聚丙交脂-乙交酯纤维的温压成形

陈 剑,易 磊,樊 新,阮建明,刘 莹,周智华,周忠诚,邹俭鹏

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:通过溶液沉析纺丝法制备聚丙交酯-乙交酯(PLGA)纤维,观察纤维的形貌并对其进行XRD和SEM表征。采用纤维温压成形法控制压力和温度得到条形的PLGA材料结合试样断口分析,研究成型压力与温度对PLGA材料的力学性能的影响。研究结果表明:非晶多孔结构的PLGA纤维可通过溶液沉析纺丝的方法获得,其孔径为0.1~ 1.0 μm;压制压力和压制温度对材料的力学性能影响较大,材料的抗弯强度、剪切强度和抗弯模量均随着温度和压力的增大而先增大后降低;在压制压力为105 MPa,压制温度为160 ℃时,试样的力学性能比较理想,此时,其抗弯强度可达到187.3 MPa,剪切强度达到100.1 MPa,抗弯模量达到2.5 GPa,可望作为非承重部位骨折愈合内固定材料。

关键词:溶液沉析纺丝;聚丙交脂-乙交酯纤维;温压成形;力学性能

中图分类号:R318.08;TB324 文献标识码:A 文章编号:1672-7207(2009)05-1222-06

Poly(lactic acid-glycolic acid) (PLGA) fiber material

fabricated by mild temperature molding

CHEN Jian, YI Lei, FAN Xin, RUAN Jian-ming, LIU Ying, ZHOU Zhi-hua, ZHOU Zhong-cheng, ZOU Jian-peng

(State Key Laboratory of Power Metallurgy, Central South University, Changsha 410083, China)

Abstract:Solvent spinning method was used to prepare Poly(lactic acid-glycolic acid) (PLGA) fiber. The fiber was observed by X-ray diffractometry (XRD) and scanning electron microscope (SEM). PLGA rectangular materials were fabricated by fiber mild temperature molding and the effects of molding pressure and temperature on the mechanical strength of PLGA were also investigated. The results show that the amorphous PLGA fiber with porous structure (0.1-1.0 μm) is obtained by diluted solvent spinning method and the mechanical properties is affected by pressure and temperature. Bending strength and shearing strength of the samples increase firstly and then decrease with the increase of molding temperature and pressure. While the molding temperature is 160 ℃ and the pressure is 105 MPa, the PLGA materials possess optimal mechanical properties, bending strength, shearing strength and bending modulus 187.3 MPa, 100.0 MPa and 2.5 GPa, respectively. The mild temperature molding PLGA materials are desired to play a grate role in non-bearing internal fixation devices.

Key words: solvent spinning method; poly(lactic acid-glycolic acid) (PLGA) fiber; mild temperature moulding; mechanical properties

生物降解材料在骨组织工程中应用越来越广[1-3]。PLGA是目前广泛应用于骨、软骨、血管、神经、皮肤等组织的生物可降解材料,其熔点和结晶度均低于PGA,其降解速度比PGA的降解速率快;同时,由于其分子链比PLLA的分子链少了1个甲基且引入乙醇酸柔性链段,使得其疏水性减弱,柔韧性和亲水性增强,生物相容性好且易被吸收[4-7],显示出良好的临床应用前景[8]。文献[9-10]报道,PLGA初始弯曲强度(57~145 MPa)太低而不能满足临床上骨固定的要求。本文作者从PLGA材料成形工艺的角度出发,研究其对骨固定器件力学性能的影响。采用温压成形工艺加工PLGA纤维,通过准确控制材料融化和成形的温度及压力,从而得到结构相对致密均匀、力学性能良好的PLGA材料,并对PLGA温压成形工艺参数进行研究。

1 实 验

1.1 实验试剂

PLGA(实验室自制,相对分子质量为21.3万);二氯甲烷(天津大茂化学试剂厂,分析纯);乙醇(天津大茂化学试剂厂,分析纯)。

1.2 PLGA溶液纺丝纤维的制备及成形

采用溶液沉析纺丝制备PLGA纤维,溶液沉析纺丝不仅可以除去聚合反应块状PLGA中的单体和催化剂等杂质,还能得到PLGA纤维,易于加工成形。具体方法如下:将自制块状PLGA粉碎溶于二氯甲烷中配成质量浓度为0.05 g/mL的高分子稀溶液,开动搅拌器(转速为500 r/min),将配好的高分子稀溶液以直径为1~3 mm的液流匀速倒入盛有乙醇的烧杯中,PLGA纤维逐渐沉析出来,缠绕在搅拌器上,取下,置于真空干燥箱中干燥待用。

