金属塑性加工工作界面非稳态润滑轧机振动控制

王桥医,黄海军,李志华

(杭州电子科技大学 机械工程学院,浙江 杭州,310018)

摘 要:针对轧机垂直系统经常发生的自激振动现象,综合运用轧制理论、流体力学理论、润滑摩擦理论以及机械振动理论,建立考虑辊缝非稳态润滑过程轧机系统振动模型。该模型综合运用工作界面上的轧制力模型、界面摩擦模型、工作辊运动模型构成的界面薄膜约束多重耦合模型,定量分析一些主要参数对轧机垂直自激振动临界速度和振幅的影响。研究结果表明:轧制润滑乳化液的黏度越大,振动的临界速度越低;轧件的出口厚度越小,入口厚度越大,振动临界速度越低;轧件的变形抗力越高,振动临界速度越低;轧辊、轧件的表面粗糙度越高,轧机振动临界速度越高;轧辊半径越大,振动临界速度越高;轧机垂直系统本身的正阻尼(工作辊间阻尼以及压下油缸阻尼)越大,振动临界速度越高,振幅也越小;轧制速度越高,振幅越大。

关键词:塑性加工;非稳态润滑;轧机;振动;耦合模型

中图分类号:TH117.2;TH113.1 文献标志码:A 文章编号:1672-7207(2010)04-1418-06

Control of mill vibration for unsteady lubrication based on

metal-forming processes

WANG Qiao-yi, HUANG Hai-jun, LI Zhi-hua

(School of Mechanical Engineering, Hangzhou Dianzi University, Hangzhou 310018, China)

Abstract: The self-excited vertical vibration of high speed rolling mill was chosen as the case for analysis. On the basis of rolling theory, hydromechanics theory, lubrication and friction theory, mechanic vibration theory, the vertical vibration model of rolling mill system based on the rolling gap at unsteady lubrication process was presented. In the analysis of vertical vibration process, the interface coupling model of thin film binding that consists of the rolling force model, interface friction model and work roll movement model was taken into account. The self-excited vertical vibration mechanism of work roll was analyzed, the negative damping character was discussed and vertical self-excited vibration of the work roll was explained. Using the simulation program, the effect of some main parameters on critical speed and amplitude for vertical vibration was analyzed quantitatively too. The results show that rolling lubricant viscosity, strip inlet thickness and strip deformation resistance are inversely proportional to the critical speed of vibration; strip outlet thickness, the roughness of roll and strip, roll radius and system positive damping are directly proportional to the critical speed of vibration; system positive damping is inversely proportional to the amplitude of vibration; and rolling speed is directly proportional to the amplitude of vibration.

Key words: metal-forming; unsteady lubrication; mill; vibration; coupling model

轧制过程是一个瞬态的、与时间有关的过程,机器结构的振动[1-2]导致润滑系统处于非稳定状态,同时摩擦力[3-5]也与时间有关。在金属成型过程中,大量生产损失都涉及到非稳定形态。由于轧制过程是最重要的大变形[6-7]金属成型过程,因此,它对研究非稳态润滑[8-10]现象具有特别重要的意义,有助于建立一个更真实的非稳态过程摩擦学模型[11],从而得到一个避免振动的策略,建立一个较精确的轧制过程动力学模型[12-13]。而现有的轧制过程摩擦学模型一般为稳态模型,不能真实反映在颤振发生期间轧机运行条件的快速变化而导致的摩擦效应的变化,为此,本文作者综合运用工作界面上的轧制力模型、界面摩擦模型、工作辊运动模型构成的界面薄膜约束多重耦合模型,结合非稳态润滑理论,建立考虑辊缝非稳态润滑过程轧机系统振动模型。

