DOI: 10.11817/j.issn.1672-7207.2016.02.005

墨水涂覆法制备硫化物全固态锂离子电池

张锦,邹忠,刘晋

(中南大学 冶金与环境学院,湖南 长沙,410083)

摘要:采用墨水涂覆技术制备基于硫化物的电解质薄膜及其全固态锂离子电池。通过N-甲基吡咯烷酮(NMP)溶剂对真空烧结法制得的Li8P2S9粉末进行处理,获得均匀、稳定的湛蓝色Li8P2S9墨水。研究结果表明:NMP溶剂处理后的Li8P2S9颗粒粒径从10 μm降低到1 μm左右,物相晶体结构不变,但改善颗粒间的接触性能。在Li8P2S9墨水中添加一定量的聚偏二氟乙烯(PVDF)黏结剂,溶解完全后将墨水滴涂在磷酸铁锂正极表面,除去溶剂即可一步实现电解质的成膜及电解质与正极的复合。当PVDF与Li8P2S9的质量比为1:10时,电解质膜30 ℃下的锂离子电导率为2.03×10-4 S/cm,25 ℃电化学窗口为5.15 V。以该墨水涂覆法制得的LiFePO4/Li电池可在室温下稳定工作,0.2C下循环100圈的平均比容量为113.7 mA·h/g,库仑效率为99%。

关键词:Li8P2S9;硫化物固体电解质;墨水涂覆法;锂离子电池

中图分类号:O646 文献标志码:A 文章编号:1672-7207(2016)02-0386-08

Facile fabrication of sulfide electrolyte based all-solid-state lithium-ion batteries by ink coating method

ZHANG Jin, ZOU Zhong, LIU Jin

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: An ink coating method was developed to prepare sulfide solid electrolyte for all-solid-state lithium ion batteries. The crystalline Li8P2S9 synthesized by vacuum sintering was dispersed in N-methyl-2-pyrrolidone (NMP) solvent to form a homogeneous ink. The results show that during the action of NMP, the particle size of Li8P2S9 decreases from 10 μm to 1 μm while the crystalline structure of Li8P2S9 is unchanged, which benefits contacts between Li8P2S9 particles. Through adding a certain amount of poly(vinylidene fluoride) (PVDF) as an organic binder, the ink is directly dropped on LiFePO4 cathode sheet and then heated at 120 ℃ to remove NMP. When the mass ratio of Li8P2S9 to PVDF is 10:1, the solid electrolyte has an ionic conductivity of 2.03×10-4 S/cm at 30 ℃ and an electrochemical window of 5.15 V at 25 ℃. In addition, the LiFePO4/electrolyte/Li batteries assembled by such facile method show good charge/discharge performance. At the rate of 0.2C, the average specific capacities of 113.7 mA·h/g for 100 cycles are delivered at room temperature with the Coulombic efficiencies close to 99% for each cycle.

Key words: Li8P2S9; sulfide solid electrolyte; ink coating method; lithium ion battery

相比于传统液态电解质锂离子电池,基于无机电解质的全固态锂离子电池具有更高的安全性能和能量密度,是未来储能领域最具潜力的电池体系[1-3]。无机固态电解质种类繁多,包括钙钛矿型电解质[4]、锂快离子导体(LISICON)型电解质[5]、氧化物非晶态电解 质[6]、硫化物非晶态电解质[7]等。硫原子相比于氧原子体积较大、极性较弱,对锂离子的束缚力较小,使得硫化物电解质往往具有更高的离子电导率[8-9],室温下可达10-4~10-2 S/cm,一直是人们关注的焦点[10-11]。硫化物电解质一般采用高能球磨法和固相烧结法制备[12-13],得到的电解质材料为硬度较高的无机粉末。对于硫化物电解质的成膜及电池制备,目前主要是通过高压压制成膜和激光脉冲沉积成膜法实现[7, 14],但这两种方法对设备要求较高,生产效率低,均不适于连续化、规模化生产的应用。因此,亟需开发简单的从无机粉末到电解质薄膜以及全固态锂离子电池的制备方法。液相涂覆法是锂离子电池电极制备的常用手段,简便、高效、易于连续化生产。采用有机溶剂将硫化物电解质均匀分散后,也可以实现液相涂覆法在硫化物电解质膜制备中的应用,但该方法在锂离子电池中的应用目前还鲜有报道。WANG等[15]研究发现:固相烧结得到的Li3.25Ge0.25P0.75S4电解质粉末可以溶解于无水肼中,形成无色透明溶液,通过旋涂法将电解质溶液制成液膜,挥发溶剂使Li3.25Ge0.25P0.75S4析出并重结晶得到电解质膜,其30 ℃下离子电导率为1.82×10-4 S/cm。TERAGAWA等[16]在对钴酸锂进行包覆改性时也应用了类似的液相法。首先采用N-甲基甲酰胺(NMF)溶剂将固相烧结得到的Li2S-P2S5电解质材料溶解成淡黄色澄清溶液,再将钴酸锂材料分散于该溶液中,干燥使Li2S-P2S5在钴酸锂表面析出,从而在钴酸锂表面形成一个Li2S-P2S5电解质包覆层,对提升全固态钴酸锂电池的容量发挥具有显著效果。在此,本文作者提供了一种新的硫化物电解质膜液相涂覆制备方法,并以此方法为基础制备了全固态锂离子电池,验证了液相涂覆法在全固态电池生产中应用的可行性。采用高温烧结法制备Li8P2S9粉末,以N-甲基吡咯烷酮(NMP)为溶剂对Li8P2S9进行分散,得到湛蓝色墨水。在墨水中添加一定量的聚偏二氟乙烯(PVDF)黏结剂,完全溶解后将墨水滴涂在磷酸铁锂(LiFePO4)正极表面,加热挥发脱除NMP溶剂,一步完成电解质的成膜及电解质与电极的复合。对提高电解质膜的致密度,提升电解质膜的电导率以及改善电极与电解质的接触性能有良好效果。