取相同质量的PLGA纤维若干份,将其放入模具中预压(压制压力为100 MPa),使铺好的PLGA纤维固定压实,然后,将样品加热到一定温度熔化后,分别在不同的压制压力(65~125 MPa)和压制温度(120~ 170 ℃)下压制成形制得PLGA条状样,以备检测。

1.3 表 征

采用Rigaku D/max 2550VB+18 kW转靶X射线衍射仪分析聚合物原料和纤维的结晶性能。采用三点抗弯法,试样长度为36 mm,跨距为24 mm,加载速度为5 mm/min,抗弯强度和抗弯模量按下式进行计算:

力学测试结束后,对样品断口喷金,用KYKY2800扫描电镜观察PLGA纤维形貌和样品抗弯断裂断口 形貌。

2 结果与讨论

2.1 PLGA纤维的SEM形貌

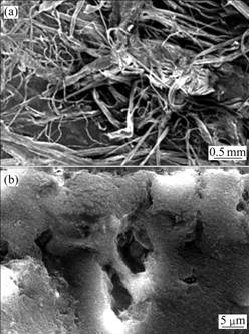

溶液沉析纺丝前后的PLGA照片如图1所示。聚合反应制备的PLGA为白色坚硬固体,溶液沉析纺丝后为白色丝状纤维。

(a) PLGA块;(b) PLGA纤维

图1 PLGA溶液沉析纺丝前、后照片

Fig.1 Photos of PLGA before and after solvent spinning

PLGA纤维的微观形貌如图2所示。从图2可以看出,溶液沉析纺丝制备的PLGA纤维呈带状或薄膜状,且具有多孔结构,孔径为0.1~1.0 μm。多孔生物材料具有较大的比表面积,有利于细胞黏附生长和营养物质的渗入以及代谢产物的排出[11-12]。多孔结构的产生可能是在沉析过程中,溶剂二氯甲烷快速析出导致纤维基体收缩而引起的。因此溶液沉析纺丝制备的PLGA纤维与采用熔融、溶液纺丝制备的PLGA纤维相比,其拉伸强度较低。但是,由于存在多孔结构,在纤维干燥过程中使得纤维中残留溶剂容易挥发出来,纤维中溶剂的残留量降低[13]。同时,采用溶液沉析制备PLGA纤维将PLGA的提纯及纤维纺丝同时完成,从而简化了PLGA纤维的制备工艺。

(a) 低倍;(b) 高倍

图2 溶液沉析纺丝制备PLGA纤维形貌的SEM像

Fig.2 SEM images of PLGA fiber morphology by solvent spinning method

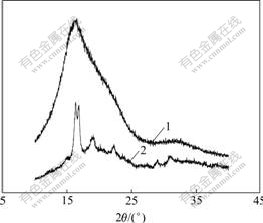

2.2 PLGA溶液纺丝前后的XRD谱

图3所示为PLGA溶液沉析纺丝前、后的XRD谱。溶液沉析纺丝前PLGA为半结晶高分子材料,在2θ=16.84?和2θ=19.03?处的衍射峰分别与PLGA的晶面(200)和(203)相对应,其结晶度约为12.4%;溶液沉析纺丝后,PLGA纤维的XRD谱中衍射峰宽化,在2θ=10?~40?之间无尖锐的衍射峰,具有典型的非晶态特征。结果表明,溶液沉析纺丝前、后,PLGA的结晶度发生了变化。主要原因是,聚合前、后PLGA的结晶环境不同,提纯过程中搅拌器高速旋转不利于PLGA结晶。