1 界面非稳态润滑模型

在轧制过程中,工作界面的润滑状态多为混合润滑,即部分流体膜润滑、吸附膜润滑、粗糙峰接触(干摩擦)并存。变形区油膜厚度是描述界面摩擦状态的1个重要参数,轧制变形区的油膜厚度主要取决于入口区的成膜能力,即入口油膜厚度。因此,对入口油膜厚度的建模和计算是关键问题之一。

在入口区,假设板带是刚性的。板带与轧辊之间的间隙是流体动压力的挤压作用而形成。在入口区内,乳化液的压应力分布可由雷诺方程[14]确定:

(1)

(1)

式中:h1为入口区内任意一点乳化液膜厚度;μ为乳化液黏度;t为时间;x为油膜位置的水平投影; 为板带和轧辊的平均表面速度。根据几何及边界条件,由方程(1)可确定入口油膜厚度h0。

为板带和轧辊的平均表面速度。根据几何及边界条件,由方程(1)可确定入口油膜厚度h0。

工作区中轧件速度u沿X方向变化。考虑轧机垂直方向的振动,Yun等[15]提出了工作区任意位置的轧件介质连续性方程,具体如下:

(2)

(2)

其中: 是轧辊辊缝间隔沿轧辊中心线垂直方向的变化率,即辊缝的变化是轧机结构的运动引起的。

是轧辊辊缝间隔沿轧辊中心线垂直方向的变化率,即辊缝的变化是轧机结构的运动引起的。

变形区油膜厚度h(x)与入口油膜厚度h0需满足流量连续条件,即

(3)

(3)

式中:u1为入口轧件速度;u(x)为轧件速度;v为轧辊表面线速度。

2 轧制力模型

对轧件取微元体分析。由受力平衡,可得轧制力分布微分方程。在X方向,力的平衡方程[16](忽略相对小的项)为:

(4)

(4)

式中:s为轧件后张力;y为轧件局部点厚度;p为局部压应力; 为局部摩擦应力。

为局部摩擦应力。

3 界面摩擦力模型

在混合润滑状态下,接合面的载荷和摩擦力一部分由粗糙接触表面承担,另一部分由接触表面凹槽中的压力乳化液承担。在混合润滑状态下,总摩擦应力的典型表达式为:

(5)

(5)

其中: (k为材料的剪切强度);

(k为材料的剪切强度); ;τa和τb分别为边界润滑摩擦应力和流体动力润滑摩擦应力。真实接触面积比A在混合润滑状态下对摩擦应力的分布非常重要,可采用轧件和轧辊表面粗糙度高度分布的高斯分布法求解。

;τa和τb分别为边界润滑摩擦应力和流体动力润滑摩擦应力。真实接触面积比A在混合润滑状态下对摩擦应力的分布非常重要,可采用轧件和轧辊表面粗糙度高度分布的高斯分布法求解。

4 工作辊运动约束方程

工作辊的运动与辊缝的开口度变化、轧件的厚度变化及界面油膜的挤压速度有关,并具有以下约束关系:

(6)

(6)

(7)

(7)

式中:y(x)为工作辊运动位移; 为轧件厚度变化;

为轧件厚度变化; 为变形区油膜厚度变化。可见:工作界面上的界面摩擦润滑模型、轧制力模型、工作辊运动模型构成了界面的薄膜约束耦合模型。在界面耦合模型中,耦合参数有τf,p,h,?H和s等。

为变形区油膜厚度变化。可见:工作界面上的界面摩擦润滑模型、轧制力模型、工作辊运动模型构成了界面的薄膜约束耦合模型。在界面耦合模型中,耦合参数有τf,p,h,?H和s等。

5 轧机系统振动模型

轧机垂直系统振动模型主要有2种建模方法:采用简化弹簧质量系统建模以及采用有限元方法建模。由于冷轧机动态辊缝的研究除了轧机垂直系统的振动模型外,还需利用辊缝入口油膜厚度和轧制压力计算模型,而已有的有限元程序不能加上这2个模型进行仿真研究,因此,采用常规的简化弹簧质量模型,即将轧机垂直系统的各个元件简化为集中的弹簧和质量。

