricated through casting instead of plastic deformation. Hence, for applicability in automotive and aerospace industries, the workability and strength of this alloy should be improved.

The ECAP process is regarded as one of the most effective severe plastic deformation (SPD) methods [15,16], which has been extensively utilized for improving the mechanical properties and microstructure of metals [17-19]. However, non-uniform strain distribution at the sample section is considered as the deficiency of this procedure [20-22]. To overcome this deficiency, several mechanical methods have been introduced to modify the ECAP process [4]. Tubular channel angular pressing (TCAP) introduced by FARAJI et al [23], can be mentioned as one of the procedure for improving the microstructural and mechanical properties of tubular components made of AZ91 alloy. By further promotion of this method, parallel tubular channel angular pressing (PTCAP) method was introduced [24]. More uniform strain distribution along the length and thickness directions of the sample as well as requirement for lower compression force are regarded as the advantages of this process. Moreover, utilization of back pressure in ECAP process [25] and employing extrusion process prior to ECAP are proposed as the solutions for augmenting the strain value besides achieving more uniform strain distribution [26,27]. The incremental equal channel angular pressing (I-ECAP) method was presented by GZYL et al [28] for the friction reduction and continuous execution of the process. The obtained results indicated the improved mechanical properties of AZ31 alloy as a result of refined grain size to 0.8 μm at 150 °C. Another mechanical process for improving the mechanical properties of specimen is known as cyclic extrusion-compression (CEC) method, which was introduced and developed by RICHERT [29]. In this process, the specimen was extruded and expanded with the help of back pressure. The requirement for the exact determination of reverse compression for performing the appropriate plastic deformation was considered as the disadvantage of this process. By eliminating the back pressure from the alternating cycle of the process, a new method called cyclic expansion-extrusion (CEE) was suggested [30]. In this process, the exit of the channel was obstructed by the material movement temporarily by expanding the material under pressure; thereby it was acted as reverse compression force. Recently, the effect of CEE method on the mechanical properties of AM60 magnesium alloy was investigated [31]. According to the conducted investigations, nonuniform material flow on the longitudinal section of the sample was revealed during the expansion and extrusion processes, and hence, different strains were exerted on the material. To overcome the mentioned limitations and disadvantages, a method known as cyclic extrusion compression angular pressing (CECAP), which was a combination of CEC and ECAP processes, was proposed [32]. In this method, a compression-extrusion step was applied on the material prior to its arrival to the angular deformation region in ECAP channel. Enhanced strength and hardness compared to conventional ECAP process were revealed by the obtained results; however, the lower hydrostatic compressive stress in CEE and conventional ECAP was reported as a drawback [32].

By reviewing the available literature, it was found that only a few studies concerning the CECAP process have been published. Hence, in this study, it is aimed to propose a new technique called CECAP+Ex, in which, in addition to the employment of extrusion/compression prior to the ECAP process, an extrusion step is also applied after CECAP process. More uniform and enhanced mechanical properties are expected through the application of this process as a consequence of increase in the pressure stresses. Moreover, CECAP+Ex process has been performed experimentally on the AM60 Mg alloy. The mechanical properties and microstructures are extracted from new CECAPed sample and compared with those of conventional methods. The values and distributions of strain as well as the required forces for the process are studied using the finite element simulation.

2 Experimental and FEM procedures

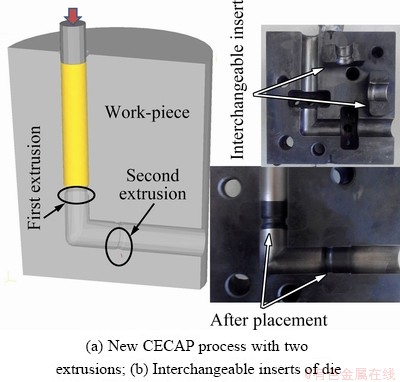

In the present study, commercial AM60 alloy (Mg-5.82Al-0.3Mn-0.024Si, wt.%) in the form of casting ingots was utilized. The specimens were machined into cylindrical form with the diameter of 15 mm and the length of 70 mm. To ensure better plastic deformation, the specimens were annealed at 450 °C for 30 min in an electric furnace. The schematic and real views of the die for CECAP+Ex process are shown in Fig. 1. As can be seen in Fig. 1(a), in the proposed CECAP process, the specimen is imported to the first extrusion insert and then expanded to attain its initial diameter (15 mm) by reaching the end of vertical channel. Then, it passes the angular channel under more pressing force; in other words, the ECAP process occurs. Subsequently, by entering the secondary extrusion zone through the horizontal channel, besides the reduction in diameter, back pressure role in the CECAP process is also maintained. According to Fig. 1(b), two interchangeable extrusion inserts are embedded in the die. In this study, the specimens were processed through two different processes, as listed in Table 1. The diameters of the first and second inserts for ECAP process were equal to the die channel. In both of the mentioned processes, the die consisted of two cylindrical channels with the diameters of 15 mm, intersecting at an angle of 90° and curvature angle of 20°. According to the die geometry, it can be said that the overall applied strain in CECAP process is the summation of strain in ECAP process [33] and the strain in the CEC process [34]. Therefore, total effective strain is