1—纺丝后;2—纺丝前

图3 PLGA溶液纺丝前、后的XRD谱

Fig.3 XRD patterns of PLGA before and after solvent spinning method

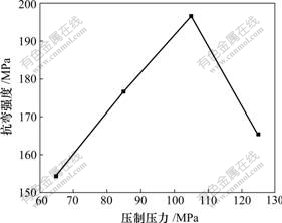

2.3 压制压力对PLGA抗弯强度及抗弯模量的影响

图4所示是温度为155 ℃时,不同压制压力对PLGA抗弯强度的影响。从图4可以看出,随着压制压力的增加,PLGA的抗弯强度先增加后降低;当压制压力达到105 MPa时,其抗弯强度达到最高值196.7 MPa。产生上述现象的原因主要有以下2个方面:一方面,由于制备的PLGA纤维是网孔状结构,材料中存在大量微孔和间隙;当压制压力较小时,压坯的变形量不足以消除PLGA纤维中的微孔及纤维之间孔隙,造成压坯的密度较小,但是,随着压制压力的增加,纤维变形量的增加使孔隙的数量减少,材料的抗弯强度有所增加;另一方面,当压制压力过高时,在压制过程中,虽然可以增大压坯的密度,但是,过大的压力在材料脱模时造成的弹性后效作用使材料中形成很多的微孔,孔隙的存在容易造成沿孔隙尖端所引起的应力集中[14],在外力的作用下,这种应力集中可能引起材料产生微裂纹,微裂纹的产生又加剧了应力集中,促使裂纹迅速扩展,引起材料断裂,因此,降低了材料的抗弯强度。可见,压力过高或过低都会导致PLGA抗弯强度下降。因此,当温度为155 ℃时,压制压力为105 MPa较合适。

图4 压制压力对PLGA力学性能的影响

Fig.4 Effect of molding pressure on bending strength of PLGA

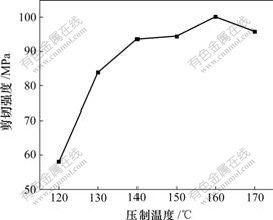

2.4 压制温度对PLGA抗弯强度、剪切强度及抗弯模量的影响

图5和6所示分别为压制压力为105 MPa、压制温度为120~170 ℃的条件下,压制温度与PLGA抗弯强度、抗弯模量及剪切强度之间的关系。可以看出,PLGA的抗弯强度及抗弯模量随着压制温度升高先增加后降低。当压制温度为160 ℃时,抗弯强度达到最大值187.3 MPa, 剪切强度达100.1 MPa,抗弯模量达到最大值2.5 GPa。成人的肱骨和股骨的抗弯强度分别是195 MPa和177 MPa,剪切强度分别是75 MPa和84 MPa[15],弹性模量为3~25 GPa[16],制备材料的力学性能与人体骨的力学性能接近,尤其是弹性模量与人体骨的弹性模量匹配,可以避免金属植入材料植入后弹性模量不匹配而造成的“应力遮蔽”现象。故该材料可以作为非承重骨部位的骨修复材料使用。

1—抗弯强度;2—抗弯模量

图5 压制温度与PLGA力学性能的关系

Fig.5 Effects of temperature on bending strength and bending modulus of PLGA

图6 压制温度对PLGA剪切强度的影响

Fig.6 Effect of temperature on shearing strength of PLGA

当压制温度很低时,部分纤维之间的结合为简单的机械咬合,纤维之间的距离较大。从分子水平来看,高聚物主要靠分子间的范德华力和氢键抵抗外力破坏。而此时纤维之间的距离远超出了范德华力的作用范围,因此,材料的强度不高[17-18]。随着温度升高,PLGA分子链的分子热运动能量增加,当温度超过玻璃转化温度(tg=55 ℃),分子热运动的能量已能足以克服内旋转的位垒时,链运动被激发,链段可以通过主链中单链的内旋转不断改变构象,PLGA逐渐进入高弹态。根据WLF方程[19],PLGA在tg(55 ℃)到tg+ 100 ℃(155 ℃)范围内黏度受温度的影响很大,同时,液体中的孔穴也随着增加和膨胀,使流动的阻力减少,聚乳酸的表观黏度降低,液体的流动性好,在外力作用下,试样的密度增高,孔隙度减小,因此,抗弯强度也随之升高。但是,当压制温度超过160 ℃时,由于PLGA的热降解作用和氧化速度加快,PLGA的抗弯强度下降。因此,采用压制温度160 ℃最为合适。