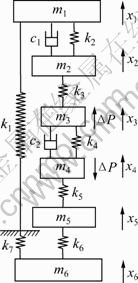

根据某大型公司2800轧机的特点,可将垂直系统简化为六自由度振动系统[17],将轧机的垂直系统简化为六质量、七弹簧的六自由度系统。图1所示为简化的2800轧机垂直系统振动模型。其中:质量m1~m6分别对应于轧机的上横梁及机架立柱、上支承辊及其轴承和轴承座、上工作辊、下工作辊、下支承辊及其轴承和轴承座、机架下横梁的等效质量;刚度k1~k7分别对应于机架立柱及上横梁的等效刚度、上支承辊中部至上横梁中部的等效刚度、上工作辊与上支承辊之间的弹性接触刚度、上下工作辊以及带材之间在轧制力P作用下的等效刚度、下工作辊与下支承辊之间的弹性接触刚度、下支承辊中部至下横梁中部的等效刚度及下横梁的弯曲等效刚度。位移x1~x6分别为质量m1~m6的振动位移增量。模型中考虑了上横梁与上支承辊之间压下油缸造成的阻尼c1以及2个工作辊之间由于轧件造成的阻尼c2。激振力采用轧制力的波动量?P。

图1 2800轧机垂直系统简化模型

Fig.1 2800 mill vertical system model

根据图1所示的简化弹簧质量模型,运用机械振动的基本理论,建立轧机垂直系统振动数学模型如下:

6 仿真计算及分析

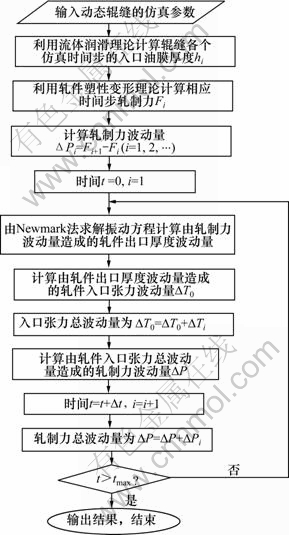

对轧机系统进行振动分析。由于各个参数对振动的影响都不是线性的,且各参数之间还相互影响,因此,这里借助计算机仿真对各参数进行定量分析。计算机仿真主要包括2部分:一部分是运用轧制力模型,轧机垂直系统自激振动反馈机制,计算由非稳态润滑所引起的轧制力波动量,以及由于系统振动所引起的轧制力波动量;另一部分是求解上述振动微分方程组。求解振动微分方程组的方法很多,由于本仿真程序要与求解轧制力波动量部分一起迭代,所以,工作量较大。仿真程序框图见图2。

图2 仿真程序框图

Fig.2 Frame of emulator

仿真框图中所要求输入的仿真参数主要为迭代步长?t和仿真时间tmax。为了取得满意的结果,一般取时间步长小于所研究系统的自由振动最小周期的1/10。由于本轧机工作辊的振动核心频率为510 Hz左右,所以,选择迭代步长为0.5 ms;由于每次仿真要计算时间较长,因此,仿真时间一般选为0.3 s。程序采用Microsoft Fortran PowerStation语言编制而成。

下面采用该仿真程序分析某大型公司2800轧机机架的振动问题,主要研究轧机动态辊缝的主要参数对轧机垂直系统发生自激振动的影响。运用仿真程序对影响轧机动态辊缝的主要参数进行定量分析,分析一些主要参数对轧机垂直自激振动临界速度和振幅的影响。图3~13所示为这些参数的影响曲线。