(1)

(1)

where φ, ψ, D, d1 and d2 are the channel angle, corner angle, channel diameter, first and second extrusion diameters, respectively.

Fig. 1 Scheme of die

Table 1 Different modes of process

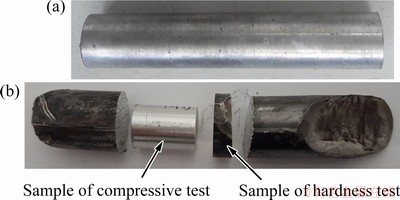

The processes were performed at the temperature of 300 °C and compression rate of 10 mm/min using MoS2 as lubricant. The microstructure of the specimen’s cross-section was evaluated through the images of scanning electron microscope (SEM). Prior to capturing the SEM images, the specimens were polished and etched (in a proper solution of 4.2 g picric acid, 10 mL acetic, 10 mL distilled H2O and 70 mL ethanol at room temperature [10]). Moreover, compression and hardness tests were utilized for extracting the mechanical properties. For this purpose, the specimens were cut, as depicted in Fig. 2. For achieving the hardness distribution on the specimen cross-section, the hardness values were measured in two hypothetical paths. The compression tests were carried out at room temperature and strain rate of 1×10-3 s-1 on the cylindrical specimens with the diameter of 10 mm and the height of 16 mm, which were cut longitudinally from the specimens before and after the desired process.

Fig. 2 Sample before processing (a) and compression and hardness test samples prepared after processing (b)

The strain and stress distributions as well as force variation during the process were studied by FEM-based DEFORM-3D software. The die and punch were modeled as rigid bodies and the billet was modeled as plastic body with 17077 tetrahedral elements. The contact surfaces of the die and work-piece were modeled by shear friction model with the friction coefficient of 0.1 [35] to simulate the similar condition as represented in the experimental tests. Reference data [36-38] were used for determination of mechanical behavior of the material. Additionally, the other conditions of the simulation were considered the same as the experimental test.

3 Results and discussion

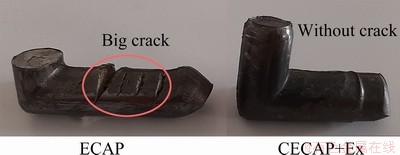

The specimens processed through the two mentioned processes are shown in Fig. 3. It can be seen that, in some of the ECAP specimens, large cracks were generated during the process; while for the CECAP+Ex specimens, no crack was observed. The formation of these cracks were related to the low ductility of Mg alloy as well as application of relatively severe shear strains on the cross sections during the process. Higher hydrostatic pressure limited the crack and micro-voids initiation and propagation, which resulted in the subsequent enhanced ductility of the metal [39,40]. Moreover, it led to the improved plasticity of hardly- deformable metals such as magnesium through the activation of different slip systems [41,42]. The second extrusion zone, which acted as back pressure, played an effective role in the enhancement of pressure stresses. Therefore, in the specimens processed by the newly proposed CECAP, no crack was observed despite the formation of severe shear strains.

Fig. 3 Samples after ECAP and CECAP+Ex processes

3.1 FEM characterization

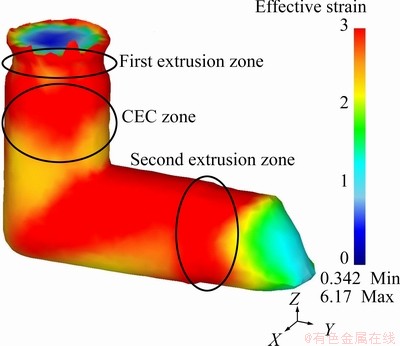

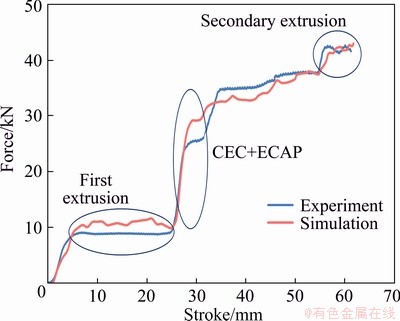

According to the results obtained by the simulation of CECAP+Ex process, a similar trend to the experimental conditions was achieved. Figure 4 represents the simulated specimen for the last stage in the first pass of CECAP+Ex process. An acceptable agreement between the simulation and experimental results for force diagram, as depicted in Fig. 5, was realized. Hence, the reliability and accuracy of the simulation procedure can be verified.