1 实验

1.1 材料

五硫化二磷(P2S5,99%(质量分数,下同),Aladdin),硫化锂(Li2S,99.98%,Sigma-Aldrich),N-2-甲基吡咯烷酮(NMP,分析纯,99%,Aladdin),聚偏二氟乙烯(PVDF,相对分子质量Mn=1 000 000,Arkema)。

1.2 Li8P2S9制备

采用高温烧结法制备Li8P2S9材料[17],按照P2S5与Li2S物质的量比为25:75取原料,在氩气手套箱中研磨混合。将混合均匀后的原料放入石英管式炉(GSL-1500X-OTF-2,合肥科晶材料技术有限公司)中烧结,得到Li8P2S9粉末。烧结温度为550 ℃,烧结时间为12 h。

1.3 材料表征方法和技术

通过X线衍射仪(XRD,Rigaku/TTR-Ⅲ,Ricoh,Japan,Cu-Kα,λ=0.154 18 nm) 表征材料的物相结构,X线扫描角度范围为10°~70°,扫描速度为5 (°)/min。通过扫描电镜(SEM,JSM-6360LV,JEOL,日本)对材料进行微观形貌观察,操作电压为20 kV。采用热重-差热测试(TGA-DSC,STA 449c,Netzsch,德国)来表征材料的热稳定性,氩气流量为15 mL/min,测试温度范围为室温~1 000 ℃,升温速率为10 ℃/min。

通过电化学工作站(PARSTAT 2273, Princeton Applied Research, USA)进行交流阻抗测试来测定电解质的锂离子电导率,交流阻抗测试频率范围为10~7×105 Hz,所加偏置电压为10 mV,测试温度采用高低温箱(GDH-2005C,重庆颢源环境试验设备有限公司)进行控制。采用电化学工作站进行线性扫描伏安测试(LSV)来表征电解质的电化学稳定性。伏安扫描速率为5 mV/s,扫描电压路径为2.0 V→-0.5 V→6.0 V。通过扣式电池测试系统(LAND CT-2001A,武汉金诺电子有限公司)对全固态锂离子电池的循环性能进行表征,电池测试倍率为0.2C,充放电截止电压分别为4.2 V和2.5 V。

2 结果与讨论

2.1 Li8P2S9结构及形貌

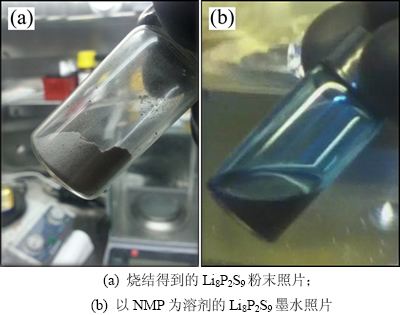

图1所示为高温烧结法制得的初始Li8P2S9材料及其分散于NMP溶剂中形成的墨水的照片。高温烧结所得初始Li8P2S9材料为灰色固体粉末(如图1(a)所示),该粉末在NMP溶剂中均匀分散后得到的墨水呈湛蓝色(如图1(b)所示)。对墨水进行干燥处理,脱除NMP溶剂,得到的固体产物呈浅紫色。通过XRD及SEM技术对NMP溶剂处理前后的材料的晶型及微观形貌进行表征,分析NMP溶剂对Li8P2S9材料的影响。

