文章编号:1004-0609(2008)06-1039-06

细晶钼铜合金的制备

陈玉柏,范景莲,刘 涛,成会朝,田家敏

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用溶胶-喷雾干燥-煅烧-氢还原方法制取晶粒尺寸为17~50 nm的超细Mo-30Cu复合粉末,研究烧结温度、时间和粉末中的氧含量对烧结致密化的影响,检测合金的拉伸力学性能,分析合金的拉伸断口形貌特征。结果表明:还原温度对粉末形貌有很大的影响;在1 050~1 200 ℃烧结即可实现材料的快速致密化,在1 050 ℃烧结后保温60 min时,合金的相对密度可达99%以上,并且晶粒细小,显微组织分布均匀;合金的最大抗拉强度可达755 MPa,伸长率为6.41%。

关键词:Mo-Cu合金;超细粉末;力学性能;断裂机制

中图分类号:TG 146.4 文献标识码:A

Fabrication of fine-grained Mo-Cu alloy

CHEN Yu-bo, FAN Jing-lian, LIU Tao, CHENG Hui-chao, TIAN Jia-min

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Ultra-fine Mo-30Cu composite powders with grain size of 17-50 nm were fabricated by sol-spray drying, calcination and subsequent hydrogen reduction process. The results show that the influence of sintering temperature, time and the oxygen content in the powder on sintering densification were investigated. Meanwhile the tensile mechanical property of alloys was examined, and the tensile fracture surface features of the alloys were analysed. The results show that the reduction temperature has a great impact on powder morphology; the rapid densification can be realized in those green compacts, which are sintered in the temperature range of 1 050-1 200 ℃; when they are sintered at 1 050 ℃ for 60 min in H2 atmosphere, the relative density can achieve 99%, and their grains are fine, and the microstructures are homogeneous. The maximum tensile strength and elongation rate of the alloy are 755 MPa and 6.41%, respectively.

Key words: Mo-Cu alloy; ultra-fine powders; mechanical property; fracture mechanism

Mo-Cu合金具备良好导电导热性、抗高温、耐烧蚀、高强度等性能特点,广泛地应用于电工电子、仪器仪表、国防军工、航空航天等领域[1-2] 。但由于Mo与Cu互不相溶,采用普通的“粉末混合+成型+液相烧结”工艺或溶渗法制取的Mo-Cu合金烧结性能较低,难以满足新的应用领域提出的更高的要求[3-4]。而超细/纳米粉末具有很高的烧结活性,容易实现材料的高致密化,因此采用超细/纳米复合粉末制备高性能细晶Mo-Cu合金就成为近年来关注的焦点。国内外学者曾采用机械合金化法、化学活化法和凝胶-共还原法制备高致密Mo-Cu合金[5-8],但都存在不足,其中 机械合金化法和化学活化法的缺点就是引入的其它元素或杂质降低了合金的导电导热性能[9-11]。迄今为止,尚未见有采用溶胶-喷雾干燥-煅烧-氢气还原制粉的方法来制备钼铜合金的研究报道。本文作者采用溶 胶-喷雾干燥-煅烧-氢气还原的方法制备出无掺杂的Mo-30Cu纳米复合粉末,并利用该粉末制备出高性 能的细晶Mo-30Cu合金,研究粉末的制备工艺、烧 结温度和保温时间及氧含量对烧结致密化的影响、分析合金力学性能以及拉伸断口形貌特征,以探索制备高性能Mo-Cu合金的新途径。

1 实验

以仲钼酸铵(NH4)6Mo7O24·4H2O和硝酸铜Cu(NO3)2·3H2O为原料,按70% Mo-30%Cu(质量分数)的配比配制成溶胶,经喷雾干燥得复合盐前驱体粉末,再经450℃煅烧,然后在不同温度下经氢气还原就可得到超细Mo-30Cu复合粉末。将该复合粉末在400 MPa压力下压制成GJB765—89型标准拉伸试样压坯(30 mm×3.7 mm×3 mm),并将该拉伸试样压坯在850 ℃下预烧90 min后再分别在1 050、1 100、1 150和1 200 ℃烧结,保温时间分别为30、60、90和120 min,由此获得拉伸试样,烧结过程中以氢气为保护气氛。

