文章编号:1004-0609(2010)02-0171-06

二次挤压对Mg-12Gd-3Y-0.6Zr合金显微组织及

力学性能的影响

刘楚明1, 2,李冰峰1,王 荣2,李慧中1,陈志永1

(1.中南大学 材料科学与工程学院,长沙 410083;

2.中国兵器科学研究院 宁波分院,宁波 315103)

摘 要:利用光学显微镜、扫描电子显微镜、X射线衍射仪等研究二次挤压对Mg-12Gd-3Y-0.6Zr合金显微组织及力学性能的影响。研究表明:该合金经二次挤压后,晶粒尺寸细化至6 μm,提高细晶强化效果;粗大Mg5Gd1?xYx相增多,降低固溶强化效果;{0002}基面织构的减弱降低织构强化效果;在三者的综合作用下,合金经二次挤压后,强度有所降低,但伸长率却大幅度提高,达到20.5%,较一次挤压态合金的伸长率提高107.1%;一次挤压态合金的断裂方式是以解理断裂为主的混合断裂,二次挤压态合金的断裂方式为韧性断裂。

关键词: Mg-12Gd-3Y-0.6Zr合金;显微组织;二次挤压;力学性能;织构

中图分类号:TG146.2 文献标识码:A

Effect of double-extrusion on microstructure and

mechanical properties of Mg-12Gd-3Y-0.6Zr alloy

LIU Chu-ming1, 2, LI Bing-feng1, WANG Rong2, LI Hui-zhong1, CHEN Zhi-yong1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083,China;

2. Ningbo Branch, Ordnance Science Institute of China, Ningbo 315103, China)

Abstract: The effect of double-extrusion on the microstructure and mechanical properties of Mg-12Gd-3Y-0.6Zr alloy was studied by optic microscopy (OM), scanning electron microscopy (SEM) and X-ray diffractometry (XRD). The results show that, after double-extrusion, the grain size of this alloy is refined to 6 μm, which improves the strengthening effect of the fine grain. The coarse Mg5 Gd1?xYx phase increases, resulting in the decreases of solution strengthening effect. The weakening of {0002} basal plane texture decreases the strengthening effect of the texture. Under the comprehensive effect of the three factors, the strength of this alloy decreases slightly after double-extrusion, whereas the elongation increases remarkably to 20.5%, which is increased by 107.1% compared with that of the as-once-extruded alloy. The fracture mechanism of the as-once-extruded alloy is compound fracture cleavage fracture, and that of the as-double-extruded alloy is toughness and fracture.

Key words: Mg-12Gd-3Y-0.6Zr alloy; microstructure; double-extrusion; mechanical properties; texture

镁合金是目前使用最轻的结构材料,它具有较高比强度、高阻尼、铸造生产率高、良好的切削加工性和完全可再生等优点,早已引起航天、航空和汽车工业的关注[1]。但镁合金高温力学性能较差,当温度升高时,它的强度和抗蠕变性能往往大幅度下降,难以作为高温长时间使用的部件。Mg-Gd-Y-Zr系合金是一种重要的高强耐热镁合金,成为近年来镁合金研究的热点之一[2?3]。但该系合金的塑性较差,应用以铸件居多,塑性加工产品少。然而,铸件的力学性能不理想,产品形状尺寸也有局限性,因此,对变形合金的需求越来越强烈。ANYANWU等[4?5]研制的Mg-Gd-Y-Zr系合金板材有优于WE54A合金的强度和抗蠕变性。