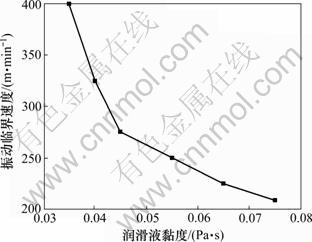

由图3可见:轧制润滑乳化液的黏度对轧机振动临界速度影响很大,黏度越大,振动的临界速度越低,也就是振动的可能性增大。这是因为乳化液的黏度增大,造成轧机入口区的乳化液膜厚度增大,进而造成辊缝间的油膜厚度增大,引起辊缝间粗糙微峰的接触区域比降低,剪切应力降低,辊缝间的摩擦力降低,导致系统的稳定性降低,系统容易发生自激振动。

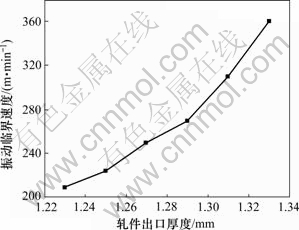

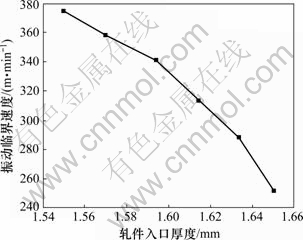

从图4和图5可见:轧件的出口、入口厚度对振动临界速度的影响很大,出口厚度越小,入口厚度越大,系统越容易发生自激振动。这是由于增大入口厚度以及减小出口厚度,则轧机的压下率增大,造成轧制力的波动量增大,由入口张力产生的界面负阻尼增大,系统越容易发生振动。

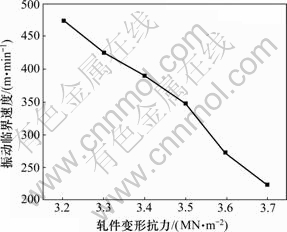

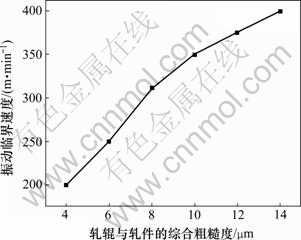

图6所示为轧件变形抗力对轧机自激振动临界速度的影响。可见:轧件的变形抗力越大,振动临界速度越小,系统越容易发生振动。变形抗力造成系统稳定性降低的原因与轧件的入口、出口厚度的影响相同。图7所示为轧辊与轧件的表面综合粗糙度对系统振动临界速度的影响。可见:粗糙度越高,轧机垂直系统的临界振动速度越高,系统越不容易发生振动。这是由于粗糙度提高造成了辊缝间粗糙微峰的接触区域比增大,增加了系统的剪切应力,提高了系统的稳定性。

图3 轧机润滑液黏度对振动的影响

Fig.3 Effect of rolling lubricant viscosity on vibration

图4 轧件出口厚度对振动临界速度的影响

Fig.4 Effect of strip outlet thickness on vibration critical speed

图5 轧件入口厚度对振动临界速度的影响

Fig.5 Effect of strip inlet thickness on vibration critical speed

图6 轧件变形抗力对振动临界速度的影响

Fig.6 Effect of strip deformation resistance on vibration critical speed

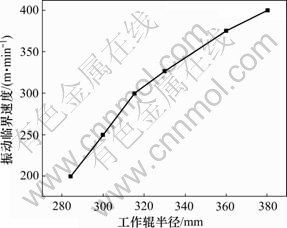

图8所示为工作辊半径对振动临界速度的影响。可见:工作辊半径越小,轧机的振动临界速度越低,越容易振动。由于工作辊半径减小造成接触弧长减小,使得整个工作区长度减小,剪切应力减小,系统的稳定性降低。