用日产3014-2Z型X射线自动衍射仪对粉末进行物相分析,用阿基米德排水法测合金的密度,用TC-436型氮/氧分析仪测粉末的氧含量,在LJ-3000A型机械式拉力实验机上测合金的抗拉强度,在日产JSM-6630LV型扫描电镜上观察粉末的形貌和合金的拉伸断口形貌特征。

2 结果与分析

2.1 粉末的制备

将溶胶-喷雾干燥得到的复合盐前驱体粉末在450 ℃下煅烧保温90 min,再分别经200和300 ℃氢还原1 h,再在700和940 ℃氢还原各2 h即可得到超细钼铜复合粉末。图1所示为粉末经低温(200 ℃和300 ℃)还原后分别在700℃和940 ℃下氢还原的XRD谱。据图1所示,复合粉末经700 ℃氢气还原2 h后,产物中只含Mo、Cu两相,根据Scherrer公式,用XRD峰半宽数据计算出该钼铜复合粉末的晶粒尺寸在17~30 nm之间, 因粉末粒子比较细小且内部含有很多微孔,粉末多团聚在一起形成粉末聚集体,如图2所示。而复合粉末经940 ℃氢还原后,衍射峰变窄,强度增加,说明Mo和Cu晶粒有所长大。根据Scherrer公式计算该复合粉末的晶粒尺寸在24~50 nm之间,粉末颗粒发生球化现象,形状比较规则,粒度分布均匀,如图3所示。与700 ℃氢还原的粉末相比,该粉末具有良好的压制性能。

图1 粉末分别在700和940 ℃下还原的XRD谱

Fig.1 XRD patterns of powders after hydrogen reduction at 700 and 940 ℃

图2 700 ℃下氢还原后粉末形貌

Fig.2 SEM micrograph of powders after hydrogen reduction at 700 ℃

图3 940 ℃下氢还原后粉末形貌

Fig.3 SEM micrograph of powders after hydrogen reduction at 940 ℃

2.2 烧结致密化

2.2.1 温度和时间对烧结致密化的影响

从图4和图5中可以看出,烧结温度和保温时间对材料的致密化程度有较大的影响。据图4可知,当保温时间为30 min时,随着烧结温度的升高,合金的相对密度逐渐增加;而当在1 050 ℃烧结时,随着保温时间的增加,合金的相对密度先是升高后又降低;在1 050 ℃保温60 min时合金的相对密度可达99%以上,而在1 200 ℃烧结保温30 min时合金的相对密度同样可达99%以上,但因温度过高,铜相会渗出合金表面,导致钼铜两相分布不均匀,结果影响合金的烧结性能,因此过高的烧结温度或过长的保温时间对合金的烧结性能都是不利的。对比图4与图5可以看出,烧结温度与保温时间对合金线收缩率的影响规律基本相同,在1 050 ℃烧结保温30 min时,烧结体的线收缩率为8.06%;当温度升高到铜的熔点(1 083 ℃)以上1 100 ℃时,因大部分的Cu相已经转变为液相,有利于填充烧结体中的孔隙,因此烧结体有较大幅度的收缩,在1 200℃烧结保温30 min时合金的线收缩率就可达到12.64%。由于通过溶胶喷雾干燥-煅烧-氢还原的方法制备的Mo-30Cu复合粉末晶粒尺寸(17~50 nm)比较小,且钼晶粒与铜晶粒相互依存,在烧结的过程中粉末颗粒间的物质传输距离较短,系统的烧结活性较高,在1 050~1 200 ℃ 之间就可实现材料的快速致密化。利用该粉末所制备的钼铜合金的显微组织均匀,且晶粒细小,如图6 所示。由图可知,在1 050 ℃烧结保温60 min时,合金的晶粒尺寸约为1 ?m,但升高烧结温度到1 150 ℃并保温60 min时,晶粒就长大到2~3 ?m。

图4 保温30 min时相对密度、线收缩率与温度关系图

Fig.4 Relationships of relative density and line contractility to temperature when holding for 30 min