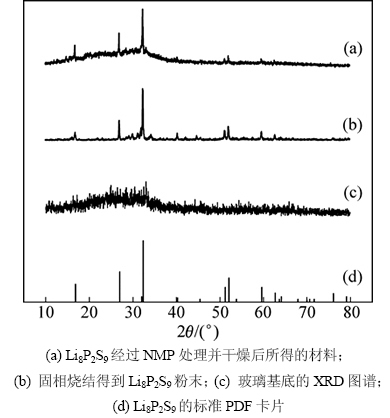

高温烧结得到的初始Li8P2S9材料以及NMP溶剂处理后的固体产物的XRD物相结构表征结果如图2所示。通过Li8P2S9标准PDF卡片对比:发现高温烧结所得硫化物图谱的特征峰与Li8P2S9标准图谱(JCPDS #34-0699)的特征衍射峰位置吻合,证明烧结所得硫化物材料晶型结构为Li8P2S9。Li8P2S9经过NMP处理并干燥后,衍射特征峰的位置仍与Li8P2S9标准图谱一致,说明NMP墨水化处理不会使Li8P2S9材料的物相晶体结构发生改变。根据文献[12]报道:Li8P2S9并不是一种单一的物相,而是由Li4P2S6和Li3PS4这2种物相按照一定比例构成的混合物。另外,NMP溶剂处理后的Li8P2S9材料在2θ=25°附近出现了一个很宽的非晶弥散峰。在相同测试条件下对测试用玻璃基底进行了XRD表征(见图2),所得弥散峰的峰形及位置均与NMP溶剂处理后材料的弥散峰相符,说明该弥散峰来自于测试用的玻璃基底。

图1 烧结得到的Li8P2S9粉末照片和以NMP为溶剂的Li8P2S9墨水照片

Fig. 1 Photos of Li8P2S9 powder as-synthesized by solid sintering and ink solution of Li8P2S9 with NMP as solvent

图2 Li8P2S9经过NMP处理并干燥后所得的材料、固相烧结得到Li8P2S9粉末以及玻璃基底的XRD图谱和Li8P2S9的标准PDF卡片(JCPDS #34-0699)

Fig. 2 X-ray diffraction patterns of Li8P2S9 obtained after NMP solvent treatment, Li8P2S9 powder as-synthesized by solid sintering and glass substrate and standard PDF card of Li8P2S9 (JCPDS #34-0699)

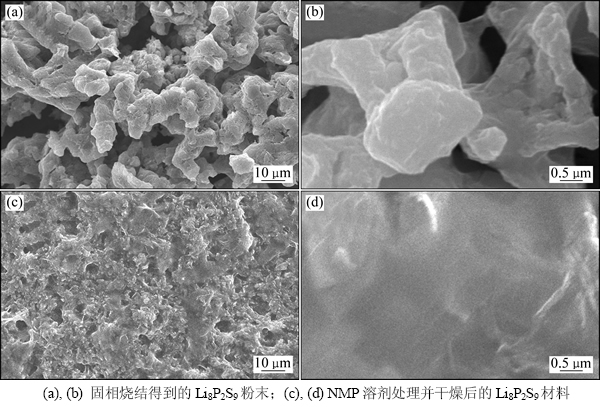

高温烧结得到的初始Li8P2S9材料及其NMP溶剂处理后所得固体产物的SEM微观形貌表征结果如图3所示。由图3(a)和3(b)可见:在不同放大倍数下初始Li8P2S9材料的微观形貌。该Li8P2S9材料颗粒粒径在10 μm左右,与其他文献报道的以相同配比及合成方式得到的结果粒径相近[18]。颗粒间团聚形成没有规则形貌的团簇体,并留有大量5~10 μm宽的孔隙。对单个颗粒进一步放大观察,可见颗粒内部也存在着大量直径1 μm左右的孔隙。颗粒不规则的形貌使得颗粒间有效接触较少,易对锂离子的迁移造成阻碍[18]。同时根据文献[18]报道:类似结构及形貌的电解质需在300 MPa以上的高压下压制,才能得到相对致密的电解质膜,以保证锂离子的有效迁移。

由图3(c)及3(d)可见:NMP溶剂处理后所得固体产物的表面形貌。通过NMP溶剂墨水化处理后,电解质的颗粒粒径明显减小,降低到1 μm左右,颗粒团聚形成的团簇体之间接触也更为紧密,电解质膜中大部分区域的颗粒间可实现如图3的所示的致密接触,有利于锂离子在电解质颗粒间的传输。综合以上结果可知:NMP溶剂墨水化处理可在不影响Li8P2S9材料晶型结构的前提下起到细化Li8P2S9材料颗粒,进而提高Li8P2S9颗粒间接触紧密度的作用。