HE等[6]和YANG等[7]研制的该系合金棒材的挤压态抗拉强度在300 MPa左右,经T5处理后,其抗拉强度超过400 MPa;张新明等[8?9]对Mg-9Gd-4Y-0.6Zr合金进行一系列的研究,经常规挤压和T5处理后的抗拉强度可达370 MPa,但伸长率不足5%。合金的塑性加工均为常规的挤压和轧制。研究表明,对Mg-Zn、Al-Li及Ti-Al合金进行二次挤压[10?12],在适当降低合金强度的情况下,可提高合金的塑性,有利于难变形金属材料的成形。由二次挤压制备的AZ91镁合金,晶粒尺寸小于10 μm,在350 ℃、7.3×10?5 s?1拉伸时,伸长率达到512%[13]。但有关Mg-Gd-Y-Zr系合金二次挤压的研究还未见报道。另外,在镁合金塑性加工过程中,通常会形成不同类型的织构,这些织构的存在均会对镁合金的塑性变形行为、加工成形性能及力学性能产生影响。研究表明[14?16],采取适当的工艺可以调整、控制镁合金中织构的形态,可改善镁合金的塑性成形性能。但有关Mg-Gd-Y-Zr系合金织构的研究也还未见报道。因此,为进一步提高Mg-Gd-Y-Zr系合金的综合性能,探讨二次挤压对该系合金的影响规律,本文作者考察二次挤压后Mg-12Gd-3Y-0.6Zr合金显微组织及力学性能的变化,探讨晶粒细化、第二相和织构演化对合金力学性能的影响机理。

1 实验

采用铸锭冶金法制备Mg-12Gd-3Y-0.6Zr(质量分数,下同)合金,实验用材料为工业纯镁、镁钆(30.47%Gd)中间合金、镁钇(31.72%Y)中间合金和镁锆(30.16%Zr)中间合金。在电阻坩锅炉中熔炼,采用CO2+SF6的混合气体保护。铸成d180 mm的圆锭,经(530 ℃,24 h)均匀化处理后,一次挤压变形至d 45 mm的棒材,对一次挤压态合金进行二次挤压。二次挤压在d50 mm的挤压桶中进行,将合金挤压变形至d15 mm,挤压比为11,挤压温度为420 ℃,挤压前严格控制保温时间。

分别对一次挤压态和二次挤压态合金进行力学性能测试,拉伸试样按照GB/T 228—2002规定进行加工,用CSS?44100万能电子实验机进行测试,拉伸速率为2 mm/min;合金用5 g苦味酸+100 mL酒精+5 mL乙酸+10 mL蒸馏水混合溶液侵蚀,用POLYVAR MET型金相显微镜观察合金光学显微组织;用Sirion 200 型扫描电子显微镜进行显微组织观察、能谱分析及断口分析;采用Bruker D8 Discover型X射线衍射分析仪对合金进行织构测定。

2 结果与分析

2.1 合金的显微组织

图1所示为Mg-12Gd-3Y-0.6Zr合金一次挤压态和二次挤压态截面的光学显微组织。从图1可以看出,一次挤压态合金的晶粒尺寸不均匀,平均晶粒尺寸约为35 μm(见图1(a));在二次挤压过程中发生明显的动态再结晶,经二次挤压后,组织由均匀、细小的等轴晶组成(见图1(b)),显微组织明显细化,平均晶粒尺寸约为6 μm。

图1 Mg-12Gd-3Y-0.6Zr合金一次挤压态和二次挤压态截面的光学显微组织

Fig.1 Optical microstructures of cross-section of Mg-12Gd- 3Y-0.6Zr alloy: (a) As-once-extruded; (b) As-double-extruded

图2所示为Mg-12Gd-3Y-0.6Zr合金一次挤压态和二次挤压态的扫描电镜照片。从图2(a)可以看出,一次挤压态合金中分散着少量方块状的第二相,经能谱分析确定为Mg2Y3Gd2相。二次挤压态合金中分散着大量的第二相,较前者明显增多(见图2(b)),经能谱分析确定这些相除少量方块状的Mg2Y3Gd2相外,大部分为Mg5Gd1?xYx相。

图2 Mg-12Gd-3Y-0.6Zr合金一次挤压态和二次挤压态的SEM像

Fig.2 SEM images of Mg-12Gd-3Y-0.6Zr alloy: (a) As-once- extruded; (b) As-double-extruded