Fig. 4 FEM-simulated sample at last stage

Fig. 5 Force distributions during CECAP+Ex process for both simulation and experiment

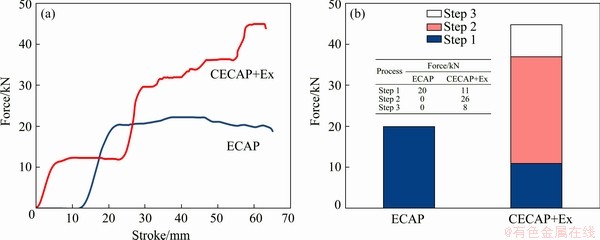

The force variations against the stroke for each process is depicted in Fig. 6. As can be seen in Fig. 6(a), existence of two extrusion steps in the CECAP+Ex process increased the required force compared to ECAP process. Figure 6(b) represents the required force in each step of the mentioned process. It can be seen that, ECAP process consisted of a single step with the required force of approximately 20 kN; whereas, in the CECAP+Ex process, three steps were presented. In the first step, approximately 11 kN was required for the initial extrusion; while in the second and third steps, in which the CEC+ECAP and secondary extrusion were carried out, the force of 11 kN was increased to 37 and 45 kN, respectively.

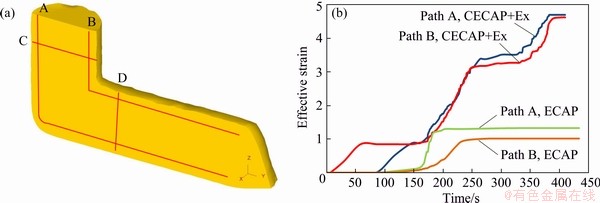

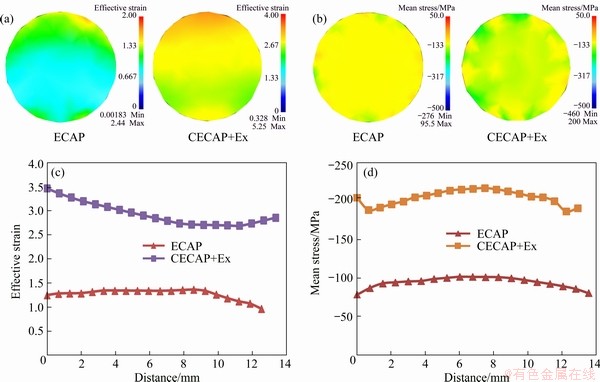

In order to determine the strain values at different stages of each process, paths were defined at the sample cross-section according to Fig. 7(a). The effective strains were obtained along A and B paths in each process and the results are provided in Fig. 7(b). It can be seen that, a significant discrepancy between the strain values at the end of ECAP process in A and B paths was observed. This discrepancy may be attributed to the non-uniformity of shear strain in the channel corners during the ECAP process [20-22]. Interestingly, for CECAP+Ex process, not only the strain values were increased considerably, but also they were converged to each other at the end of the process. On the other hand, increasing the values and homogeneity of the applied plastic strain could improve the mechanical properties in accordance with the hydrostatic compressive stresses. For better understanding, the effective strain and compressive stress contours (Figs. 8(a, b)) and diagrams along the C and D paths (specified in Fig. 7(a)) were compared for both of the processes (Figs. 8(c, d)). Regarding Fig. 8(c), a significant increase in strain values of CECAP+Ex was observed in comparison with ECAP process. The same trend was also obtained for compressive stresses, as shown in Fig. 8(d). This increase in compressive stresses in the newly proposed method could be justified by the presence of a CEC-like process prior to the ECAP and secondary extrusion, which acted as a back pressure. In addition, 110% enhancement in the compressive stress of the CECAP+Ex was achieved with respect to the ECAP. Moreover, the results showed the improved strain in CECAP+Ex process compared to conventional ECAP as well as CECAP method.