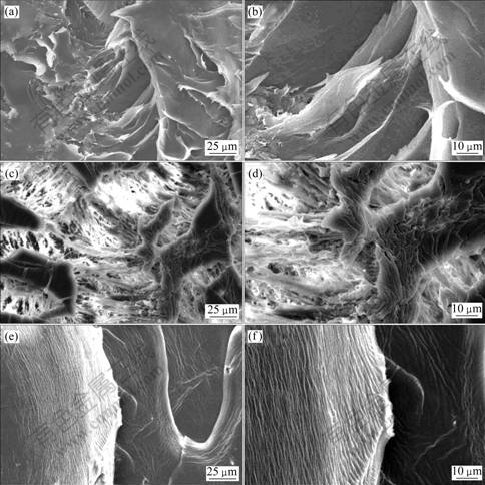

2.5 试样断口形貌SEM分析

图7所示为压制温度分别为130,160和170 ℃时PLGA抗弯试样断口的SEM像。可以看出,温度为130 ℃时断口光亮,有撕裂痕迹,且断裂方向与正应力垂直,断口上有鱼骨花纹,有明显的脆性断裂的特征,同时,纤维之间仍然有机械咬合的痕迹,强度不高。在160 ℃时,出现了大量直径不等的圆形或椭圆形的凹坑。由于抗弯检测是试样在垂直于轴向的应力作用下,此时试样受到弯曲力矩的而作用,显微孔洞所受应力不同,沿受力较大的方向韧窝被拉长,拉长过程吸收了一定的冲击功。试样具有延性断裂的特征,从而提高了试样的抗弯强度。当温度为170 ℃时,断口不平整,出现河流状花样有脆性断裂的特征。在该温度下,PLGA的纤维接近熔融态,压制完成后,冷却时间较快,弹性后效的效果明显,产生微裂纹;再加上温度升高,导致PLGA的氧化和热降解作用增强,使试样的强度与 160 ℃时的强度相比有所下降。

(a) 130 ℃,低倍;(b) 130 ℃,高倍;(c) 160 ℃,低倍;(d) 160 ℃,高倍;(e) 170 ℃,低倍;(f) 170 ℃,高倍

图7 不同温度下PLGA抗弯试样断口的SEM像

Fig.7 SEM images of cross-section of PLGA materials at different temperatures

3 结 论

a. 用溶液沉析纺丝法制备了非晶的具有多孔结构的PLGA纤维,其孔径为0.1~1.0 μm。

b. PLGA纤维在温压成形过程中,压力和温度对材料力学性能影响较大,其合适的温压成形工艺条件是:压制压力为105 MPa,压制温度为160 ℃。在此条件下,材料抗弯强度可达到187.3 MPa,剪切强度达到100.1 MPa,抗弯模量达到最大值2.5 GPa。

c. 温压成形制备的PLGA材料可望用作非承重的骨修复材料。

参考文献:

[1] 余 斌, 高成杰, 全大萍, 等. 低热高压法制作PLGA支架的降解及生物力学研究[J]. 第一军医大学学报, 2003, 23(5): 416-420.

YU Bin, GAO Cheng-jie, QUAN Da-ping, et al. In vitro degradation and subsequent biomechanical changes of poly (lactide-co-glycolide) scaffolds prepared by mild heating under high pressure[J]. Journal of First Military Medical University, 2003, 23(5): 416-420.

[2] 樊 新, 陈 剑, 阮建明, 等. 聚乳酸类可降解材料研究进展[J]. 粉末冶金材料科学与工程, 2008, 13(4): 187-194.

FAN Xin, CHEN Jian, RUAN Jian-ming, et al. Research and progress on poylactide biodegradable materials[J]. Materials Science and Engineering of Powder Metallurgy, 2008, 13(4): 187-194.

[3] 樊 新, 陈 剑, 阮建明, 等. 骨粉/PLLA新型内固定复合材料的制备[J]. 中南大学学报: 自然科学版, 2008, 39(6): 1213-1218.

FAN Xin, CHEN Jian, RUAN Jian-ming, et al. Fabrication of novel bone meals/PLLA composites for internal fixation plates[J]. Journal of Central South University: Science and Technology, 2008, 39(6): 1213-1218.

[4] 汪朝阳, 赵耀明. 聚乙醇酸类生物降解高分子[J]. 广州化学, 2004, 29(1): 50-57.

WANG Zhao-yang, ZHAO Yao-min. Polyglycolid acid biodegradable polymer[J]. Guangzhou Chemistry, 2004, 29(1): 50-57.

[5] 吴 颖, 郭士明, 唐 闻. 生物降解聚酯——聚乙丙交酯的合成研究及其应用[J]. 化工新型材料, 2000, 28(1): 22-24.

WU Ying, GUO Shi-ming, TANG Wen. Study and application biodegradable polyglycolide-lacide[J]. New Chemical Materials, 2000, 28(1): 22-24.

[6] 赵耀明, 黄俊豪, 陈军武, 等. 生物降解材料——聚乙交酯医用纤维的研究[J]. 华南理工大学学报: 自然科学版, 1994, 22(6): 71-79.

ZHAO Yao-ming, HUANG Jun-hao, CHEN Jun-wu, et al. Biodegradable materials of polyglycolide as a medical fiber[J]. Journal of South China University of Technology: Natural Science, 1994, 22(6): 71-79.

[7] 汪朝阳, 赵耀明, 郑绿茵, 等. 生物降解材料聚(乳酸-乙醇酸)研究进展[J]. 江苏化工, 2005, 33(2): 9-12.