图5 1050 ℃时相对密度、线收缩率与时间关系图

Fig.5 Relationships of relative density and line contractility to time at 1050 ℃

图6 不同条件下制备的钼铜合金的金相显微组织

Fig.6 Microstructures of Mo-Cu alloys prepared under different conditions: (a) At 1 050 ℃ for 60 min; (b) At 1 150 ℃ for 60 min

2.2.2 氧含量对烧结致密化的影响

当对高含铜量的钼铜材料进行液相烧结时,铜液很容易渗出烧结体的表面,导致钼铜材料的成分偏析进而影响其烧结性能。其原因可能是因为在液相烧结时,粉末中所含的氧与氢气反应生成的水蒸气残留在烧结体闭孔中,造成烧结体内部蒸气压力的增大,又因高温下铜液的流动能力增强,当内部压力足够大时,铜液就渗出合金表面。以下是通过热力学公式近似计算烧结体内的水蒸气压力。

反应(1)的生成自由能为

且

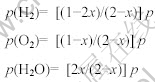

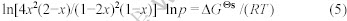

式中 R是摩尔气体常数(R = 8.314 J/(mol?K))。由于在平衡状态下,1-x mol的O2与1-2x mol的H2反应生成2x mol的H2O,所以平衡时气体总摩尔数是2-x mol。每种气体的分压可以表示为

因此,Kp可以表示为

将式(4)代入式(3)可得:

本实验所制备的钼铜复合粉末的氧含量为0.31%,通过查热力学数据可计算出在1 400 K时的自由能 ,根据式(5)可计算出烧结体内的蒸气压力p。当x = 0.001 mol时,p =1.76 Pa;当x = 0.01 mol时,p =183 Pa;当x = 0.1 mol时,p = 22 904 Pa。可见,烧结体内的蒸气压力是随着水蒸气量的增加即粉末中氧含量的增加而增大的,因此,粉末中的氧含量越高越不利于烧结体的致密化。

,根据式(5)可计算出烧结体内的蒸气压力p。当x = 0.001 mol时,p =1.76 Pa;当x = 0.01 mol时,p =183 Pa;当x = 0.1 mol时,p = 22 904 Pa。可见,烧结体内的蒸气压力是随着水蒸气量的增加即粉末中氧含量的增加而增大的,因此,粉末中的氧含量越高越不利于烧结体的致密化。

2.3 合金的力学性能

合金的抗拉力学性能与烧结温度和时间的关系如图7和8所示。由图7可以看出,烧结温度与保温时间对合金的抗拉强度的影响规律与合金的致密化程度基本相同,其中在1 200 ℃烧结保温30 min时合金的抗拉强度最大达到了755 MPa。据图8可知,随着烧结温度的升高和保温时间的延长,合金的伸长率都呈增加的趋势,但是温度对合金伸长率的影响要大于时间对合金伸长率的影响,当在1 050 ℃烧结保温120 min时,合金的伸长率就达到6.41%,可见升高烧结温度或延长保温时间有利于提高合金的伸长率。与传统相同成分的Mo-Cu合金相比,采用溶胶喷雾干燥等工艺制备的Mo-Cu合金具有更高的密度和更好的抗拉力学性能。因为采用溶胶喷雾干燥-煅烧-氢还原的方法制备的Mo-30Cu复合粉末晶粒尺寸比较小,且Mo、Cu晶粒分布均匀,在相对低的烧结温度下粉末烧结体就能够接近全致密;又因Mo晶粒细小,分布均匀(如图6所示),且 Mo相和Cu相在界面处相互固溶[12],Mo-Cu界面处Mo相和粘结相Cu之间的作用力相对较强,因此合金具有良好的抗拉力学性能。

图7 保温30 min时抗拉强度、伸长率与温度关系图

Fig.7 Relationships of tensile strength and elongation to temperature when holding for 30 min