Fig. 6 Values of force during two modes of process (a) and in different steps for each of processes (b)

Fig. 7 Defined paths on cross section (a) and effective strain along A and B paths during ECAP and CECAP+Ex processes (b)

3.2 Mechanical properties

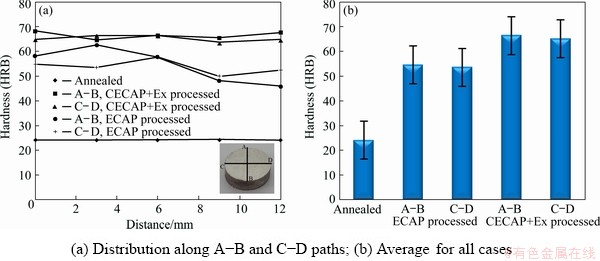

The results of hardness test for the cut cross- sections depicted in Fig. 2(b) are provided in Fig. 9. For the determination of hardness distribution, the hardness values were measured along two hypothetical paths shown in Fig. 9(a). As it is evident, the hardness of the specimens were enhanced considerably after processing. According to Fig. 9(b), the average hardness of HRB 24.2 was measured for annealed specimen, which was increased to HRB 54.34 and HRB 65.92 for ECAP and CECAP+Ex processed specimens, respectively. Microstructure of the specimen is considered as one of the influential factors in increasing the hardness. For the HCP-structured magnesium alloys with lack of slip system, the mechanical properties are highly dependent on grain size [43,44]. On the other hand, the microstructure evolution in hot forming processes is affected by the rate and amount of the applied strain [45,46] such that dynamic recrystallization (DRX) is considered as the main process of microstructural evolution occurring under intense plastic straining for Mg alloys [14]. Furthermore, the hardness of β-phase is notably more than that of α-phase [47]. Therefore, another influential factor in increasing the hardness of the specimen is the strain distribution and the resultant dispersion uniformity in the β-phase. According to the obtained results, approximately 125% increase in the stain of CECAP+Ex was obtained compared to ECAP. Hence, the consequent increase and uniformity in the hardness can be expected.

Fig. 8 Distributions of effective strain (a), mean stress (b), effective strain along Path D (c) and mean stress along Path C (b) on cross section

Fig. 9 Hardness test results for all modes of processed samples

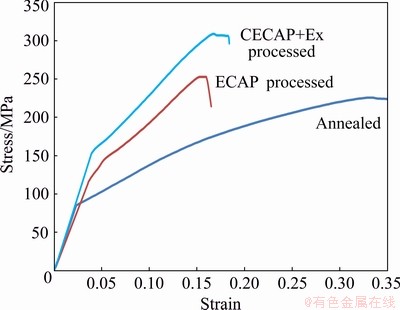

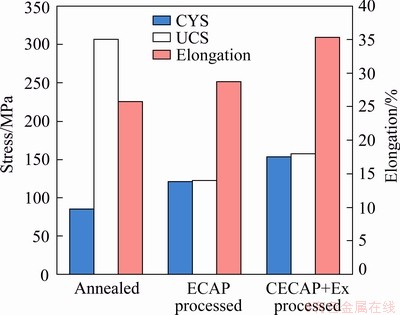

The results of compression test for the annealed, ECAP and CECAP+Ex processed specimens at room temperature are provided in Fig. 10. The highest ductility was associated with the annealed specimen despite the restricted deformability of Mg alloys. This can be explained by the increased mobility of dislocations after annealing process (annealed at 450 °C for 30 min). According to Fig. 11, the compressive yield strength (CYS) was increased by about 42% after only one pass of ECAP process compared to the annealed sample. This improvement was related to the resultant microstructure from DRX phenomenon during the ECAP process [9,10]. As it is clear, through the use of newly proposed technique, a remarkable increase in the strength from 85.3 MPa for the annealed specimen to 153.3 MPa for the CECAP+Ex processed specimen was attained. This confirmed the effectiveness of CECAP+Ex methods in enhancing the mechanical properties. The obtained results were also consistent with well-known Hall-Petch equation, which stated the enhanced strength of the specimen as a consequence of grain refinement after SPD process [48]. However, despite the higher applied strains in the proposed method and the subsequent enhancement in strength, no considerable change was observed in fracture elongation of the specimen. Additionaly, the insignificant improvement in the ductility of the CECAPed specimen might be attributed to hydrostatic pressures, which assisted the activation of different slip systems [41,42]. As it is obvious, through the use of CECAP+Ex method, better grain refinement in microstructure and therefore improved strength equal to 26.7% would be achieved compared to ECAP process. In addition, β-phase can be also considered as the other effective factor in the present results. For the sake of evaluating and comparing the microstructure evolution, the SEM images were used.