2.2 墨水涂覆法制备全固态锂离子电池

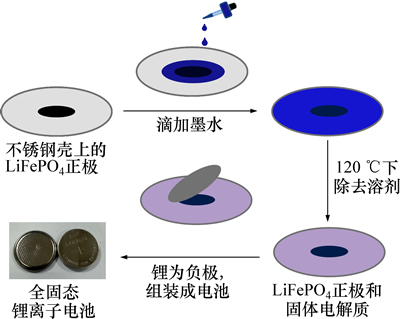

采用墨水涂覆法制备电解质膜及其全固态锂离子电池,相比于高压压制、磁控溅射等方法更简单易行。图4描述了墨水涂覆法制备磷酸铁锂锂离子电池的过程。以NMP为溶剂,将Li8P2S9与PVDF粉末(Li8P2S9与PVDF质量比为10:1)分散和溶解,制成电解质墨水。PVDF在电解质膜中起黏结剂的作用,可使得Li8P2S9颗粒之间的黏结以及电解质膜与电极之间的接触更稳定。将LiFePO4正极极片置于扣式电池正极壳的中央,并将含PVDF的电解质墨水滴加在正极表面形成薄层液膜,120 ℃下加热24 h去除NMP,得到附着有浅紫色电解质薄膜的正极。依次将锂片、镍网及负极壳叠加在电解质膜表面,封口得到LiFePO4/Li8P2S9-PVDF/Li全固态扣式电池。

图3 固相烧结得到的Li8P2S9粉末及NMP溶剂处理并干燥后的Li8P2S9材料在不同放大倍数下的SEM图片

Fig. 3 SEM morphologies of as-synthesized Li8P2S9 powder by solid sintering method and Li8P2S9 obtained after NMP solvent treatment with different magnification factors

2.3 Li8P2S9-PVDF固体电解质及其电池性能

锂离子导电率是决定固体电解质电池阻抗的重要因素,对电池的容量发挥、倍率性能都有显著影响[19]。按照图4所述的墨水涂覆制备方法,将Li8P2S9墨水(含PVDF黏结剂)滴涂在不锈钢电极(SS)表面,制成SS/Li8P2S9-PVDF/SS电池进行交流阻抗测试,来表征电解质膜的锂离子电导率。

图4 墨水涂覆法制备LiFePO4/Li8P2S9-PVDF/Li全固态电池的流程(在氩气气氛下完成)

Fig. 4 Schematic flow of preparation of LiFePO4/Li8P2S9-PVDF/Li battery by ink coating method (conduct under argon atmosphere)

SS/Li8P2S9-PVDF/SS电池交流阻抗测试中,电解质膜与不锈钢电极间界面接触的充分性及紧密性也是影响电池阻抗的重要因素。为了削减界面接触不同带来的误差,对3个不同电解质膜组装的电池进行了阻抗测定,并以其电导率的平均值来衡量该Li8P2S9-PVDF固体电解质膜的电导率水平。3个电解质膜样品分别标记为1号、2号和3号。

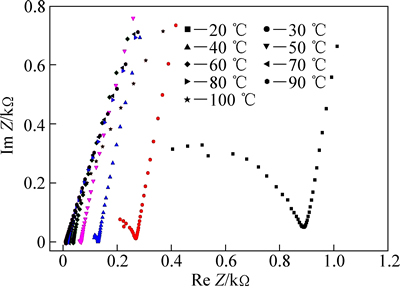

图5所示为以1号电解质膜为例展示了SS/Li8P2S9-PVDF/SS电池在20~100 ℃温度区间内的交流阻抗图谱。取交流阻抗图谱中高频区直线与中频区半圆弧的交点为电解质的本体阻抗(Rb),根据下式计算电导率(σ)。

图5 1号Li8P2S9-PVDF固体电解质膜在20 ℃到100 ℃下的交流阻抗谱

Fig. 5 AC impedance spectra of No. 1 Li8P2S9-PVDF electrolyte film at 20 ℃ to 100 ℃

(1)

(1)