2.2 合金的织构

图3所示为Mg-12Gd-3Y-0.6Zr合金一次挤压态和二次挤压态的{0002}基面极图。由图3可以看出:一次挤压态和二次挤压态中都存在{0002}基本平行于挤压方向(ED)的织构;一次挤压态的最大极密度值为4.02(见图3(a));二次挤压态的最大极密度值为2.19,仅为前者的54.4%(见图3(b));二次挤压后合金的晶体择优取向发生了转变,{0002}基面发生了转变,最大极密度下降。

Level: 0.36, 0.73, 1.10, 1.46, 1.83, 2.19, 2.56, 2.93, 3.29, 3.66, 4.02

图3 Mg-12Gd-3Y-0.6Zr合金一次挤压态和二次挤压态的{0002}基面极图

Fig.3 {0002} pole figures of Mg-12Gd-3Y-0.6Zr alloy: (a) As-once-extruded; (b) As-double-extruded

2.3 合金的力学性能

Mg-12Gd-3Y-0.6Zr合金一次挤压态和二次挤压态的力学性能如图4所示。从图4可以看出:一次挤压态合金的抗拉强度和屈服强度分别为368.8 MPa和324.8 MPa,伸长率为9.9%。二次挤压态合金的抗拉强度和屈服强度有所降低,分别为326.9和241.2 MPa,但伸长率却大幅度提高,达到20.5%,较一次挤压态合金提高107.1%。

图4 Mg-12Gd-3Y-0.6Zr合金一次挤压态和二次挤压态的力学性能

Fig.4 Mechanical properties of Mg-12Gd- 3Y-0.6Zr alloy: (a) As-once-extruded; (b) As-double-extruded

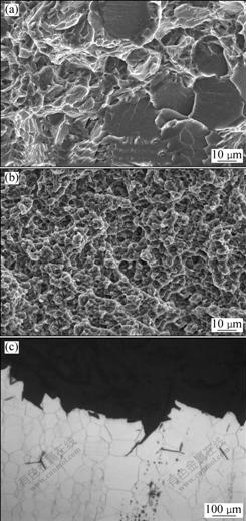

2.4 合金的断口形貌

图5所示为Mg-12Gd-3Y-0.6Zr合金一次挤压态和二次挤压态的断口形貌。一次挤压态合金的断口形貌如图5(a)所示。由图5(a)可知,断口有大块的解理面,在图5(a)左边也存在部分韧窝,说明也发生韧性断裂。因此,一次挤压态合金的断裂方式以解理断裂为主,同时发生韧性断裂。图5(c)所示为一次挤压态合金断口纵截面的光学显微组织。解理断裂通常沿着一定的晶面断裂(即解理面),并且只在六方和体心立方金属中出现。从图5(c)中可以看出,裂纹从一个晶粒到另一个晶粒地穿过,这是解理断裂的典型特征。根据以上对一次挤压态合金的织构分析可知,镁合金在挤压过程中形成纤维织构,且呈现基面取向特征,则

晶面垂直于挤压方向,因此在挤压变形镁合金中,解理发生在

晶面垂直于挤压方向,因此在挤压变形镁合金中,解理发生在 面上。二次挤压态合金拉伸时

面上。二次挤压态合金拉伸时

出现缩颈,产生典型的杯?锥型断口,其断口形貌如图5(b)所示。由图5(b)可知,断口存在大量的韧窝,韧窝是塑性变形的特征,韧窝越多,塑性越好,表明多次挤压合金的塑性明显高于一次挤压态合金的,其断裂方式为韧性断裂。

图5 Mg-12Gd-3Y-0.6Zr合金一次挤压态和二次挤压态的断口形貌

Fig.5 Fracture morphologies of Mg-12Gd-3Y-0.6Zr alloy: (a), (c) As-once-extruded; (b) As-double-extruded