WANG Zhao-yang, ZHAO Yao-min, ZHENG Lu-yin, et al. Research progress of biodegradable polymer material poly (lactic acid-glycolic acid)[J]. Jiangsu Chemical Industry, 2005, 33(2): 9-12.

[8] 何晨光, 高永娟, 赵 莉, 等. 静电纺丝的主要参数对PLGA纤维支架形貌和纤维直径的影响[J]. 中国生物工程杂志, 2007, 27(8): 46-52.

HE Chen-guang, GAO Yong-juan, ZHAO Li, et al. The influence of several chief parameters in electrospinning on the morphology and the fiber diameter of PLGA fiber scaffolds[J]. China Biotechnology, 2007, 27(8): 46-52.

[9] 全大萍, 袁润章, 卢泽俭, 等. 高分子量聚DL-丙交酯的合成及热降解[J]. 应用化学, 2000, 17(3): 268-271.

QUAN Da-ping, YUAN Run-zhang, LU Ze-jian, et al. Synthesis and thermal stability of poly(DL-lactide)[J]. Chinese Journal of Applied Chemistry, 2000, 17(3): 268-271.

[10] Cam D, Marucci M. Influence of residual monomers and metals on PLLA thermal stability[J]. Polymer, 1997, 38: 1897-84.

[11] 罗丙红, 全大屏, 廖凯荣, 等. 低热-高压法制备PLGA多孔支架及其体外降解研究[J]. 功能高分子学报, 2003, 16(2): 149-154.

LUO Bing-hong, QUAN Da-ping, LIAO Kai-rong, et al. Scaffolds with high porosity for tissue engineering fabricated by low heat-high pressure and their degradation in vitro[J]. Journal of Functional Polymers, 2003, 16(2): 149-154.

[12] 蔡 晴, 贝建中, 王身国, 等. 乙交脂/丙交脂共聚物的体内降解行为及生物相容性研究[J]. 功能高分子学报, 2000, 13(3): 249-254.

CAI Qing, BEI Jian-zhong, WANG Shen-guo, et al. Study on biocompatibility and degradation behavior of poly(l-lactide- co-glycolide) in vitro and in vivo[J]. Journal of Functional Polymers, 2000, 13(3): 249-254.

[13] 申雄军, 张海波, 阮建明, 等. 改进的溶液纺丝法制备聚乳酸纤维及其模压成型[J]. 中南大学学报: 自然科学版, 2006, 37(5): 831-836.

SHEGN Xiong-jun, ZHANG Hai-bo, RUAN Jian-ming, et al. Preparation of poly(L-lactide) fiber by improved method of liquid filature and moulding of fibrillated compression[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 831-836.

[14] 彭大暑. 金属塑性加工原理[M]. 长沙: 中南大学出版社, 2004.

PENG Da-shu. The principle of metal plastic working[M]. Changsha: Central South University Press, 2004.

[15] 顾志华, 高瑞亭. 骨伤生物力学基础[M]. 上海:同济大学出版社, 1990.

GU Zhi-hua, GAO Rui-ting. Biomechanics foundation of injured bone[M]. Shanghai: Tongji University Press, 1990.

[16] 封彦锋, 党新安. 人骨微孔结构三维有限元力学优化分析[J]. 制造业自动化, 2007, 29(9): 86-97.

FENG Yan-feng, DANG Xin-an. The three-dimensional finite-element analysis and optimization for the bone microstructure[J]. Manufacture Automatization, 2007, 29(9): 86-97.

[17] Billmeyer F W. Textbook of polymer science[M]. 2nd ed. New York: Interscience Publishers, 1971.

[18] 何曼君, 陈维孝, 董西侠. 高分子物理[M]. 上海:复旦大学出版社, 1990.

HE Man-jun, CHEN Wei-xiao, DONG Xi-xia, et al. High polymer physics[M]. Shanghai: Fudan University Press, 1990.

[19] 复旦大学高分子化学教研室. 高分子化学[M]. 上海: 复旦大学出版社, 1995.

Staff Room of High Polymer Chemistry in Fudan University. High polymer chemistry[M]. Shanghai: Fudan University Press, 1995.

收稿日期:2008-10-04;修回日期:2008-12-03

基金项目:国家自然科学基金资助项目(50774096,50604017)

通信作者:阮建明(1956-),男,河北霸州人,教授,从事粉末冶金及生物材料研究;电话:0731-88836827;E-mail: jianming@mail.csu.edu.cn