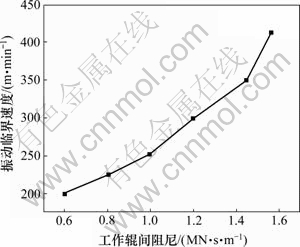

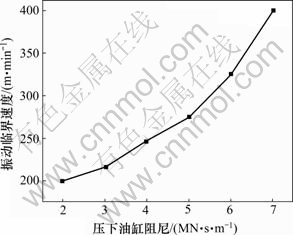

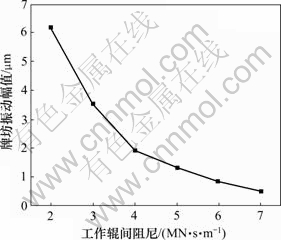

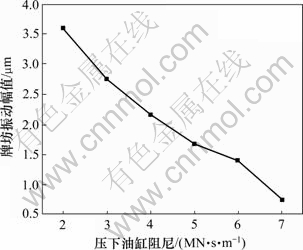

图9和图10所示为工作辊间的阻尼以及压下油缸的阻尼对振动临界速度的影响。由图9和10可见:阻尼越大,振动临界速度越高,系统的稳定性越好,这是由于阻尼增大,系统需要消耗的能量增大,轧机自激振动的可能性也就降低。工作辊之间阻尼对振动临界速度的影响比压下油缸阻尼的影响大。

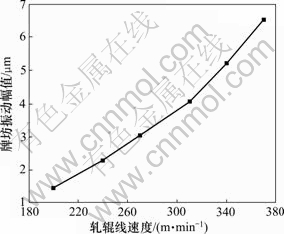

对系统振幅影响较大的参数主要包括轧制速度和阻尼。其他参数对振幅的影响关系与其对振动临界速度的影响关系一致。图11所示为轧制速度对发生自激振动时振幅的影响关系曲线,以振动发生0.4 s时对轧机牌坊的振动位移幅值进行比较。由图11可见:轧制速度对振幅的影响很大,轧制速度越高,振幅越大,所以自激振动一旦发生,只能采取降速措施。图12和图13所示分别为工作辊间阻尼和压下油缸阻尼对振幅的影响。由图12和13可见:阻尼的增大,可以有效地降低振动的幅值。同样,工作辊之间的阻尼对振幅的影响比压下油缸阻尼的影响大。

图7 轧辊与轧件的综合粗糙度对振动临界速度的影响

Fig.7 Effect of roughness of strip and roll on vibration critical speed

图8 工作辊半径对振动临界速度的影响

Fig.8 Effect of work roll radius on vibration critical speed

图9 工作辊之间的阻尼对振动临界速度的影响

Fig.9 Effect of damping between work roll on vibration critical speed

图10 压下油缸阻尼对振动临界速度的影响

Fig.10 Effect of damping for oil vat on vibration critical speed

图11 轧辊线速度对振幅的影响

Fig.11 Effect of rolling speed on vibration amplitude

图12 工作辊之间阻尼对振幅的影响

Fig.12 Effect of damping between work roll on vibration amplitude

图13 压下油缸的阻尼对振幅的影响

Fig.13 Effect of damping for oil vat on vibration amplitude

7 结论

(1) 针对轧机垂直系统经常发生的自激振动现象,综合运用轧制理论、流体力学理论、润滑摩擦理论以及机械振动理论,建立了考虑辊缝非稳态润滑过程轧机系统振动模型。该模型综合运用了工作界面上的轧制力模型、界面摩擦模型、工作辊运动模型构成的界面薄膜约束多重耦合模型。

(2) 轧制润滑乳化液的黏度越大,振动的临界速度越低;轧件的出口厚度越小,入口厚度越大,振动临界速度越低;轧件的变形抗力越高,振动临界速度越低;轧辊、轧件的表面粗糙度越高,轧机振动临界速度越高;轧辊半径越大,振动临界速度越高;轧机垂直系统本身的正阻尼 (工作辊间阻尼以及压下油缸阻尼) 越大,振动临界速度越高,振幅也越小;轧制速度越高,振幅越大。

参考文献:

[1] Swiatoniowski A, Bar A. Non-linear vibrations in cold rolling mills[J]. Journal of Materials Processing Technology, 2003, 134(2): 214-224.