3 讨论

二次挤压后,Mg-12Gd-3Y-0.6Zr合金力学性能的变化与合金的晶粒细化、第二相及织构演变有关。

从图1可知,二次挤压后晶粒尺寸从35 μm细化至6 μm,由Hall-Petch公式:

式中:σy为屈服强度;σ0为单晶体的屈服极限;K为常数;d为晶粒尺寸。由式(1)可知,随着晶粒尺寸的减小,合金屈服强度逐渐提高,因此,二次挤压态晶粒的细化应该使合金的屈服强度提高。但由图4可知,二次挤压态合金的屈服强度降低,说明在合金中,某些因素起主导作用降低合金的强度。

另外,晶粒细化提高了合金的塑性,晶粒细小,塞积在晶界的位错群所产生的应力场将会影响到相邻晶粒的整个体积,也就容易启动相邻晶粒的位错源而产生协调变形,从而减小变形的不均匀程度获得较大的变形量,伸长率较高,因此,二次挤压过程中,晶粒细化使合金的伸长率提高。但这仅是塑性提高的一方面,另一方面,晶粒细化能激活镁合金中棱柱面和锥面等潜在的非基面滑移系。微观研究发现[17],细晶镁合金中非基面滑移系被激活是其塑性得以大幅度改善的最根本原因。非基面滑移对总应变的贡献可达40%左右,并有效地抑制孪晶的形成。研究表明,在晶界附近容易发生非基面滑移。晶粒尺寸在100 μm以下时,非基面滑移的范围大约在距晶界10 μm左右。当晶粒细化至10 μm以下时,非基面滑移可以贯穿整个晶粒内部。二次挤压态合金的晶粒尺寸为6 μm,非基面滑移能贯穿整个晶粒,从而使合金的塑性提高。

固溶强化是Mg-Gd-Y-Zr系合金主要的强化机制之一,合金中的Gd和Y原子有很强的固溶强化作用,粗大Mg5Gd1?xYx相的增多(见图2(b))使基体中Gd和Y的含量降低,降低Mg-12Gd-3Y-0.6Zr合金的固溶强化效果,从而使合金强度降低,这就是合金强度降低的因素之一。

织构分析表明[18?20],挤压态合金中大部分晶粒的{0002}基面平行于挤压方向,拉伸时各晶粒基面滑移系的Schmid因子(m)几乎为零。根据Schmid定律:

式中:τc为临界剪切应力,属于晶体的本征参数,当τ达到某一临界值τc时,滑移过程开始;λ为滑移方向与外力轴线的夹角;φ为滑移面与外力轴线的夹角,cosλcosφ为Schmid因子,表征滑移面和滑移方向与外力间的取向关系。在式(2)中,当λ或φ为90?时,Schmid因子为零,不管τc的数值如何,σs均为无穷大,在外力作用下不能产生滑移,从而产生强化。因此,一次挤压态合金高性能的部分原因是织构效应。由于二次挤压态合金织构强度明显减弱,因此,织构强化效应也明显减弱,使合金强度明显降低。这就是合金强度降低的另一因素。

根据Cottrell-Petch脆塑性断裂转变理论[21],晶粒尺寸d、晶体平均取向因子 与脆塑性断裂转变有如下关系:

与脆塑性断裂转变有如下关系:

式中:μ为切变模量;γ为比表面能;β为与应力状态相关的常数;τc为临界剪切应力;σ0为单晶体的屈服极限;r为相邻晶粒内滑动位错距领先塞积位错的距离。式中等号表示脆塑性转变的条件,大于号表示呈脆性断裂。由此可见,二次挤压后,d和 降低,这都有利于合金断裂方式向韧性断裂转变。