Fig. 10 Stress versus strain curves at room temperature for initial and three modes of samples

Fig. 11 Compressive yield stress (CYS), ultimate compressive stress (UCS) and elongation for samples

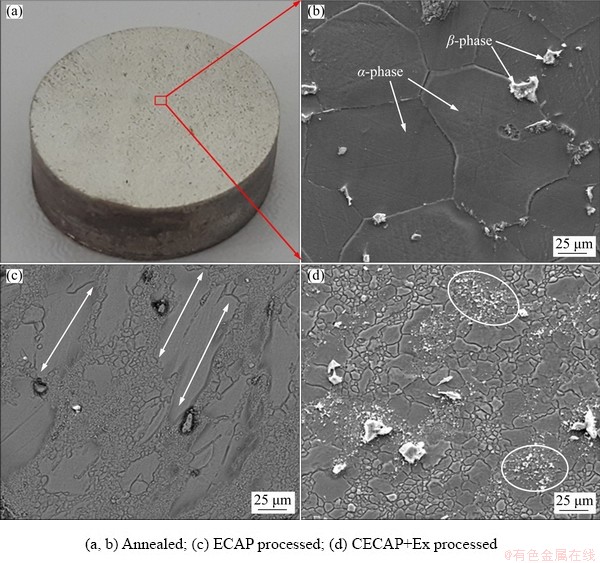

3.3 Microstructure

The SEM images of the specimen micro- structure before and after the processes are depicted in Fig. 12. The α and β phases in the initial specimen with coarse grains are characterized by the arrows, as depicted in Figs. 12(a, b). As it was mentioned before, β-phase was mostly located at the grain boundaries, which is one of the reasons for the low ductility as a consequence of dendritic structure formation around the grains. Despite the remarkable refinement of the grains after ECAP process, some of the initial grains were still remained (depicted with two-way arrow in Fig. 12(c)). The observed heterogeneity of grain size in this case would result in heterogeneous properties. According to the discussion in previous sections, higher strains and more hydrostatic compressive stresses would be achieved by the newly proposed method with two extrusion steps. The developed microstructural variations were expected considerig the significant role of shear deformation component in grain refinement during SPD methods [49-51]. Hence, by applying higher strains in the CECAP+Ex process, finer grains with more uniform structure, and consequently improved mechanical properties would be achieved. As can be seen in Fig. 12, the average grain size decreased from 76.42 μm for the annealed sample to 3.53 μm for the CECAP+Ex processed sample. As mentioned, the presence of β-phase and its dispersion in structure are regarded as the other important factors in the determiantion of mechanical properties of this alloy. As it is evident from Fig. 12(d), the β-phase was broken by the shear strains and hence, more disperion along the boundaries of refined grains was obtained. Indeed, the second extrusion in CECAP+Ex process led to higher hydrostatic pressures in material during the process. Therefore, more grain refinement and β-phase dispersion can be seen compared with the ECAPed sample. Finally, it can be said that the improvement in the mechanical properties of this alloy was predictable due to the amount of plastic strain applied to the cross section.

Fig. 12 SEM images for samples

4 Conclusions

(1) Embedding two extrusion steps in the ECAP process (before and after the ECAP) caused a significant increase in the process force. Secondary extrusion was performed in the third step of CECAP+Ex process, through which, an increase of the required force from 20 kN in ECAP to 45 kN for CECAP+Ex was achieved.

(2) In the CECAP+Ex process, besides the increase in strain values, acceptable convergence at the end of the process was also observed. This improvement can be attributed to the hydrostatic compressive stresses. On the other hand, the incorporation of secondary extrusion, which acted as a back pressure, increased the compressive stress by about 110% compared to ECAP.

(3) The strain values in the new process were 125% higher than those of the ECAP process. Hence, hardness enhancement as well as more uniform distribution can be expected. According to the obtained results, the average hardness of HRB 54.34 for ECAP samples was increased to HRB 65.92 for CECAP+Ex samples.

(4) The compression test results indicated the enhanced compressive yield strength by about 42% after only one pass of ECAP process compared to the initial sample. In addition, the new technique led to a remarkable increase in strength from 85.3 MPa for initial sample to 153.3 MPa.

(5) Finer grains with higher homogeneity were achieved by the application of higher strain in the new process, which might justify the improvement of mechanical properties. In addition, the average grain size decreased from 76.42 μm for initial sample to 3.53 μm for the CECAP+Ex process.

References

[1] MOSTAED E, VEDANI M, HASHEMPOUR M, BESTETTI M. Influence of ECAP process on mechanical and corrosion properties of pure Mg and ZK60 magnesium alloy for biodegradable stent applications [J]. Biomatter, 2014, 4: e28283.