[2] Bland D R, Sims R B. Chatter in rolling with strip tension[J]. J Iron Steel Inst, 1998, 217(2): 245-249.

[3] Tieu A K, Liu Y J. Friction variation in the cold rolling process[J]. Tribology International, 2004, 37(2): 177-183.

[4] CHENG Gang-sun. Investigation of interfacial behaviors between the strip and roll in strip rolling by finite element method[J]. Tribology International, 2005, 38(4): 413-422.

[5] Dick K, Lenard J G. The effect of roll roughness and lubricant viscosity on the loads on the mill during cold rolling of steel strip[J]. Journal of Materials Processing Technology, 2005, 168(1): 16-24.

[6] Wilson W R D, Chang D F. Low speed mixed lubrication of bulk metal forming processes[J]. ASME Journal of Tribology, 1996, 118(1): 83-89.

[7] 胡忠举, 陆名彰, 彭成章. 铝薄带超常铸轧辊套温度场研究[J]. 湖南大学学报: 自然科学版, 2004, 31(1): 33-36.

HU Zhong-ju, LU Ming-zhang, PENG Cheng-zhang. Study on the shell’s temperature field in the high speed thin gauge twin roll casting for aluminum belt[J]. Journal of Hunan University: Natural Sciences, 2004, 31(1): 33-36.

[8] Kudish I. On formulation of a non-steady lubrication problem for a non-conformal contact[J]. Tribology Trans, 1999, 42(1): 53-57.

[9] Saniei M, Salimi M. Development of a mixed film lubrication model in cold rolling[J]. Journal of Materials Processing Technology, 2006, 177(1): 575-581.

[10] Stephany J, Ponthot P. Efficient algorithmic approach for mixed-lubrication in cold rolling[J]. Journal of Materials Processing Technology, 2004, 153(2): 307-313.

[11] Schey J A. Surface roughness effects in metalworking[J]. Lubr Eng, 1983, 39(6): 376-382.

[12] HU Pei-hua, Ehmann K F. A dynamic model of the rolling process, Part Ⅰ: Homogeneous model[J]. International Journal of Machine Tools & Manufacture, 2000, 40(1): 1-20.

[13] HU Pei-hua, Ehmann K F. A dynamic model of the rolling process, Part Ⅱ: Inhomogeneous model[J]. International Journal of Machine Tools & Manufacture, 2000, 40(1): 21-31.

[14] Chang D F, Wilson W R D. Lubrication of strip rolling in the low speed mixed regime[J]. Tribology Trans, 1996, 39(2): 407-415.

[15] Yun I S, Wilson W R D. Chatter in the strip rolling process. Part 1: Dynamic model of rolling; Part 2: Dynamic rolling experiments; Part 3: Chatter model[J]. Journal of Manufacturing Science and Engineering, 1998, 120(2): 330-348.

[16] 赵志业. 金属塑性变形与轧制理论[M]. 北京: 冶金工业出版社, 1996: 57-96.

ZHAO Zhi-ye. Metal plasticity deformation and roll theory[M]. Beijing: Metallurgical Industry Press, 1996: 57-96.

[17] 张材, 谭建平. 基于遗传算法-反向传播模型的板形模式识别[J]. 中南大学学报: 自然科学版, 2006, 37(2): 294-299.

ZHANG Cai, TAN Jian-ping. Strip flatness pattern recognition based on genetic algorithms-back propagation model[J]. Journal of Central South University: Science and Technology, 2006, 37(2): 294-299.

收稿日期:2009-08-18;修回日期:2009-11-10

基金项目:国家自然科学基金资助项目(50575228);湖南省自然科学基金资助项目(07JJ3089)

通信作者:王桥医(1966-),男,湖南湘乡人,博士,教授,从事复杂系统动力学性能及其控制技术、摩擦润滑等研究;电话:0571-86919057;E-mail: wangqiaoyi1989@163.com

(编辑 赵俊)