降低,这都有利于合金断裂方式向韧性断裂转变。

综上所述可知,二次挤压态合金的强度有所降低,塑性大幅度提高是由晶粒尺寸、第二相和织构这3个方面综合影响的,其中晶粒细化对塑性影响最大。通过控制晶粒尺寸、第二相形态和织构形态,使塑性较差的Mg-12Gd-3Y-0.6Zr合金的伸长率达到20.5%,塑性大幅度提高。

4 结论

1) 二次挤压态Mg-12Gd-3Y-0.6Zr合金的抗拉强度和屈服强度有所降低,但伸长率却大幅度提高,达到20.5%,较一次挤压态合金提高107.1%。

2) 二次挤压态Mg-12Gd-3Y-0.6Zr合金的晶粒尺寸细化至6 μm,提高细晶强化效果;粗大的Mg5Gd1?xYx相增多,降低了固溶强化效果;{0002}基面织构的明显减弱降低了织构强化效果。挤压态合金的强度特征是细晶强化、固溶强化和织构强化综合作用的结果。

3) Mg-12Gd-3Y-0.6Zr合金经二次挤压后,合金的断裂方式从以解理断裂为主,同时发生韧性断裂。

REFERENCES

[1] MATUCHA K H. 非铁合金的结构与性能[M]. 丁道云, 译. 北京: 科学出版社, 1999.

MATUCHA K H. Structure and properties of nonferrous alloys[M]. DING Dao-yun, transl. Beijing: Science Press, 1999.

[2] MORDIKE B L. Creep-resistant magnesium alloys[J]. Mater Sci Eng A, 2002, 324(1/2): 103?112.

[3] 张新明, 彭卓凯, 陈健美, 邓运来. 耐热镁合金及其研究进展[J]. 中国有色金属学报, 2004, 14(9): 1443?1450.

ZHANG Xin-ming, PENG Zhuo-kai, CHEN Jian-mei, DENG Yun-lai. Heat-resistant magnesium alloys and their development[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(9): 1443?1450.

[4] ANYANWU A, KAMADO S, KOJIMA Y. Aging characteristics and high temperature tensile properties of Mg-Gd-Y-Zr alloys[J]. Materials Transactions, 2001, 42(7): 1206?1211.

[5] ANYANWU A, KAMADO S, KOJIMA Y. Creep properties of Mg-Gd-Y-Zr alloys[J]. Materials Transactions, 2001, 42(7): 1212?1218.

[6] HE S M, ZENG X Q, PENG L M. Microstructure and strengthening mechanism of high strength Mg-10Gd-2Y-0.5Zr alloy[J]. Journal of Alloys and Compounds, 2007, 427(1/2): 316?323.

[7] YANG Z, LI J P, GUO Y C. Precipitation process and effect on mechanical properties of Mg-9Gd-3Y-0.6Zn-0.5Zr alloy[J]. Mater Sci Eng A, 2007, 454/455: 274?280.

[8] 彭卓凯, 张新明, 陈健美, 肖 阳, 蒋 浩, 邓桢桢. Mn, Zr对Mg-Gd-Y合金组织与力学性能的影响[J]. 中国有色金属学报, 2005, 15(6): 917?922.

PENG Zhuo-kai, ZHANG Xin-ming, CHEN Jian-mei, XIAO Yang, JIANG Hao, DENG Zhen-zhen. Effects of Mn, Zr on microstructure and properties of Mg-Gd-Y alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 917?922.

[9] 张新明, 陈健美, 邓运来, 肖 阳, 蒋 浩, 邓桢桢. Mg-Gd-Y-(Mn,Zr)合金的显微组织和力学性能[J]. 中国有色金属学报, 2006, 16(2): 219?227.

ZHANG Xin-ming, CHEN Jian-mei, DENG Yun-lai, XIAO Yang, JIANG Hao, DENG Zhen-zhen. Microstructures and mechanical properties of Mg-Gd-Y2(Mn, Zr) magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 219?227.