图8 1 050 ℃时抗拉强度、伸长率与时间关系图

Fig.8 Relationships of tensile strength and elongation to time at 1 050 ℃

2.4 Mo-Cu合金的拉伸断口形貌

Mo-Cu合金的拉伸变形断裂主要是靠粘结相Cu带动钼引起的Mo、Cu两相的协调变形断裂。由图9所示的拉伸断口形貌可知,此Mo-30Cu合金拉伸断裂主要是以脆性断裂与韧性断裂共存的形式存在的,其中包括粘结相Cu的撕裂、Mo-Cu界面的分离和Mo-Mo界面脱开3种形式[13]。不同烧结温度不同保温时间的粉末烧结体其拉伸力学性能的大小是由3种断裂形式的分布多寡决定的。如图9(a)所示,合金的拉伸断裂主要是粉末体的脆性断裂,另外还有少量的粘结相Cu的撕裂和Mo-Cu界面的分离,断口形貌中含有较浅的韧窝,韧窝的存在主要是由于在拉伸的过程中Mo颗粒从粘结相Cu中拔出形成的。如图9(b)所示,断裂时的韧窝明显变深,Mo-Mo界面脱开、粘结相Cu的撕裂和Mo-Cu界面的分离增多,此时合金的抗拉强度相对较好;如图9(c)所示,随着保温时间的增加,韧窝明显减少并变浅,断裂主要以粘结相Cu的撕裂和Mo-Cu界面的分离为主。由于此时的相对密度较低,孔洞较多,因此合金的抗拉力学性能较低。如图9(d)所示,随着温度的升高,Mo颗粒有所长大,Cu相较均匀地包覆在Mo颗粒上,韧窝增多,断裂主要以Mo-Mo界面脱开、粘结相Cu的撕裂以及Mo-Cu界面的分离为主的脆性断裂与韧性断裂共存的断裂。图9中没有观察到Mo颗粒的断裂。由于Mo颗粒细小,且弥散均匀分布,其断裂强度σMo要大于Mo-Mo界面脱开强度σMo-Mo、粘结相Cu的撕裂强度σCu以及Mo-Cu界面的分离强度σMo-Cu,因此拉伸过程中Mo颗粒还没有来得及断裂,粉末烧结体就已经断裂了。

通过拉伸断口形貌分析,可以用图10所示的断裂模型说明合金的拉伸断裂过程。随着拉伸应力的增加,铜粘结相首先发生塑性变形,接着钼铜两相开始协调变形,在相界面处萌生微裂纹,最终发生Mo-Cu界面的分离、Mo-Mo界面脱开与粘结相Cu的撕裂,最后合金断裂。

图9 不同条件下制备的Mo-Cu合金的拉伸断口SEM像

Fig.9 Fracture SEM images of Mo-Cu alloys prepared under different conditions: (a) At 1 050 ℃ for 30 min; (b) At 1 050 ℃ for 60 min; (c) At 1 050 ℃ for 120 min; (d) At 1 150 ℃ for 60 min

图10 拉伸变形断裂模型示意示意图

Fig.10 Schematic diagram of tensile fracture model

3 结论

1) 采用溶胶喷雾干燥-煅烧-氢还原的方法制备了超细钼铜复合粉末,其晶粒尺寸为17~50 nm之间;经700 ℃还原制备的粉末形状不规则,并多团聚在一起;而经940 ℃还原制备的粉末形状规则,多为球状,粒度分布均匀,具有良好的压制性能。

2) 用该粉末制备的试样在1 050~1 200 ℃ 烧结可实现材料的快速致密化,控制粉末的氧含量有利于烧结致密化。合金的相对密度可达99%以上,抗拉强度最大可达到755 MPa,伸长率为6.41%。

3) 合金的拉伸断裂主要包括粘结相Cu的撕裂、Mo-Cu界面的分离和Mo-Mo界面脱开3种形式。在同一温度下,随着保温时间的延长,粘结相Cu的撕裂和Mo-Cu界面的分离所占比例先增加后减少;而升高温度时,断裂主要以Mo-Mo界面的脱开、粘结相Cu的撕裂以及Mo-Cu界面的分离为主。

REFERENCES

[1] CHWA S O, KLEIN D, LIAO H, DEMBINSKI L, CODDET C. Temperature dependence of microstructure and hardness of vacuum plasma sprayed Cu-Mo composite coatings[J]. Surface & Coatings Technology, 2006, 200: 5682-5686.

[2] 李在元, 翟玉春, 田彦文, 王天然. 铜钼化合物氢还原制备铜钼复合粉研究[J]. 纳米材料与结构, 2003, 4: 23-26.