[2] AMANI S, FARAJI G, MEHRABADI H K, ABRINIA K, GHANBARI H. A combined method for producing high strength and ductility magnesium microtubes for biodegradable vascular stents application [J]. Journal of Alloys and Compounds, 2017, 723: 467-476.

[3] WITTE F. The history of biodegradable magnesium implants: A review [J]. Acta Biomaterialia, 2010, 6: 1680-1692.

[4] POINERN G E J, BRUNDAVANAM S, FAWCETT D. Biomedical magnesium alloys: A review of material properties, surface modifications and potential as a biodegradable orthopaedic implant [J]. American Journal of Biomedical Engineering, 2012, 2: 218-240.

[5] GE Q, DELLASEGA D, DEMIR A G, VEDANI M. The processing of ultrafine-grained Mg tubes for biodegradable stents [J]. Acta Biomaterialia, 2013, 9: 8604-8610.

[6] MOSTAED E, FABRIZI A, DELLASEGA D, BONOLLO F, VEDANI M. Microstructure, mechanical behavior and low temperature superplasticity of ECAP processed ZM21 Mg alloy [J]. Journal of Alloys and Compounds, 2015, 638: 267-276.

[7] MEHRABADI H K, FARAJI G, AMINI S, KARIMPOUR M, GHANBARI H. Fabrication of ultrafine-grained Mg micro tubes using a combined severe plastic deformation process for biomedical application [J]. Modares Mechanical Engineering, 2016, 16: 605-611.

[8] KULYASOVA O, ISLAMGALIEV R, MINGLER B, ZEHETBAUER M. Microstructure and fatigue properties of the ultrafine-grained AM60 magnesium alloy processed by equal-channel angular pressing [J]. Materials Science and Engineering A, 2009, 503: 176-180.

[9] FIGUEIREDO R B, LANGDON T G. Grain refinement and mechanical behavior of a magnesium alloy processed by ECAP [J]. Journal of Materials Science, 2010, 45: 4827-4836.

[10] AKBARIPANAH F, FERESHTEH-SANIEE F, MAHMUDI R, KIM H. The influences of extrusion and equal channel angular pressing (ECAP) processes on the fatigue behavior of AM60 magnesium alloy [J]. Materials Science and Engineering A, 2013, 565: 308-316.

[11] KIM W, HONG S, KIM Y, MIN S, JEONG H, LEE J. Texture development and its effect on mechanical properties of an AZ61 Mg alloy fabricated by equal channel angular pressing [J]. Acta Materialia, 2003, 51: 3293-3307.

[12] FERESHTEH-SANIEE F, AKBARIPANAH F, KIM H, MAHMUDI R. Effects of extrusion and equal channel angular pressing on the microstructure, tensile and fatigue behaviour of the wrought magnesium alloy AZ80 [J]. Fatigue & Fracture of Engineering Materials & Structures, 2012, 35: 1167-1172.

[13] FINOVA S, KUNZ L. Fatigue properties of magnesium alloy AZ91 processed by severe plastic deformation [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2015, 42: 219-28.

[14] BETTLES C, BARNETT M. Advances in wrought magnesium alloys: Fundamentals of processing, properties and applications [M]. Elsevier, 2012.

[15] SEGAL V, REZNIKOV V, DOBRYSHEVSHIY A, KOPYLOV V. Plastic working of metals by simple shear [J]. Russian Metallurgy (Metally), 1981, 1: 99-105.

[16] SEGAL V. Materials processing by simple shear [J]. Materials Science and Engineering A, 1995, 197: 157-164.

[17] ABD EL AAL M A, SADAWY M M. Influence of ECAP as grain refinement technique on microstructure evolution, mechanical properties and corrosion behavior of pure aluminum [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3865-3876.

[18] GUNDEROV D V, POLYAKOV A V, SEMENOVA I P, RAAB G I, CHURAKOV A A, GIMALTDINOVA E I, SABIROV I, SEGURADO J, SITDIKOV V D, ALEXANDROV I V, ENIKEEV N A, VALIEV R Z. Evolution of microstructure, macrotexture and mechanical properties of commercially pure Ti during ECAP-conform processing and drawing [J]. Materials Science and Engineering A, 2013, 562: 128-136.

[19] STEPANOV N, KUZNETSOV A, SALISHCHEV G, RAAB G, VALIEV R. Effect of cold rolling on microstructure and mechanical properties of copper subjected to ECAP with various numbers of passes [J]. Materials Science and Engineering A, 2012, 554: 105-115.