其中:l为电解质厚度;S为电解质与电极的接触面积。

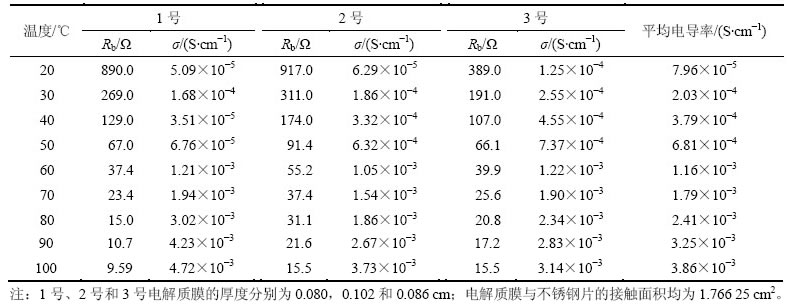

1号、2号和3号电解质膜在不同温度下的本体阻抗、计算所得的电导率及不同温度下电导率的平均值如表1所示。随着温度升高,电解质的阻抗降低明显,电导率也随之上升。以1号电解质膜为例,其20 ℃的本体阻抗为890.0 Ω,80 ℃下则降低至15.0 Ω,为20 ℃下阻抗的1.7%。30 ℃下Li8P2S9基固体电解质膜的平均电导率为2.03×10-4 S/cm,60 ℃及100 ℃下的平均电导率为1.16×10-3 S/cm和3.86×10-3 S/cm,分别为30 ℃下电导率的6倍和19倍。与高压压制成膜法(>300 MPa)制得的相应结构硫化物电解质相比,该电解质膜的电导率与之相当[18, 20],但制备工艺更简单,具有更好的应用前景。

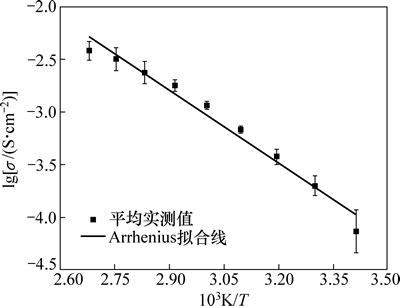

图6所示为电解质平均电导率随温度变化的趋势。其lgσ与1 000/T之间呈线性关系,符合Arrhenius方程的变化规律[21]。

(2)

(2)

式中:σT为不同温度条件下电解质膜的电导率;σ0为指前因子;T为热力学温度;k为气体常数,8.314 J/(mol·K);Ea为离子跃迁活化能。

使用1STOP软件对锂离子电导率的变化进行Arrhenius方程拟合,拟合结果如图6中直线所示。拟合值与测试值间基本吻合,拟合相关系数为0.987。根据拟合计算,得到拟合参数σ0为3.89 S/cm,Ea为0.46 eV。据文献[17,22],本文得到的电解质膜的活化能与相似结构电解质的活化能相近。

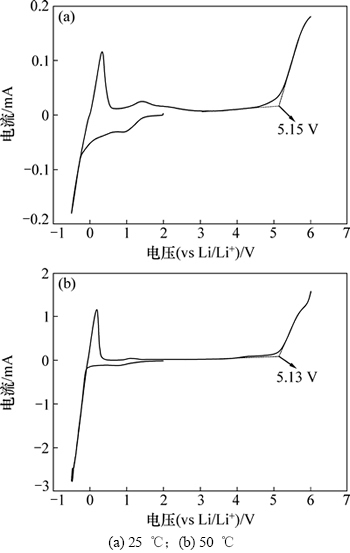

电化学窗口是表征电解质电化学稳定性的一个重要参数。采用墨水涂覆制备方法制得SS/Li8P2S9-PVDF/Li电池,通过线性扫描伏安测试对电解质膜在25 ℃及50 ℃下的电化学窗口进行研究,扫描电压路径为2.0 V→-0.5 V→6.0 V,结果如图7所示。25 ℃及50 ℃下电解质的电化学窗口分别为5.15 V和5.13 V,均高于镍锰酸锂等高电压正极材料的工作电位,说明Li8P2S9-PVDF固体电解质膜可在高电压电池体系中应用。线性扫描伏安图谱中-0.50 V位置的还原峰及0.35 V位置的氧化峰属于Li+/Li氧化还原对,分别对应着锂离子在不锈钢电极表面的电化学沉积和溶解过程。从图7(a)可见:25 ℃下的伏安图谱在1 V左右也出现了1对氧化还原对。该氧化还原对的氧化还原电位与α-Fe2O3电极的脱嵌锂电位相符[23],据此可推断此处的氧化还原过程来自于钢片表面锈蚀产生的少量α-Fe2O3,其脱嵌锂反应过程如式(3)所示[23]。50 ℃下的伏安图也在1 V左右出现了该氧化还原对,但由于温度升高时,电解质本身的氧化电流及脱嵌锂的电流密度较大,使得α-Fe2O3的脱嵌锂电流相对微弱,因此该氧化还原峰较为不明显。