LI Zai-yuan, ZHAI Yu-chun, TIAN Yan-wen, WANG Tian-ran. Research on preparation of Cu/Mo compound powder by hydrogen reducing Cu/Mo compound[J]. Nanomaterial﹠Structure, 2003, 4: 23-26.

[3] 周贤良, 叶志国, 华小珍, 张建云. 熔渗和液相法烧结Mo-Cu合金的组织和性能[J]. 有色金属, 2006, 58(2): 1-4.

ZHOU Xian-liang, Y E Zhi-guo, HUA Xiao-zheng, ZHA N G Jian-yun. Tissues and properties of Mo-Cu alloy prepared by inf iltration and liquid-phase sintering[J]. Nonferrous Metals, 2006, 58(2): 1-4.

[4] 陈国钦, 朱德志, 张 强, 武高辉. 挤压铸造法制备高致密 Mo/Cu及其导热性能[J]. 中国有色金属学报, 2005, 15(11): 1864-1868.

CHEN Guo-qin, ZHU De-zhi, ZHANG Qiang, WU Gao-hui. Highly dense Mo/Cu composites fabricated by squeeze casting and their thermal conduction properties[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1864-1868.

[5] 程继贵, 弓艳飞, 宋 鹏, 李 洁. 凝胶-共还原法制备超细Mo-Cu粉末及其烧结性能[J]. 中国有色金属学报, 2007, 17(3): 422-427.

CHENG Ji-gui, GONG Yan-fei, SONG Peng, LI Jie. Characterization and sintering behavior of ultra-fine Mo-Cu powder prepared by gelatinization-coreduction method[J]. The Chinese Journal of Nonferrous Metals 2007, 17(3): 422-427.

[6] MART?NEZ V D P, AGUILAR C, MAR?N J, ORDO?EZ S, CASTRO F. Mechanical alloying of Cu-Mo powder mixtures and thermodynamic study of solubility[J]. Material Letters, 2007, 61: 929-933.

[7] AGUILAR C, ORDO?EZ S, MAR?N J, CASTRO F, MART?NEZ V. Study and methods of analysis of mechanically alloyed Cu–Mo powders[J].Mater Sci Eng, 2007, 25: 288-294.

[8] 李增峰, 汤慧萍, 刘海彦, 黄愿平添加活化元素Ni对Mo-Cu合金性能的影响[J]. 稀有金属快报, 2006, 25(1): 29-32.

LI Zeng-feng, TANG Hui-ping, LIU Hai-yan. Influence of activated element Ni on properties of Mo-Cu alloy[J]. Rare Metals Letters, 2006, 25(1): 29-32.

[9] JOHNSON J L, GERMAN R M. Role of solid-state skeletal sintering during processing of Mo-Cu composites[J]. Metall Mater Trans A, 2001, 32(3): 605-613.

[10] ARIKAWA T, ICHIDA A, TAKEQOSHI E. Mechanical properties of Cu-Mo composites[J]. Journal of the Society of Materials Science Japan, 1999, 48(3): 295-300.

[11] ZWEBEN C. High performance thermal management materials[J]. Electronic Cooling Magazine, 1999, 5(3): 36-42.

[12] 李晓红, 解子章, 杨 让. 高含Cu量Mo-Cu合金的液相烧结[J]. 北京科技大学学报, 1996, 18(4): 330-333.

LI Xiao-hong, XIE Zi-zhang, YANG Rang. Liquid phase sintered molybdenum-rich copper alloy[J]. Journal of University of Science and Technology Beijing, 1996, 18(4): 330-333.

[13] 周 俊, 王志法, 郑秋波, 吴 泓. 70MoCu合金变形性研究[J]. 中国钼业, 2006, 30(6): 35-39.

ZHOU Jun, WANG Zhi-fa, ZHENG Qiu-bo, WU Hong, Study of the deformation behavior about 70MoCu composites[J]. China Molybdenum Industry, 2006, 30(6): 35-39.

收稿日期:2007-10-24;修订日期:2008-02-26

通讯作者:范景莲,教授,博士;电话:0731-8836652;E-mail: fjl@mail.csu.edu.cn

(编辑 何学锋)