[20] ZHANG J, ZHANG K S, HWAI-CHUNG W, YU M H. Experimental and numerical investigation on pure aluminum by ECAP [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 1303-1311.

[21] KIM H S. On the effect of acute angles on deformation homogeneity in equal channel angular pressing [J]. Materials Science and Engineering A, 2006, 430: 346-349.

[22] PATIL B V, CHAKKINGAL U, KUMAR T P. Influence of outer corner radius in equal channel angular pressing [J]. World Academy of Science, Engineering and Technology, 2010, 62: 714-720.

[23] FARAJI G, MASHHADI M M, KIM H S. Tubular channel angular pressing (TCAP) as a novel severe plastic deformation method for cylindrical tubes [J]. Materials Letters, 2011, 65: 3009-3012.

[24] FARAJI G, BABAEI A, MASHHADI M M, ABRINIA K. Parallel tubular channel angular pressing (PTCAP) as a new severe plastic deformation method for cylindrical tubes [J]. Materials Letters, 2012, 77: 82-85.

[25] SHEN J, GARTNEROVA V, KECSKES L J, KONDOH K, JAGER A, WEI Q. Residual stress and its effect on the mechanical properties of Y-doped Mg alloy fabricated via back-pressure assisted equal channel angular pressing (ECAP-BP) [J]. Materials Science and Engineering A, 2016, 669: 110-117.

[26] MATSUBARA K, MIYAHARA Y, HORITA Z, LANGDON T. Developing superplasticity in a magnesium alloy through a combination of extrusion and ECAP [J]. Acta Materialia, 2003, 51: 3073-3084.

[27] STRASKA J, JANECEK M, CIZEK J, STRASKY J, HADZIMA B. Microstructure stability of ultra-fine grained magnesium alloy AZ31 processed by extrusion and equal- channel angular pressing (EX–ECAP) [J]. Materials Characterization, 2014, 94: 69-79.

[28] GZYL M, ROSOCHOWSKI A, BOCZKAL S, OLEJNIK L. The role of microstructure and texture in controlling mechanical properties of AZ31B magnesium alloy processed by I-ECAP [J]. Materials Science and Engineering A, 2015, 638: 20-29.

[29] RICHERT M W. Features of cyclic extrusion compression: Method, structure & materials properties [J]. Solid State Phenomena: Trans Tech Publ, 2006, 114: 19-28.

[30] PARDIS N, TALEBANPOUR B, EBRAHIMI R, ZOMORODIAN S. Cyclic expansion-extrusion (CEE): A modified counterpart of cyclic extrusion-compression (CEC) [J]. Materials Science and Engineering A, 2011, 528: 7537-7540.

[31] AMANI S, FARAJI G, ABRINA K. Microstructure and hardness inhomogeneity of fine-grained AM60 magnesium alloy subjected to cyclic expansion extrusion (CEE) [J]. Journal of Manufacturing Processes, 2017, 28: 197-208.

[32] ENSAFI M, FARAJI G, ABDOLVAND H. Cyclic extrusion compression angular pressing (CECAP) as a novel severe plastic deformation method for producing bulk ultrafine grained metals [J]. Materials Letters, 2017, 197: 12-16.

[33] IWAHASHI Y, HORITA Z, NEMOTO M, WANG J, LANGDON T G. Principle of equal-channel angular pressing for the processing of ultra-fine grained materials [J]. Scripta Materialia, 1996, 35: 143-146.

[34] RICHERT M, MC-QUEEN H, RICHERT J. Micrbband formation in cyclic extrusion compression of aluminum [J]. Canadian Metallurgical Quarterly, 1998, 37: 449-457.

[35] LANGE K. Handbook of metal forming [M]. McGraw-Hill Book Company, 1985: 1216.

[36] CHALASANI D, JAIN M K, SHANKAR S, FAZELI F. Workability characteristics and deformation mechanisms of die-cast AM60 and AZ91 magnesium alloys: Correlation with processing maps [J]. Journal of Materials Engineering and Performance, 2019, 28: 123-139.

[37] MATHIS K, CHMELIK F, TROJONOVA Z, LUKAC P, LENDVAI J. Investigation of some magnesium alloys by use of the acoustic emission technique [J]. Materials Science and Engineering A, 2004, 387: 331-335.

[38] LICHY P, CAGALA M, BENO J. Investigation of the thermomechanical properties and microstructure of special magnesium alloys [J]. Materials and Technologies, 2013, 47: 503-506.