(3)

(3)

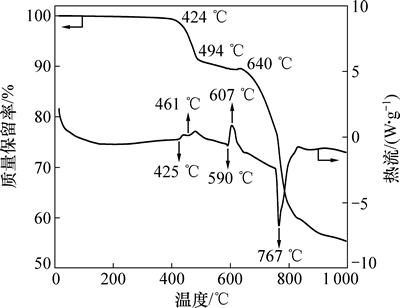

热稳定性是决定电池安全性能的一个重要性质。对墨水涂覆法制备的Li8P2S9-PVDF电解质膜进行了热重-差热测试,结果如图8所示。从图8可看出:在25~1 000 ℃之间,电解质材料有3个质量损失过程,分别发生在424~494 ℃,494~640 ℃和640~1 000 ℃温度区间。差热曲线则显示:在25~1 000 ℃范围内,有4个吸热峰分别存在于425,461,590和767 ℃,

1个放热峰存在于607 ℃。在室温至424 ℃区间,电解质无质量损失,说明电解质在424 ℃以下可稳定存在,不会发生分解。在424~494 ℃之间质量损失率约为9%,与电解质中PVDF的质量分数(9.09%)相近,归属于PVDF的分解[24]。在494~640 ℃之间发生缓慢质量损失,质量损失率约为2%,该过程可能与烧结中没有完全反应的P2S5(沸点为514 ℃)的挥发有关。值得注意的是在接近640 ℃时出现了微弱的质量增加,大约为0.3%。可能是由于硫化物在607 ℃下发生分解[25],与周围还未来得及被氩气排出的P2S5气体反应导致的。在640~1 000 ℃之间质量损失率为35%,对应于电解质主体成分Li8P2S9的分解,生成磷化物和硫化物[25]。在1 000 ℃时,电解质的质量保留率为54%。

表1 不同温度下Li8P2S9-PVDF固体电解质膜的电导率计算

Table 1 Ionic conductivities of Li8P2S9-PVDF electrolyte films at various temperatures

图6 不同温度下的电导率及其Arrhenius方程拟合线

Fig. 6 Lithium ion conductivities at different temperatures and Arrhenius equation fitting result

图7 墨水涂覆法制得的SS/Li8P2S9-PVDF/Li电池在25 ℃和50 ℃下的线性扫描伏安测试结果(电位扫描路径为2.0 V→-0.5 V→6.0 V)

Fig. 7 Linear sweep voltammograms of the SS/Li8P2S9- PVDF/Li batteries prepared by ink coating method at 25 ℃ and 50 ℃ (sweeping route is 2.0 V→-0.5 V→6.0 V)

图8 墨水涂覆法制得的电解质膜的热稳定性分析结果

Fig. 8 Thermal analysis for thin film electrolyte prepared by ink coating method

2.4 充放电性能研究

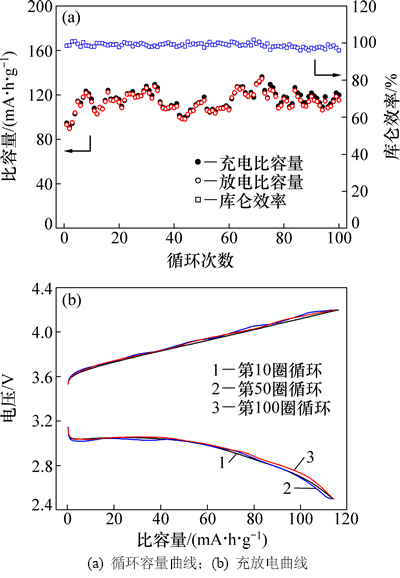

对墨水涂覆法制得的LiFePO4/Li8P2S9-PVDF/Li全固态电池的室温循环性能进行测试,来探索墨水涂覆法在实际应用中的前景。图9(a)所示为LiFePO4/Li8P2S9-PVDF/Li电池在0.2C倍率下的循环-比容量曲线,其充放电截止电压分别为4.2 V和2.5 V。由于测试过程中日夜温度在15~25 ℃之间波动,电池的充放电比容量也随之变化。其1~100圈循环的平均放电比容量为113.7 mA·h/g,库仑效率均接近99%。相比于传统液态电解质电池,全固态锂离子电池的容量随温度波动产生的变化较为明显,这是由固体电解质的本体阻抗在电池整体阻抗中所占的比例较大引起的。