[10] 张振栋, 刘楚明, 常亚喆, 李慧中, 王 荣, 周海涛. 挤压次数对Mg-Zn-Zr-Re合金组织和性能的影响[J]. 中南大学学报: 自然科学版, 2008, 39(2): 228?233.

ZHANG Zhen-dong, LIU Chu-ming, CHANG Ya-zhe, LI Hui-zhong, WANG Rong, ZHOU Hai-tao. Effect of number of extrusion times on microstructure and properties of Mg-Zn-Zr-Re alloys[J]. Journal of Central South University: Science and Technology, 2008, 39(2): 228?233.

[11] 张新明, 石其年, 尹志民, 陈振华, 左铁镛. 多次挤压对Al-Li合金挤压织构及力学性能的影响[J]. 中南矿冶学院学报, 1991, 22(2): 174?183.

ZHANG Xin-ming, SHI Qi-nian, YIN Zhi-min, CHEN Zhen-hua, ZUO Tie-yong. Effect of double extrusion processes on extrusion texture and properties of Al-Li alloy[J]. Journal of Central South Institute of Mining and Metallurgy, 1991, 22(2): 174?183.

[12] LEYENS C, PETERS M. 钛与钛合金[M]. 陈振华, 译. 北京: 化学工业出版社, 2005: 324?325.

LEYENS C, PETERS M. Titanium and titanium alloys[M]. CHEN Zhen-hua, transl. Beijing: Chemical Engineering Press, 2005: 324?325.

[13] CHEN R S, BLANDIN J J, SUERY M, WANG Q D, HAN E H. Thermomechanical processing and superplasticity of AZ91 magnesium alloy[J]. Journal of Materials Science and Technology, 2004, 20(3): 295?297.

[14] STANFORD N, ATWELL D, BEER A, DAVIES C, BARNETT M R. Effect of microalloying with rare-earth elements on the texture of extruded magnesium-based alloys[J]. Scripta Materialia, 2008, 59(7): 772?775.

[15] MUELLER K, MUELLER S. Severe plastic deformation of the magnesium alloy AZ31[J]. Journal of Materials Processing Technology, 2007, 187/188: 775?779.

[16] WATANABE H, TAKARA A, SOMEKAWA H, MUKAI T, HIGASHI K. Effect of texture on tensile properties at elevated temperatures in an AZ31 magnesium alloy[J]. Scripta Materialia, 2005, 52(6): 449?454.

[17] KOIKE J, KOBAYASHI T, MUKAI T, WATANABE H, SUZUKI M, MARUYAMA K, HIGASHI K. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys[J]. Acta Materialia, 2003, 51(7): 2055?2065.

[18] WANG Y N, HUANG J C. Texture analysis in hexagonal materials[J]. Materials Chemistry and Physics, 2003, 81(1): 11?26.

[19] 路林林, 杨 平, 王发奇, 钟伟珍. 形变热处理对AZ80镁合金组织及性能的影响[J]. 中国有色金属学报, 2006, 16(6): 1034?1039.

LU Lin-lin, YANG Ping, WANG Fa-qi, ZHONG Wei-zhen. Effects of thermomechanical treatments on microstructure and mechanical properties of AZ80 magnesium alloy[J].The Chinese Journal of Nonferrous Metals, 2006, 16(6): 1034?1039.

[20] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1?11.

CHEN Zhen-hua, XIA Wei-jun, CHEN Yong-qi, FU Ding-fa. Texture and anisotropy in magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1?11.

[21] 何肇基. 金属的力学性能[M]. 北京: 冶金工业出版社, 1982.

HE Zhao-ji. Mechanical properties of metal materials[M]. Beijing: Metallurgical Industry Press, 1982.

基金项目:国防重大基础研究资助项目

收稿日期:2009-02-03;修订日期:2009-05-07

通信作者:刘楚明,教授,博士;电话:0731-88877502;E-mail:cmliu@mail.csu.edu.cn

(编辑 龙怀中)