[39] FARAJI G, KIM H. Review of principles and methods of severe plastic deformation for producing ultrafine-grained tubes [J]. Materials Science and Technology, 2017, 33: 905-923.

[40] ABDOLVAND H, SOHRABI H, FARAJI G, YUSOF F. A novel combined severe plastic deformation method for producing thin-walled ultrafine grained cylindrical tubes [J]. Materials Letters, 2015, 143: 167-171.

[41] MCKENZIE P W J, LAPOVOK R, ESTRIN Y. The influence of back pressure on ECAP processed AA 6016: Modeling and experiment [J]. Acta Materialia, 2007, 55: 2985-2993.

[42] KANG F, LIU J Q, WANG J T, ZHAO X. The effect of hydrostatic pressure on the activation of non-basal slip in a magnesium alloy [J]. Scripta Materialia, 2009, 61: 844-847.

[43] CHINO Y, KOBATA M, IWASAKI H, MABUCHI M. An investigation of compressive deformation behaviour for AZ91 Mg alloy containing a small volume of liquid [J]. Acta Materialia, 2003, 51: 3309-3318.

[44] FARAJI G, MASHHADI M, KIM H. Microstructure inhomogeneity in ultra-fine grained bulk AZ91 produced by accumulative back extrusion (ABE) [J]. Materials Science and Engineering A, 2011, 528: 4312-4317.

[45] SARKAR A, CHAKRAVARTTY J. Investigation of progress in dynamic recrystallization in two austenitic stainless steels exhibiting flow softening [J]. International Journal of Metallurgical Engineering, 2013, 2: 130-136.

[46] WEI G B, MAHMOODKHANI Y, PENG X D, HADADZADEH A, XU T C, LIU J W, XIE W D, WELLS M A. Microstructure evolution and simulation study of a duplex Mg-Li alloy during double change channel angular pressing [J]. Materials & Design, 2016, 90: 266-275.

[47] YOO M S, KIM J J, SHIN K S, KIM N J. Effect of second phases on the high temperature mechanical properties of squeeze cast Mg-Al alloys [C]//Magnesium Technology 2002. Seattle, 2002.

[48] FARAJI G, MASHHADI M M, KIM H S. Microstructural evolution of UFG magnesium alloy produced by accumulative back extrusion (ABE) [J]. Materials and Manufacturing Processes, 2012, 27: 267-272.

[49] SHIN D H, KIM I, KIM J, ZHU Y T. Shear strain accommodation during severe plastic deformation of titanium using equal channel angular pressing [J]. Materials Science and Engineering A, 2002, 334: 239-245.

[50] CHOI Y C, KIM H S, HONG S I. The effects of alloying and pressing routes in equal channel angular pressing of Cu-Fe-Cr and Cu-Fe-Cr-Ag composites [J]. Metals and Materials International, 2009, 15: 733.

[51] LEE K M, KANG H G, HUH M Y, ENGLER O. Effect of strain paths on development of shear textures during rolling in aluminum sheets [J]. Metals and Materials International, 2010, 16: 851-856.

Siroos AHMADI1, Vali ALIMIRZALOO1, Ghader FARAJI2, Ali DONIAVI3

1. Department of Mechanical Engineering, Urmia University, Urmia 57153165, Iran;

2. School of Mechanical Engineering, College of Engineering, University of Tehran, Tehran 11155-4563, Iran;

3. Department of Industrial Engineering, Urmia University, Urmia 57153165, Iran

摘 要:利用新型大塑性变形(SPD) 技术提高镁合金的冶金性能。在此过程中,先进行循环挤压-压缩-角挤压(CECAP)过程,再在出口处进行挤压,起到附加背压的作用。因此,与等径角挤压(ECAP)相比,期望获得更加均匀和优异的力学性能。为了评价这种新方法的有效性和能力,对AM60镁合金进行加工。有限元分析表明,新方法的应变值和均匀应变分布均显著提高。此外,与传统的ECAP相比,新方法的压应力增加约110%。实验结果表明,经新工艺处理后,试样的硬度和强度均有显著提高,这是由于其晶粒细化,显微组织更加均匀,并且细化的β相沿晶界均匀分布。因此,该新工艺在未来镁合金生产中具有广阔的应用前景。

关键词:循环挤压-压缩-角挤压;AM60合金;应变分布;力学性能;晶粒细化

(Edited by Bing YANG)

Corresponding author: Vali ALIMIRZALOO; E-mail: v.alimirzaloo@urmia.ac.ir

DOI: 10.1016/S1003-6326(21)65527-9

1003-6326/ 2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press