图9(b)所示为LiFePO4/Li8P2S9-PVDF/Li全固态电池0.2C循环中第10圈、50圈及100圈的充放电曲线。电解质常温下的本体阻抗较大,使得电池工作过程中的极化较为严重,充电时没有明显的平台,放电时的平台电压为3.0 V,比LiFePO4的平衡电位低0.4 V。10圈、50圈及100圈的充放电曲线基本重叠,展示了良好的循环稳定性,同时也说明了图9(a)中的容量波动并不是由电池本身不稳定导致,而只是由温度变化引起的。

图9 LiFePO4/Li8P2S9-PVDF/Li固态电池在室温条件下的循环容量曲线及充放电曲线

Fig. 9 Capacity variation curve and charge-discharge curves at certain cycles of LiFePO4/Li8P2S9-PVDF /Li solid battery at room temperature

3 结论

1) 通过固相烧结法合成了Li8P2S9材料,并将其在NMP溶剂中分散,形成稳定的湛蓝色墨水。经NMP溶剂墨水化处理后,颗粒的粒径得到细化,从10 μm降低到1 μm左右,同时材料的晶型结构不会发生改变。

2) 利用Li8P2S9材料可墨水化的特点,发展墨水涂覆法制备电解质膜及其电池,相比于高压压制成膜法、激光脉冲沉积成膜法更简洁、高效,易于在实际生产中应用。

3) 采用墨水涂覆法制备了Li8P2S9电解质膜(含一定量的PVDF黏结剂),其30 ℃下电导率为2.03×10-4 S/cm,25 ℃电化学窗口为5.15 V,可满足锂离子电池的使用要求。

4) 采用墨水涂覆法制备的LiFePO4/Li8P2S9- PVDF/Li全固态电池可在室温下稳定工作,0.2C下循环100圈,平均比容量为113.7 mA·h/g,展示了良好的应用前景。

参考文献:

[1] 刘晋, 徐俊毅, 林月, 等. 全固态锂离子电池的研究及产业化前景[J]. 化学学报, 2013, 71(6): 869-878.

LIU Jin, XU Junyi, LIN Yue, et al. All-solid-state lithium ion battery: Research and industrial prospects[J]. Acta Chim Sinica, 2013, 71(6): 869-878.

[2] 郑洪河, 曲群婷, 石静, 等. 无机固体电解质用于锂及锂离子蓄电池的研究进展(Ⅱ): 玻璃态锂无机固体电解质[J]. 电源技术, 2007, 31(12): 1015-1020.

ZHENG Honghe, QU Qunting, SHI Jing, et al. Research progress of inorganic solid electrolyte materials for lithium and lithium ion batteries II: glassy-state lithium inorganic solid electrolytes[J]. Chinese Journal of Power Sources, 2007, 31(12): 1015-1020.

[3] OUDENHOVEN J F M, BAGGETTO L, NOTTEN P H L. All-solid-state lithium-ion microbatteries: a review of various three-dimensional concepts[J]. Advanced Energy Materials, 2011, 1(1): 10-33.

[4] BONANOS N, KNIGHT K S, ELLIS B. Perovskite solid electrolytes: structure, transport properties and fuel cell applications[J]. Solid State Ionics, 1995, 79(95): 161-170.

[5] OHTSUKA H, YAMAJI A. Preparation and electrical conductivity of LISICON thin films[J]. Solid State Ionics, 1983, 8(1): 43-48.

[6] KHARTON V, MARQUES F, ATKINSON A. Transport properties of solid oxide electrolyte ceramics: a brief review[J]. Solid State Ionics, 2004, 174(1/2/3/4): 135-149.

[7] KANNO R, MURAYAMA M. Lithium ionic conductor thio- LISICON the Li2S-GeS2-P2S5 system[J]. Journal of the Electrochemical Society, 2001, 148(7): A742-A746.

[8] 王衍行, 祖成奎, 何坤, 等. 硫系锂离子导电玻璃及微晶玻璃的研究[J]. 功能材料, 2010, 41(S1): 23-27.

WANG Yanhang, ZU Chengkui, HE Kun, et al. Study on chalcogenide lithium-ion conducting glasses and glass-ceramics[J]. Functional Materials, 2010, 41(S1): 23-27.

[9] ADAMS S, PRASADA R R. Structural requirements for fast lithium ion migration in Li10GeP2S12[J]. Journal of Materials Chemistry, 2012, 22(16): 7687-7691.

[10] KAMAYA N, HOMMA K, YAMAKAWA Y, et al. A lithium superionic conductor[J]. Nature Materials, 2011, 10(9): 682-686.

[11] 吴显明, 李新海, 许名飞, 等. 锂离子固体电解质的研究回顾[J]. 电源技术, 2003, 27(S1): 255-259.

WU Xianming, LI Xinhai, XU Mingfei, et al. Review of the research on Li-ion solid-state electrolyte[J]. Chinese Journal of Power Sources, 2003, 27(S1): 255-259.

[12] NAGAO M, IMADE Y, NARISAWA H, et al. All-solid-state Li-sulfur batteries with mesoporous electrode and thio-LISICON solid electrolyte[J]. Journal of Power Sources, 2013, 222: 237-242.

[13] HAYASHI A, HAMA S, MINAMI T, et al. Formation of superionic crystals from mechanically milled Li2S-P2S5 glasses[J]. Electrochemistry Communications, 2003, 5(2): 111-114.

[14] SAKUDA A, HAYASHI A, OHTOMO T, et al. All-solid-state lithium secondary batteries using LiCoO2 particles with pulsed laser deposition coatings of Li2S-P2S5 solid electrolytes[J]. Journal of Power Sources, 2011, 196(16): 6735-6741.

[15] WANG Yaoming, LIU Zhanqiang, ZHU Xiaolong, et al. Highly lithium-ion conductive thio-LISICON thin film processed by low-temperature solution method[J]. Journal of Power Sources, 2013, 224: 225-229.

[16] TERAGAWA S, ASO K, TADANAGA K, et al. Preparation of Li2S-P2S5 solid electrolyte from N-methylformamide solution and application for all-solid-state lithium battery[J]. Journal of Power Sources, 2014, 248: 939-942.

[17] ECKERT H, ZHANG ZHENGMING, KENNEDY J H. Structural transformation of non-oxide chalcogenide glasses: the short-range order of lithium sulfide (Li2S)-phosphorus pentasulfide (P2S5) glasses studied by quantitative phosphorus-31, lithium-6, and lithium-7 high-resolution solid-state NMR[J]. Chemistry of Materials, 1990, 2(3): 273-279.

[18] SAKUDA A, HAYASHI A, TATSUMISAGO M. Sulfide solid electrolyte with favorable mechanical property for all-solid-state lithium battery[J]. Scientific Reports, 2013, 3: 2261.

[19] TATSUMISAGO M, HAMA S, HAYASHI A, et al. New lithium ion conducting glass-ceramics prepared from mechanochemical Li2S-P2S5 glasses[J]. Solid State Ionics, 2002, 154(12): 635-640.

[20] OHTOMO T, HAYASHI A, TATSUMISAGO M, et al. All-solid-state batteries with Li2O-Li2S-P2S5 glass electrolytes synthesized by two-step mechanical milling[J]. Journal of Solid State Electrochemistry, 2013, 17(10): 2551-2557.

[21] NAGAMEDIANOVA Z,  E. Conductivity studies on LiX–Li2S–Sb2S3–P2S5(LiX=LiI or Li3PO4) glassy system[J]. Ionics, 2006, 12(4/5): 315-322.

E. Conductivity studies on LiX–Li2S–Sb2S3–P2S5(LiX=LiI or Li3PO4) glassy system[J]. Ionics, 2006, 12(4/5): 315-322.

[22] MIZUNO F, HAYASHI A, TADANAGA K, et al. New, highly ion-conductive crystals precipitated from Li2S-P2S5 glasses[J]. Advanced Materials, 2005, 17(7): 918-921.

[23] WANG B, CHEN J S, WU H B, et al. Quasiemulsion-templated formation of α-Fe2O3 hollow spheres with enhanced lithium storage properties[J]. Journal of the American Chemical Society, 2011, 133(43): 17146-17148.

[24] LIU Fu, HASHIM N A, LIU Yutie, et al. Progress in the production and modification of PVDF membranes[J]. Journal of Membrane Science, 2011, 375(1/2): 1-27.

[25]  A, CERDA-MONJE A, et al. Electrical and magnetic properties of quaternary rare earth thiophosphate: K4Sm2[PS4]2[P2S6][J]. Journal of the Brazilian Chemical Society, 2009, 20(8): 1499-1503.

A, CERDA-MONJE A, et al. Electrical and magnetic properties of quaternary rare earth thiophosphate: K4Sm2[PS4]2[P2S6][J]. Journal of the Brazilian Chemical Society, 2009, 20(8): 1499-1503.

(编辑 杨幼平)

收稿日期:2015-02-04;修回日期:2015-04-09

基金项目(Foundation item):湖南省自然科学基金资助项目(2015JJ4079)(Project (2015JJ4079) supported by the Natural Science Foundation of Hunan Province)

通信作者:刘晋,教授,从事全固态电池研究;E-mail:jinliu@csu.edu.cn